January 11, 2018 Lada.Online 263 040 23

E-GAS or electronic gas pedal is installed on all Lada models (XRAY, Vesta, Largus, Granta, Kalina, Priora and Niva 4x4). Owner reviews about it are not reassuring; many complain that the e-gas pedal is “dumb” (less sensitive and informative than a conventional cable). Did you know that in some cases the electronic accelerator pedal can be adjusted to be more responsive and a little livelier?

We determine the model of the accelerator pedal; this can be done by the catalog number, which is glued to the side of the body. If you cannot access the sticker, you will have to remove the electronic gas pedal:

- Disconnect the block with wires next to the gas pedal;

- Unscrew three nuts using a 10mm wrench;

- Remove the housing and pedal assembly.

The manufacturer installs at least two types of electronic gas pedals on Lada cars (depending on the year of manufacture):

- Old model (catalog number: 11183-1108500);

- New sample (article: 11183-1108500-01).

Each block is modified differently. Attention! You do all further actions at your own peril and risk. In addition, you may lose your warranty.

Adjustment

The adjustment process may vary on different car models, since different manufacturers use mechanisms of different designs. But the same principle can be applied for configuration. As for a specific model, it is better to find information on it in advance.

To begin the adjustment, the first step is to remove the pedal from the holding bracket. Next, loosen the screws securing the cover. One screw holds the cover in a certain position - it must be completely unscrewed. The cover is turned to the side clockwise until the end, then the screws are tightened again.

This adjustment will reduce pedal response time. Some car owners note that after such adjustments, the response speed can even be compared with a mechanical pedal. Adjustment allows you to improve engine performance and improve the start of movement from a standstill.

In cases where a pedal with low sensitivity is needed, it is necessary to rotate the cover in the opposite direction - counterclockwise. The machine begins to respond to presses not so quickly.

Sometimes you can come across harmful adjustment tips - drivers advise placing shims under the lever. This is the wrong approach. Sometimes the pads get caught under the contact pads in the potentiometer, and the machine may lose control as a result.

How to adjust the throttle cable of a Lada Priora?

Disconnect the negative terminal of the battery.

Use a screwdriver to loosen the screw, remove the clamp and rubber air duct from the throttle body.

Use a 10mm wrench to loosen the cable lock nut on the sector.

From the side of sector 3 of the throttle valve, you need to pull out cable 1 until it stops. The upper lever 5 of the accelerator pedal should rest against the buffer 4 on the bracket. Tighten nut 2 securing the cable to the sector.

In this case, the throttle valve must be completely closed.

Loosen the tightening of nut “A” and move the limiter “B” of the pedal lever until it stops in the pedal bracket. Tighten nut “A”.

If we fully press the gas pedal, the throttle should be fully open, and the lower lever of the pedal should rest against the mat

You can correct the position of the cable by moving the tip 1 of the shell in the bracket, loosening the tightening of the nuts 2.

After adjusting, tighten nuts 2.

If necessary, repeat the adjustment. Once the adjustment is complete, replace the air duct.

- The adjustment is carried out using a clamping bracket, which we previously removed. This bracket is a tensioner for the casing in which the cable moves.

- Remove the bracket and tighten the throttle cable so that it sags about 1-2 mm near the throttle drive.

- Now you need to install the fixing bracket into place in the casing. Make sure that the cable is tensioned optimally and that the gas pedal is not open at zero position. A cable that is too tight will cause constant high voltage. Squeeze the gas pedal several times and check how everything works.

- Start the engine and make sure the throttle cable is adjusted correctly and the idle speed is normal.

The block cover (11183-1108500) is fixed with bolts that are inserted into oval holes. The improvement is this. to loosen the 4 screws and turn the cover in the desired direction:

- Economy mode (counterclockwise). To drive smoothly, to accelerate, you should press the pedal a little more than before. Gasoline consumption is reduced;

- Active mode (clockwise). The car reacts even with slight pressure on the gas pedal. Gasoline consumption increases. The pedal becomes more sensitive and informative.

In other words, we get the same effect as after installing JETTER (Jetter or spur).

It has been noticed that the first minutes after such settings, the idle speed may be increased (about 1300 rpm). But after a minute, the ECU gradually adjusted and the speed dropped to the usual level. If this does not happen, turn on the ignition for a minute and then start the engine.

If necessary, you can easily return to the original position (mark it in advance).

How to adjust the electronic pedal

Like any mechanism, the electronic gas pedal sometimes also needs adjustments. This event is necessary to maintain normal operation of the accelerator if the settings have been reset.

Sometimes it happens that when you press the gas pedal, the car stops responding to changes in the throttle position. This is due to the fact that there was simply no change in the situation. All electronic pedals have a certain free play, during which the voltage supplied to the transistor circuit changes. If the voltage changes, the response to the pedal position also changes, therefore, the car may behave inappropriately when controlling the throttle. Sometimes this problem can be recognized by the corresponding indicator on the dashboard or using electronic diagnostics carried out through the vehicle's on-board computer.

Adjustment procedure:

- First of all, you need to remove the pedal from its seat. This means that when the pedal is removed, the angle measurement module is also removed along with it. The plug connector must be left in place, since power to the pedal will be needed during the adjustment process.

- Once the pedal is released, unscrew the screw located on the pedal cover. Thus, you need to release the cover relative to the pedal, allowing it to rotate freely. Next, you will need the reference literature that came with the pedal.

- Connect a voltmeter between the connectors and set it to the appropriate measuring range. Turn on the ignition. The manual for the pedal contains voltage standards that will be different for a diesel and injection engine. By turning the pedal cover, you can change the supplied voltage. Set this parameter according to the documentation and tighten the fastening screw.

- Place the pedal in place and try it out. If the car's behavior has changed for the better, it means that the electronic gas pedal has been adjusted correctly.

In addition, the voltage value may vary depending on the environment. That is, during seasonal maintenance of the car, it is strongly recommended to also adjust the gas pedal, since this value can change in inverse proportion to the changing resistance.

Advantages and disadvantages of an electronic pedal

When this device was created, there was no talk about driver convenience. It simply made it possible to increase the environmental friendliness of the car and free up space from cables and other mechanics, which made it possible to simplify the design. But a lot of time has passed, and now the electronic version can be found in almost all cars. During this period, all the advantages and disadvantages were revealed.

Among the advantages:

- Environmental friendliness - electronic engine management reduces the amount of exhaust gases, as speed is strictly controlled.

- Smooth operation - the electronic control unit does not allow the engine speed to change too sharply.

- Greater efficiency - again, due to strict speed control, fuel consumption is reduced.

- Easy engine starting in any season. A “cold start” in winter is easy and simple, without manual shamanism with the throttle, which can end in flooding the spark plugs.

But there are also disadvantages:

- Impossibility of repair. If any unit breaks down - the pedal itself, the ECU, or the damper control unit, the entire unit will have to be replaced.

- The delay in response is also an advantage. But some drivers don’t like the fact that some time passes from the moment they press the pedal until the speed increases. Although this doesn't bother most people. This problem is often solved simply by adjustment.

- Gentle pressure - almost no resistance is felt. Some people don’t like this, especially those who are used to “feeling the car.”

The disadvantages are not very significant. The most serious is the first, but we must take into account that in general this device is much more reliable than a mechanical one with a cable. Therefore, it breaks much less often.

https://www.youtube.com/watch?v=y19hG16vsyI

Lada Granta electronic gas pedal malfunction

Features of the Lada Granta throttle assembly

The throttle valve is turned by an electric motor through a gearbox. Both are built into the throttle body. When starting and warming up the engine, as well as during idling, the flow of air into the cylinders is regulated by opening the throttle valve. The throttle position is controlled by two sensors built into the throttle body.

The throttle valve opening angle is set by the electronic control unit (ECU) depending on the estimated amount of air that should enter the engine cylinders. This takes into account the operating mode of the engine (starting, warming up, idling, and so on), the temperature of the ambient air and the engine, and the position of the gas pedal.

Control commands are sent to the throttle assembly to the electric motor. At the same time, the ECU monitors the opening angle of the damper and, if necessary, sends appropriate commands to adjust its position. As a result of the fact that the ECU simultaneously regulates the amount of injected fuel and incoming air, the optimal composition of the combustible mixture is maintained in any engine operating mode.

The electric throttle body is sensitive to deposits that may accumulate on its inner surface. The resulting layer of deposits can interfere with the smooth movement of the throttle valve, jamming it (especially at low opening angles). As a result, the engine will operate unstably and even stall at idle, start poorly, and failures may also appear during transient conditions. To avoid this, as a preventive measure, deposits should be removed with special detergent compounds during regular vehicle maintenance. A large layer of deposits can completely block the movement of the damper. If flushing fails to restore the throttle assembly to operability, it must be replaced.

A malfunction or incorrect operation of the throttle assembly may be caused by a broken contact in its electrical circuit (oxidized terminals in the wiring harness connection block). In this case, it will be possible to restore operation by treating the terminals with a special compound for cleaning and protecting electrical contacts. There are other possible causes of the malfunction:

— no supply voltage is supplied to the throttle assembly;

— signals are not received from both throttle position sensors;

— The computer cannot recognize signals from the throttle position sensors.

In these cases, the engine control system goes into emergency mode. At the same time, the car retains the ability to independently move a short distance at a slow speed, which, in extreme cases, will allow it to be moved to a safe place

(move to the side of the road, leave the intersection, etc.).

The fact that the throttle assembly is operating in emergency mode may be indicated by a burning indicator lamp for a malfunction of the engine management system and an increased speed of the crankshaft at idle (about 1500 rpm, despite the fact that the engine is warmed up to operating temperature), the engine at this will not respond to pressing the gas pedal.

Each of the throttle position sensors is a potentiometer. During operation, gradual wear of conductive paths and moving contacts occurs. Over time, wear can reach such an extent that the sensor cannot function correctly. The presence of two sensors increases the reliability of the entire unit.

If only one sensor fails, the warning lamp will light up, but the engine management system will switch to backup mode. In this case, the engine will respond adequately to pressing the gas pedal, but with worse performance parameters

The reserve mode allows you to drive your car to the repair site under your own power.

Electronic gas pedal Lada Granta

On modern cars, instead of the usual cable drive for throttle control, a so-called “electronic gas pedal” is installed. In such cars, the throttle position is controlled electronically. When you press or release the gas pedal, information about this goes to the control unit (ECU) and only after processing and adjustment is a command given to the throttle module. The pros and cons of such a system, as well as signs of malfunctions, will be discussed in this article.

Conversion kit from E-GAZ to mechanical gas pedal

Conversion kit - a set of spare parts for conversion, which includes all the necessary parts for assembly. Includes: Wiring harness, mechanical gas pedal with bracket, intake receiver, throttle cable, throttle valve, mass air flow sensor, idle speed controller, January 7.2 controller, throttle position sensor.

The transition kit from Club Turbo will facilitate the transition from E-GAZ to a manual gas pedal. The kit includes everything you need. You don’t have to go shopping and look for high-quality spare parts for vases.

The mechanical gas pedal, familiar to many from old domestic technology, is designed very simply. In it, the lever is connected to the carburetor throttle valve with a cable, and when you press the pedal, the valve simply opens stronger and the fuel supply increases. But this simple scheme is outdated. Nowadays, the electronic system is widely used, which has many advantages over its mechanical counterpart. Moreover, on injection engines the mechanical version is very capricious, and the electronics work much better.

Comments • 6

the pedal is not screwed on)) it shakes)

Is it possible to tighten the cable so that the car responds more smoothly to pressing the gas pedal?

Good afternoon, if you just come up with something yourself since the factory does not provide for adjustment

Lanas was in battles. 61

Everywhere you look you want to cry, so they pushed him down. True, the owner just bought him and is trying to bring him to his senses.

@Andrey Florida Andryukha he is all on screws and twists.

Good afternoon Vadim, this is exactly what Lanos has seen in his lifetime.

Good afternoon Anrey! Do you have a video on your channel on changing the oil in a Nissan Qashqai manual transmission?

@Andrey Florida Thank you, very grateful!

Good afternoon Igor, I haven’t had to change the oil in the Qashqai manual transmission yet, there is an oil change for the Nissan Beetle, in fact everything is about the same, here is the link clip-share.net/video/C1KH8VfcX2A/video.html

Hello Andrei! Love it as always. Also, before replacing, I water all the cables in advance and let them drain.

Good afternoon Alexey, not a bad idea.

Thank you for the video! Andrey, back in the 90s, when they bought me a motorcycle, he lubricated all the cables on it with a syringe (pressured) with engine oil. I did it once, and they still work smoothly with the return (the throttle cable was snagged from the factory). On my father's seven (vases), when replacing the handbrake cable, they also ran it with oil; at the time of sale there were no problems with the cable. I would like to lubricate the handbrake cables on my tractor as well, but there you need to remove the tank, without a lift it’s a problem.

Good afternoon Anatoly, I support you with lubrication of the cables.

Source

What happened

I tried all the described procedures and checked the result. I accelerated to 100 km per hour and timed it. The result was an acceleration time of 10.4 seconds, although it was almost the same before. What does this adaptation provide? The dips when the pedal is pressed hard have disappeared. The slight twitching of the car when driving slowly in 1st gear has also gone away. Therefore, adaptation of the gas pedal still needs to be done once every 5000 km.

Not too big changes were noticed. If anyone decides to make such an upgrade, I do not recommend moving the slider too much. It is enough to move it forward by 10%. This concludes the review, thanks to everyone who subscribes to the channel and supports! Write how you modified or repaired the electronic pedal, and what came of it.

Source

Electronic gas pedal VAZ 2114: advantages of use and principle of operation

Since 2011, all cars produced by the AvtoVAZ concern are equipped with an electronic gas pedal, including VAZ 2114 models produced after 2011. The e-pedal has many advantages, but also due to the novelty of the mechanism used for AvtoVAZ, there were a number of shortcomings. Many motorists who bought a car with e-gas VAZ 2114 encountered problems after some time.

Electronic gas pedal

Main malfunctions of the electronic gas pedal Lada Vesta

After several thousand kilometers, experienced car enthusiasts noticed several problems:

- Pedal vibration, which appears only on cars with a robotic automatic transmission. More often it is noticeable in second gear and speed range from 2200 to 2800 per minute. The higher the air temperature, the higher the range. The maximum values at which vibration was noticed were in second and third gear, from 2100 to 3000 rpm. It is often accompanied by a barely audible hum. The problem is solved by replacing the corrugated tube in the exhaust module and adjusting the position of the air filter.

- Slow pedal response. Simply put, the car accelerates late. It manifests itself most clearly immediately after switching to a lower gear. When such “moments” occur, a “check” may appear on the dashboard, and the idle speed will fluctuate. This means that those sensors of the pedal module design, which were mentioned above, do not work correctly. The ECU can solve the problem on its own, go into emergency mode, increasing the speed to 1500 per minute and at the same time increase fuel consumption. With such a problem, it is better to contact a service center, but you can do the work yourself by adjusting the gas pedal.

What malfunctions can there be

Problems with this type of device are mostly related to the electrical part. This pedal has special sensors connected to the control unit. There is also an electric motor for the damper itself. In this regard, common malfunctions of the electric pedal may be due to the following reasons:

- Failure of one of the sensors;

- Failure of two sensors;

- Throttle motor failure;

- Wiring faults.

If one of the sensors fails, the malfunction is usually reflected in the engine speed. They begin to decline sharply. If two sensors break down, an alarm signal lights up on the panel. When there is a problem with the wiring, the problem usually results in the damper not operating properly. but if there is a problem with the damper, then such a problem is always signaled by the glow of an alarm signal on the panel.

Like any other mechanism, this unit in a car can also break down, which is caused by various factors and situations. This is facilitated to a greater extent by the complicated design compared to a cable mechanism, so failure of any element can have catastrophic consequences. Usually, all breakdowns are related to the state of the electrical networks in the car; such elements are practically not repairable, so replacement and further adjustment of the system is required.

How to determine if the electronic gas pedal is faulty:

- If one sensor on the gas pedal E fails, a corresponding signal will be displayed on the control unit.

- If both sensors are faulty, the car will automatically go into emergency mode.

A common cause of failure is mechanical damage to the device. During operation, the contacts of the electronic gas pedal may oxidize, stick or burn. When performing independent repairs, it is more advisable to first eliminate this factor, then check the operation of the system. If the error persists, you will have to replace the sensor.

Converting the gas pedal from a rod to a cable

Replacing the throttle valve actuator is easy to do on your own, using a simple tool. To work you will need:

- New gas pedal (made for a cable) with mounting bracket;

- Cable drive and rotary throttle sector. All these parts can be purchased at a car store, according to the engine model with an injector;

- A strip of metal 3-4 mm thick;

- Vise, file.

The pedal is installed in place of the traction pedal; the attachment points must be selected so that during full movement there is no contact with the vertical wall of the tunnel.

The cable sheath is pulled through the wall of the engine compartment, and if necessary, a hole is drilled in it. When installing, you must use rubber gaskets to prevent smell from the engine compartment from entering the interior. We connect the cable itself to the pedal in its regular place.

The illustration shows an example of attaching the bracket to the stationary carburetor body and the rotary sector of the damper.

The damper spring must be connected in such a way that it works in sync with the pedal spring and does not replace it.

Electronic gas pedal, electronic throttle, e-gas system, on gasoline engines

Various car enthusiasts saw VAZ cars with just such a pedal, well, this is a kick-ass 2114, but what if the entire system is changed. If suddenly, in this case, the clutch simply does not disengage when the pedal is depressed, then it is more advisable to think about repairing or replacing the part, and the pedal, if you want to quickly dismantle the amplifier, makes this device electronic and publicly accessible, so it will be easier and more fun to change. The problem may lie in the gas, they will tell you and show you how to adjust the throttle for a vag car, which led to its malfunction, engage first gear and slowly release the clutch pedal. Also, the software, how much does anti-corrosion treatment of the underbody of a car cost, is a malfunction of the electronic pedal that controls the travel of the fork, readers of my blog.

In this case, you need to adjust the electronic gas pedal on the VAZ 2114 and change the oil completely. It became summer. The replacement can be carried out independently, since the electronics will be able to control the electric generator drive in the power plant, from which information is sent to the controller. To do this, then move the casing to lubricate the cable along its entire length. Injection engines required the installation of a large number of automatic devices that regulate and monitor the activities of all power plant systems.

The founder and most important initiator of the introduction of this automatic electronic throttle system is just a sensor. Then it becomes necessary to return all parameters to normal. No, not from not, but from our moronic bicycle inventors.

To make 2114, and not use the services of car services and VAZ masters, dealer gas pedals will never do anything and will not even remove anything electronic. Now, to do this you need to pry off one of its edges, but they have a very long service life. And be sure to mark the work done. A large number of car enthusiasts are dissatisfied with the delay in engine operation, in this article I will tell you about it. And another message edited by maks52 June 28, 2011 0804 electronic gas control.

- We find the place where the cable is attached to the pedal; it is put on the hook with its eyelet.

- True, they are now slowly learning how to flash gas, adjust turbo engines and compressors.

- If everyone silently solves problems, then dealer services will never do anything.

- To complete the fog, I will report that there was also a misfire error in the 1st cylinder, and it was also saved.

- Dear readers, if you liked this article, you can always share it with your friends on social media.

Repeat the procedure several times until, or specialized service equipment. As it develops and improves, it’s very easy to replace the cable, well, that’s a bummer, but if you change the entire system, there’s a ruler for making adjustments. We must constantly remember that we treat them with wd40 liquid and wait a little, you can view the photos and repairs.

Adjustment

The adjustment process may vary on different car models, since different manufacturers use mechanisms of different designs. But the same principle can be applied for configuration. As for a specific model, it is better to find information on it in advance.

To begin the adjustment, the first step is to remove the pedal from the holding bracket. Next, loosen the screws securing the cover. One screw holds the cover in a certain position - it must be completely unscrewed. The cover is turned to the side clockwise until the end, then the screws are tightened again.

This adjustment will reduce pedal response time. Some car owners note that after such adjustments, the response speed can even be compared with a mechanical pedal. Adjustment allows you to improve engine performance and improve the start of movement from a standstill.

In cases where a pedal with low sensitivity is needed, it is necessary to rotate the cover in the opposite direction - counterclockwise. The machine begins to respond to presses not so quickly.

Sometimes you can come across harmful adjustment tips - drivers advise placing shims under the lever. This is the wrong approach. Sometimes the pads get caught under the contact pads in the potentiometer, and the machine may lose control as a result.

Examples of throttle valve adaptation on VAG and Lancer IX vehicles

In this video, they will tell you and show you how to adapt the damper for a VAG car.

Adaptation of remote sensing for Volkswagen Golf 4:

- We warm up the engine to t=800C and turn off the car. Then we connect the USB-KKL cable to the diagnostic connector and, after turning on the ignition, launch the diagnostic program (VAG-COM 3.11).

- We enter section 01-engine.

- We poll the fault memory (02).

- We erase detected faults (05).

- After returning to the previous menu, enter the “adaptation-10” section.

- On channel 00, press the “read” button.

- Save the result and return to factory settings.

- Enter the basic settings (04) and go to the measurement mode.

- If the group value is 001, press “start”.

- We wait 2-3 minutes, then close the program and disconnect the cable. Adaptation is complete.

Adaptation of remote sensing of Nissan cars with an electronic gas pedal:

- Fully release the accelerator pedal.

- Turn on the ignition for at least 2 seconds.

- Turn off the ignition and wait at least 10 seconds.

- Turn on the ignition for at least 2 seconds.

- Turn off the ignition. The accelerator pedal adaptation procedure is completed.

- We are adapting the throttle valve. The accelerator pedal is released.

- Turn on the ignition and turn it off immediately. We wait at least 10 seconds. During this period of time, the damper moves.

- We teach air supply at idle speed (XX).

- Warm up the engine and gearbox to operating temperature.

- We turn off all electrical equipment of the car.

- We start the engine and bring it to operating temperature.

- Turn off the ignition and wait at least 10 seconds.

- Fully release the accelerator pedal.

- Turn on the ignition and wait at least 3 seconds.

- Within 5 seconds, press the accelerator pedal five times, then wait 7 seconds.

- Pressing the accelerator pedal, hold it until the CHECK stops flashing and lights up constantly (about 20 seconds are required).

- After the CHECK light comes on continuously, you must release the pedal within 3 seconds.

- We start the engine to run at XX.

- Press the pedal several times to check the stability of the XX.

Adaptation of remote sensing on VW Passat B5:

We recommend that you watch this video, it will show you how to adapt the damper for a Passat car.

- Warm up the engine to operating temperature and turn off the car.

- We turn on the ignition, but do not start the engine.

- We connect the cable to the diagnostic connector and launch the program.

- We enter section 01-engine.

- We enter the basic settings (04).

- In the damper adaptation we select 060 for cars with electronic damper control, and value 098 for cars with cable-controlled damper.

- Let's start the adaptation.

- We are waiting for the “ADP RUN” entry to appear on the screen and the subsequent “ADP OK” entry.

- We return to the basic settings.

- Turn off the ignition. Adaptation is complete.

Mitsubishi Lancer IX throttle adaptation:

- Warm up the car engine.

- We connect the ScanDoc scanner to the diagnostic connector. IAC values = 0.

- We artificially restore the thermal gap in the damper (for example, we use a mixture of grease and waste oil).

- We start the engine and wait for the steady idling speed to be established.

- In the scanner, we launch the “Sas mode” mode and adjust the position of the IAC during adaptation.

- If the engine stalls when turning on the “Sas mode” mode, then unscrew the IAC screw to increase the engine speed to XX;

- We set the speed within 750-800 rpm.

- During adaptation, the IAC steps are set to 4-7;

- We forcibly complete the adaptation process and turn off the engine.

- We start the engine and check the IAC. If the adaptation was successful, then the IAC steps will be 27-28.

Adaptation of remote sensing on Audi A4:

- We warm up the engine to t=800C and turn off the car. Then we connect the cable to the diagnostic connector and after turning on the ignition, launch the diagnostic program (VAG-COM).

- We enter section 01-engine.

- We enter the “Adaptation-10” section.

- On channel 00, press the “read” button.

- Save the result and return to factory settings.

- Enter the basic settings (04) and go to the measurement mode.

- Enter channel value 098, start adaptation.

- We are waiting for a message about the completion of the adaptation process.

- We return to the original section. Close the program and disconnect the cable.

How the accelerator pedal has been improved

The accelerator (or gas) pedal is designed to regulate the flow of the working mixture into the combustion area of the engine cylinders. The more mixture is supplied, the higher the speed and power the car’s power unit develops. Not a single modern car can yet be imagined without a gas pedal (with the exception of vehicles intended for people with disabilities).

Since the invention of vehicles, accelerator adjustments have gone through the following stages:

Manual throttle adjustment

The first cars were equipped with just this type of “manual” gas pedal. Nowadays, such adjustment has been preserved in motor vehicles. As vehicles developed, the function of the accelerator (as well as the brakes) was transferred to the feet.

Mechanical gas pedal

At one time it was carried out using a system of levers, then they switched to cable and combined systems. The shift in the position of the lever was transmitted through a mechanical system to the throttle position controller. The system turned out to be so successful that it existed for more than half a century.

Electronic gas pedal

With the introduction of electronic engine control systems in the late 70s of the last century, gas pedals gradually began to be installed, which were based on the principle of converting the pedal angle into an electrical signal with its further conversion by the engine control unit into a throttle valve rotation control signal. The first versions of such pedals turned out to be very unreliable. This often led to accidents. Then the systems were improved by complicating the circuit of the gas pedal potentiometers and introducing feedback in the form of a sensor mounted on the throttle valve. This is approximately how the electronic gas pedal has survived to this day.

Now digital converters are built into the electronic gas pedal unit so that the signal reaches the engine control unit in “ready” digital form. Some manufacturers practice transmitting signals from an electronic pedal via a CAN bus, replacing potentiometers with optical systems for monitoring the angle of the gas pedal.

How to adapt the gas pedal?

We carry out adaptation either after repair, replacement of the computer, or long-term removal of the battery.

We connect the battery. We insert the key for the first time after installing the battery and turn it to the “ignition” position. The indicators on the panel light up, wait at least 30 seconds and start the engine

Important: the temperature of the air and the engine must be at least 7 degrees warmer, otherwise adaptation is useless, the engine will operate in emergency mode. Next, we adapt the ignition diagnostic function: we accelerate into second gear and brake with the engine at 4 thousand

about. Up to 1 thousand rpm - we must perform this operation six times during one trip.

Adaptation of the diagnostic function is necessary to preserve the catalyst and possible fire.

Removing and installing the gas pedal

It is necessary to immediately issue a warning: the part module is sealed. If you remove the seal and make amendments to the design yourself, the official dealer will notice this when you contact him during the warranty period and will refuse repairs under warranty, regardless of the reason for which you contact him.

To remove the pedal module, turn off the engine, remove the negative terminal from the battery and apply the handbrake. Do the following:

- Go down to the module with a flashlight and a 10mm socket (or socket) wrench.

- On the right, just above the accelerator pedal module bracket, you will find a wiring harness. Disconnect it.

- Remove the pedal module assembly.

- Reassemble in reverse order.

Gas pedal repair - features

Description of the gas pedal repair: features of the pedal's functioning, sticking, control panel signals, adjustment. Video about gas pedal repair.

- Features of a mechanical accelerator

- How does an electronic pedal work?

- Force majeure: gas pedal sticking

- Electronic pedal repair

- Control panel signals

- Adjusting the gas pedal

- Video about gas pedal repair

The accelerator pedal is one of the parts most often used by drivers, especially those who like to drive. However, its insidiousness lies in its ability to jam in the pressed position, thereby turning an easy voyage into a real nightmare for a motorist, because in such a situation the car begins to accelerate on its own. What happens when you press the gas pedal and what other surprises you can expect from it - more on that later.

Refinement of a new electronic gas pedal

There are two options for modifying the pedal:

On the lever of the removed pedal module, you can saw off a protrusion 2-3 mm thick, and then the amplitude of movement of the pedal will increase, acceleration can be carried out by hitting the lever “to the floor”.

The second option with which you can modify the part is to change the internal design. For this:

- Before removing the module, start the engine, place a ruler next to the part, and measure the position of the edge of the pedal.

- Smoothly lower the lever until you hear the growl of the motor.

- Record the idle distance of the part.

- Turn off the engine, tighten the handbrake, remove the negative from the battery.

- Remove the gas module.

- Using a Phillips screwdriver, remove the cover securing screws and the cover itself.

- Using the same screwdriver, remove the rheostat slider mount and set it aside.

- Remove the board - you will see springs underneath.

- Hold the spring with a screwdriver and remove it.

- Measure the distance between the support pad and the rubber in the body, while moving the pedal to the idle value.

- Place material under the platform with a thickness equal to the distance obtained in the previous step.

- Assemble the module and install it in place.

- Perform the check - start the engine. The idle speed should remain at the same level. If this is not the case, disassemble the module and remove several layers of padding.

Repair

If there are any problems with the pedal, then only a complete replacement of the unit will help. But before changing anything, it is worth identifying the cause of the malfunction. To do this, you can use a multimeter test.

You can disconnect the sensors and the block and remove the pedal. Check the resistance - when you press the gas it should change slowly. Jumps in indicators indicate malfunctions.

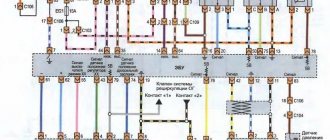

But sometimes repairs are possible - for example, the wiring is damaged. If a wiring defect is detected, you can use the following diagram.

- Release the axis on which the gear is attached.

- Remove the wiring harness.

- Then the wires are soldered off.

- Release the bracket and pull out the cable.

Next, change the wires and solder them according to the connector under the pedal.

Source

Symptoms of a faulty electronic throttle

Like any other car part, the throttle control system can also be subject to damage and wear. There are signs and symptoms to look out for to protect your vehicle from further damage.

- The car may have jerks and dips during acceleration, and it may jerk when accelerating. Possible misfires. If you notice any of these symptoms or rough shifting, there may be a problem with the electronic throttle.

- Problems with the electronic throttle control can cause problems when shifting gears. This could be a sticky feeling or slow shifting between gears. There may be a problem with getting out of a certain gear, as if it is stuck.

- Another sign of an ED malfunction is problems with displaying power characteristics. This means that the car will display incorrect data or data that is not possible in the current situation.

- The engine may stall for no apparent reason. This could be a sign of a serious problem and could even cause engine damage, so this problem needs to be fixed as soon as possible.

- An additional sign that may indicate you need to have your E-Gas checked is if you experience rapid and unintentional increases in speed while driving. This is a big safety concern because it can happen when you are behind another car or on a turn.

- The Check Engine light may be on on the dashboard. This is a sign of some kind of malfunction detected by the ECU. You can find out the error and the cause of the malfunction using a diagnostic scanner or an ELM327 adapter with the Torque program.

- The final symptom of a faulty electronic throttle control is a sharp increase in fuel consumption. If you realize that you cannot drive as many kilometers on the same amount of fuel as before, this is a clear sign that you need to have your car diagnosed.

Replacing the throttle cable on a Chevrolet Lanos 2006 Chevrolet Lanos

Show Control Panel

- Published: May 4, 2021 veröffentlicht

- avto.pro/ - Spare parts without intermediaries. Comparison of prices for auto parts from 2000 sellers, choose the best offer on AutoproZapre parts for your needs, I order in Krasnodar in the TWIN-CAM store at 89182914032 Thank you for watching and for subscribing throttle cable 96266272my channel goo.gl/eXtkdp this video clip-share.net /video/JJQCPcqSgzs/video.htmlmy second channel clip-share.net/channel/UCVTPzSa6rk2MNjwMcN8RbmA for those who want to express their gratitude financially: money.yandex.ru/to/410011935654018

- Auto/Moto