Replacing the ABS block on Kalina

The control unit for the anti-lock brake system on a Lada Kalina car is one of the most expensive electronic parts. And its cost is even close to electric power steering. A new unit can cost about 20,000 rubles. Of course, it will be imported, most likely from Bosch.

Fortunately, it is extremely rare to replace this unit, but if this happens, it is most often due to increased voltage on the on-board network. To independently replace the abs unit on Kalina, you will need the following tool:

- 13mm wrench - preferably a special split one for loosening brake pipes

- 10 mm head

- Ratchet handle

The main causes of ABS malfunction

There can be quite a lot of problems with the anti-lock braking system; there are 4 common causes of ABS malfunction:

- There are breaks in the abs sensor wire or a malfunction of the controller unit. In this case, an error is displayed, signals about changes in angular velocities stop being sent, and the entire system turns off.

- Failure of wheel sensors. When the ABS, after switching on, undergoes self-diagnosis and finds an error, but continues to work. The reason is most often oxidation of the contacts, poor connection to the system power supply, or a short circuit of the wheel sensors to ground.

- Different tire pressures and tread patterns. As a rule, information about the angular velocity in this case comes from an additional device. When one of the wheels is flat or the tread of one wheel is rougher than the others, it begins to slow down. In addition, the same effect can be observed if you install tires with different degrees of wear.

- Mechanical damage to elements - wheel bearing separators, grilles, broken wire near the sensor, wear of the wheel bearing, presence of play and fracture of the wheel sensor rotor. With these breakdowns, the ABS does not start at all. This could also include a failure of the ABS pump.

All of the above problems can be solved on your own; sometimes it is enough to identify the problem and repair some ABS units rather than having to completely replace the expensive equipment. The most vulnerable in the ABS circuit are the wheel sensors, which are located next to the rotating hubs and axle shafts. The location of the sensors is poor, since dirt and increased play in the hub bearings can cause a malfunction in their operation, thereby nullifying the entire operation of the anti-lock brake system.

ABS sensor on a car wheel

Often the performance of the unit is affected by the voltage between the battery terminals. If the voltage is reduced to 10.5V or lower, the system itself may abruptly shut down through the safety block. Since the safety relay always reacts to unacceptable surges and voltage fluctuations in the vehicle network. Such situations can be avoided if you do not disconnect the electrical connectors with the ignition on and the engine running. You need to constantly monitor the connection contacts on the generator and do not start the engine by “lighting up”.

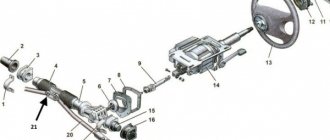

Dismantling the hydraulic unit block on Kalina

The first step is to pump out the brake fluid from the reservoir, or drain it completely. After this, using a wrench, unscrew the 4 brake pipes, which are clearly shown in the photo below.

The result of the action performed is clearly visible in the photo:

And there are still two pipes that go from the master brake cylinder to the Kalina ABS block.

Now we remove the block with the power wires, having first pulled the latch (bracket) up.

And disconnect it, the result of which is demonstrated below in the photo.

Now you can begin to dismantle the block itself by unscrewing the two fastening nuts using a 10 mm socket and a ratchet handle.

All that remains is to lift the block up or remove it by pulling it to the side from the studs.

Installation of a new unit is carried out in the reverse order of removal. Of course, after performing this repair, it will be necessary to bleed the brake system to get rid of air in the pipes.

Source

Problem with brakes on Kalina with ABS

At a minimum, you need to remove the fuse in the main unit itself.

PS on the site there is a harmful example with a detour of a cat - FUCK THE FUCK Boar and elk, it makes sense to go around your loved one - a dog or a cat - FOR THE FUCK. sometimes people left several times for the sake of a cat.

no big deal A LITTLE Features of bleeding brakes with ABS:

in cars in which the following units are located in one unit: a hydraulic valve block, a hydraulic accumulator and a pump

, replacing the brake fluid and bleeding the brake system with ABS is done in the same way as bleeding the brakes on a car without ABS (you need to turn off the system by removing (disabling) the fuse). Bleeding of the circuits is carried out with the brake pedal pressed, the RTC bleeder fitting must be unscrewed. The ignition is turned on and the pump expels air from the circuit. The bleeder screw is tightened and the brake pedal is released. An extinguished ABS fault light is evidence that your actions were correct.

And then you need to connect and disconnect something there

And then there’s no need to wait at all

Bleeding the brake system with ABS, in which the hydraulic module with valves and the hydraulic accumulator are separated into separate units, is carried out using a diagnostic scanner to retrieve information from the ABS ECU. It's unlikely you have one. Therefore, bleeding of brakes with ABS of this type should most likely be done by you at a service station. Bleeding the brake system with ABS and electronic activation systems (ESP or SBC) is carried out only under service conditions.

Only ABS can break down and block the transfer of brake fluid to the cylinders.

Source

ABS Lada Vesta error codes and their interpretation

Diagnosing ABS yourself is a rather difficult task if you do not have diagnostic equipment (cable, laptop, and software). If you have the ability to read errors, then by comparing their codes with the description, you can much faster determine the cause of the malfunction. The following are the errors that “light up” the anti-lock braking system malfunction light:

Thanks for subscribing!

- U0121 - no data from the ABS system controller

- U0122 - no data from ESP system controller

- U0415 - incorrect data from the ABS system controller

- U0416 - Invalid data from the ESP system controller

In most cases, the absence of data from the controller indicates a malfunction. If the diagnostics indicate errors U0415 or U0416, then there is a high probability of sensor malfunction or damaged wires. Also, do not forget that with different tire pressures, the control system may receive incorrect data from the controller and indicate the last two errors.

How to check the resistance of the abs sensor

The abs sensor of a Priora car is placed near the wheels. It comes in front and back. The ABS unit is placed near the engine on the right, if you open the hood and stand in front of the car. When AbS (ABC) lights up on the panel, it means there is a problem with the system. Why do cars need this system? Abs affects the braking of the car, Priora with this system brakes 2 times faster than without it. The wheels brake in small portions, measured by a computer. Initially in 2008 there were cars without it. Read the article to the end and find out what the error is, what it is responsible for and why the ABS lights up and does not work. Priora has sensors and an ABS unit. Failure of any spare part leads to problems. On the Prior, there are 18 errors belonging to the braking system.

The appearance of an icon on the dashboard indicates an error occurring in the operation of the vehicle. There are serious errors on the Priora, if they occur, you should not tempt fate and move on, but there are errors that can be postponed. For example, the ABS system is considered very valuable for a modern driver in a car.

The Priora's ABS system saves you during unexpected and sudden braking and makes the process itself more efficient, reducing the braking distance. Therefore, when the ABS light is on on the Priora’s dashboard, strange feelings of uncertainty arise - knowing that the road situation can be so unpredictable that you will have to brake sharply, you involuntarily have to look for the reason why the icon appeared on the dashboard.

As in many systems, this behavior of the car's control unit may result in the ABS sensor on the Priora having to be replaced. A large system with a fairly simple device is worth checking - for your own safety.

Features of the system

ABS is installed on the braking system and makes its own adjustments to its operation. From the name itself you can understand that its task is to prevent wheel locking during braking.

The peculiarity of car wheels is that their rolling friction force is higher than sliding friction. That is, a wheel that rolls has better adhesion to the road surface than a wheel sliding along the road surface, which happens if it is completely blocked. As a result, the braking distance of the car increases.

Also, wheel sliding does not always occur in a straight direction, since lateral forces can prevail over longitudinal ones, which is why the trajectory of movement of such a wheel changes. The result of this is unpredictable and uncontrolled movement of the machine.

But if you create a force on the braking mechanism that will slow down the rotation speed as much as possible, but without blocking it (keeps it on the edge), then the braking distance will be shortened and the car will not lose control.

In cars without this system, experienced drivers use the method of repeatedly pressing the pedal (intermittent braking) to obtain maximum braking effect. To prevent the wheels from becoming blocked, the driver presses the pedal when braking, then releases it and repeats this many times.

The essence of this method is very simple - to catch the moment on the brake mechanisms when they slow down the wheels as much as possible without causing them to lock, but this is not always possible, especially if the wheels are moving on different surfaces.

Intermittent braking (press and release) does not allow the wheels to completely lock, since the driver simply periodically loosens the force on the brake mechanism. ABS uses the same principle.

Standard sensor and ABS unit - article number and price

The anti-lock braking system operates the rear and front wheels. It contains several brackets, brackets, and other fasteners that ensure accurate operation of the ABS and hydraulic unit damper (article 11180353832400, price - about 30 rubles). But only three items are considered the main ones in ABS:

ABS control unit (“brain”) - article number 11180353801001, cost - about 10,000 rubles; Front wheel speed sensor - catalog number 11180353835000, cost - about 1,000 rubles; Rear wheel sensor - catalog number 11180353837000, cost - 1000-1200 rubles. Often, to solve the problem, you only need to buy an anti-lock sensor from Priora, so the scale of financial costs is not as huge as it seems at first.

ABS fault codes (ABS error codes)

| Code | Code Description |

| S0035 | Front left DSC circuit failure or unreliable signal |

| C0040 | Failure in the front right DSC circuit or unreliable signal |

| C0045 | Failure in the rear left DSC circuit or unreliable signal |

| C0050 | Failure in the rear right DSC circuit or unreliable signal |

| S0060 | Failure in the exhaust circuit of the front left EMC |

| C0065 | Failure in the intake front left EMC circuit |

| S0070 | Failure in the exhaust circuit of the front right EMC |

| S0075 | Failure in the intake circuit of the front right EMC |

| C0080 | Failure in the exhaust circuit of the rear left EMC |

| S0085 | Failure in the intake rear left EMC circuit |

| C0090 | Failure in the exhaust circuit of the rear right EMC |

| S0095 | Failure in the intake rear right EMC circuit |

| C0110 | Failure in the EWH circuit |

| C0121 | Failure in the EMC power supply voltage relay circuit |

| C0161 | Brake light switch circuit failure |

| C0245 | Error when measuring DSC frequency |

| C0550 | Internal ECU fault |

| S0800 | Supply voltage is below or above operating range |

In case of malfunction with code C0035, C0040, C0045 and C0050, it is necessary to check the electrical circuit to the corresponding DSC for a short circuit or open circuit, as well as the supply voltage of this DSC.

In case of a malfunction with code C0110, it is necessary to check the supply voltage at the contact of the second block of the harness to the hydraulic unit. For code C0121, check the supply voltage at the contact of the third block of the harness to the hydraulic unit.

If there is a malfunction with code C0161, check the electrical circuit to the brake light switch for a short or open circuit.

At contact 20 of the harness block to the hydraulic unit there should be: - low-level input voltage no more than 0.3 U power; — high level input voltage of at least 0.8 U supply.

If there is a malfunction with code C0245, it is necessary to check the fastening of the DSC and the gaps between the DSC and the rotor. Gap dimensions: between the front wheel speed sensor and the teeth of its rotor should be 0.45-1.55 mm; between the rear wheel speed sensor and its rotor is 0.2-2.3 mm.

ABS device on Priora

The main task of ABS is to prevent the wheels from locking during braking. To fulfill its task in Priora, the anti-lock braking system works like this:

- At the moment of braking, the ECU receives data from ABS sensors that read the speed (they are located behind the hubs).

- The anti-lock braking system ECU is a unit with internal brake fluid pressure valves and an electric return pump. Its location is the front left side member.

- When the sensors transmit data about a sharp jump - instantaneous braking of the wheels - the fluid pressure is gradually released using valves.

- A malfunction of any system leads to the transmission of an error signal through the computer, which appears to the driver as a “burning ABS on the dashboard.”

Why is ABS needed in a car?

ABS is needed to prevent the wheels from completely locking when braking, which eliminates the possibility of skidding and reduces the braking distance. The theory behind the anti-lock braking system is that when braking, sliding friction occurs between the locked wheel and the road surface, the force of which is lower than rolling friction (when the wheel rotates). In addition, when sliding, lateral forces prevail over longitudinal ones and it is easier for the wheel to “go” to the side than to maintain a given trajectory - a difficult-to-control skid occurs. But if the wheel turns during braking, the car will not skid and will maintain its trajectory, and the braking system will work with maximum efficiency.

How to disable ABS on a Lada Priora with your own hands: video instructions

One of the negative factors in car operation when ABS is turned off is an increase in braking distance, which is especially noticeable in poor traffic conditions, on wet and slippery roads, as well as in snowfall. There may also be problems with the vehicle's handling. Among car enthusiasts there is no clear opinion about whether it is good or bad to have ABS, but some turn it off. This material will discuss exactly this, but we emphasize that responsibility for all the consequences of such manipulations lies with the owner of the car, and whether the ABS can be turned off or not is up to everyone to decide for themselves. Let’s immediately make a reservation that, as experienced car owners note, including incorrectly disabling ABS on the Lada Priora, this can lead to operational problems, as well as unnecessary questions in service centers. Moreover, if the car is under warranty, the fact that the ABS is turned off may even lead to warranty service being denied.

Basic malfunctions of the ABS system

Any driver who has ever had an ABS light come on in a Priora will tell you about the sensor. But it could be worse - if the ABS in Priora does not work. There are several options in which to look for the source of the problem:

- wiring damage;

- mechanical damage to the brake fluid pressure valve block;

- failure of speed sensors.

The first thing you need to do when you see the light (ABS lights up) is to read the error symbols using a special diagnostic scanner. Each item in the ECU is indicated by a corresponding code:

- C0040 – the speed sensor (DSC) of the right front wheel is faulty;

- C0035 – DSC of the left front wheel is faulty;

- C0050 – DSC of the rear right wheel is faulty;

- C0045 – DSC of the rear left wheel is faulty;

- C0065 – front left valve (intake);

- C0060 – front left valve (exhaust);

- C0075 – front right valve (intake);

- C0070 – front right valve (exhaust);

- C0085 – rear left valve (intake);

- C0080 – rear left valve (exhaust);

- C0095 – rear right valve (intake);

- C0090 – rear right valve (exhaust);

- C0161 – the braking signal does not turn off;

- C0121 – power to the valves does not turn on;

- C0110 – electric return pump.

- C0550 – error in the “brains” - ECU;

- C0245 – error in receiving data from sensors;

- C0800 – power surges.

The solution may be simpler: an ABS sensor is installed under the fender liner. Dirt often gets into this area; an unprotected piece of wiring near the DSC connector can be damaged. Replacing it will help.

What to do first?

It is necessary to check the ABS sensors located near each wheel hub. Your task is to detect a violation in the connection of the sensors, a broken wire or damage to the ABS sensor housing. In any of these cases, you will one way or another see the corresponding indicator on the panel, well, provided that the system control unit itself is working and not “buggy”.

Checking the ABS sensor - measuring the resistance

- We jack up the wheel on which you think the inoperative or faulty sensor is located, or each wheel in turn if you don’t know exactly which sensor is faulty.

- Next, remove the wheel and gain access to the sensor.

- Remove the housing, as well as the protective control unit and connectors that supply power to the sensors.

- After that, we insert wires into the circuit of wires with PIN connectors and connect them with the sensor and multimeter.

- We measure the resistance and compare it with the one that should be by default (you can find it in the manual) or with a representative of the manufacturer of your car.

- We check the wiring for breaks or short circuits.

- Rotate the wheel while watching the multimeter readings, the resistance should change.

- Device - leg - 5-26 Ohm.

- Device - "ground" - from 20 kOhm or more.

For more details on how to check the ABS sensor, watch this video:

Checking the ABS sensor using a tester - measuring the voltage

- Let's jack up the wheel.

- Turn on the multimeter, set the DC voltage measurement mode.

- We connect the electrodes of the device to the connectors and check the readings, while rotating the wheel (about 1 rpm).

- A working ABS sensor will show voltage on the device

0.25-1.2 Volts. If the wheel rotation speed is higher, the readings will increase accordingly.

How to check a sensor with an oscilloscope?

To diagnose the serviceability or malfunction of the ABS sensor, you can even use an oscilloscope or, more simply, a tester. When connected, a graph will be displayed on the device; using amplitude analysis, you can judge the serviceability or malfunction of the sensor.

Checking the sensor resistance

Before starting the testing procedure, it is advisable to know the standard resistance value of the ABS sensors installed in your car. This information can be found either on the manufacturer's website or on the Internet. The algorithm for checking the sensor resistance is quite simple:

- We hang the wheel using a jack and remove it.

- We find the ABS sensor and disconnect its connector from the wiring leading to the control unit.

- We switch the multimeter to resistance measurement mode.

- We connect the probes to the contacts of the sensor connector and look at the readings of the device.

- If the ohmmeter shows “0”, this means that there is an open circuit in the sensor coil. This sensor must be replaced. Device readings that exceed the nominal value by 2–3 times also indicate a malfunction of the sensor, namely that its coil is “burnt” and the signals coming from it to the control unit are incorrect.

Replacing the ABS block

For repair you need to prepare:

The procedure for working with Priora is as follows:

- Stop the car and raise it. Disconnect the minus from the battery.

- Drain the brake fluid from the cylinder brake hose.

- Unscrew the brake pipes connected to the block. There are 6 of them in total.

- Unhook the power lock and disconnect the wires.

- Unscrew the nuts fastening to the car body.

- Slowly pull the block and remove it.

- Install the unit by connecting everything in reverse order. Don't forget to bleed the brake system.

Replacing the ABS sensor

To replace the anti-lock braking system sensor on a Priora, do the following:

- Raise the car. Hang up the wheel. The ideal position is on a car lift. First remove the negative terminal from the battery.

- The wheel behind which the faulty sensor “hides” is removed. To do this, working in a circle, smoothly, one by one, unscrew all the bolts and pull the wheel towards you.

- Behind the hub you will see the DSC mount: unscrew the screw that secures it using Torx T30.

- Disconnect the wiring harness.

- Replace the ABS sensor and reassemble everything in reverse order.

How the ABS status indicator should work

The ABS system can be divided into several functional blocks to make it easier to understand the problem that causes the corresponding indicator on the instrument panel to light up. Note that the anti-lock braking system consists of:

- Rotation sensors. Usually there are 4 of them - one on each wheel;

- ABS module;

- Devices for monitoring the correct operation of the ABS module;

- ABS indicator on the instrument panel.

If the anti-lock braking system light on the instrument panel lights up after starting the engine or while the car is moving, the ABS system is disabled. Many drivers mistakenly believe that when the ABS light is activated they have problems with the braking system, but this is not at all the case. Responsible for diagnosing brakes on a car.

In the first seconds after the engine starts, all indicators on the instrument panel should light up. If the ABS light does not light up at this moment, it means it is faulty.

Based on the ABS device, we can come to the conclusion that the system malfunction indicator may light up for the following reasons:

- Problems with sensors installed on wheels;

- Malfunctions in the ABS system control unit;

- The cables between the elements that transmit information about their status are faulty;

- There are problems with the crown on the hub.

All the described malfunctions can appear while driving. For example, vibrations on rough roads often lead to wire breaks. When driving off-road, dirt may stick to the sensors or sand may become clogged with them, which will not allow them to transmit the correct information to the system control unit, and it will indicate a malfunction by turning on the ABS light on the instrument panel.

Symptoms of a problem

To monitor the operation of the system, there is a yellow or orange indicator light. In normal conditions, when the ignition is turned on, a lamp on the instrument cluster is activated, then self-diagnosis of system elements is carried out and the icon automatically goes out.

Signs of breakdown of ABS system elements:

- turning on the system warning lamp while driving;

- stable wheel locking during heavy braking;

- absence of sounds indicating ABS operation (brake pedal vibration);

- the appearance in the memory of the electronic system of error codes related to the ABS.

Purpose of the ABS sensor and operating principle

The ABS sensor is one of the three main components of the system, which also includes the control module and hydraulic unit. The device determines the moment of wheel locking based on its rotation frequency. When this undesirable event occurs, the electronic control module receives the sensor signal and forms an effect on the hydraulic unit installed in the line immediately behind the main brake cylinder.

ABS sensor with wire and connector

The block reduces or even stops the supply of brake fluid to the locked wheel cylinder. If this is not enough, the solenoid valve will direct the fluid into the outlet line, relieving the pressure already in the master cylinder. When wheel rotation is restored, the control module removes the pressure from the valves, after which the hydraulic line pressure is transferred to the wheel brake cylinders.

Each wheel of the car is equipped with an ABS sensor.

How the anti-lock braking system works

How to diagnose ABS yourself? — to answer this question with confidence, it is important to know the structure of the system itself. To do this, let’s look at several individual parts of it:

- Speed sensors. Sensors are located near each wheel of the car. They transmit information about the rotation speed of each wheel to the ABS control unit.

- ABS control unit. The control unit receives signals from speed sensors, analyzes the situation, and, in the event of a wheel lock, transmits a command to the hydraulic control unit.

- The hydraulic control unit, having received a signal about a blocked wheel, closes the brake fluid channel going to this wheel.

The result is that as soon as the wheel is locked, the system “releases” it. Once this happens, it is blocked again. All this happens with high frequency, and as a result, the wheels rotate at maximum effort, but without switching to skidding.

What is ABS

Subaru Forester 2.0 IS EyeSight Cross Logbook Classic Emblem for Forester

The anti-lock braking system was developed when it became clear that when the wheels suddenly jam, the car loses stability and is difficult to control. Moreover, the quality of braking did not improve, and the car was pretty much carried off the road. Therefore, a system was developed that, by regulating the pressure in the brake system pipes, allows the wheels to turn slightly. This significantly improves vehicle dynamics, allowing the driver to control the vehicle more confidently. But despite its apparent simplicity, this is a rather complex process that requires the coordinated operation of many mechanisms included in the anti-lock braking system. If any of the components fails, a warning lamp lights up on the instrument panel.

Important! You can often hear the question from drivers: “Why is the ABS sensor on?” It is important to know that when the warning light comes on, it does not necessarily indicate a faulty wheel sensor.

How to brake correctly in a car with ABS?

ABS system control unit on a car

To improve the performance of the ABS system, you need to remember and follow a few simple rules.

In theory, everything is simple in case of emergency braking - pedal to the floor, and the ABS unit will do the rest itself. But in practice this does not always happen. In order to get the most from the anti-lock brake system, significantly increase braking efficiency, reduce the likelihood of wheel locking and skidding of your car, improve maneuverability on wet asphalt, and reduce tire wear, you need to follow simple rules:

- The brake pedal must be pressed smoothly, with increasing force.

- Do not release the pedal during reverse kickback.

- Use tires according to the season.

- Do not completely rely on the system, since the ABS unit does not always work correctly.

But, like everything, the system has its drawbacks. On a road with a loose surface, be it snow or sand, ABS will not help you, but, on the contrary, will lengthen the braking distance.

The need to replace the device

Malfunctions in the ABS system are indicated by a warning lamp located on the dashboard of the car. In normal mode, the indicator lights up when the engine starts and goes out after 3–5 seconds. If the controller behaves incorrectly - it turns on while the engine is running or blinks chaotically when the car is moving - this is the first sign of a sensor failure.

The ABS indicator should go out 3-5 seconds after starting the engine

Also, a possible device malfunction is indicated by:

- an error code appears on the on-board computer display;

- continuous wheel locking during heavy braking;

- absence of characteristic vibration on the brake pedal when it is pressed;

- the parking brake indicator lamp has been activated when the handbrake is off.

If any of these problems occur, the device should be fully diagnosed. It is not at all necessary to trust this question to highly paid car service technicians - checking the ABS sensor yourself takes little time and is done without expensive equipment. If diagnostics reveal that the device is broken, it will have to be replaced with a new one.

Why did the ABS light come on?

The ABS system in a car is responsible for high-quality braking. All modern cars are equipped with special electronic control units that help the car stop (brake) correctly, competently, and efficiently. The ABS system helps with emergency braking, and when braking during a turn (anti-skid), and when braking on slippery surfaces. Without ABS, driving a car would be much more dangerous.

And once the ABS light comes on, it means something happened with the “smart braking system”, something went wrong. And perhaps the brakes may not work at all - they may fail at the most inopportune moment!

ABS repair

Therefore, if the ABS light is on on the dashboard, then urgently take the car to our specialized car service center. Here, your car will be taken care of by professionals who will find out why the ABS light came on, what condition the ABS unit is in, whether the ABS sensor is working correctly and what condition the entire brake system is in.

After qualified diagnostics of the car, after finding out the true cause of the ABS light that came on, you can order competent ABS repairs from us.

Is it possible to repair the sensor?

In the event of a malfunction, the device requires replacement (how to remove the ABS sensor was discussed above). Before starting work, contact your dealer and order a new part. After carrying out the work, test the device to ensure it is working properly. To do this, find a flat section of the road, accelerate the car to 30-40 kilometers per hour, and then sharply squeeze the brake.

If everything is done correctly, then impulses will be felt under your foot, and the car will stop. If the wiring is damaged, the latter must be replaced, and then diagnose the system using the algorithm already discussed.

Remember that if the sensor fails, it cannot be repaired. The only way out is replacement. What can be fixed is the wiring, which is changed or repaired with a soldering iron and electrical tape.

Some nuances

Replacing sensors that are installed on the steering knuckles of the front wheels is much faster, since access to these parts is more convenient:

- The car is jacked up and the required wheel is removed.

- The bolts that secure the sensor are unscrewed, and the device is removed from the seat.

- The wiring fastening is released and the connector plug is disconnected.

- Installation of a new sensor is carried out in the reverse order.

Attention! When installing a new sensor, you must ensure that no dirt gets into the place where it fits.

Before replacing the sensor, reasons that could cause it to malfunction should be eliminated. Particular attention should be paid to specific problem areas found in each car model. For example, all FORD cars manufactured before 2005 suffer from interruptions in the operation of electrical equipment that occur as a result of frequent short circuits, and the pain point of the ABS system of these cars is the quality of wiring insulation. In this case, it will be possible to repair the sensor instead of completely replacing it.

Ways to check functionality

To determine the condition of a part, we will perform a series of steps to diagnose it, moving from simple to complex:

- Let's check the fuses by opening the unit (inside the passenger compartment or in the engine compartment) and inspecting the corresponding elements (indicated in the repair/operation instructions). If a burnt component is found, we will replace it with a new one.

- Let's inspect and check:

- integrity of connectors;

- wiring for abrasions that increase the risk of a short circuit;

- contamination of the part, possible external mechanical damage;

- fixation and connection to ground of the sensor itself.

If the listed measures do not help to identify a device malfunction, it will have to be checked using instruments - a tester (multimeter) or an oscilloscope.

Tester (multimeter)

This method of diagnosing the sensor will require a tester (multimeter), instructions for operating and repairing the car, as well as PIN - wiring with special connectors.

The device combines the functions of an ohmmeter, ammeter and voltmeter

Tester (multimeter) is a device for measuring electric current parameters, combining the functions of a voltmeter, ammeter and ohmmeter. There are analog and digital device models.

To obtain complete information about the performance of the ABS sensor, you need to measure the resistance in the device circuit:

- We lift the car with a jack or hang it on a lift.

- Remove the wheel if it prevents access to the device.

- Remove the cover of the system control unit and disconnect the controller connectors.

- We connect the PIN to the multimeter and the contact socket of the sensor (the connectors for the rear wheel sensors are located inside the cabin, under the seats).

We connect the PIN to the tester and the contact socket of the sensor

The device readings must correspond to the data specified in the repair and operation manual for a particular vehicle. If the device resistance:

- below the minimum threshold - the sensor is faulty;

- approaches zero - short circuit;

- unstable (jumping) at the moment of twitching of the wire - a violation of contact inside the wiring;

- infinity or no readings - wire break.

Attention! The resistance of the ABS sensors on the front and rear axles is different. The operating parameters of the devices are 1–1.3 kOhm in the first case and 1.8–2.3 kOhm in the second.

Video “Diagnostics of the ABS sensor”

How to check using an oscilloscope (with connection diagram)

In addition to self-diagnosis of the sensor with a tester (multimeter), it can be checked using a more complex device - an oscilloscope.

How to check ABS sensors - visual inspection

Alternatively, the ABS system can be checked using an ELM-327 scanner . An induction type sensor is an induction coil paired with a toothed metal disk located above an impulse rotor connected to the drive shaft or wheel hub. If the sensor is broken, you can find out with a tester, a soldering iron , or repair pin Next, proceed to measuring the resistance voltage in the node.

Around the pole core there is a winding connected to the magnet. This proximity allows the magnetic field to freely pass to the inductor. And since the rotor rotates and the interdental cavities change, the magnetic flux passing through the winding core changes. Such changes create alternating voltage, the level of which must be measured. The voltage frequency and amplitude depend on the number of wheel revolutions.

The pins are attached to the connectors, and the tester measures the resistance of the abs sensor. When measuring, the resistance rate is within 800-1200 ohms , but it is better to look at the passport and check with the permissible unit. When the network increases to infinity, a network break has occurred, and if the resistance shows zero, then a short circuit has occurred in the sensor circuit. To conduct a complete diagnosis of the sensors, you need to test all the wiring of the device with a tester. When everything is normal the readings will be like this:

- insulation resistance level – more than 20 kOhm ;

- leg – front right abs sensor 7-25 Ohm ;

- leg – rear right ABS sensor 6–24 Ohm .

When a breakdown is detected during inspection of the sensor, there is no point in repairing it. If a malfunction is not found, then it is not recommended to interfere with the operation of the central unit yourself. Technicians will review the fault codes previously stored in the device and take appropriate action.

Driving along a snow-covered road, the ABS indicator came on, there was 15-20 centimeters of snow on the road, I was driving along the right side, while the left side was following a well-worn track. Because I have ABS, then this is not just a contact closure. I looked into Google, the most common breakdown of this unit (if there is ABS itself) is a break in the wiring from the sensor plug. I was tormented for a month by the fact that the ABS indicator was on. But when I looked in, I didn’t notice anything suspicious; I didn’t want to take it to the service station, there was no hole. But somehow it caught fire and decided, after lying around in the snow, to find what was wrong, I got down on my knee, once again looking under the car, and there was the plug, hanging right under the right threshold, one wire had broken off from the plug, the insulation of the second had burst.

Checking the quality of work performed

After replacing the sensor, its functionality is checked. To do this, it is enough to accelerate to a speed of 40 km/h on a flat, safe section of the road and perform sharp braking. If the car stops without pulling to the side, vibration is transmitted to the pedal and a specific sound of brake pads being activated is heard - the ABS system is operating normally.

Today you can easily find and buy any ABS sensors - from expensive original devices to analog parts at an affordable price. Remember that proper selection of system elements plays an important role in its uninterrupted operation. When choosing a sensor, study the manufacturer's instructions and make sure that it fits the car, and this review will help you replace the device yourself.