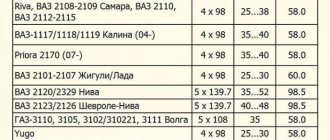

Minimum and maximum possible parameters of non-standard disks

So, the smallest disk diameter provided by the VAZ-2107 manufacturing plant is 13 inches.

The maximum size should not exceed 15 inches, provided that low-profile tires are available. The wheel rim must either correspond to the parameters of the VAZ-2107 hub according to PCD - 4x98 mm and according to DIA - 58.5 mm, or its installation will require the use of special adapter spacers. The product with PCD – 4x100 mm can be installed using fasteners with an eccentric.

You can try to get around the 5J-6J rim width limitation by changing the “ET” value. The use of spacers will reduce the size of the offset, which will allow the installation of wider wheels. But the question immediately arises about the appropriateness of these actions.

Giving a more modern look to any older car model is quite appropriate and acceptable in most cases. Changing disks in this sense is no exception. However, if you are carried away by tuning the VAZ-2107, you should not forget about the technical characteristics.

Any re-equipment must be accompanied by an improvement in both appearance and performance. Or at least you should try not to spoil what was originally there.

Features of measurements

As we have already mentioned, PCD is the diameter of the circle on which special holes for fastening the wheel are located (we have already looked at the example with disk markings).

So, we have the PCD 5*100 parameter. The first number is clear - it indicates the number of bolts used to secure the wheel.

As for the diameter of the circle, here you can use a simple calculation method.

Take a caliper and take measurements between the walls of the holes located next to each other.

So, for each bolt pattern there is a different calculation:

- for three holes the diameter is X * 1.55,

- for four holes – X*1.414,

- for five holes – X*1.701.

It is advisable to check the resulting number with the data in the manufacturer’s special tables. This will ensure that the measurements are correct.

Please note that on standard steel wheels the bolt pattern dimensions are not indicated - their marking is carried out taking into account the internal factory code.

To clarify the parameters more precisely, you can contact an official dealer.

Many drivers have a question about how to find out the wheel bolt pattern.

Below are the parameters of popular car brands.

VAZ cars.

Disc options

About wheel bolt patterns on Chevrolet cars

The modern market for wheels for the VAZ-2115 is quite extensive and involves different designs and models. At the moment there are three main groups of disks:

- steel;

- cast;

- forged.

Steel wheels

As a rule, when producing cars, AvtoVAZ equips them with steel wheels. But their appearance very often confuses car enthusiasts, so they are not particularly popular. The main advantage of such discs is their low price.

Since stamped steel wheels are very cheap, but their appearance leaves much to be desired, there is a need to additionally purchase plastic or rubber caps. The technical characteristics of these wheels are truly excellent, as the car behaves confidently on the road, maneuverability increases and braking distance decreases.

You should choose such wheels based on the technical characteristics and equipment of the VAZ-2115. To install the disks, you do not need to buy anything additional, because the kit already contains the necessary bolts, nuts and studs. For a more presentable appearance, you can purchase caps.

Alloy wheels

For the manufacture of cast wheels, a light alloy with admixtures of aluminum and magnesium is used. The biggest advantage of these wheels is their appearance. A wide selection of designs allows you to satisfy any car owner. The cost of such disks is slightly higher than steel ones, but much cheaper than forged ones. Therefore, car enthusiasts are increasingly choosing these models.

First of all, when choosing alloy wheels for a VAZ-2115, you should immediately pay attention to the bolts. Often the center hole is slightly wider than the standard bolts

To avoid problems with installing disks, you must additionally purchase an instep support (spacer).

Choosing a suitable arch support is easy when you take into account two parameters:

- The external size must match the size of the central hole of the disk.

- The internal size should be commensurate with the hub.

For example, the central hole of the selected disks is 67.1 mm, the hub is 58.6 mm, therefore, it is necessary to purchase an instep spacer measuring 67.1-58.6 mm.

For alloy wheels, you should buy bolts with smaller heads, since regular bolts are somewhat wider and simply will not fit the holes. In any specialized store you can find a suitable option for a particular disc. Considering these nuances, installing alloy wheels will not take much time and effort.

Advantages of alloy wheels

Alloy wheels are universal and suitable for most vehicles, including the VAZ-2115. The advantages over steel models are obvious, as they:

- Lighter, self-cleaning and does not rust.

- Alloy wheels do not require caps and the car's handling becomes better with them.

- Properly distribute the load on the suspension.

Advantages over forged wheels:

- Affordable price segment.

- Wide choice of designs.

- Fairly light weight.

Forged wheels

The most expensive model on the modern market is forged wheels. They are made from light alloy material under high pressure. At the same time, to obtain the required shape, the disks are processed using special high-precision equipment.

Forged models are characterized by high strength, which exceeds established standards by almost 2.5 times. Therefore, when sports tuning a VAZ-2115, it is better to use this type of disc. If the car is used as usual, then it is recommended to opt for more budget options.

Tire selection and storage

- The tire type must be appropriate for the season and road surface conditions. When the average daily temperature is below 5 degrees, you should switch to winter tires, and when it is warmer, to summer tires.

- Summer tires harden at low temperatures and lose grip on the road surface. Winter ones wear out intensively at high temperatures.

- You should not buy studded winter tires if you have to drive on city streets cleared of snow without leaving the city. The studs are good on snow and mud, but do not perform well on asphalt.

- Before storage, tires must be cleaned of dirt and washed.

- Tires should be stored upright on the floor or rack without any sharp edges that could damage the rubber.

- It is unacceptable to store tires hanging from the inner surface - in this position, the edge of the tire adjacent to the rim will be deformed.

- Do not store tires in direct sunlight or outdoors.

- It is unacceptable to place heating devices near tires.

gsnake

29-03-2014 21:19

ASDER_K

29-03-2014 21:54

There are wheels with alloy disks, where the hole parameters are 4x98, but on a car you need 4x100. Do you think this is possible? I have studs on the hub. I read that you can’t do this with bolts, but for some reason it’s better with studs.

Kroilovo leads to Padalov.

greed is one of the most vile vices. conclusion. sell these discs. corresponding to the size buy. and don't skimp on condoms. treatment is more expensive.

gallak

29-03-2014 21:57

It will be bad. In the 90s, the former market In the USSR, a ton of new and used 4*100 disks appeared - many VAZ employees rushed to install them, but an obliquely twisted bolt (in this case, a nut (because studs)) quickly broke the fit of the disk and sometimes the disk broke off at the most inopportune moment...

HARON

29-03-2014 22:04

It is forbidden. On the contrary, no matter what, it’s impossible.

ASDER_K

29-03-2014 22:29

On the contrary, no matter what, it’s impossible.

on the contrary, it didn’t go anywhere either

HARON

29-03-2014 22:34

ASDER_K

29-03-2014 22:43

quote: Originally posted by HARON: They put it the other way around, but since the vehicle wants it, it doesn’t. I didn’t come up with this, I’ve seen it on the Internet many times.

so not from a great mind.

and out of great greed... at best, the cutting wheel will lead to the replacement of the hub... Union_Jack

29-03-2014 23:32

someone recently rubbed in that 98 are suitable instead of 100

HARON

30-03-2014 08:45

quote: Originally posted by Union_Jack: someone recently said that 98 are suitable instead of 100

Maybe I got it wrong too.

polex

30-03-2014 10:01

quote: sell these discs. corresponding to the size buy.

Couldn't have said it better

HARON

30-03-2014 11:54

If the landing diameter is what you need, I would try it.

gsnake

30-03-2014 12:02

I just assume that these two millimeters will go into tolerances...

HARON

30-03-2014 12:07

They won’t go away, but it should fit. If the central diameter does not match, then there is no point in trying it on - screw it on, but it will beat.

Volga sky

30-03-2014 17:48

quote: Originally posted by gsnake: where are the hole parameters

There are only black holes, and only in space. Everything else is holes.

Kroilovo leads to Padalov.

I already told him this, he doesn’t believe me.

quote: Originally posted by HARON: but it should fit.

It will fit, but then, when the nut enters the cone, it will begin to bend the stud towards the center of the cone.

There are a lot of potholes on the roads... HARON

30-03-2014 17:54

quote: Originally posted by Volga sky: It will fit, but then, when the nut enters the cone, it will begin to bend the stud towards the center of the cone. There are a lot of potholes on the roads...

Well, all the studs will bend a little; they all work in tension, not shear. If the landing gear is identical, I would install it, since there are disks.

Comrade Beria

30-03-2014 18:10

Try boring it in the machine so as not to lose alignment. When unpleasant consequences occur, think about post number 2.

gsnake

30-03-2014 18:23

thanks for the advice. I won't do that.

But then another question - if the wheels fit on the studs, and the central hole is hefty - is that acceptable?

HARON

30-03-2014 18:27

Acceptable, you need to buy or grind an adapter.

gallak

30-03-2014 18:37

quote: if the rims fit on the studs, and the central hole is hefty, is that acceptable?

This is the situation with most “aftermarket” alloy wheels - because

Different automakers have different centering diameters, it is expensive to make wheels only “for Nissan” or “Toyota”, they make them with the largest diameter, and offer adapter rings for smaller ones. These adapters are always available in stores/car service centers that sell discs. If you know the manufacturer of your disc, it’s easy to find the corresponding rings. Their cost is 2-3 dollars apiece - cheaper than turning them... Kir*

31-03-2014 12:48

ASDER_K

31-03-2014 01:28

Bolts are possible. Easy and relaxed. 1 mm on each side is nothing. You need to pull evenly. But how to tighten the disc onto the studs?

muhaha.

don’t forget to write a will in advance and buy wheel bearings... Kir*

31-03-2014 01:43

muha ha or not mu ha ha but 3 years everything is OK

Kir*

31-03-2014 01:44

As for the wheel bearings, it’s completely nonsense.

Ramil

31-03-2014 07:10

Tazovskie to Nexia - this is no longer poverty, this is drug addiction nonsense

Maxim V

31-03-2014 07:29

And these people teach me how to live... Never once did such a thought occur to me - nailing the wheels with a hammer...

Pavel_A

31-03-2014 08:00

There were similar disks. They didn’t fit on the basin, so I sawed all 5 pieces with a grinder and sold them for scrap.

About the centering rings - nonsense. They do not center anything if tapered nuts or bolts are used.

If you don’t want to lose your wheels, don’t even think about installing them.

HARON

31-03-2014 08:09

And so many connoisseurs... And if you didn’t have to tighten the Fiat size, then with the centering rings you have run tens of thousands... Connoisseurs will be even more surprised - these rings also come in plastic. And they are so scared - the hubs will fall apart, and a will is necessary...

Pavel_A

31-03-2014 08:26

quote: Originally posted by HARON: And so many experts... And if I didn’t have to tighten the Fiat size, then I’ve run tens of thousands with the centering rings.

The topic of rings was already discussed here several years ago.

There are two types of wheel alignment. By the hub and by bolts/studs. It makes no sense to mix these two alignment methods. Kir*

31-03-2014 11:55

As I remember now. In '94 or '95, my father bought himself a new Omega and gave me a VW Jetta. So I screwed the alloy wheels from the TAZ onto it. Until 1998, she rode them safely without any problems. When I bought my wife a pointer with a 4x100 bolt pattern, I remembered that I had a 15 forging with good summer tires from a 8 lying around at my dacha. And I remembered that Jetta felt great with the same problem. I bought good original cone bolts. Screwed it on. This summer will be the 4th that the car will be driven on these wheels.

PS What is the most important thing in a bolted wheel? So that it is well pressed with its inner seating plane to the hub/brake disc.

Makc k-113

31-03-2014 13:15

On a disk with mismatched holes for bolts/studs, you can slowly and sadly get to the place where it will be replaced with a standard one. Driving on such a disk as on a standard one - well, in principle, Kutlhu does not prohibit it. But he doesn’t forbid Russian roulette either - he doesn’t care about the fun of two-legged people.

HARON

31-03-2014 13:19

Okay, I’ll offer an option - adapter spacers. From any size to any desired, and studs and bolts... Well, the stem will most likely change and the cost is inhumane, but is it an option?

ASDER_K

31-03-2014 13:31

quote: Originally posted by Kir*: When I bought my wife a pointer with a 4x100 bolt pattern, I remembered that I had a 15 forging with good summer tires from a 8 lying around at my dacha. And I remembered that Jetta felt great with the same problem. I bought good original cone bolts. Screwed it on. This summer will be the 4th that the car will be driven on these wheels.

You have to be so greedy...

Kir*

31-03-2014 13:31

It's not something to joke about with takeout. Here the load on the bearing is increased. And all the factory suspension settings are down the drain. It’s okay when there’s still a 3-5 mm difference in the offset on the disc itself. But the spacer is at least 15-20 mm.

However, on the Porchik I had spacers at the back of 5 centimeters on each side. And 10 inch wheels. and nothing.

ASDER_K

31-03-2014 13:44

quote: Originally posted by Kir*: Why should good things go to waste? a set of wheels cost about fifty dollars. Forging with Toyo 888.

This is exactly what I’m talking about...

Kir*

31-03-2014 13:48

quote: Originally posted by ASDER_K: this is exactly what I’m talking about...

Yes, we are Jews like that

perstkov

31-03-2014 14:13

Of course you can, just buy a tap to correct the thread, and insure your life, it’s a small thing, but your relatives will be pleased

Kir*

31-03-2014 14:20

ASDER_K

31-03-2014 14:24

quote: Originally posted by Kir*: By the way, if we are talking about wills and insurance: I would be more wary of screwing wheels with a universal 2nd 3rd drill onto the car. So there this knot is weakened

is this like that?

Kir*

31-03-2014 14:36

quote: Originally posted by ASDER_K: all sorts of crap happens... is it like that?

ASDER_K

31-03-2014 14:52

The most important question is - nakera one nada?

Kir*

31-03-2014 15:04

quote: Originally posted by ASDER_K: the most important question - nakera one nada?

HARON

31-03-2014 15:15

quote: Originally posted by Kir*:

Wow! Yes, but this is a homemade thing, but there are factory wheels of this kind. Moreover, if the Japs, at the very least, make them more or less durable, then China is generally tough...

ASDER_K

31-03-2014 15:18

quote: Originally posted by Kir*: One disk for different machines. Versatility.

what for?

HARON

31-03-2014 15:38

quote: Originally posted by ASDER_K: why?

ASDER_K

31-03-2014 15:46

quote: Originally posted by HARON: One article instead of three to five.

those.

for the convenience of the manufacturer and seller? why buy such disks for their convenience? Kir*

31-03-2014 15:48

quote: Originally posted by HARON:

Isn’t there a piece of iron in luminthium?

Well, I didn’t cut such a disc with a grinder. But I highly doubt that there is anything inside. This will further weaken the structure. It’s at least reinforced aluminum as a monolith, but inside there’s a plate that’s in no way connected to the aluminum.

HARON

31-03-2014 15:57

I didn’t saw with a grinder either... But judging by the fact that someone is practicing this, the alloy is not homogeneous, there are inserts... However, when buying recyclable materials, there is a separate price list for alloy wheels, they are sold as is.

ASDER_K

31-03-2014 16:07

quote: Originally posted by HARON: the alloy is not homogeneous, there are inserts...

I’ve seen broken ones more than once... there were no irregularities in the broken parts.

HARON

31-03-2014 16:13

ASDER_K

31-03-2014 16:14

quote: Originally posted by HARON: Why then go through the trouble of sawing luminium with a grinder, so that you can then get three kopecks in a metal purchase?

I can’t know

Kir*

31-03-2014 16:54

quote: Originally posted by HARON: Why then go through the trouble of sawing luminium with a grinder, so that you can then get three kopecks in a metal purchase?

Probably so that people don’t buy them whole and then sell them whole... Or maybe they’re too lazy to remove the rubber during installation.

ASDER_K

31-03-2014 16:56

quote: Originally posted by Kir*: Or maybe I’m too lazy to remove the rubber during installation.

not laziness, but worth the money...

HARON

31-03-2014 17:08

quote: Originally posted by ASDER_K: not lazy, but worth the money...

Is it really that expensive? Anyone who has ever cut aluminum with a grinder will not save on tire fitting.

ASDER_K

31-03-2014 17:18

quote: Originally posted by HARON: Is it really that expensive? Anyone who has ever cut aluminum with a grinder will not save on tire fitting.

As the example of even this topic shows, greed has no limits.

Kir*

31-03-2014 17:28

quote: Originally posted by ASDER_K: as the example of even this topic shows, greed has no limits.

HARON31-03-2014 22:30

quote: Originally posted by Makc k-113: How is it not? 4*98 - all VAZs except all-wheel drive. And 4*100 - almost all other cars with 13-14″ wheels.

Not just vases. I'm sure Fiat also uses 4/98.

Any owner of a VAZ-2109 sooner or later has a question: what is the bolt pattern on the rims of their car? It is usually asked at the moment when they begin to think about replacing these important wheel elements that ensure traffic safety and the image appeal of the vehicle.

In general, the concept of “bolt pattern” implies the distance from the center of one disk mounting hole to another. For the most part, this parameter is the same for all products of the Volzhsky Automobile Plant, but in general no standard values have been developed. That’s why the holes for the bolts on the hubs are located differently among different manufacturers.

Alloy wheels for fourteen

Scheme for rearranging wheels on a passenger car with front-wheel drive. changing wheels on a front wheel drive car

The production of cast wheels, as their name implies, is based on the use of casting metal alloys into special prepared molds. Engineers use an alloy of aluminum and magnesium as the starting material. It does not rust, does not rot, and is lighter than steel. Let us briefly touch upon the issue of mass. Many are convinced that cast wheels are much lighter than stamped ones. This is partly true, but there are nuances.

Alloy wheels come in a variety of shapes

The fact is that the alloy of aluminum and magnesium is light, but fragile. Therefore, when in the 90s of the last century the first such samples began to appear in the vastness of our country, soon many car owners were faced with a situation where, when driving on domestic roads with a large number of holes, they simply cracked. Manufacturers drew the appropriate conclusions and simply increased the amount of alloy used to produce each disc, thus increasing their mechanical strength. However, this affected the mass, increasing it. Therefore, today the difference in weight between four stamped and alloy wheels is only 10…12 kg. Thus, one should not expect a significant increase in dynamic indicators.

Many car owners think that 14-radius alloy wheels on a VAZ will significantly increase the price of the car. In fact, the high cost of a car is often due to the presence, in addition to alloy wheels, of climate control, parking sensors, cruise control and other additional systems that create comfort for the driver and passengers.

Next, let's look at the advantages of 14-inch alloy wheels on a VAZ:

- Beauty and style. Nowadays you can buy alloy wheels in a variety of shapes.

- Reduced weight. As described above, the difference is small, but it is there. This factor ensures less load on the suspension, faster recovery of the trajectory at speed (less inertia, which has a positive effect on the car’s handling at speed), lower fuel consumption, and less wear on the brake pads.

- Easier balancing. Typically, alloy wheels themselves are stiffer, so they hold their shape better.

But if there are positive aspects, then there must be negative ones. These include:

- Because. Since alloy wheels do not bend, but crack, they cannot be driven at high speed on bad roads. Unfortunately, for our country this parameter is critical. Especially if you use budget drives.

- Unsuitable for repair. In some cases, alloy disks are soldered, but in any case, after such a procedure, their mechanical strength will be lower than the original one.

- When hitting a bump on the road, they transfer its energy to the suspension, which is harmful to its components and the system as a whole.

- Servicing alloy wheels is more expensive, since the procedure itself for removing and installing rubber costs more. In addition, balancing weights are also more expensive.

- Alloy wheels are used on light and medium-duty vehicles. So, they are never used on trucks. This is due to their fragility.

In accordance with traffic regulations, a car with wheels that differ significantly from the factory ones cannot pass inspection. However, as practice shows, traffic police officers are calm about 14-diameter alloy wheels. But the 15th may already cause disapproval on their part.

Next, as promised, we will draw conclusions whether it is worth using alloy wheels on a VAZ of 14 diameters or whether you can get by with standard stamped ones.

What is a bolt pattern?

4 bolt holes are 4

- The first number “4”

indicated in the parameters indicates the number of holes located on the hub, intended for screwing wheel bolts into them. - The second number “98”

indicates the diameter in millimeters of the circle in which those same mounting bolts are located.

Wheels from Logan (bolt pattern 4*100)

Based on safety requirements, wheels with such a bolt pattern cannot be installed on a VAZ-2112. But, some drivers use spacers or eccentric bolts

install such disks.

The engineering staff of any automaker carefully calculates the compatibility and ability of the vehicle to withstand the design loads for all systems. A vehicle of the declared weight and dimensions must satisfy its technical characteristics, dynamic and load-carrying parameters. One of the most critical parts is the wheel hub, which bears at least 25% of all permanent, long-term and short-term loads that act on the car. This is how the wheel bolt pattern parameter is created.

Bolt pattern is a calculated characteristic of wheels, which determines the number of mounting holes and the diameter of their location circle. This characteristic is the same for almost all AvtoVAZ models and depends on the following vehicle indicators:

Wheels for VAZ 1111

- The weight of the car in running order, that is, fully equipped, with passengers and the maximum possible weight of cargo in the trunk.

- The nature of the vehicle’s operation, namely how important overloads are for a given vehicle. If we are talking about a city sedan, then a bolt pattern of 4 studs is quite enough for it, but a crossover or SUV is certainly equipped with 5 or 6 threaded rods, because off-road driving can temporarily increase the load on the wheel several times.

- Dynamic properties of the car. When entering a turn at high speed, as well as getting into holes, the impact increases the load on the hub studs exponentially.

Automotive plant engineers prescribe the bolt pattern depending on the maximum load on the vehicle with the required safety factor.

Wheels for model 2104

Preparing for adjustment

Wheel size.ru

Most often, the VAZ 2110 camber and alignment are installed at a service station, but you can do it yourself. First of all, check whether there is play in the bearings and whether the steering is loose. At the same time, check the diameter and absence of deformation of the disks, air pressure in the tires, and tread wear.

VAZ 2110 front suspension assembly diagram

Naturally, if a wheel is loose, action will need to be taken, and one with improper tread wear may need to be replaced. Wheels standing on the ground need to be pulled relative to the vertical. If you find any play, have a helper apply the brake and check the play again.

If it disappears, the bearing needs to be replaced. If after this the size of the play not only does not disappear, but only decreases slightly, the suspension needs to be checked, repaired, and sometimes replaced.

Front wheel hub diagram

After this, hang the wheel and check the play again. It is possible that the play has disappeared, but the wheel turns jerkily or is simply difficult, then you need to slightly expand the diameter of the bearing installation site.

Rear suspension

If you hear a grinding noise, the bearing needs to be replaced.

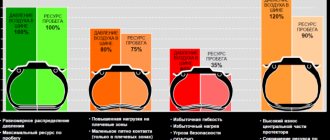

Tire pressure VAZ 2107

The nominal tire pressure depends on the type of tire and the load on the vehicle. If the wheels are overinflated or low, the contact patch between the tire and the road changes. This causes deterioration in controllability and an increase in braking distance. In addition, uneven accelerated wear of the tread begins. Over-inflated tires increase wear on the center of the tire, while under-inflated tires increase wear on the edges.

It is recommended to check tire pressure after 500 km, but in practice it is better to do this more often. Small tire punctures, disc and spool defects cause air to escape from individual tires. In this case, the car may drift off course, especially when braking.

The nominal pressure in VAZ 2107 tires depends on the tire size:

- 165/80R13 - 1.6 for front, 1.9 for rear wheels;

- 175/70R13 - 1.7 for front, 2.0 for rear wheels.

In hot weather and when driving, tire pressure increases. With an aggressive driving style, taking sharp turns at high speed, the pressure can increase to 3-4 atmospheres. The tire material is designed for this and can withstand such changes. But if there is a hernia or cut on the tire, it may explode. A front tire explosion is especially dangerous, after which it is very difficult to keep the car on the road.

As pressure decreases, rolling resistance increases, which leads to increased fuel consumption. The tire also bends and the car becomes less responsive when maneuvering.

If the tire pressure is too low, the tires may even fall apart when cornering sharply.

Bolt difference.

Wheel bolts also differ not only in length, but also in the material from which they are made: steel or black iron, and coating: chrome, nickel or molybdenum. But any coating of them - a surface protective layer - is not a real guarantee against corrosion.

From an aesthetic point of view, the most attractive and popular among motorists are bolts with a chrome coating, but any of the coatings on wheel bolts cannot protect them from corrosion, since their service life is the same as that of bolts with a nickel or molybdenum coating. It all depends on the quality of car care and operating conditions.

Wheel selection rules

For the “ten”, the original wheels are 13- or 14-inch with a 4x98 bolt pattern, where 4 is the number of holes, 98 is the diameter of the circle on which they are located.

In fact, there is nothing complicated about it. It is not necessary to put your life in danger by installing discs with a drill even 1 mm more or less than permissible. Any wheels from Italian and some French cars are perfect for cars of the tenth family. Of course, with the same bolt pattern.

Here are just some of these cars:

Table with bolt pattern 4x98.

It is worth noting that new VAZ cars have changed the Italian size to French. This happened with the arrival of the French B0 platform

, on which Vesta, Largus, Xray are being built. Their disc drilling parameter is 4x100 mm. Select the right discs and do not forget about safety!

Syverlovka and bolt pattern of VAZ wheels

Wheel bolt pattern on VAZ 2107

The design of the seven involves drilling 4x98 wheels, where the number 4 indicates the number of bolts, and 98 indicates the diameter of the holes on the disc structure.

Many foreign cars use a bolt pattern with similar parameters – 4×100. In the first situation, the distance between the centering bolts is 69.3 mm, and in the second case - 70.7 mm. The error is 1.4 mm and does not allow for tight fixation of a non-standard disc.

In addition, installing a car disk with non-standard parameters can lead to deformation of elements, namely mounting holes and bolts.

There are other methods for attaching 100x4 rims to the seven. For example, you can use extended bolts, adapter rings, studs and eccentrics. However, these parts can ultimately complicate or impair the mounting of the wheel product.

Therefore, it is recommended to install standard car wheels and tires so as not to lead to wheel imbalance and vibration while driving.

Wheels on the VAZ 2107 are equipped with 13-inch stamped wheels or analogues with identical parameters. Tires have dimensions 175/70/R13.

| Bus parameters | Disc sizes | Bolt pattern | Width | Departure | Center hole |

| 175/70/R13 | 13” | 4×98 | 5.0J | ET 29 | DIA 60.1 |

The nominal pressure in “seven” tires directly depends on the tire sizes:

175/70/R13 – 1.9 rear, 1.6 front wheels;

165/80/R13 – 2.0 rear, 1.7 front.

Wheel bolt pattern on model 2106

For a six, the wheel bolt pattern is 4×98. As for the factory dimensions of the disks, then:

- standard width is 5.0J,

- centering hole 58.5 mm,

- departure ET

Tire size for the six is 175/70/R13.

As a restyling, you can install wheels 185/60/14, 195/50/R15.

| Tire parameters | Factory bolt pattern | Non-standard disk parameters |

| 155/R13/82Q | 4×98 | 4.5Jx13 ET37 |

| 175/70/R13 82 S | 4×98 | 5Jx13 ET29 |

| 175/70/R13 82T | 4×98 | 5.5Jx13 ET32 |

| 175/65/R14 82S | 4×98 | 5.5Jx14ET29 |

Drilling on the VAZ 2109 model

The VAZ 2109, “nine”, has factory settings for the wheel bolt pattern of 4×98. The factory equipment was equipped with 175/70/R13 tires and 13-inch wheels.

| Tire sizes | Disc sizes | Bolt pattern | Departure | Center hole |

| 175/70/R13 | 13 | 4x98 5Jx13 | ET29 | 58,6 |

| 175/65/R14 | 14 | 4×98 5.5Jx14 | ET29 | 58,6 |

| 195/50/R15 | 15 | 4×98 6.5Jx15 | ET32 | 58,6 |

| 205/45/R16 | 16 | 4x98 7Jx16 | ET34 | 58,6 |

Wheel bolt pattern on VAZ 2110

The tenth VAZ model is equipped with factory stamped 13-inch wheels and 175/70/R13 tires. There were also dozens of configurations with 14-inch casting and 175/65/R14 tires.

As for the dimensions of VAZ factory wheels, the width is 5.0-5.5J, drilling is 4×98, as on other models, the centering hole is 58.5 mm and the offset is ET 37-40.

Drilling on 2111

The Lada station wagon 2111 was equipped with 13 or 14-inch wheels from the factory, depending on the vehicle's configuration. Both options could be used.

Tire sizes: 175/70/R13, 175/65/R14, rims: width 5.0J, drilling 4×98, centering hole 58.6 mm, offset ET40.

Drilling on the VAZ 2114 model

Lada Samara 2113, 2114 cars were equipped with factory stamps with a 4x98 drill bit.

As for the rims, the offset was ET40, width 5.0 J and centering hole 58.5 mm. Wheels 175/70/R13.

Drilling on the VAZ 2115 model

The fifteenth model Lada 2115 is equipped with factory stampings with dimensions of 13 and 14 inches, and a 4 × 98 drill.

| Disk size | Tire parameters | Sverlovka | Departure | Center hole |

| 13 | 175/70/R13 | 5.0J 4×98 | ET40 | 58.5 |

| 14 | 175/65/R13 | 5.5J 4×98 | ET37 | 58.5 |

As a restyling option, you can use car tires:

205/45/R16;

195/50/R15;

185/60/R14.

Drilling on the VAZ 2121 model

The first Russian SUV Niva from VAZ or Lada 4x4 is equipped with 16-inch steel factory wheels and tires with sizes 175/80/R16 and 185/75/R16.

Disc dimensions: offset ET40, drilling 5x139.7, centering hole 98.6 mm and width 6.5J.

Wheel bolt pattern on a Niva Chevrolet car

The Russian Niva Chevrolet SUV is equipped with factory-made 15- and 16-inch rims with drilling parameters of 5×139.7, offset ET40-48, centering 98.6 mm and width 6-6.5J.

Wheel sizes: 205/75/R15 and 215/65/R16.

Features of wheel sizes for the most popular VAZ models

Among several dozen VAZ modifications, the most popular models over the entire 50 years were only 2 of them, as can be judged by the number of copies sold. The wheel sizes for these cars had the following parameters, which varied depending on the year of manufacture, technical equipment and equipment of the car:

- VAZ is the latest modification of the “classic”, produced on the plant’s conveyors for 30 years: from 1982 to 2012. During this time, it never changed its appearance, and the disc bolt pattern was the same - 4x98 with a central hole diameter of 58.6 mm.

The width of the rim varied slightly depending on the model year.

If in 1982 the plant produced models with tire dimensions ranging from 5J to 5.5J, then at the end of production the concern increased the permissible size to 6J.

You might be interested in this About wheels for Land Rover Freelander 2

The radius of the wheels invariably varied from R13 to R15, which made it possible to alternate them by season, periodically changing the side profile of the tire, or immediately use all-season tires with a diameter of R14.

The VAZ 2107 tire size invariably consisted of only 3 main parameters - 175/70/R13, 185/60/R14 and 185/55/R15. The last of the listed parameters was actively in demand among lovers of fast driving on smooth city roads.

On a note.

As for the R13 rubber, it allowed the driver to feel as comfortable as possible when driving over rough terrain, as well as in winter, when the high cord profile took part in adhesion to the road surface. But the most popular parameter remained the universal size R14 and the largest number of tires were sold in this dimension.

If we look at the concern’s earlier cars, we can see that the wheelbase of the Zhiguli has remained virtually unchanged for more than 40 years. This leads to moral backwardness of the technical equipment of the plant's products. At the same time, the lack of new developments greatly reduces both the speed of release from the assembly line and the cost of engineering equipment, which leads to a very attractive retail price for the vehicle.

- VAZ 2114. Produced in a smaller range - from 2001 to 2013. The car was just a restyled modification of the classic “nine”. The legacy of the outdated model did not affect the high popularity of this Lada, and all the wheels that were installed on hubs in the basic version had the same traditional bolt pattern 4x98, DIA 58.6 mm.

European standard bolt pattern 4x100 for Lada X-Ray

- Like the bolt pattern of the VAZ 2114, the width of the wheel rims was not much different from the “seven” and fluctuated between 5J – 6J for the entire production period. As for radius, the concern has completely eliminated the 15-inch diameter from the factory equipment, without prohibiting drivers from installing this parameter as an option. The bolt pattern of VAZ 2114 wheels in the current size also made it possible to install standard 4x100 wheels in accordance with the sizes usual for Europe.

Not a single Lada model has ever looked aggressive; the hallmark of the product was practicality and reliability in operation. The concern did not use extreme overhang indicators, and the wheels were always hidden under the body arches. The average ET limit values for both VAZ 2107 and 2114 were ET25...35 mm, and deviations from this characteristic obligated drivers to install additional mudguards on the side parts of the body and change the design of the hubs, making them more durable to avoid deformations.

Important!

The bolt pattern of the VAZ 2114 wheels, as well as all other dimensions of the hub and disks, were used on the brand’s followers - Kalina and Priora. With the arrival of new management at the domestic concern, this parameter ceased to exist altogether, since the plant had a new orientation to the West and possible import of products to the nearest CIS countries.

5 studs on VAZ 2121 wheels

Parameters of standard nuts

One of the main parameters of nuts or bolts is the shape of their pressing surface, which can have several varieties. When selecting the necessary nuts, you should proceed from the shape of the recess in the mounting hole of the disk.

Most often it is necessary to use bolts or nuts with a cone-shaped clamping part. As a rule, the cone has an angle of 60°. Sometimes such bolts may have a 1.3 mm head and a nose at the end of the nut.

The clamping surface of the fastener can also be flat or hemispherical

It is important that the clamping planes of the fastener and the disk fully correspond to each other. Otherwise, over time, as a result of strong dynamic loads, the attachment point will weaken

When choosing nuts with closed heads, you should pay attention to their length

If the pin prematurely rests on its inner part, then it will not be possible to fully tighten it. Also, nuts that are too short may not leave room for the socket head of the impact wrench. Some wheel models only allow the use of hex or star nuts.

When choosing bolts, you need to consider their length. A reliable connection can only be achieved if the bolt is screwed in to the entire threaded thickness of the hub. However, if it is too long, then when the car moves, such fasteners will begin to cling to internal structures.

Conclusion

Wheel rim bolt pattern is an important parameter that should be taken into account when choosing. Remember that any PCD discrepancy and installation errors are, first of all, a big risk for your life.

So, in your quest to decorate your car at any cost, weigh the pros and cons. Maybe it’s worth abandoning dangerous changes in favor of another type of tuning.

Any owner of a VAZ-2109 sooner or later has a question: what is the bolt pattern on the rims of their car? It is usually asked at the moment when they begin to think about replacing these important wheel elements that ensure traffic safety and the image appeal of the vehicle.

In general, the concept of “bolt pattern” implies the distance from the center of one disk mounting hole to another. For the most part, this parameter is the same for all products of the Volzhsky Automobile Plant, but in general no standard values have been developed. That’s why the holes for the bolts on the hubs are located differently among different manufacturers.

Information on wheel bolt patterns on domestic VAZ vehicles

All VAZ cars from the very foundation of the plant to the present day had only 3 main types of bolt patterns, since most modifications were made on a single platform, only their appearance changed. The bolt pattern for most Lada models looked like this:

The smallest representative of the automaker - VAZ 1111, popularly called "Oka", was produced in the Russian Federation for 20 years - from 1987 to 2008. Considering that the weight of this especially small class car was only 975 kg, and the load on the wheel was less than 250 kg, Oka became one of the few representatives in its class for which a bolt pattern of 3 studs was used.

The final parameter was 3x98, with a mounting hole diameter of 58.1 mm. This was quite economical for the Oka owners.

It was quite problematic to find a similar wheel size on the market, so stamped products with a radius of R12 and R13 were often re-drilled in order to successfully fit on the hub.

Bolt pattern VAZ 2107 4x98

The vast majority of models of the AvtoVAZ concern, starting from 2101 and ending with the Lada Priora or Kalina, were produced from the assembly line in the form of sedans, liftbacks, hatchbacks or station wagons of the compact or subcompact class.

On a note. The wheel load and dynamic parameters of these vehicles are very similar to each other.

Starting from 1966, when the concern released its first “penny”, and ending in 2015, the wheel bolt pattern for these cars was 4x98 mm, the diameter of the central hole was 58.1 mm.

The most popular Lada models today, for which wheels with a 4x98 bolt pattern are still sold, are VAZ 2106, 2107, 2109, 2110, 2112, 2114.

The latest VAZ models, such as Vesta, Granta and X-Ray, produced since 2015, have a wheel pattern as close as possible to the international standard for compact cars. This parameter on the specified modifications is 4x100.

However, this difference does not mean that the 4x98 bolt pattern does not allow the installation of X-Ray wheels on older cars. On the contrary, all products are fully compatible; drivers do not even need to use spacer plates, since the nut can be screwed all the way and securely fixes the wheel.

Among all the products of the AvtoVAZ concern, such models as the VAZ 2121, or the classic Niva and all derivatives of this SUV have always stood out: the 5-door Taiga, Chevrolet Niva and other models. Due to increased loads on the hubs and wheels due to unsatisfactory road conditions, for which all parameters of the Niva were designed, these compact all-terrain vehicles traditionally had a disc bolt pattern of 5x139.7, with a central hole diameter of 98.5 mm.

These increased indicators allowed the wheel to freely resist bending moment, absorb large loads when the center of gravity is shifted to one side when moving on an inclined plane or when the wheels are forced to hang, and also allowed the car to transmit more torque to the tire treads when driving uphill without the risk of breaking parts .

Wheels for VAZ 2114 Important! Despite the paucity of assortment when equipping vehicles and a small selection of cars of different classes, the plant has achieved maximum versatility in compatibility and the possibility of interchangeability of rims for cars produced in 2021 or 50 years ago.

Bolt pattern compatibility table for Zhiguli wheels

Bolt pattern Chevrolet Cruze 1.3i HR51S 2001-2003

This table of correspondence of geometric characteristics to brands and modifications of domestic cars is given below:

| Make and model VAZ | Disc diameter, inches | Rim width, inches | Wheel offset, ET, mm | Bolt pattern, pcs x mm | Central hole diameter, mm |

| VAZ 1111 (“Oka”) | 12, 13 | 4; 4,5; 5 | 35, 40 | 3x98 | 58,1 |

| VAZ 2101…2115, “Kalina”, “Priora” | 13, 14, 15 | 5; 5,5; 6 | 25, 30, 32, 35 | 4x98 | 58,6 |

| "Lada Granta", "Vesta", "X-Ray" | 13, 14, 15, 16 | 5; 5,5; 6; 6,5 | 22, 25, 30, 32, 34, 35 | 4x100 | 58,6 |

| VAZ 2121 (“Niva”), 2123, 2131, Chevrolet Niva | 15, 16, 17 | 5; 5,5; 6; 6,5; 7 | 15, 35, 58 | 5x139.7 | 98,5 |

Interior of rims for VAZ cars

The bolt pattern of VAZ wheel rims is a very important indicator of the model, which significantly limits the range of products offered for sale. If the driver suddenly takes a fancy to a disc that has different characteristics, he will have to completely change the design of the hub and install the studs in a new order. Experts say that such a practice is fraught with unpredictable consequences during the operation of the vehicle.

- Tire sizes from to , width from to and profile from to .

- Minimum tire size: 175/70R13, maximum:

Tips for using tires and wheels from AvtoVAZ

The Volzhsky Automobile Plant has established a list of wheel sizes in diameter and width, as well as the sizes and pressure values of rubber tires that can be installed on the Lada Vesta. The manufacturer regulates the following parameters:

- the size of the tire profile, its diameter, as well as the width of the protective tread; AvtoVAZ advises not to allow such pressure in the tires, which differs significantly from what is indicated in the vehicle's passport recommendations. Using such tires for a long time, the driver thereby worsens the stability and controllability of Vesta.

New Lada: Checklist: Lada Vesta caliper - replacement, article number, faults

Another nuance that can affect tire pressure is a worn spool valve, which allows air to leak. It is recommended to regularly check the condition of the valve. Installation of new tires is carried out at a service station, or independently using the appropriate equipment. After replacement, it is recommended to have Lada Vesta wheels balanced at a dealer station.

What kind of drilling on a VAZ-2114: photo and video

Beauty, of course, requires sacrifice, but it’s still not worth going beyond the boundaries of healthy logic. When choosing wheels for a VAZ-2114, you need to be guided not only and not so much by the design of casting or stamping, but also by the dimensions in the first place. Compliance of the factory seating dimensions with the dimensions of the new wheels will guarantee safe operation of the vehicle.

What kind of drilling is on the VAZ-2114

One of the main parameters that you should pay attention to when replacing standard disks on a VAZ-2114 car is the dimensions, location and diameters of the mounting holes, PCD, pitch circle diameter, or, in simple terms, drilling or bolt pattern.

Bolt pattern on a VAZ-2114 wheel

Bolt pattern - this characteristic is expressed in two numbers and indicates the distance between the centers of the mounting holes and their number.

Drilling for all VAZ cars (except Oka and Niva) - 4x98, four holes, the centers of which are located at a distance of 98 mm from each other.

However, this is a simplified designation for the user. The disc manufacturer is required to take into account both the diameter of the holes, their number, the distance between their centers, and the diameter along which the centers of the holes are located. Such a designation would complicate the selection of disks by the user, so knowing drilling in the “number of holes/distance between them” format is considered sufficient.

A few more wheel parameters

The drill bit can be measured using the spare wheel. In all SAMARA drilling 4*98

There are several more parameters that relate to the original VAZ-2114 rims - the width of the stock rim is 5.0J, the offset of the ET45 rim, the diameter of the centering hole at the hub is 58.5.

How to install a 4x100 disk on a VAZ-2114

Most older foreign cars have a 4x100 drill. This makes it possible to diversify the choice of disks almost indefinitely. However, we must take into account that simply installing, without modifications, 4x100 wheels on a 4x98 seat will not lead to anything good. The fact is that the tolerance in the manufacture of the disk does not exceed 0.7-1 mm. That is, it is theoretically possible to put on a disk with a 4x100 fit, but this will lead to the fact that only one bolt out of four will fit exactly on the cone. The remaining fasteners simply will not tighten all the way and, as a result, the disk will sit with a distortion that is almost impossible to check by eye.

Disc with bolt pattern 4*100

The disc will not fit with its mating plane to the hub, and this will lead to the fact that it will have a runout.

Systematic runout can not only lead to the fact that the only bolt that is tightened correctly will quickly become loose, but also to instant wear of the wheel bearing, and the remaining bolts will loosen on their own. There is a way out of this situation.

Disc runout leads to rapid wear of the wheel bearing

To install a disc with a 4*100 bolt pattern, you need to either install a spacer or install studs with nuts instead of bolts.

A less reliable option is to install bolts with an offset head. A not entirely correct option is to install studs, for example, from the cylinder head and nuts from Niva, but the studs are not designed for torsional force, so the most reliable option would be to install spacers. You can carve them yourself or buy them ready-made.

But here you need to take into account several nuances:

- The width of the spacer must be at least 20 mm, since only in this case we will ensure proper thread strength.

- In this case, the offset of the disk will increase by the same 20 mm, which must be taken into account when selecting a disk.

- In this case, the disc must be selected with a minimum offset in order to remove the load from the hub and somehow compensate for the difference in offset.

Using offset eccentric bolts class=”aligncenter” width=”500″ height=”375″|fcw3qayjh5a| src=»https://autoprivat.ru/img/kak_postavit_diski_4h100_na_stupicu_4h98_21.jpg» class=»aligncenter» width=»500″ height=»375″[/img]Install wheel spacers

Installing studs with eccentric nut

Corrosion protection

For reliable operation of the chassis, everything is important: the bolt pattern, the dimensions of all components, the alignment/camber settings, and even the protection of the arches from corrosion. It is the arches that are more susceptible to adverse factors than other parts of the body - from ordinary moisture during rain to reagents on winter roads

To ensure reliable protection of the arches, it is best to install lockers (fender liners) on the VAZ 2110. Such protection will cost much less than subsequent repairs of rusted arches

It is important to choose the correct size of the lockers and ensure their tight fit in the area of the arches

https://youtube.com/watch?v=o2FUAvK29RU

We hope that by completing all the repair work yourself, you will provide your VAZ 2110 with many years of trouble-free service on the road.

Installing 4*100 disks

Let's consider several methods used by car craftsmen to install disks from foreign cars on a VAZ 2110:

- Sometimes holes are drilled into the disc hub on a lathe so that it will be possible to install the discs you currently have. Both 98 and 100 bolt patterns are suitable. And if you need to replace the disk, then this is also not difficult to do. The bolt sizes are standard;

- The simplest, but not the best way is to install the disk using extended bolts of regular diameter for wheels. But don’t be surprised later that this replacement led to the disc dangling, wheel play appearing, and it is impossible to establish the correct camber and toe, as well as the longitudinal inclination angles;

- A popular, relatively safe method is to install standard size bolts with an eccentric on a VAZ 2110 (an option is also possible if the bolt has an offset center). Today, online stores offer many sets of such bolts; Wheel bolt with eccentric

- Some people use special spacers. But in this case, the wheel offset will definitely increase by the width of the spacer. For safety, the width must be at least 20 mm. A compensating measure could be the installation of discs that have a short offset;

If you replace the standard wheels of a VAZ 2110 with those with a 4x100 bolt pattern, then when you gain speed you will find that the wheel dangles, and during sharp braking it may even fall off, and how this “adventure” will end is unknown.