Consequences of air leaks

An air leak will cause unwanted air to enter the engine where it is not intended. This reduces engine performance and causes some systems that rely on vacuum to malfunction.

Because air leaks cause engine inefficiency, you will notice the "Check Engine" light on your dashboard. You will also experience acceleration problems - this is because fuel is not delivered efficiently to the combustion chambers. Vacuum is used to operate actuators, sensors or brakes.

If there is a vacuum leak, some of the sensors may begin to malfunction, forcing you to make unnecessary repairs.

Diagnostics

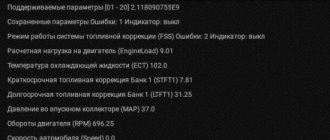

To check your car for leaks, you can use the ELM327 scanner, you can read how to do this here. This scanner is capable of diagnosing your car and indicating whether it has this malfunction. But, checking with a scanner will not always be a reference, since the leak may be insignificant and the ECU simply may not notice it.

It is best to check the suction using the old proven method, or rather several, which are given below.

First way

It is necessary to unscrew the mass air flow sensor from the air filter housing. It is secured with two 10mm key bolts. We take out the mass air flow sensor and start the engine.

With the internal combustion engine running, we close the sensor hole with our hand or a bag, the car should stall and the intake corrugation should shrink. A vacuum is created in the engine, which, in the absence of air leaks, will persist for a long time and the corrugation will remain compressed.

Compressed corrugation due to vacuum

If the corrugation on your car instantly straightened out or did not shrink at all, then this indicates the presence of suction.

Second way

To diagnose using this method, you will need a pump or compressor.

Here, just like in the first case, you need to unscrew the mass air flow sensor from the body and insert the bag between it. Then screw it back, thereby blocking air access to the engine.

On the receiver we find a fitting with a plug. We remove the plug and connect the pump there, pump up pressure into the receiver and listen to where the hissing will come from. To more accurately determine the location of the leak, you can use a soap solution with a spray bottle. We spray the areas of possible leakage with this solution and look for the appearance of bubbles.

Video on methods 1 and 2

Video on the first and second methods

Third way

This method is widely used at service stations. The search for suction is carried out using a smoke generator. This method is similar to the second, but instead of air, smoke is pumped into the receiver. If there is a suction in the engine, then smoke will flow out of this place.

Engine Inspection

To identify air leaks, you must first understand how the engine intake system works.

Air enters through the air filter. The throttle valve controls it by creating a vacuum. Know that a car is leaking air when it makes a hissing sound after starting.

Vacuum hoses wear out during operation and become brittle. This leads to their damage. Carefully inspect the hoses on the engine and replace them if necessary. The engines are different from each other. Refer to the repair manual for hose identification.

Air entering the fuel system

Air leak points on carburetor engines:

- Mixture quality adjusting screw.

- The gasket under the carburetor does not provide a tight seal.

- The throttle valve does not fit tightly.

- It can also suck in through the throttle axles.

- The tightness of the diaphragm of the throttle damper, economizer and starter is broken.

Places for air leaks in cars with diesel engines:

- unsealed low pressure fuel system tubes - from the tank to the filter;

- unsealed low-pressure fuel system pipes - from the filter to the injection pump;

- The drive shaft seal is not sealed, as is the axis of the diesel fuel supply control lever or the high pressure fuel pump cover.

New generation diesel engines suck air more often than older diesel engines. This is due to the fact that older engines used brass tubing, which provides reliable, long-lasting performance. And in new engines, plastic quick-release tubes are installed. It is clear that the service life of new tubes is shorter.

On cars with mileage of 150 thousand km. Tubes and tube rings wear out more frequently. Due to engine vibration, the O-rings of the tubes wear out and the plastic tubes wear out.

The diesel fuel system can become airy due to damage on both the direct and return lines.

Methods for checking tightness

There are several ways to check for leaks. Some are faster than others, and some require expensive equipment. Consider the following methods to find the best solution for your case.

Inspect and check for loose hoses on the engine

The first place to check for vacuum leaks is the hoses on the engine. Check for cracks or loose fasteners. Each car has a unique vacuum tube pattern. Make sure the clamps are tight enough.

Try moving the clamps from the side. If they move easily, they need to be tightened. If you still cannot determine the location of the leak, inspect the surfaces further.

Spray soapy water around the intake area

This is probably the easiest and cheapest way to check for air leaks. Spray soapy water around the intake manifold and damaged hoses while the engine is running. You will see air bubbles in the leak areas.

Watch a video on how to look for air leaks using a soap solution:

Use a smoke generator

This is the professional way. Auto mechanics use it to check air leaks within a few minutes. But this will require expensive equipment.

Spray carburetor cleaner

There are those who use carburetor cleaner to detect air leaks. To do this, start the engine at idle speed. Spray cleaner onto areas you suspect of leaks. The engine speed will begin to increase when there is air leakage.

This is because carburetor cleaner will get into the engine and burn with the fuel.

This is a dangerous method for checking air leaks. Sprays are highly flammable. Have a fire extinguisher ready!

A few words about troubleshooting

It was possible to find an air leak in the VAZ 2112, 2114 engine, now it should be eliminated. The algorithm for eliminating the problem will be different, depending on the location of the gap. If the culprits are the clamps, tighten them. If this is not possible due to the hardness of the rubber pipes, it is better to replace them with new ones. Leaky gaskets are also replaced with new ones. In some cases this can be a time-consuming process, such as when replacing the gasket between the cylinder head and block.

For this, desire alone is not enough, since you will need to use a torque wrench to tighten the cylinder head bolts, a diagram for their installation and screwing. After a short run they will have to be pressed again. It will be a little easier to replace the intake tract gasket, but you will also have to dismantle and then reinstall a number of parts.

Advice! If this is the first time such an operation is performed, write down the order in which components and parts are removed. This will make them easier to install during assembly.

Mechanics have noted cases where VAZ 2112, 2114 power units had air leaks in the fuel rail. For some reason, VAZ manufacturers install a rubber hose, compressed with two clamps in the fuel supply system. After compressing them again, the problem usually goes away. Most often, replacing “outdated” rubber products in the intake tract solves all problems that have arisen.

It is much more difficult to eliminate malfunctions of intake tract sensors such as MVR, idle speed, and idle air control. We are not talking about replacing gaskets, but about sensor malfunctions, which can cause air leaks in the engines. Experts do not undertake to eliminate air leaks in these devices; they simply replace them with new ones. It is possible to repair conductive paths, eliminate contamination or oxidation. The appearance of air leaks in VAZ cars in the fuel system is accompanied by the presence of leaks.

Important! If the driver ignores the resulting fuel leak, there is a risk of a fire.

This may be the connection between the electric fuel pump and the fuel line, the fuel pressure regulator, and other places. Before starting work immediately after stopping the engine, you should relieve the pressure in the fuel system. Otherwise, fuel may escape and ignite.

This article is not a direct guide to action, it is for informational purposes only. It is difficult to describe all the possible causes of the problem and how to eliminate them. If readers have questions, watch the video: https://vk.com/video240089429_170844002

Today in the Community I explained how to check an engine for “air leaks”. And so as not to write anymore how and what, I decided to do it in a photo.

1. Unscrew the air filter cover 2. Start the car 3. With the car running, insert the bag into the air pipe (there is a mesh) that leads to the mass air flow sensor.

The package will be attracted, the car will convulse, the air pipe will compress and the car will stall

- that means there is no suction!

This is the simplest way, allowing you to 80-90% understand whether the engine is sucking air from outside or not.

Even today I glued the panel a little, it creaked in the area where the silver trim fits. This can be seen from the abrasions. I taped the air duct and grille. There were also some creaks.

PS a little later the info on air conditioners is in my login.

Leaks in the intake manifold

If your hoses are fine, the problem may be with the intake manifold. The intake manifold gasket leaks from time to time, causing air leaks. It is located between the cylinder head and the manifold.

To check the tightness of the intake manifold, place the car on the handbrake. Start the engine and let it idle for a few minutes.

Apply the soap solution to the area between the intake manifold and the cylinder head or at the base of the carburetor. Listen to the sound coming from the engine. If it is smoothed out, then air leaks occur at the intake manifold and require repair.

Signs and causes of suction

When an engine develops a leak that allows extra air to pass through, the following symptoms are observed:

- The first sign is “floating” idle speed. The engine draws in excess air, and the control unit, which analyzes the composition of the exhaust gases using a lambda probe, tries to properly prepare the fuel mixture. But the mass air flow sensor (or DBP) does not take into account part of the inflow, so the speed is unstable (signs of a sensor malfunction are written here).

- The proportion of fuel in the combustible mixture decreases, hence the difficulty of starting the power unit “cold” when enrichment is necessary.

- Due to a lean mixture, engine power is lost - the car starts and accelerates more difficult.

- As the driver begins to press the gas pedal harder and forcefully increase the speed, fuel consumption increases.

Reference. On carburetor engines, stray airflow causes revs to jump to 2000 rpm or more, drawing gasoline through the main fuel jets, bypassing the idle system. The adjustment screws do not work.

There are several reasons why the tightness of the connections is broken and the engine sucks in air:

- deformation of adjacent planes (for example, the suction manifold to the cylinder head) as a result of overheating;

- too frequent use of car cleaning chemicals, which can soften gaskets and sealants;

- leaky hoses or clamps on the vacuum intake pipes in the engine.

On diesel engines, air is sometimes drawn in by the fuel pump through leaks in the line running from the tank. In carburetors, the path for air flow opens through worn axles and worn out valves.

Symptoms of air leaks

The first sign of air leaks is the Check Engine light coming on. There are many reasons to turn on this light bulb. You'll need to rule out other problems before you decide it's a leak. But be sure that it is an air leak if it is accompanied by hissing from the engine and loss of power.

Is your car not developing full power? It could be an air leak.

Leaking can cause additional engine problems such as fuel inefficiency.

Vacuum hose repair

If your vacuum hose is damaged, you don't have to buy a new one. The hose is long. You can cut off the damaged part and reattach it to the engine.

The most common damage is at the ends of the tubes. Always ensure that the clamps are tight to prevent further leaks.

After repairs, start the engine and leave it idling. Listen for any hissing sounds.

If you decide to replace the vacuum hose, use one that is similar in length and diameter. Vacuum tubes are designed for specific locations, such as the brake booster or PCV (Power Crankcase Ventilation) system.