The serial models VAZ 2114 and VAZ 2115 are equipped with generators of domestic and foreign production, namely: Russian KZATE and German BOSCH.

Many car enthusiasts preferred to choose a car with a pre-installed German-type PG, since the service life of the latter is 30 - 45 thousand longer than the domestic one.

The process of repairing and do-it-yourself maintenance of a generator on a VAZ 2114, VAZ 2115 is not complicated, but it requires basic knowledge in the field of vehicle maintenance. If any difficulties arise, please consult a service station specialist.

Which generator is installed on the VAZ 2114 and VAZ 2115

The standard AC power source has the following characteristics:

| Name | Indicators |

| Maximum voltage | 13.18 V - 14.70 V |

| Maximum current | 80 Amps |

| Belt drive deflection | 0.8 cm per 10 kg |

| Weight | 5.0 kg |

| Electrical energy source | KATEK 2114 / 15 |

| Rated voltage | 12 Volt |

| Power | 450 W |

Possible malfunctions and ways to eliminate them

Before you remove the generator and start repairing it, you need to make sure that the unit is working properly.

For example, if, when you activate the ignition in a car, the indicators on the dashboard do not light up and the sensors do not function, the reason may be:

- in the event of a break in the electrical wiring, diagnosis is carried out by checking wire 0 for a break;

- if the safety device fails, then it will need to be replaced;

- if there is a break in the section of the circuit connecting the ignition switch, as well as the safety block, in this case you will need to check all the wires.

Originals, analogues, prices, articles

| Catalog item | Serial number | Price | |

| KATEK ELD-A-2114-90A (original) | BOSCH (9402.3701) (original) | From 3500 – 4000 | |

| 9402.3701 | FINWHALE 6РК-698-05 | 6202 2RS / 180202 | From 3500 – 4000 |

| KZATE 9427.3749 | Electromash 977.3701 | SKL 2114-6202 2RS | From 3500 – 4000 |

| 2114-3701010 (HORT) | KATEK 2114-3701010 | Contitech 6PK-1115 | From 3500 – 4000 |

| PRAMO-Electro 2114-3701984 | PRAMO- 3701953 | PRAMO-Electro 2114-3701747 | From 3500 – 4000 |

| *prices are as of July 2021 |

Operating principle of the electrical energy source

There are 8 coils installed in the GU housing. The material is copper, the connection method is “star”. The rotor is a steel shaft, on the back surface of which magnetic circuits are pressed, between which a winding is installed.

Excitation winding wires and copper-graphite brushes are soldered to the shaft rings. After the ignition is activated, the current from the battery passes through the brushes and winding, forming a magnetic field.

Thus, the rotor is driven, and the alternating current is converted into direct current through the coils.

On the back side of the GU there are two terminals marked “+” and “–”. Accordingly, the terminals with the indicated polarity are connected to the battery.

To rotate the PG you need a battery. When the actual voltage during operation of the unit is higher than the battery voltage, the generator will begin to supply power to the battery consumers. Thanks to this, the on-board network current is maintained within a specified range.

Characteristic reasons for the failure of the main control unit on the VAZ 2114 (2115)

- insufficient tension of the drive belt;

- contamination of contacts on rings;

- mechanical damage to the rectifier unit;

- excessive wear of brushes;

- jamming (freezing) of brushes;

- short circuit in the winding;

- power supply interruption;

- the voltage regulator is faulty;

- roller bearing wear;

- pulley fixation is loose;

- Fan blades are damaged.

Methods for troubleshooting generator VAZ 2114 (2115)

- carrying out preventive measures;

- replacement of the PG assembly (in a comprehensive manner);

- drive belt tension;

- centering the fan blades;

- installation of new brushes;

- replacement of the rectifier bridge;

- voltage regulator prevention;

- inserting a new roller bearing;

- replacing the fuse in the mounting block.

Typical signs of a faulty control unit on a VAZ 2114 (2115)

- the battery charge lamp on the dashboard flashes periodically (systematically);

- indication of battery overcharging, GU does not charge the battery;

- dim headlights;

- weakened sound of the horn, as there is little current, the reason is low voltage;

- the appearance of extraneous noise when the power source is running.

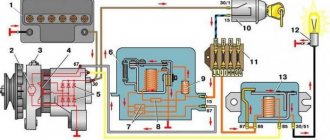

Electrical circuit diagram

Below is a diagram of the generator electrical circuit:

What problems may arise in the operation of the generator and options for solving them.

- If the brushes or voltage regulator malfunction, you will have to replace the entire assembly due to the fact that it is not collapsible.

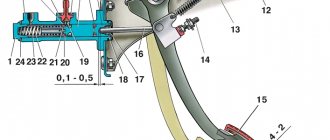

- Rotor bearings and their replacement. We have already discussed in detail how to change a bearing on a generator, so let us just remind you that there are two bearings in the generator. One is pressed into the front cover and if it malfunctions, it is most often replaced along with the cover assembly. The second bearing is attached, rolled onto the rotor shaft, it is removed using a special puller and a new one is pressed in its place.

- Additional diodes. If the diode malfunctions, its leads can be unsoldered and then, carefully trying not to break the rectifier unit with blows, pulled out of the holder. Clean the area from epoxy resin, then install the diode and solder it. After the entire procedure, the lead of the diode, which has a color mark, is soldered to the bus, and the diode body is attached to the holder with epoxy resin.

- The generator tension belt needs adjustment. But this must be done competently and carefully, since excessive tension can increase the load on the bearing and lead to its unsuitability in a short period of time.

Many of these problems may seem trivial, but they could mean you need a new generator.

You can repair the generator yourself, but to do this you need to have certain skills, so we still recommend leaving this work to knowledgeable craftsmen. The alternator bearing is an integral part of the alternator and its failure may result in malfunction. In this case, only replacing the generator bearing can help.

On devices from different manufacturers, this process is carried out in different ways, and the bearings of the Bosch generator are most easily replaced. Car enthusiasts often ask the question of how to change a bearing in a generator. So, this is done in the following way:

Remember that even if the bearing on your car looks great, the alternator bearing will still need to be replaced.

Install the generator bearing only using a press, and never use hammers or blows.

It is important that the bearing itself sits completely in place, then install the impeller and pulley on the shaft. The next step is to put the rear bearing of the generator with the cover in place, again, do not use any blows, only using a press. Next, you just need to perform the opposite actions to those taken during removal, and that’s it, you replaced the generator bearing yourself!

Next, you just need to perform the opposite actions to those taken during removal, and that’s it, you replaced the generator bearing yourself!

Sources

- https://remontavtovaz.ru/vaz-2110/samostoyatelnaya-zamena-podshipnikov-generatora-vaz-2110.html

- https://nadomkrat.ru/elektrooborudovaniye/kak-pomenyat-podshipnik-generatora-na-vaz-2114

- https://vaz-2114-lada.ru/2012/06/kak-zamenit-podshipnik-generatora/

Replacement and repair of generator on VAZ 2114 (2115)

Location: engine compartment, to the left of the power unit, at the end.

Preparatory stage:

- a set of keys, heads, cranks;

- a torque wrench to check the tension of the drive belt;

- mounting spatula to remove the belt;

- flat head screwdriver

Step-by-step replacement instructions:

- We fix the vehicle on a level platform.

- Squeeze the parking brake.

- Turn off the ignition.

- Open the hood.

- Disconnect the terminals from the battery.

- Unscrew the fastening of the “+” and “-” terminals from the generator set.

- We turn out the coupling bolt of the support bracket.

- We lower the unit down and remove the drive belt from the groove.

- We unscrew the studs and turn out the coupling bolt.

- To change the GU, we remove it from its regular place.

Do-it-yourself dismantling of the control unit on the VAZ 2114 (VAZ 2115) is completed. We carry out comprehensive preventative maintenance of the equipment, clean the housing and elements from dirt and dust, blow through the windings with a stream of compressed air, and dry the contacts.

We replace worn parts and components with new ones as necessary, if defects are detected. The generator must be completely replaced if cracks are detected in its housing.

In this case, further use of the equipment is strictly prohibited.

We measure the resistance of the excitation winding with a multimeter and check the diode bridge for operability. We also inspect the fuse for integrity and replace it with a new one if damage is detected.

DIY generator installation:

- We fix the GU on the support brackets, put on a pin and a spring washer.

- Place the belt in the groove.

- We screw in the fastening bolts.

- We move the GU body up, tighten the mounting bolts of the bar.

- We tighten the generator fasteners with a torque wrench with a force of 28.0 Nm.

- We check the belt deflection; the range should not exceed 12 mm. tighten as needed.

- We clamp the power cables on the installation.

- We put on the battery terminals.

To reduce the frequency of replacing power units, some car owners install generators from Priora (injector, 8 valves). The equipment is more powerful in terms of technical characteristics, which means it ensures stability in the generation and supply of current to the motor.

A new generator set is 500 - 750 rubles more expensive than a standard one. The holes for fasteners completely coincide with the factory ones on the VAZ 2114 (VAZ 2115).

Recommendations for care and maintenance of PG on VAZ 2114

- strictly adhere to the technical inspection deadlines;

- when purchasing consumables and spare parts, check the correspondence of catalog articles;

- give preference to original parts where the manufacturer guarantees quality;

- in the absence of experience, carry out prevention in certified workshops;

- when purchasing components, require the manager to provide documents for the products he sells;

- Always use the vehicle’s operating manual and consult with car service specialists.

Signs of unstable operation or generator failure

The main signs of a malfunction in the car's main power supply:

- The engine does not start well. If the generator stops working normally, the battery does not receive electricity to restore normal voltage. It should be within 13.5 volts. Without recharging, it will constantly decrease. A battery with low voltage will not be able to quickly crank the starter. Consequently, there will be problems starting the engine.

- Weak or constantly blinking headlights. The second sure sign we can get when the headlights are on. This is also noticeable in the dashboard lighting and interior lighting. The light wakes up significantly weaker than usual, a sure sign of a lack of electricity in the vehicle’s on-board system. As you know, the main energy supplier to the system is the generator.

- The warning lamp in the form of a battery on the instrument panel is on or flickering. The operation of this warning lamp is possible if the vehicle's power system is powered only from the battery. Urgent measures need to be taken.

- Whistling or smell of burnt rubber in the engine compartment. This sign lets you know that the drive belt of the main power source is slipping, therefore, the rotor shaft rotates slowly or does not rotate at all. In this case, the car's electricity consumers experience a shortage of electrical energy.

- A grinding and rustling noise is heard under the hood. Based on this noise, one can judge the failure of the rotor shaft bearings. The gap in them has increased, a backlash has appeared in which the rotor touches the stator. It follows that electrical energy is not generated in the required quantity.

There is a sure way to confirm all the causes of a malfunction. With the engine running, it is enough to disconnect the ground or remove the negative terminal from the battery. If the engine stalls or begins to operate intermittently, it means that the main power source of the car must be urgently repaired.

“>