Hi all! I am dealing with a typical and common problem: the Niva Chevrolet fuel pump does not work. Yesterday I got into the car, started it - it started, but immediately stalled. The first thought that came to mind was that the fuel pump was broken. When you start the engine, you can hear the pump humming, after which the relay is activated and it stops pumping fuel. I left the car, the next day I tried to start it - the pump did not hum and the pump did not start. What to do?

You correctly noted that when you turn the ignition key, the relay is activated and the fuel pump starts working, supplying fuel to the cylinders through the lines. If you can't hear the pump whirring, it's most likely broken. To find out if this is actually the case, you need to do a few simple steps. Let's talk about everything in order.

Chevrolet Niva fuel pump does not work: what to check?

Once upon a time I also wondered what to do and where to look first if the fuel pump does not work. To begin with, I recommend that you remove the negative terminal of the battery in order to “reset” the brains of the on-board computer. If after this the pump starts working, great, the problem is solved. But this doesn't happen every time.

So, the order of further actions is as follows:

- We open the hood, find the fuel rail, there is a cap on the side, under which there is a spool. Find the valve there, click on it. Is there a small trickle of fuel? If yes, great!

- No fuel flow? Try turning the ignition key several times, and then press the valve again

- If nothing works, then most likely there is no pressure in the system, therefore, it is the fuel pump that has broken down

Don't forget to check the fuse. It may burn out, then the pump simply will not be able to work. We move the front passenger seat and find the fuse under the dashboard. We check it, if it works, we move on. If it burns out, we replace it with a new copy.

How to determine if a relay is working properly

To determine the serviceability of the fuel pump relay, you can use several methods:

- The first method requires the presence of a working part. We find the relay according to the above instructions and put a working one in its place. After completing the steps, we check the functionality. That is, we try to start the car, if the fuel supply is successful, then we can proudly note that the breakdown has been fixed.

- However, not every driver has a spare relay with him. If it is not available, you can make a jumper from wire. Due to the fact that the current will be insignificant, the cross-section of the wire does not necessarily have to be large. You need to short-circuit contacts numbered 30 and 87 (you can determine where they are located from the diagram on the relay). After the procedure, you need to turn on the ignition: if after turning on the pump stops, then the problem is not in the relay, but if it works, then you will have to change the device.

It is worth knowing that jumpers should only be used to check whether the relay is working or not working. It is strictly forbidden to drive with them on a regular basis, as you can damage other parts or even start a fire in the car.

Tips for motorists

The operation of any internal combustion engine is impossible without supplying fuel to the combustion chamber. This process is equally important for both carburetor and injection engines. The fuel mixture is supplied by a fuel pump, which for systems with distributed fuel injection is electrically driven. Therefore, failure of its operation on this car is almost always associated with the electrical circuit of the car.

What to do in this case

This is a very unpleasant moment, especially when this happens on a busy city highway, and even during rush hour. If there is no help available, you should remove the car from the roadway and try to “revive” the gas pump yourself. It is advisable to have a car tester for this or at least a control light. The first sign of such a malfunction is that the engine does not start, and when the ignition is turned on, the sound of the electric fuel pump motor is not heard.

Auto electricians recommend removing the battery terminal for a few minutes and trying to start the engine again. If the problem is not solved, continue troubleshooting. Now you need to get to the pump to check the presence of supply voltage at its terminals. One terminal of the warning lamp or tester should be connected to the ground of the machine, and the second is connected to the gray wire of the electrical connector on the fuel pump. There are two options for checking: the presence of voltage or its absence. The first case indirectly confirms the breakdown of the electric motor, the second suggests continuing the search.

Where is the fault located?

Failure of an electric motor is a rather rare phenomenon, so we will focus on the case when there is no supply voltage at the pump terminals. When checking the presence of power, you should take into account the fact that the control unit initially issues a pulse to turn on the pump lasting only 5 seconds. If the motor does not start, the impulse will no longer be received. Therefore, before checking the supply voltage, you need to relieve the fuel pressure in the rail.

Power is supplied through the relay contacts. Checking it is not very easy, since you have to remove the plastic trim under the glove box on the front panel. There is a relay block and a fuel pump fuse deep inside. To check the relay, it must be replaced with another one. Quite often the culprit is the burnt contacts of this relay. In some cases, problems are created by an additional relay that is part of the alarm system. When the car is put into security mode, it blocks the power supply circuit of the fuel pump, preventing the engine from starting.

The fuel pump does not pump when the ignition is turned on

First of all, you need to check the fuel pump terminals and the power to them. In the photo, the terminals were worn out, which caused the contact to close and the fuel pump to melt.

What to do if such a situation arises. The verification algorithm is described below. Briefly check the presence of voltage at the fuel pump terminals. Based on this, further conclusions are drawn.

Checking the fuel pump circuit

Checking the power circuit.

If you know that the pump is working (to do this you need to gain access to it, remove it and connect it to an alternative power source), then the reason should be looked for in the car's wiring. To do this, the control light should be connected to the gray wire that goes to the pump.

This is exactly what is a plus. If the light does not light up, then power is not supplied to the unit.

Checking relays and fuses

Here you should initially check the fuses and relays. The fuse box is located behind the left of the driver under the dashboard, and therefore is not easy to access. You will have to unscrew two bolts and remove the decorative protective cover.

If these components are faulty, they should be replaced. The relay is checked in the same way as the pump, by connecting a test light to the input and output . The fuse can be checked visually.

The fuel pump relay is marked with a green arrow.

If the car still does not start, you should check the connector block. It is located behind the driver's side fuse box in the passenger compartment. Here you can also use a test light or tester, with which you can check the voltage at the inputs/outputs.

Purpose of the fuel pump

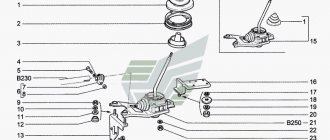

The very name of the part indicates that it is needed to pump fuel from the tank to the vehicle line. A submersible fuel pump is installed on a Chevrolet Niva car. It is a commutator motor, where two magnets play the role of a stator. But most often, a fuel pump means not only the motor itself, but a whole module, which includes:

The body is made of plastic. It performs a load-bearing function, since the main elements of the module are attached to it. Usually it does not cause problems during the entire period of operation of the car, unless it is subject to mechanical stress.

The filter is considered a consumable item. It has to be changed when it gets dirty. It is impossible to accurately indicate the resource, since it depends on the quality of the fuel used.

The level sensor is designed to supply a signal, which, after conversion, is sent to the dashboard. The ability to control the amount of fuel today is an integral function of any car. In addition, the on-board computer can calculate the consumption or remaining amount of gasoline.

The pressure regulator is a bypass valve. The pressure in the line cannot increase indefinitely, and the injection system is not always capable of consuming the amount of gasoline that comes from the fuel pump.

To get to the module, you just need to fold down the rear seat, so you don’t have to remove the gas tank. The purpose of the pump is not only to pump fuel, but also to create a certain pressure in the entire system. And if there is excess pressure, the valve is activated and gasoline is poured back into the tank.

Video “How to find the cause of a pump failure”

For more details on finding the cause of a fuel pump failure, watch the video (author - Sergey L).

Hi all! I am dealing with a typical and common problem: the Niva Chevrolet fuel pump does not work. Yesterday I got into the car, started it - it started, but immediately stalled. The first thought that came to mind was that the fuel pump was broken. When you start the engine, you can hear the pump humming, after which the relay is activated and it stops pumping fuel. I left the car, the next day I tried to start it - the pump did not hum and the pump did not start. What to do?

How does a Chevrolet Niva fuel pump work?

After dismantling the module, it is necessary to begin disassembling it, since the motor itself is located inside the housing. The disassembly algorithm is intuitive. The electric motor is inserted into a special housing, held by a cotter pin on the guides. An impeller with blades is attached to the rotor. When it rotates, a swirl of fuel is formed, as a result of which gasoline acquires kinetic energy and enters the highway. When a unit fails, the entire unit is replaced, as it is considered non-separable.

The float lever is connected to the rheostat slider. When the fuel level in the tank changes, the resistance of the sensor resistor changes.

The command to turn on the motor comes from the computer, but the circuit is controlled by the electromagnetic relay of the fuel pump.

It is located under the glove compartment on the passenger side and is closed with a decorative lid. A circuit fuse is installed in the same block. These two details need to be paid attention to, as they often cause malfunctions.

Video instructions for replacement:

Electronics-related breakdowns are common in cars. For an inexperienced driver, this is a dark forest, because for most it is much easier to deal with a mechanical breakdown than with the so-called brains of the car. One of the most common breakdowns in a Niva Chevrolet car is a problem with the fuel pump relay.

You should be aware that the following factors can cause fuel pump failure:

- clogging in the filter;

- broken wires;

- damage to tubes;

- failure of fuses;

- breakdown of the fuel pump itself.

Due to the above, before fixing a broken relay, you should be sure that it is the problem. How to determine this will be discussed below.

Design and principle of operation

The Chevy Niva fuel system uses a submersible fuel pump, which is based on a commutator motor with two permanent magnets on the stator.

Power is supplied to the pump through a relay, the control contact of which is connected to the engine control unit. The circuit is protected by a fuse, which prevents the electrical wiring from catching fire in the event of a short circuit.

The relay is located inside the car under the glove compartment. The fuse box is located nearby.

Often, a fuel pump is not called the electric motor itself, but a module that includes:

- A plastic case that performs a load-bearing function.

- Coarse filter that retains coarse-grained contaminants.

- The pressure regulator is a bypass valve that returns excess fuel to the tank.

- A sensor and float that read information about the fuel level in the tank and transmit the data to the on-board computer.

The electric pump is installed below the gasoline level. This ensures lubrication and cooling of its parts. If you run out of fuel completely and force the electric pump to run dry, it will quickly break down.

The rotation of the pump impeller ensures pressure in the fuel line within 3.6-4 Bar. If this indicator is exceeded, the pressure regulator bypass valve is activated.

Gasoline enters the impeller through a mesh filter, which protects the assembly from large foreign particles. Fine contaminants do not harm the fuel pump.