Every car owner knows what a spar is - it is a longitudinal beam on a frame on which the body rests, springs and a number of parts are attached. It often breaks at the point where it comes into contact with the stabilizer, which makes the steering wheel stable, even despite the presence of amplifiers. Cracks appear there, which can be noticed when checking the chassis. And the deformation of the body geometry is associated with the active operation of the car in Russian conditions. If the owner of the car has not yet changed the VAZ 2110 spar, but is faced with its breakdown, the part is replaced with his own hands.

Please note that in a neglected state, the spar (VAZ 2110) is not repaired, but replaced.

The main thing is to pay attention to the breakdown in time and eliminate it by welding in the internal part of the product.

The key causes of failure are:

- poor quality of road surface;

- driving over potholes at high speeds;

- weak fastenings. If the rigidity in the steering mechanism decreases, cracks appear near the bolts. Then there is play on the body, and then the wheels get toe defects.

Another problem: how to pull out the spar with your own hands? The procedure is required when it is bent to the side during an accident and involves a bench hood.

Replacing the spar

VAZ 2110 spar burst

To replace the spar you will need:

- standard set of wrenches;

- grinder with multiple disc variations;

- drill with drills;

- sledgehammer;

- file;

- chisel.

Spar repair options

The spar is made of an extremely strong steel alloy, which is almost impossible to deform; its strength is incredibly high. However, as everyone knows from junior school physics classes: force is speed multiplied by mass. For example, a light car collided with a KAMAZ, as a result the passenger car was completely deformed, and the body of the KAMAZ was only partially, but still deformed. It should be objectively understood that even a very strong material can be deformed, it all depends on the force that acts on it. The point of direction of the force, as well as the degree of its application, determine the nature of the damage. Any significant traffic accident almost always damages the spar, sometimes completely. In this case, you have to completely replace it.

Note. If there is no confidence in the objectivity of the assessment of the exact nature and extent of damage to the car, then the most rational option would be to seek help from a car maintenance service.

The spar in the VAZ 2110 burst

If the spar is only partially damaged, for example, in the form of a crack, then you can try to eliminate this defect by welding. However, it is also necessary to objectively understand that not every defect can be eliminated by using welding. For example, if the attachment of the spar to the body of the vase is damaged, then most likely welding will be ineffective. The only way to eliminate the defect is to make a complete replacement.

What is better to eliminate the existing spar defect or completely replace it?

Of course, the best option would be to weld a new spar instead of the old one, and also pre-strengthen the body. However, it all depends on the repair budget; the more financial resources are invested, the more effective the repair will be. Each motorist has different financial capabilities, so this nuance must be taken into account objectively. Therefore, the option of repairing the spar cannot be immediately discarded.

Note. If a motorist is not sure that he is able to do everything on his own, then it is better not to take risks and resort to the services of a car service. Observe the work of the car service employees and the next time replace the spar yourself.

The right side member of a VAZ 2110 burst

If there is a need to use welding, then it is best to use a semi-automatic machine with carbon dioxide. Also, when replacing the spar, it may become deformed, so be sure to first install spacers under the side members. Additionally, it is imperative to take into account the condition of the case, since sometimes its integrity is under very significant doubt.

Note. To reliably repair the spar, you need to make sure that the body itself does not have any defects, otherwise you will have to spend even more money on repeated repairs.

Also, do not forget about the well-known axiom that with each welding, the strength of the metal decreases, and this must always be taken into account without fail. If you do not pay attention to this technical nuance in time, an unpleasant cascade of negative consequences may occur:

- wheel alignment, and subsequently their complete collapse;

- the rate of tire wear will increase significantly;

- the car will not spontaneously constantly partially change its given motion vector;

- the transmission will begin to fail too prematurely and without any obvious external reasons;

- extremely rapid deformation of the body, literally within a few weeks, etc.

The cost of performing body welding work in technical maintenance services is on average 4,500 rubles. Additionally, you will need to purchase a certain set of parts. However, there is a very real opportunity to do everything yourself, the main thing is to have a little knowledge about the structure of the body and a little experience in using welding. A crack after an accident can be welded, but the main thing is that the metal is strong enough.

Replacement algorithm

To remove the side member (VAZ 2110), follow the instructions:

- remove the door using a screwdriver;

- Raise rugs, heat and sound insulation;

- in the area where the splash guard is located, clear the surface of flammable products;

- remove the car fender;

- secure the VAZ to the front on stands;

- install the beam on the bridge in front to prevent displacement;

- dismantle the springs, remove several fasteners from the ball and remove the lever;

- if the fasteners between the timber and the beam cannot be removed, cut them off using a grinder;

- unscrew the brace on the beam and cut the mudguard;

- divide the product into 2 parts and dismantle it from the body by making a cut behind the beam;

- After cleaning the fasteners, proceed with the installation of a new longitudinal beam.

Front right fender in color for VAZ 2110-2112

Right headlight mounting bracket (new model) TZTO for VAZ 2110

Left headlight mounting bracket (new model) TZTO for VAZ 2110

Front left floor threshold connector (jack) for VAZ 2110-2112

Front left fender in color for VAZ 2110-2112

Rear left door in color for VAZ 2110, 2112, Lada Priora sedan, hatchback

Front right floor threshold connector for VAZ 2110-2112, Lada Priora

Main types

Depending on the design features of the car, the following types of their location can be classified:

- opposite each other in a horizontal position;

- horizontal arrangement with a certain angle of inclination;

- slightly curved in a vertical position;

- curved and horizontal.

Trucks are characterized by a parallel type of arrangement of side members, which are in a horizontal position. Other types of arrangement are typical for cars and SUVs. The inclined type provides maximum turning radius of the wheels. Thanks to the vertically curved side members, a relatively lower floor height in the vehicle interior is ensured. Horizontally curved elements also affect the floor level, but in addition to this, passive safety is further increased in the event of an emergency with a side collision.

The cross members are responsible for the level of rigidity of the main parts of the car. They are located between the side members. There are three main types of crossbars:

Mostly metal materials are used for manufacturing. In large trucks, the side members and cross members are connected by riveting, and in passenger cars, these two components are simply welded. At the same time, special brackets are used to firmly connect the frame, body, main parts of the transmission and engine. They, in turn, come in many sizes and also have a high level of strength.

Replacing the front spar on a VAZ 2110 on your own

Front spar burst

If the car owner has never encountered such a factor as replacing the front side member of a VAZ 2110, you should either contact specialists or carefully study the method of removing it and installing a new one. Most often, a breakdown occurs at the attachment point of the stabilizer, which is responsible for lateral stability, and the place where the steering wheel is attached. Despite the amplifiers available in these places, the spars fail and require either repair or replacement. Replacing the front side member on a VAZ 2110 can be easily done with your own hands.

Changing parameters

The spar, like other parts of the car, is subject to heavy loads and as a result, breakdowns or wear are possible. Since this is an important part of the vehicle, it becomes clear that in the event of a breakdown, literally everything stops working as intended.

For example, if the wing of a car is torn off, it continues to move, but if a spar breaks, it will no longer be able to drive. Then increased wear of the rubber occurs, the body begins to break, and the car itself is difficult to drive.

The spar on a VAZ 2110 burst - what to do

- 1 Replacing the spar 1.1 Options for repairing the spar

- 1.2 What is better to eliminate the existing defect in the spar or completely replace it?

- 1.3 Algorithm for replacing a damaged spar

VAZ 2110 spar burst

From a practical point of view, the side member represents the frame of the car and is one of the main elements not only of the body, but also of the entire car. If a spar on a VAZ 2110 bursts, there can only be one solution - a complete replacement. In rare cases, partial, if the integrity of the spar has not been compromised. In the case where a spar has burst on a VAZ 2110, the work can be done with your own hands.

How to pull out a spar

You can pull out the spar at home. To perform this work, it is necessary to prepare the necessary instruments and other devices. Of course, a lot depends on the availability of skills when performing repairs. In the case where such work has never been performed before, there are no ideas in the field of car repairs, it would be more correct to entrust this task to specialists. If you still decide to do everything yourself, you should prepare the following tools:

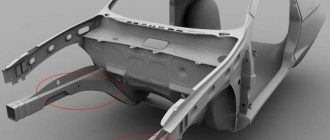

Body geometry

VAZ 2110 rear spar

A spar that has become unusable disrupts the proportions of the body. Repairs must begin with correcting the body parameters:

- The car is lifted on a rack lift; if there is no such thing, lift the rear of the car with jacks.

- Place it on reliable supports, taking into account the availability of work on replacing parts and straightening the body (see Repairing a VAZ body - from a car repairman’s textbook).

- After completing work to correct the geometry of the body, the rear wings are removed.

Removing the spar

VAZ 2110 rear spar

Dismantling begins with the following:

- One side is hung on the jack to relieve stress on the metal.

- The rear suspension is removed to facilitate the work of cutting the spar.

- Parts are cleaned of debris and dirt.

Rear spar VAZ 2110

Installation

Installation

Having dismantled the old spar, the new one is tried on. If necessary, you need to trim the part to length. Drill the new spar at the attachment point by welding in three places with a pitch of 3 mm. It is recommended to try on the spar very carefully so as not to spoil the part. So:

- The finished part is secured in its original position using clamps, without violating the linear dimensions according to pre-applied marks.

- Then carefully, using a semi-automatic welding machine, it is tacked in three places along the previously drilled holes.

- Having installed the first spar, carry out the same work relative to the second.

- Checking their installation along the longitudinal lines of the body, we study the manual on carrying out body welding work.

- Additional metal plates are applied to the bottom and inside and welded to strengthen the structure.

- After finishing the welding work, carefully use a grinder with a grinding disc to clean the welding areas.

Methods for replacing the spar

To replace the spar with your own hands, you must first align it and only then remove it. This is done by cutting. Incisions are made only along clearly defined lines. After this, a new one is installed in place of the old spar. For this purpose, special spot welding is used.

Partial replacement

If there is no need for a complete replacement, then it is quite possible to do it partially. This refers to the renewal and improvement of weakened areas. Only those sections of the side members that do not bear the entire load can be replaced. Most often, through partial replacement with your own hands, the spars are given shock-absorbing properties, and this is done as follows:

- In the production process of stamping parts, special unique folds are provided. They are necessary so that in the event of an accident the spar does not deform, but simply folds into an accordion in a given place;

- installation in the main S-shaped building;

- installation in a housing of variable cross-section, as well as special holes and chamfers.

Do-it-yourself partial replacement has its positive sides. No coupling or specific type of welding is required. This part is installed very easily, and after all the work is done, it is adjusted to the required dimensions and installed back.

Complete replacement of the rear spar

If the spar is severely deformed or does not fulfill its main shock-absorbing tasks and does not fully provide the strength of the body, then its complete replacement will be required. To make the operation easier, the machine is driven onto an overpass or inspection pit. In cases where this is not possible, a regular jack will come to the rescue.

You should start by dismantling the parts attached to the spar, after which pulling is carried out. It is clear that it will not be possible to give it its original shape, but it is worth trying to get closer to this. Afterwards the protective coating is removed, and only then the spar itself is removed, that is, cut off from the fastenings.

If the spar has been successfully removed, it is time to prepare a grinder for further work, on which a special type of stone is mounted. Using this device, all welding residues are removed, and areas where corrosion processes have begun are also removed.

Upon completion of these works, the wheel arch is prepared, which is connected to it. Installation of the spar is carried out in the reverse order and is secured using welding. After installation, a thorough check. To do this, use the chiseled method.

Using a grinder, you need to refine all the places where the welding joint was made. To do this, the welding is removed using a grinder, and then these places are covered with a special sealant.

The process of replacing the front spar is carried out using a similar method.

Tools and materials

Replacing the spar (VAZ 2110) requires the following consumables:

- bolts that secure the steering mechanism (left) or pendulum (right);

- fasteners for the steering gearbox (3 pieces each);

- fasteners for beams (bolts and nuts);

- fasteners for the lever on top;

- bracket for longitudinal beam;

- splash guard;

- set of fasteners for ball joint;

- spar (VAZ 2110). It is sold separately or together with the mudguard. Experts advise buying a kit and not wasting time on welding. This ensures that a secure fastening is created. Please note that a separate purchase of the longitudinal beam will entail the need to purchase the necessary parts.

If damage is noticed in time, it can be repaired by welding with penetration into the inner part of the spar.

Replacing the front spar of a VAZ 2110 requires an examination of the engine shield - the part of the car body that separates the engine compartment from the car interior. The mudguard is attached there.

If there is corrosion on the surface, treat it with anti-corrosion agent, sand it and apply a patch.

To unscrew the ball joint, special fasteners are required. Of the tools you should have:

- grinder;

- impact and standard screwdrivers;

- chisel;

- welding machine;

- ties that compress springs.

Equipment and tools

Replacing rear side members on a VAZ 2110

Repair work to replace the spar must be carried out in an equipped and spacious garage. It is necessary to prepare equipment and tools:

- welding machine or gas welding;

- rear side members complete with rear suspension;

- two jacks, hydraulic racks;

- drill;

- Bulgarian;

- chisel;

- plumber's hammer;

- disc on a grinder for stripping metal where the old part was cut.

Before starting repairs, you must remove the battery and drain all remaining gasoline from the gas tank. If possible, cover the gas tank with fireproof material. To prevent spontaneous combustion from remaining gasoline vapors in the gas tank. Since the repair will be carried out using a power tool that produces a spark.