Issues discussed in the material:

- What is the working principle of a vacuum brake booster?

- How to check the operation of the vacuum brake booster

- How to adjust and repair VUT

One of the most important parts in a car's brake system is the vacuum booster. Its operation allows reducing the effort exerted by the driver when pressing the brake pedal. The efficiency of the braking system remains unchanged. Like any other machine part, the vacuum brake booster (VBR) is subject to wear and tear, which means it can fail during long-term use. Therefore, it is necessary to periodically check the VUT. We will tell you how to check the vacuum brake booster below.

What is VUT and why is it needed?

To determine the malfunction of the VUT, it makes sense to describe its purpose, operating principle, as well as the effect of the vacuum booster on engine operation. So, the main task of the “vacuum man” is to increase the physical force (usually 3...5 times) applied by the driver to the car’s brake pedal. This is vital because even a very strong person is not able to create enough force in the hydraulic brake system so that all the brake pads are compressed to the required value at the critical moment. This force is created due to rarefaction of air, and the area in the engine intake manifold is used as its source or is pumped by an additional pump.

Structurally, the VUT consists of two chambers - atmospheric (on the driver’s side) and vacuum (on the engine side). The vacuum chamber is connected to the intake manifold using an appropriate pipeline. When you press the brake pedal, the vacuum chamber is connected to the atmospheric chamber using a pusher, which has a so-called tracking valve. Next, the diaphragm is connected to the rod and brake fluid is pumped to the brake cylinders. If there is no force on the brake pedal, then under the influence of the return spring the diaphragm returns to its place, the pressure on the brake fluid weakens, which is why the brake pads move apart and braking stops.

VUT device

In the simplest case, the vacuum brake booster takes vacuum from the intake manifold. To do this, it is connected to it by an appropriate pipeline. However, in many modern cars there are separate vacuum pumps for the vacuum pump. They come in two types. The first is mechanical, it is driven by the engine camshaft. The second is electric and is driven by a separate electric motor. The use of additional pumps not only increases the comfort of using the braking system, but also increases its reliability (for example, in the event of damage and/or depressurization). But still, the pump is only an auxiliary element, and the main vacuum is taken from the intake manifold.

This is interesting: How does the traction control system work?

Principle of operation

The clamping force of the brake pads in cars, the design of which does not require the installation of VUT, is pumped up by the force created by the driver when pressing the pedal. A vacuum brake booster uses differences in atmospheric pressure to create a vacuum, thereby helping to build up pressure in the brake line.

Let's start with the fact that the working diaphragm divides the body into atmospheric and vacuum (located on the GTZ side) chambers. It is connected through a pusher to the pedal. When the brakes are not applied, the follower valve maintains equal pressure in the two chambers. Depressing the brake pedal causes the follower valve to “cut” the connection. The bypass valve equalizes the pressure of the atmospheric part of the body with the engine compartment. The vacuum, which has been maintained in the VUT housing all this time, now attracts the diaphragm. As soon as the driver releases the brake pedal, the return spring returns the elastic partition to its original position.

The low pressure in the housing, which drives the vacuum booster, is created through a hose connecting the vacuum part to the intake manifold. It occurs due to the vacuum created by the piston descending to BDC during the intake of the fuel-air mixture. If the vacuum of a gasoline engine is sufficient for the normal operation of the VUT, then diesel engines are necessarily equipped with a vacuum pump designed to pump up the vacuum. Depending on the design (petal, membrane), such a device is driven by: injection pump, generator or camshaft.

Signs of VUT malfunction

Partial output of the vacuum brake booster will certainly manifest itself, and from the worst side and quite clearly. So, symptoms of a malfunctioning amplifier include:

- Significant effort when pressing the brake pedal . To feel this for yourself, you can press the pedal four or five times with a known good vacuum seal and the engine turned off. At the last squeeze, the force on the pedal will increase significantly. Sometimes the opposite situation occurs - the pedal is too soft. This indicates “airing” of the brake system.

- The influence of the vacuum booster on engine operation . Since the VUT takes vacuum from the intake manifold, the engine can change its operating mode during braking (although this should not happen in normal mode). This happens because excess air is sucked into the manifold, affecting the composition of the air-fuel mixture.

- The vacuum brake booster hisses . In particular, hissing occurs when the pedal is depressed. A hissing sound clearly indicates the presence of depressurization either in the vacuum amplifier itself (for example, when the diaphragm ruptures), or in its pipeline or in the check valve (for example, when its rubber seals are significantly worn).

- Vacuum pumps knocking . If a mechanical vacuum pump fails, the usual sign of this is a hum emitted by its drive rod (error p1479 may also appear). If an electric vacuum pump is installed on a car, then motorists often experience overheating of its drive motor.

- Knocking noise when braking hard . Moreover, the sound is inertial in nature, since it is caused by the membrane fastening becoming loose.

Accordingly, the occurrence of one or more signs directly indicates to the car owner that it is necessary to check the vacuum brake booster and its components.

Error p1479

In modern cars equipped with an electronic control unit (ECU), an error code p1479 is often generated in the device’s memory - “Brake booster vacuum system mechanical malfunction.” Owners of a wide variety of cars encounter it - Audi, Volkswagen (Touareg, Passat), Ford and others. The cause of an error in the control unit can be very different. For example, when air is sucked in the hose between the intake manifold and the vacuum brake booster itself.

Another common option is the result of measuring the vacuum value with a vacuum sensor. In particular, it occurs if moisture appears inside the vacuum booster and/or its tubes. The solution is to clean and dry the tubes, and in rare cases, replace the sensor itself.

It also makes sense to check the integrity of the fuse going from the control to the sensor. Each machine will have its own electrical circuit, so it is impossible to provide specific information within the framework of this material.

Another option is the performance of the electric vacuum pump. In particular, its electric motor, impeller, bearings, fastenings, connection blocks, as well as relays and fuses.

Checking the membrane and chamber tightness

There are several ways to check the serviceability of the vacuum brake booster (VBS), but to ensure that it is 100% operational, it is better to use them all. First of all, press the brake pedal several times with the engine off. When pressed for the first time, the pedal will lower with a fairly insignificant force by about 1/3 of the full stroke, with each subsequent press it should become tighter and the stroke should decrease. If this does not happen, the VUT is most likely faulty, and diagnostics of the vacuum brake booster is required. Next, we will tell you how to check the vacuum brake booster on Kalina.

If VUT diagnostics have shown ambiguous results and it is difficult to determine the difference in pedal stroke and pedal stiffness, you can try another method. Press the brake pedal two or three times and start the engine without removing your foot. There are several options for the development of events:

- If the pedal goes deeper a few centimeters, the vacuum brake booster is working properly. You can finally verify this by turning off the engine and not releasing the brake pedal for 30 seconds.

- If the pedal starts to rise, this indicates a leak in the vacuum chamber.

Operating principle of a vacuum brake booster

Everyone probably knows that the brake system of a modern car is a hydraulic system.

Pressing the pedal creates pressure in the brake fluid, which presses on the pistons, and the pistons, in turn, press the brake pads against the surface of the brake discs. Accordingly, the main force and the force from which it all begins is the force of a person’s foot on the brake pedal. So, thanks to VUT, this effort can be increased several times. The vacuum brake booster consists of two chambers separated by a special membrane. The chamber located closer to the master cylinder is a vacuum chamber and is maintained at low pressure. The chamber facing the brake pedal is called atmospheric. This atmospheric chamber, with the help of a monitoring valve, can be connected either to the chamber where we create a vacuum, or to the immediate environment, that is, to an environment in which the air pressure is a certain and fairly significant value. The VUT also includes a follower valve pusher, which connects directly to the brake pedal, and another important component of the brake booster is the diaphragm return spring.

As for the diaphragm, which separates the two chambers, it is equipped with a special nickel in the center, which presses on the piston rod of the master cylinder. When you release the brake pedal, the return spring, true to its name, returns the membrane to its original position.

Now let's describe the operation of the vacuum brake booster, so to speak, in dynamics. The vacuum chamber is connected through a special hose to a device capable of creating a vacuum, or, more simply, a kind of vacuum. Such a device can be either the engine itself, if it is a gasoline engine, or a special vacuum pump. Such pumps are required to be installed in vehicles with diesel power plants. Although, recently VUTs have also begun to be equipped with pumps in gasoline-powered cars. This is necessary for consistently high efficiency of the amplifier at different engine operating modes.

When the car is moving and there is no need to brake, a rarefied area is maintained in both chambers. But, as soon as you press the brake pedal, the valve closes the connection between the chambers and opens access to the atmospheric chamber, atmospheric air at the appropriate pressure. It is this air, plus the force of the person pressing the pedal, that acts on the piston of the master brake cylinder, which ensures the injection of brake fluid into the system. Essentially, a vacuum booster allows us to use atmospheric pressure to increase braking force. As they say: everything ingenious is simple. As for amplifiers that are equipped with vacuum pumps, this solution, in addition to increasing the stability of the VUT, is almost always used for the operation of electronic assistants in driving a car. For example, it is these vacuum pumps that ensure the operation of the ESP system, which is responsible for the car’s stability on turns and corners.

Methods for diagnosing VUT

If one of the above symptoms is detected, you should immediately check the vacuum brake booster for functionality without removing it from the car. Diagnosis is simple:

- Start and warm up the engine.

- Leaving the engine idling, use your hand or pliers to press down the vacuum outlet pipe leading from the manifold. Another option is to disconnect it from the fitting and plug the latter with a wooden wedge.

- Constant behavior of the motor indicates the tightness of the system. The serviceability of the air valve is checked in another way, described below.

- If the speed of the power unit has stabilized or increased, air is leaking through the VUT or supply hose.

Having determined that the amplifier is faulty, exclude the vacuum transmission hose from the list of “suspects”. Disconnect the pipe and inspect for cracks and tears. Check the condition of the clamps, install new clamps if necessary.

If sealing the pipe does not produce results, proceed to checking the “vacuum tank” itself:

- Without starting the engine, sit in the driver's seat and apply the brake 3-5 times. The first presses will be light, but on the last ones the stroke will be greatly reduced. In this case, the diaphragm draws air through the hose and pumps it inside the housing; a check valve prevents it from coming out. Remember, the atmospheric channel is closed.

- Having completed the last movement, hold the pedal depressed and start the engine.

- After starting the engine, the pedal should go down about halfway.

This brake booster test identifies problems with the check valve or air valve.

If the first one is faulty, then it will not be possible to pump air into the housing - the pedal will sag all the way. A worn air valve will not open the air passage while the engine is running and the pedal lever will remain in the up position or drop very slowly. The tightness of the VUT housing is checked as follows:

- Start the power unit.

- Squeeze the brake all the way.

- Without releasing the pedal, turn off the engine.

If the amplifier housing or diaphragm does not allow air to pass through, the pedal lever will remain depressed. Otherwise, it will return to its original position under the action of the spring. Then you need to remove the mechanism and replace it with a new one. Repairing a VUT in a garage is a rather difficult task, since the body of the element is held together by factory rolling.

Design and operating algorithm

The first passenger cars produced in the last century were not equipped with “vacuum seals”. To sharply slow down the car in case of emergency braking, the pedal had to be pressed with a force of about 80 kg. The device of the vacuum brake booster installed on modern vehicles makes it possible to reduce the mentioned force to a light press.

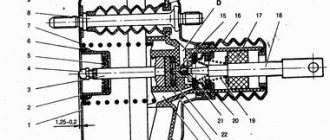

To diagnose malfunctions of this unit, you need to know its design and operating principle. The amplifier is a cylindrical metal housing, inside of which the following elements are located:

- a diaphragm pushed by a return spring;

- air valve with two channels - atmospheric and vacuum;

- in the center of the body there is a rod connected at one end to the brake pedal, the other to the main cylinder, and a diaphragm is attached to it;

- vacuum supply pipe from the engine intake manifold connected to the check valve.

We recommend: Selecting and changing the fog lamp bulbs yourself

In fact, the body of the “vacuum generator” is divided by a membrane into 2 separate chambers. The first is supplied with vacuum from the power unit, while in the second the air pressure is equal to atmospheric pressure. The chambers communicate with each other through the channels of the air valve, which alternately open when the driver presses and releases the pedal.

The classic vacuum brake booster works according to the following algorithm:

- Until the driver activates the brake system, both chambers communicate via a vacuum channel. Since the pressure in them is the same, the pusher and rod remain motionless.

- After pressing the pedal, the rod moves forward and the connection between the two chambers through the vacuum channel is interrupted. The valve opens another passage connecting the atmospheric chamber with outside air.

- Due to the pressure difference, the diaphragm bends towards the vacuum, thereby helping to put pressure on the pusher and the piston of the main hydraulic cylinder.

- When the driver takes his foot off the pedal, the valve produces the opposite effect - it closes the atmospheric channel and opens the vacuum channel. The pressure in the chambers is equalized, the spring pushes the membrane back to its original position.

Reference. In diesel and some gasoline cars, the vacuum is created not by the intake manifold, but by a separate vacuum pump in the brake system. Such a scheme operates reliably in high altitude conditions with low atmospheric pressure, where a conventional membrane amplifier loses its functionality.

If the brake pedal is held down by the driver, the diaphragm also stops and exerts a constant force on the rod. Thanks to the described operating principle of the VUT, the driver’s work is greatly facilitated, and the system responds to the pedal much faster.

How to check VUT

In reality, checking the correct operation of a vacuum device is quite simple , which even a beginner can handle. We will give three ways to check the vacuum seal for serviceability.

Option 1

- Start your car and let it idle for about 7 minutes.

- Stop the engine and fully depress the brake pedal to create a vacuum in the brake system.

- First release the pedal and then press it again.

If the vacuum brake device fails, then the second time you press the pedal, you will feel a significant reduction in its travel (compared to the first press). This occurs because airless space can no longer be created. But if when you press again you do not feel a difference, then this indicates that the brake system is working normally . Let's move on to the second verification option.

Option 2

- With the car engine turned off, press the “brake” 6-8 times.

- Depress the brake pedal to the maximum and start the engine.

If there are no problems in the vacuum brake device , airless space begins to create in the system. For this reason, the diaphragm begins to press on the rod, which will pull the pusher connected to the pedal. And the brake pedal (even when it is fully depressed) will go down a little.

If this does not happen after starting the power unit, it means that there is no vacuum in the brake system. And, this means that there are malfunctions that impede this process.

Option 3

This vacuum brake test helps determine if there are air leaks.

- Start the engine.

- Depress the brake pedal all the way and immediately turn off the engine.

The depressed pedal should remain in this position for approximately 30 seconds. This shows that there are no problems . But if it begins to move to its original position, it means that the pressure in the working chamber increases. This indicates problems with the mechanism.

Checking the vacuum booster

This is interesting: How to check the support bearing of a shock absorber strut

Checking the vacuum booster: all methods

There are several effective ways to check VUT. The procedures are simple, you can do it yourself, you don’t need to dismantle anything from the car.

First way

The simplest option:

A decrease or heavier pedal stroke when pressed again will indicate problems in the operation of the vacuum pump. On the contrary, if the second pressing occurs without any differences from the first, one can judge the serviceability of the VUT and successful discharge.

Second way

This time, during diagnostics, you should press the pedal several times - 6 or 8. For the last time, press it to the limit and start the engine. If everything is fine with the vacuum system, the pedal should drop even lower - almost halfway. If it does not move, there is a problem with the valve.

Third way

This checks the tightness of the housing. You need to start the engine, squeeze the brake all the way and turn off the engine. If the pedal begins to press on your foot, trying to return to its original position, this will indicate a malfunction. When there is an air leak in the amplifier, the pressure inside the chamber increases.

Fourth method

Here's what else you can do:

Damage to the vacuum seal requires urgent repair. If you need to dismantle the device, be careful not to damage the tube connecting the amplifier to the collector!

Source

Why does the VUT fail?

If the VUT breaks down, the brake system remains operational, but it is difficult to depress the pedal. There are two typical reasons for mechanism failure: loss of tightness of chambers/tubes and damage to the check valve.

A special hose connects the vacuum unit to the vehicle’s intake manifold, from which in most cases it receives a vacuum. Some amplifier models are equipped with an additional pump. But still, the VUT takes the main part of its energy from the collector. Therefore, if the tube breaks or its connections become loose, the mechanism stops working.

Checking the VUT check valve

The cause of poor performance of the vacuum brake booster may be a malfunction of the check valve to which the hose from the intake manifold is connected. To diagnose the latter, you need to remove the hose, remove the valve from the VUT body and put a rubber bulb from a syringe or hydrometer on it from the outside (to which the hose is connected) and squeeze it. If, after releasing the bulb, it remains compressed, the check valve is working properly.

Otherwise, it must be replaced. In a similar way, you can check the inlet hose for leaks in the absence of a compressor.

Diagnostics of the vacuum brake booster can be easily carried out in just a few minutes through simple manipulations without the use of any measuring instruments or tools. For a more objective check, try the various methods suggested in the article. Before doing this, do not forget to check the condition of the hose leading to the VUT from the intake manifold.

What are the signs to identify a faulty VUT?

During the operation of a vehicle in which a vacuum brake booster is installed, one should not ignore the tightness of the structure of the booster itself and the hoses leading to it. Here are some signs of a malfunction that will help the driver always keep the situation under control:

- the driver has a need to apply more effort when braking in order to achieve the same efficiency;

- reducing the brake pedal travel;

- the car continues to brake even after the brake pedal is returned to its original position;

- there is a “suction” in the vacuum hose, and therefore there is unevenness in the speed of the power unit;

- when braking, extraneous sounds like hissing are heard;

- VUT completely “refuses” to work;

- fuel consumption increases when operating the vehicle in normal mode;

- the car suddenly begins to “tweak”;

- Candles don't work.

VUT

Sometimes a brake booster malfunction may manifest itself in a slightly different way, but if you feel one of the mentioned symptoms, then this becomes a reason to check the brake system.

Vacuum brake booster device

Structurally, the vacuum amplifier is a sealed round-shaped housing. It is installed in front of the brake pedal in the engine compartment. The main brake cylinder is located on its body. There is another type of device - a hydraulic vacuum brake booster, which is included in the hydraulic part of the drive.

Brake booster circuit diagram

The vacuum brake booster consists of the following elements:

- frame;

- aperture (for two cameras);

- follow-up valve;

- brake pedal pusher;

- brake hydraulic cylinder piston rod;

- return spring.

The body of the device is divided by a diaphragm into two chambers: vacuum and atmospheric. The first is located on the side of the main brake cylinder, the second on the brake pedal side. Through the check valve of the amplifier, the vacuum chamber is connected to a source of vacuum (vacuum), which on cars with a gasoline engine is used by the intake manifold before supplying fuel to the cylinders.

Vacuum pump

In a diesel engine, the source of vacuum is an electric vacuum pump. Here the vacuum in the intake manifold is insignificant, so the pump is a mandatory element. The check valve of the vacuum brake booster disconnects it from the source of vacuum when the engine is stopped, as well as in cases in which the electric vacuum pump fails.

The diaphragm is connected to the piston rod of the main brake cylinder from the vacuum chamber side. Its movement ensures the movement of the piston and the injection of brake fluid to the wheel cylinders.

The atmospheric chamber in the initial position is connected to the vacuum chamber, and when the brake pedal is pressed, it is connected to the atmosphere. Communication with the atmosphere is provided by a follower valve, the movement of which occurs using a pusher.

In order to increase the braking efficiency in an emergency, the vacuum brake design can include an emergency braking system in the form of an additional electromagnetic rod drive.

What to do with a faulty device?

As usual, there are two options: repair and replacement . Their choice depends on the degree of damage to the VUT. To eliminate them, you need to know the amplifier well and have a repair kit suitable for the specific model of the device in your garage.

If the vacuum booster fails, you will have to spend more effort to brake, and the response of the braking system will be very slow. In some situations, this can lead to an accident, so if signs of failure of the VUT are observed, it should be replaced. Note that at home there is no point in trying to get the amplifier into working condition without a special set of spare parts and tools.

Engine misfire (misfire) when pressing the brake pedal

An air leak through the brake booster can cause misfires while the engine is running. Damage to the diaphragm or internal valve leads to the fact that the optimal ratio of air and fuel is disrupted. Misfire usually occurs when you press the brake pedal while idling.

If checking the vacuum hose, connections and check valve does not reveal anything, you need to perform the following check:

- start the engine at idle speed;

- tighten the handbrake;

- ask another person to press the brake pedal;

- pinch the vacuum hose using pliers (do not forget to place a rag so as not to damage the hose);

- If the engine does not stall and its operation stabilizes, the vacuum brake booster is the culprit for misfires.

Checking engine vacuum using a vacuum gauge

Sometimes the VUT copes well with its tasks, but the motorist still has certain doubts that it is fully operational. If the amplifier on your car did not pass or barely passed the previous tests, you need to make sure that there is enough vacuum. Such diagnostics are performed using a vacuum gauge.

- Disconnect the vacuum hose from the brake booster and connect it through a tee so that you can use a vacuum gauge.

- Start the power unit.

- The sensor should display approximately 400-540 mmHg. Art. If you see a lower value, there is a vacuum leak through the intake manifold (gaskets or crack), hose, engine (cylinder head gasket, etc.) or other components.

Operating principle of a vacuum brake booster

The vacuum brake booster operates due to different pressures in the chambers. In this case, in the initial position, the pressure in both chambers will be the same and equal to the pressure created by the vacuum source.

When you press the brake pedal, the pusher transmits force to the follower valve, which closes the channel connecting both chambers. Further movement of the valve facilitates the connection of the atmospheric chamber through a connecting channel with the atmosphere. As a result, the vacuum in the chamber decreases. The pressure difference in the chambers moves the piston rod of the master cylinder. When the braking ends, the chambers are reconnected and the pressure in them is equalized. The diaphragm, under the action of the return spring, takes its original position. The vacuum cleaner works proportionally to the force of pressing the brake pedal, i.e. The harder the driver presses the brake pedal, the more efficiently the device will work.