Geometric compression ratio (BL) is the ratio of the total volume of space above the piston when it is at BDC (bottom dead center) to the volume of the combustion chamber. The total volume of the combustion chamber (CC) consists of: the volume of the CV in the cylinder head, the volume of the CV in the piston, the volume of the cylinder hole in the cylinder head gasket (in its compressed state), the volume formed due to the piston not reaching the plane of the cylinder block at TDC . If the piston has a displacer, its volume is included in the calculations with a minus sign (similarly, if the piston exits the block at TDC, which is acceptable in some cases).

Don't confuse compression ratio with compression.

Do not confuse geometric compression ratio with dynamic compression ratio.

Introduction

As always, to consider any issue, let us recall the information we already know on the topic of compression ratio. The majority of people, of course, will say that the compression ratio is a dimensionless quantity that reflects the ratio of the volume of the cylinder to the volume of the combustion chamber. It is also known that for a modern naturally aspirated gasoline engine it is approximately 9-11, for turbocharged engines 7-8. But what is its physical meaning? What effect does it have on the processes occurring in the engine? Let’s consider this issue in more detail.

Theoretical explanation

So, let's consider what the compression ratio is from a physical point of view, in its classical sense. As we already know, this is the ratio of the volume of the cylinder to the volume of the combustion chamber, i.e. in other words, we mean by this that the volume of air entering the cylinder during the intake stroke is equal to the volume of the cylinder... But is this really so? We know, for example, that for engines with 2 valves per cylinder, the effective filling (volumetric efficiency) is 75-80% for civil engines, for 16 valve engines this figure is slightly higher - 80-85%. Thus, it turns out that, in the best case, about 85% of the cylinder volume will get into the engine. And also, looking ahead a little, it should be noted that this will happen in maximum filling mode. As we can see, the actual compression ratio will differ. Also, we must understand that the compression ratio will be equal to the calculated one if the decrease in volume (compression) of the fuel assembly occurs in a closed space from Volume V1 to V2. Roughly speaking, compression will begin when the piston is at BDC and will end when the piston reaches TDC. But again, in fact, this does not happen in a real engine, because the intake valve closes with a certain delay after BDC, and in fact, the compression of the fuel assembly itself begins with a delay relative to BDC. What do we see? It turns out that the volume of air in a real engine involved in compression and the physical volume is much smaller, and accordingly, the compression ratio we calculated earlier is incorrect, or, let’s say, not very informative. Indeed, in addition to the physical volume of the cylinder, different engine designs have completely different and other geometric parameters, ranging from cylinder diameter, piston stroke and ending with different camshafts, as well as different variable valve timing systems. Thus, it is advisable to introduce a certain value that will allow us to take into account all the parameters that affect the actual compression ratio - let's call this value Dynamic Compression Ratio (DCR).

Concept of DCR

Dynamic compression ratio (DCR) is a value that allows us to take into account various aspects of the internal combustion engine design that during operation influence the final pressure at the end of the compression stroke; it is the final pressure that will be the beneficiary of our calculation. Also, we need to systematize the data obtained according to the correspondence of the DCR value - the specific octane number of the fuel.

Design overview

For a better understanding of the physical meaning of DCR, consider the designs of some engine models, using an example, let’s see what DCR values they have, as well as what causes this. For simplicity, let’s compare the well-known engines of the VAZ family and trace their evolution in terms of the parameter we introduced. So, the first engine that we will consider is the VAZ 2106, the main parameters, such as cylinder diameter, piston stroke and others can be easily found on the Internet, I have already made all the necessary calculations, and for simplicity, I will indicate already abbreviated data. This engine has a geometric compression ratio of 8.5 and a valve closing angle of 55°, based on all the data, the DCR value for this engine will be 7.5. Let's compare with the value from the table, we find that for this type of engine it is permissible to use 92 gasoline, and with a small margin. In principle, for the time when this engine was developed, the octane rating of the fuel was 91, and the engine control systems did not allow for precise tuning, so a certain reserve was of course necessary. Now consider another engine from this family - VAZ 21213. This engine has a larger volume compared to the 2106 engine, and it was also installed on a car that had increased requirements for cross-country ability; accordingly, the engine had to operate uninterruptedly under prolonged loads, without having detonation. Since the cylinder volume has increased, but the cylinder head design has remained virtually unchanged, this inevitably led to the fact that this engine has a geometric compression ratio of 9.3. It turns out that the compression ratio increased by almost one compared to the previous engine, but the fuel used remained at the same level, and the loads at low speeds did not decrease, but even increased, so what’s the matter? Logically, it would be necessary to use fuel with a higher octane number and have more precise settings for the ignition and fuel supply systems. Of course, another option would be to change the design of the cylinder head (increase the combustion chamber), but this is not cost-effective; on a mass production scale, it would be necessary to manufacture individual components of an almost identical engine. Therefore, the designers took a different path, namely, they changed the parameters of the camshaft, and even only that part that touches the intake cam - they made the closing angle of the VC equal to 73°, as opposed to 55° on 2106, which is 18° later. Thus, the DCR value was 7.45 - which is normal for the use of 92 gasoline. Using the example of these motors, we were clearly convinced that the value of the geometric compression ratio in fact does not give us practically any information about the processes that actually occur in the engine. It is also interesting to trace the development of engines of the family of front-wheel drive VAZ cars. For example, due to, again, not enough modern control systems, the 21083 engine, having what seemed for that time a fairly high geometric compression ratio - 9.8, has a DCR of 7.4 - which also fits into the concept of using 92 gasoline. Subsequently, an electronic engine control system began to be installed on the 2110 engine, which led to a number of changes in the design of the engine itself - a camshaft with an earlier VC closing of 51.5° versus 80° than on the previous model began to be used, which in turn, with a geometric degree compression, also equal to 9.8, made it possible to raise the DCR to a value of 8.8 - which also made it possible to use 92 gasoline, but at the same time the combustion processes occurred more efficiently. And, in the end, the Lada Granta car is equipped with a 21116 engine with a geometric compression ratio of 10.5, and a DCR value of 9.4, which was made possible thanks to the use of an electronic throttle valve and the use of gasoline with an octane rating of at least 95.

Compression: what is it?

Compression is the pressure of gases in the engine cylinders at the end of the compression stroke during rotation of the shaft by the starter with the ignition off. It is while the starter is rotating that the compression needs to be measured, since the pressure changes while the engine is running. This parameter is a physical quantity, and a special device is used to measure it - a compression meter.

In theory, compression and compression ratio are equal, but in practice the situation is different: compression ratio is almost always less than compression.

There are reasons for this. These values will be equal to each other if the gas in the cylinders is compressed indefinitely, isometrically. In this case, the energy released during gas compression would be completely absorbed by the piston, cylinder walls, block head and other parts of the engine, so the thermal balance would not change. The gas, which is compressed, gives off heat and does not press on the pressure gauge with greater force than the calculated one.

In practice, everything is completely different. In real life, the process of gas compression occurs against the background of rising temperature, that is, the process is adiabatic. In simple terms, all the heat released by the compressed gas simply does not have time to be absorbed by the cylinder walls, and due to the remainder, increased pressure is created in the cylinder.

Older engines will have lower compression than new ones. This occurs due to tightness: the new engine is more sealed than the old one, so the ring locks and other places in the cylinders will not allow a sufficiently large amount of heat to pass through for the compression to drop significantly.

If the engine is running properly, the compression is often 1.2 - 1.3 times greater than the calculated compression ratio. In theory, gas pressure changes in inverse proportion to the change in gas volume to the power of 1.4.

But such a calculation is valid only when there are no air leaks and heat is not transferred by the surrounding walls. Due to the fact that all this exists in real life, a similar ratio is fair (1.2 – 1.3 times). There is an empirical formula that relates compression ratio and compression: E = (P+3.9)/1.55, where P is the measured pressure and E is the compression ratio.

Compression is measured in order to assess the condition of the engine and the degree of wear of the cylinder-piston group. The lower the compression level, the more worn out the valves and cylinder-piston group are. If the indicators are too low (less than 10 atm. in the case of a non-turbocharged engine that runs on gasoline), then we can say that the engine is in poor condition. Also, the difference in compression levels in different cylinders by more than 1 atm may also indicate engine wear.

The worst option is the presence of both the first and second “bells”. In this case, you need to contact specialists to carry out a major overhaul of the “filling” of the car.

You can measure compression in this way: you need to warm up the engine, then unscrew the spark plugs, press the gas pedal, which will cause the starter to crank the engine until the pressure becomes stable.

It is necessary to warm up the engine so that the crankshaft rotates at a sufficient frequency and the battery is discharged. The higher the crankshaft rotation speed, the shorter the contact time of the compressed gases and the cylinder walls will be, that is, the compression will be higher. That is why both the starter and the battery must be in good working order. Using compression, you can also determine the place where the engine is most worn out. This is possible due to the fact that the gas pressure drops due to leaks in valves and rings. To specify the location of the gas leak (“valves or rings are to blame”), you need to pour 10–30 g of engine oil into the cylinder, after which you need to measure the compression again. Due to its viscous structure, the oil seals the ring locks and the gap between the cylinder wall and the piston for a certain time, that is, the places where the largest amount of gas “escapes”.

If the compression gauge readings do not change, then the valves are faulty, and if they increase, then the cause is worn out rings.

Many novice motorists who recently purchased their vehicle are trying to understand the features of its design. In particular, it's helpful to understand what's under the hood. And the engine is of particular interest in this regard. This is an extremely complex mechanism consisting of various parts. Therefore, it is worth understanding this matter, at least in order to independently eliminate a number of malfunctions. At the same time, inexperienced car enthusiasts are not able to fully understand the difference between compression and compression ratio. But there is a difference, because each of these terms corresponds to its purpose.

WHAT IS ENGINE COMPRESSION RATIO AND COMPRESSION?

Good afternoon, today we will learn what automotive indicators of an internal combustion engine are, such as the compression ratio and compression of the power plant, and how they differ from each other. In addition, we will define the concepts of compression and compression ratio, talk about the main features of these engine indicators, and also establish why the values of these parameters are so important for a particular vehicle engine. In conclusion, we will talk about how the final compression values of the power plant influence the identification of possible engine malfunctions, and also why the compression ratio directly affects the power parameter of the car’s engine.

In order to understand why the compression indicators and compression ratio of an internal combustion engine are needed, as well as how they differ from each other, it is necessary to know their definitions, to understand the importance of each parameter that directly or indirectly affects the durability of the vehicle’s power plant. We will discuss these issues in our story in order to get a comprehensive understanding of the compression ratio and compression ratio of the engine, and also why there is no need to confuse these somewhat similar indicators for measuring engine performance. In addition, let's consider a frequently asked question by many car enthusiasts: “How do the parameters of the compression ratio and engine compression differ from each other, and also which indicator is most important?”

1

.

Compression ratio.

Concept and features of an automobile indicator The compression ratio of a power plant is the ratio of the volume of the working area of the cylinder to the volume of the combustion chamber of the fuel-air mixture. On a gasoline engine, depending on the specific task, the compression ratio can be in a different range of values from 7 to 11 points. As for diesel power plants, due to certain design features of the device, their compression ratio significantly exceeds gasoline ones and averages from 13 to 19 points.

Today, the engine compression ratio or indicator is indicated on almost all modern vehicles. Based on this parameter, the manufacturer in the documentation and also, as a rule, on the gas tank flap of a particular vehicle indicates the fuel recommended for refueling; for example, if the vehicle is equipped with a gasoline engine, there will be an indication of the brand of gasoline AI-92 or AI-95.

In order to imagine in more detail how and where the compression ratio is created in a car engine, you first need to imagine the cylinder block and the pistons that move in it. The fact is that each piston has, so to speak, its own “dead spots” in the cylinder block. This point is called the upper plane of the block, when the fuel is compressed to the limit and is waiting for the moment to ignite. The lowest point is the plane where the piston goes down, and the space is filled with a new portion of the fuel mixture or, conversely, is already filled with gases that have expanded from ignition.

In the case when the piston is located in the upper part of the block, that is, at the “top dead center,” then a certain volume remains above it, in which the fuel-air mixture is compressed under a certain pressure. This space or area is called the combustion chamber of the mixture. When the piston descends to the lower region of the cylinder block, so to speak, to the “bottom dead center,” then the volume located above the piston is added to the space of the combustion chamber. Therefore, it is quite simple, knowing the above-described theoretical principles of the operation of the piston in the cylinder block, to determine how much the fuel-air mixture of our engine can be compressed when the engine unit moves from the bottom “dead center” to the top. For reference, we note that when measuring this indicator, variable values are displayed as volumetric values divided by each other, that is, V2 (volume) / V1 (volume).

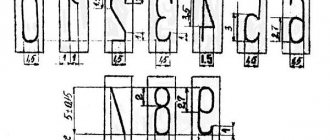

Thus, using the usual division of volume V2 (volume above the piston) by V1 (volume under the piston), we get an indicator that will tell us how many times the fuel-air mixture is compressed when the piston moves from the bottom dead center of the cylinder block to the top. In the image below we tried to clearly demonstrate our calculations of the compression ratio ( Click on the image to enlarge

).

As a rule, car manufacturers indicate these characteristics in the documentation for the vehicle. Therefore, you often do not need to calculate this parameter yourself; to find it, you just need to open the instructions for your car.

In most cases, the compression ratio is indicated in the range from 9 to 14 points. This indicator will tell us that the fuel-air mixture, which entered the combustion chamber when the piston moves in the cylinder block from the “top dead center” to the bottom point, on the intake stroke, will be compressed 9, 10, ... or 14 times, from initial state (volume), and after that it will be ignited by the spark plug.

2

.

Engine compression.

Concept and features of the indicator Compression is the maximum air pressure in the combustion chamber at the very end of the compression stroke of the fuel-air mixture. In other words, compression is a certain level of pressure in the cylinder area, which in one way or another depends on the degree of compression of the mixture in it. For reference, we note that the pressure indicator in a small volume will always be higher, since as the compression ratio increases, the compression level increases. The compression level indirectly or preliminary indicates the condition of the vehicle's power plant. Therefore, it is so important to correctly perform the compression measurement

in the motor.

Note that the higher the compression indicator on the scale of a special pressure gauge during measurement, the more power the car’s power plant can develop. Quite often, car owners wonder why this happens? Everything is quite simple and lies on the surface. The fact is that increasing the compression level contributes to optimal compression of the fuel in the cylinder chambers, since its ignition can occur much more efficiently than with a low level. In addition, high compression provides a large boost to the piston. Thus, there is a direct relationship between the crankshaft speed and the power of the power plant.

But it is worth noting that under no circumstances should you constantly increase the compression, since the fuel-air mixture, usually gasoline, can overheat and spontaneously ignite, which will result in detonation. And this can already lead to disastrous and destructive consequences for internal components, as well as engine parts. As they say, this process will certainly not extend the life of the power plant. That is why today on the new car market you can increasingly find cars equipped with special engines, and at gas stations you can now often see high-octane brands of gasoline that form high compression.

As a rule, most car manufacturers indicate an average compression rating. For example, if, when measured, our compression indicator differs even by a couple of points from the factory one, then it’s worth thinking about, since in almost 90 percent of cases this may mean that there are serious problems with our engine. In this case, it is necessary to begin diagnosing malfunctions of power plant parts from valves, valve stem seals and ending with compression rings, which are located on the pistons, and so on along the chain.

3

.

Distinctive features of the compression ratio from engine compression

In order to understand what is the difference between the compression ratio and engine compression, let's remember a little about the tasks we described earlier, which are performed by one and the second indicator. And so, the degree of compression is, first of all, a coefficient that is calculated using volumes, and compression, on the contrary, is measured with a special device called a compression manometer.

If we consider the differences in indicators from a practical point of view, then the engine compression will be slightly greater than the compression ratio. For example, with a compression ratio of 9 points, the compression will be in the range from 10.5 to 11.5 points.

Many may now ask the question: “Why are the final indicators of these indicators so different?” The fact is that when measuring the compression of a power plant, the pressure can heat up the fuel-air mixture and, consequently, its temperature increases. In principle, to some extent, the indicators of the degree of compression and compression could be equated if the process took place in an isothermal and hermetically sealed housing, which would exclude any influence of temperature, both outside and inside. However, due to the fact that in reality it is not possible to ensure complete tightness of the units, the final values will always differ.

In conclusion, we note that for gasoline power plants, the higher the compression ratio, the higher the specific power of the engine. However, if you increase the compression ratio of the engine excessively, this can significantly reduce the service life of its components and at the same time the risk of unscheduled engine overhauls when refueling with “diluted” fuel increases. When engine compression decreases, the most important thing is to immediately determine the cause of this decrease. Often the cause of low compression is problems with the piston rings or valve mechanism. To be sure to determine the malfunction, vehicle maintenance and repair specialists use a regular syringe to inject approximately 20 grams of motor oil into the “suspicious” cylinders. Then the procedure is repeated. If after these manipulations the compression gauge readings increase, then the cause of the drop is the piston rings, and if they remain in the same places, then the problem is in the valves.

Source

Why is it necessary to change the compression ratio?

You can calculate the compression ratio of an internal combustion engine if you perform the calculation using the formula ξ = (Vр Vс)/ Vс; where Vр is the working volume of the cylinder, Vс is the volume of the combustion chamber. From the formula it is clear that the compression ratio can be increased by reducing the volume of the combustion chamber. Or by increasing the working volume of the cylinder without changing the combustion chamber.

The working volume of a cylinder can be calculated by knowing the cylinder diameter - D and the piston stroke - S. The formula for calculating it looks like this: Vр = (π*D2/4)* S.

The higher the compression ratio, the greater the compression of the internal combustion engine and its power (all other things being equal). By increasing the compression ratio, we also help increase engine efficiency by reducing specific fuel consumption. The compression ratio of the internal combustion engine determines the octane number of gasoline used to operate the engine. Thus, low-octane fuel will cause engine detonation with a high value of this coefficient. An excessively high octane number of fuel will not allow a power unit, the compression of which is low, to develop full power.

Initial data

Octane number of fuel used for gasoline engines with various compression ratios.

- 7.0–7.5 octane number 72–76.

- 7.5–8.5 octane number 76–85.

- 5.5–7 octane number 66–72.

- 10:1 octane number 92.

- From 10.5 to 12.5 octane number is 95.

- From 12 to 14.5 octane number is 98.

Aligning the interface between the head and the block by cutting off the metal layer leads to a reduction in the combustion chamber of the motor. This causes the compression ratio to increase by an average of 0.1 when the head thickness decreases by 0.25 mm. Having this data at your disposal, you can determine whether it will exceed the permissible limits after repairing the cylinder head. And shouldn't measures be taken to reduce it? Experience shows that when a layer of less than 0.3 mm is removed, the consequences may not be compensated.

The need to change this parameter of the internal combustion engine occurs quite rarely. We can list just a few reasons to do this.

- Boosting the engine.

- The desire to adapt the engine to run on gasoline with a different octane number. There was a time when gas equipment for cars was not available for sale. There was no gas at gas stations either. Therefore, Soviet car owners often modified engines to run on cheaper low-octane gasoline.

- Unsuccessful engine repair, to eliminate the consequences of which requires adjustment of the compression ratio. For example, milling a block head after too much thermal deformation. When it is possible to level the surface mating to the cylinder block at the cost of removing an excessively thick layer of metal. This increases the value of the coefficient so much that operation on gasoline, for which the engine was designed, becomes impossible.

Magnification methods:

- Boring of cylinders and installation of larger pistons.

- Reducing the volume of combustion chambers. It is carried out by removing the metal layer from the side of the plane where the head meets the block. Due to the softness of aluminum, this operation is best done on a milling or planing machine. A grinding machine should not be used, as its stone will constantly become clogged with ductile metal.

Ways to reduce:

- Removing a layer of metal from the piston bottom (this is usually done on a lathe).

- Installation of a duralumin spacer between the head and the cylinder block between two gaskets.

Air is pumped into the cylinders of a turbocharged engine by a compressor at a pressure slightly greater than atmospheric pressure. This means that to determine the compression ratio of such a motor, you need to multiply the value that you get as a result of the calculation using the formula by the turbocharger coefficient. Turbocharged gasoline engines operate on fuel with an octane rating higher than gasoline, which is consumed by the same engines without turbines, precisely because their ξ coefficient is higher.

How to increase engine compression ratio

If you need to increase this indicator, use several methods:

- boring the block and installing pistons with a large diameter;

- reducing the volume of the combustion chamber by removing the metal layer at the cylinder head connection.

We must not forget that in some cases the installation of upgraded pistons will be required. This is done to eliminate such an undesirable consequence as the pistons meeting the valves. In particular, the valve recesses on the elements are increased. Also, the valve timing must be adjusted again.

Interestingly, Japanese manufacturers have revealed the potential of internal combustion engine compression ratios best of all. While European auto companies went the route of improving hybrid engines, the Japanese managed to increase the SSD to 14 units on gasoline power units, using a variable value. But how is this possible without detonation moments? Everything turned out to be simple. It turns out that you need to cool the chamber where the fire occurs. Then you can safely compress the mixture. And it is not at all necessary to use cool air for this: it is enough to modernize the exhaust system.

Types of pistons

Most manufacturers use cast pistons. They are made of aluminum alloy containing silicon (from 9% to 18%), so they are quite heavy. There are also cast pistons with recesses.

During the manufacturing process of forged pistons, a heated aluminum alloy with a low silicon content is pressed into a mold. Such parts are not cheap, and they are mainly intended for very powerful machines. By design, pistons are divided into domed, recessed and flat bottom. The level of compression and combustion rate of the mixture in the cylinders depend on the configuration of this element. By installing a recessed piston, additional space is created for valve clearance.

Pistons are also available in high-compression and low-compression types. The former increase compression, the latter, respectively, reduce it.

Increasing the torque on the crankshaft will increase the torque. The torque depends on the engine volume and the pressure in the cylinder. The crankshaft rotation speed actually has no effect on this value. Therefore, we must maximize the volume and pressure in the cylinder. This is done by increasing the compression ratio. But the capabilities of this option are limited by detonation.

There is another method: we drive more air-fuel mixture into the unit, and when it burns in the cylinder, more heat will be released. This will increase the pressure. But this method can only be used in naturally aspirated engines.

Why do you need to check engine size?

Most often, they find out the engine size when they want to increase the compression ratio, that is, if they want to bore the cylinders for tuning purposes. Because the higher the compression ratio, the greater the pressure on the piston during combustion of the mixture, and therefore the engine will be more powerful. The technology of increasing the volume in order to increase the compression ratio is very beneficial - after all, the portion of the fuel mixture is the same, but there is more useful work. But everything has its limit and its excessive increase threatens self-ignition, as a result of which detonation occurs, which not only reduces power, but also threatens to destroy the engine.

Subscribe

to our channel in

Index.Zen

Even more useful tips in a convenient format

What should be the maximum compression taking into account the octane number of the fuel?

The fact that compression is measured using instruments does not mean that there are no standards in this regard. Each engine manufacturer calculates them for a certain amount of compression to which the fuel mixture must be subjected during operation of the internal combustion engine.

Usually the formula is used for calculations:

K = SS x X

Where K is compression, CC is the size of the compression ratio, and X is a specific coefficient depending on the design of the internal combustion engine. For example, for gasoline engines with spark ignition it is usually 1.2 - 1.3. But at the same time, you also need to take into account the features of a particular model.

Accordingly, normally for modern gasoline internal combustion engines, compression should be somewhere from 10.5 to 16 kg/sq.m. cm. In this case, the rule applies: the higher the compression ratio (and, accordingly, compression) - the higher the octane number of the fuel should be. Old ICE models, where the CV is only 7–8 units, can run on A-76, but new engines are mainly designed for “ninety-five” or even “ninety-eighth” gasoline.

This rule does not apply to diesel engines. The fact is that their operating principle is different: not ignition of the mixture from a spark, but spontaneous combustion in air pre-compressed in the cylinder. Therefore, other coefficients apply there, and normally for a diesel engine, CC should be from 20 to 32 kg/sq.m. cm. In the same case, if the engine is designed for operation in extreme cold, the value of this parameter can reach 40 kg/sq. cm.

Compression ratio in a turbo engine

One of the most important and perhaps the most difficult tasks when designing a turbo engine is deciding on the compression ratio. This parameter affects a large number of factors in the overall characteristics of the car. Power, efficiency, throttle response, knock resistance (a parameter on which the operational reliability of the engine as a whole greatly depends), all these factors are largely determined by the compression ratio. This also affects fuel consumption and exhaust gas composition. In theory, calculating the compression ratio for a turbo engine is not difficult.

First, let's look at the concept of “Compression” or “Geometric compression ratio”. It is the ratio of the total cylinder volume (displacement volume plus the compression space remaining above the piston at top dead center (TDC)) to the net compression space. The formula is as follows: Ɛ=(VP+VB)/VB

Where Ɛ is the compression ratio VP is the working volume VB is the volume of the combustion chamber

We must not forget about the significant discrepancies between the geometric and actual compression ratios, even on naturally aspirated engines. In turbo engines, the mixture pre-compressed by the compressor is added to the same processes. How much the compression ratio will actually increase from this can be seen from the following formula: Ɛeff=Egeom*k√(PL/PO) Where Ɛeff is the effective compression Ɛgeom is the geometric compression ratio Ɛ=(VP+VB)/VB, PL is the boost pressure ( absolute value), PO - ambient pressure, k - adiabatic exponent (numerical value 1.4)

This simplified formula will be valid provided that the temperature at the end of the compression process for supercharged and naturally aspirated engines reaches the same value. In other words, the higher the boost pressure, the lower the possible geometric compression. So, according to our formula for a naturally aspirated engine with a compression ratio of 10:1 at a boost pressure of 0.3 bar, the compression ratio should be reduced to 8.3:1, at a pressure of 0.8 bar to 6.6:1. But, thank God, this is a theory. All modern turbocharged engines do not operate at such extremely low values. The correct compression ratio for operation is determined by complex thermodynamic calculations and extensive testing. All this is from the field of high technology and complex calculations, but many tuning engines are assembled on the basis of some experience, both our own and those taken as an example from well-known automobile manufacturers. These rules will be valid in most cases.

There are several important factors that influence the calculation of the compression ratio and must be taken into account during design. I will list the most important

Of course, this is the desired boost, the octane number of the fuel, the shape of the combustion chamber, the efficiency of the intercooler, and, of course, the measures that you are able to take to reduce the temperature stress in the combustion chamber. The ignition timing angle (IAF) can also partially compensate for the increased loads. But these are topics for another conversation, and we will certainly touch on them later in future articles.

Source

Checkpoint calculation

The gearbox calculator allows you to calculate the dependence of the vehicle speed on the engine operating speed in each gear, taking into account a number of parameters: gear ratio of the gearbox row, the main pair (gearbox), wheel size. The calculation is carried out for two different gearbox configurations to conduct a comparative analysis.

This allows you to choose the right tuning range and GP for the gearbox. The results of the PPC calculation are displayed in tabular and graphical form.

The graphs allow you to perform a visual analysis, evaluate the “length” of each gear, and the “gap” between them (by how much the engine speed drops when switching to a higher gear). Fill in the columns of the wheel parameters: width and height of the tire profile (look for the marking on the sidewall of the tire) and diameter wheel disk.

Please note: the R marking on a tire means its design is radial, for example, R14 is a radial tire with a diameter of 14 inches. Enter the gear ratio of the main pair and each gear in the appropriate columns of the gearbox calculator (the fractional separator is a dot). If there is no sixth gear, enter zero. Press the “Calculate gearbox” button

Gearbox rows of front-wheel drive VAZ (design 2108) gearbox row 1st gear 2nd gear 3rd gear 4th gear 5th gear 6th gear standard 3.636 1.950 1.357 0.941 0.784 – 5th row 2.923 1.810 1.276 0.969 0.784 6th row 2.92 3 1.810 1.276 1.063 0.941 Row 7 2.923 2.050 1.555 1.310 1.129 8 row 3.415 2.105 1.357 0.969 0.784 11 row 3.636 2.222 1.538 1.167 0.880 12 row 3.170 1.950 1.357 1.031 0.784 15 row 3.170 1.810 1.276 0.941 0.730 18 row 3.170 2.105 1.480 1.129 0.880 20 row 3.170 1.950 1.276 0.941 0.730 102 row 3.170 1.950 1.357 0.941 0.730 103 row 2.923 1.950 1.357 0.941 0.692 104 row 2.923 1.950 1.357 1.031 0.692 111 row 3.170 2.222 1.538 1.167 0.880 200 row 2.923 2.222 1.76 1.39 1.167 Wheel parameters width: profile: rim diameter: speed / rpm gearbox configuration #1 gearbox configuration # 2 Main pair main pair I III III IV VI III III IV VI 0 0 0 0 0 0 0 0 0 0 0 500 4 7.4 10.7 15.4 18.4 0 4.1 6.6 9.5 12.6 16.5 0 1000 8 14.8 21.3 30.7 36.9 0 8.2 13.3 19.1 25.1 33 0 1500 11.9 22.2 32 46.1 55.3 0 12.3 19.9 28.6 37.7 49.6 0 2000 15.9 29.7 42.6 61.5 73.8 0 16.3 26.6 38.2 50.2 66.1 0 2500 19.9 37.1 53.3 76.8 92.2 0 20.4 33.2 47.7 62.8 82.6 0 3000 23.9 44.5 63.9 92.2 110.6 0 24.5 39.9 57.3 75.4 99.1 0 3500 27.8 51.9 74.6 107.5 129.1 0 28.6 46.5 66.8 87.9 115.6 0 4000 31.8 59.3 85.2 122.9 147.5 0 32.7 53.1 76.4 100.5 132.2 0 4500 35.8 66.7 95.9 138.3 166 0 36.8 59.8 85.9 113.1 148.7 0 5000 39.8 74.1 106.5 153.6 184.4 0 40.9 66.4 95.4 125.6 165.2 0 5500 43.7 81.6 117.2 169 202.8 0 44.9 73.1 105 138.2 181.7 0 6000 47.7 89 127.8 184.4 221.3 0 49 79.7 114.5 150.7 198.2 0 6500 51.7 96.4 138.5 199.7 239.7 0 53.1 86.3 124.1 163.3 214.8 0 7000 55.7 103.8 149.2 215.1 258.2 0 57.2 93 133.6 175.9 231.3 0 7500 59.6 111.2 159.8 230.5 276.6 0 61.3 99.6 143.2 188.4 247.8 0 8000 63.6 118.6 170.5 245.8 295 0 65.4 106.3 152.7 201 264.3 0 8500 67.6 126 181.1 261.2 313.5 0 69.5 112.9 162.3 213.6 280 .8 0 13.5 7.2 5 3.5 2.9 0 13.1 8.1 5.6 4.3 3.2 0

Calculation of compression ratio (compressor)

Registration 11/27/2010 Messages 3,655 Likes 5 I got 8.71(0.000785*d^2*h) this volume +KS(27+46+gasket=4) (594+77)\77 Registration 11/29/2011 Messages 2,679 Likes 1 Address When the piston is at the bottom, its volume is 400cc or more.

+/- 20cc will not make any difference. Before you write, take it and count it and you will see that the life cycle changes noticeably. PS: I found a good calculator PS: the puddle in the piston is taken into account when it is at BDC Registration 01/20/2012 Messages 147 Likes 0 The address is not much off topic, but maybe someone can tell me. Prioro motor SZh = 11, how to change the SZh if instead of the cylinder head 21126 you put a head from Viburnum 1.4 16V (they are the same in everything, except for the volume of the combustion chamber in the cylinder head).

Why won't anyone tell me? Registration 29.

Some interesting facts

Methanol race car engines have a compression ratio of over 15:1. By comparison, a standard carbureted engine consuming unleaded gasoline has a maximum compression of 1.1:1.

Of the production models of gasoline engines with 14:1 compression, there are models on the market from Mazda (Skyactiv-G series), installed, for example, on the CX-5. But their actual coolant is within 12, since these engines use the so-called “Atkinson cycle”, when the mixture is compressed 12 times after the valves are closed late. The efficiency of such engines is measured not by compression, but by expansion ratio.

In the middle of the 20th century, in the global engine industry, especially in the USA, there was a tendency to increase the compression ratio. Thus, by the 70s, the bulk of American automobile industry samples had a coolant ratio from 11 to 13:1. But the normal operation of such internal combustion engines required the use of high-octane gasoline, which at that time could only be produced by the ethylation process - by adding tetraethyl lead, a highly toxic component. When new environmental standards appeared in the 1970s, leaded lead was banned, and this led to the opposite trend - a decrease in coolant in production engines.

Modern engines have an automatic ignition angle control system, which allows the internal combustion engine to operate on “non-native” fuel - for example, 92 instead of 95, and vice versa. The OZ control system helps to avoid detonation and other unpleasant phenomena. If it is not there, then, for example, if you fill an engine with high-octane gasoline that is not designed for such fuel, you can lose power and even fill the spark plugs, since the ignition will be late. The situation can be corrected by manually setting the OZ according to the instructions for a specific car model.

Calculator for calculating the working volume of an internal combustion engine

The working volume of a cylinder is the volume located between the extreme positions of the piston movement. The formula for calculating a cylinder has been known since the school curriculum - the volume is equal to the product of the base area and the height.

And in order to calculate the engine volume of a car or motorcycle, you also need to use these multipliers. The working volume of any engine cylinder is calculated as follows: where, h is the piston stroke length mm in the cylinder from TDC to BDC (Top and Bottom Dead Centers) r is the piston radius mmp - 3.14 is not a nominal number. To calculate the engine displacement you will need calculate the volume of one cylinder and then multiply by the number of cylinders in the internal combustion engine.

And it turns out: Veng = Pi multiplied by the square of the radius (piston diameter) multiplied by the stroke height and multiplied by the number of cylinders. Since, as a rule, the piston parameters are indicated everywhere in millimeters, and the engine volume is measured in cm.

To calculate the volume of the engine you are interested in, you need to enter 3 numbers in the appropriate fields - the result will appear automatically. All three values can be found in the car’s passport data or technical data.

characteristics of a particular part, or you can determine what piston volume a caliper will help you with. Thus, if, for example, you find that the volume is 1598 cm³, then in liters it will be designated as 1.6 liters, and if the number is 2429 cm³, then 2, 4 liters.

Long-stroke and short-stroke piston Also note that with the same number of cylinders and displacement, engines can have different cylinder diameters, the piston stroke and power of such engines will also be different. An engine with short-stroke pistons is very power hungry and has low efficiency, but achieves great power at high speeds.

And long-stroke ones are where traction and efficiency are needed. Consequently, the question “how to find out the engine size by horsepower” can be given a firm answer - no way. After all, although horsepower has a connection with engine volume, it will not be possible to calculate it from them, since the formula for their relationship also includes many different indicators. So the cubic centimeters of an engine can be determined solely by the piston parameters.

Most often, they find out the engine size when they want to increase the compression ratio, that is, if they want to bore the cylinders for tuning purposes. Because the higher the compression ratio, the greater the pressure on the piston during combustion of the mixture, and therefore the engine will be more powerful.

Zhurikhin › Blog › Calculation of Dynamic Compression Ratio (DCR)

For simplicity, we will compare the well-known engines of the VAZ family and trace their evolution in terms of the parameter we have introduced. So, the first engine we will consider is the VAZ 2106, the main parameters, such as cylinder diameter, piston stroke and others can be easily found on the Internet, I have already made all the necessary calculations, and for simplicity, I will indicate already abbreviated data. This engine has a geometric compression ratio of 8.5 and a valve closing angle of 55°, based on all the data, the DCR value for this engine will be 7.5. Let's compare with the value from the table, we find that for this type of engine it is permissible to use 92 gasoline, and with a small margin.

In principle, for the time when this engine was developed, the octane rating of the fuel was 91, and the engine control systems did not allow for precise tuning, so a certain reserve was of course necessary. Now consider another engine from this family - the VAZ 21213.

Engine chip tuning to increase performance

An increase in power is possible without intervention in the design of the power unit. Tuning through programming makes it possible to customize engine parameters for yourself. The stages of chip tuning include:

- changing the fuel-air mixture ratio,

- changing the ignition angle,

- adjustment of engine operating modes according to crankshaft speed.

For naturally aspirated engines, chip tuning gives an increase of about 10%, for turbocharged engines - up to a 30% increase in power and torque. The difference in chip tuning for turbocharged engines is that the turbine pressure and the moment of its inflation are adjusted.

Some interesting facts

Methanol race car engines have a compression ratio of over 15:1. By comparison, a standard carbureted engine consuming unleaded gasoline has a maximum compression of 1.1:1.

Of the production models of gasoline engines with 14:1 compression, there are models on the market from Mazda (Skyactiv-G series), installed, for example, on the CX-5. But their actual coolant is within 12, since these engines use the so-called “Atkinson cycle”, when the mixture is compressed 12 times after the valves are closed late. The efficiency of such engines is measured not by compression, but by expansion ratio.

In the middle of the 20th century, in the global engine industry, especially in the USA, there was a tendency to increase the compression ratio. Thus, by the 70s, the bulk of American automobile industry samples had a coolant ratio from 11 to 13:1. But the normal operation of such internal combustion engines required the use of high-octane gasoline, which at that time could only be produced by the ethylation process - by adding tetraethyl lead, a highly toxic component. When new environmental standards appeared in the 1970s, leaded lead was banned, and this led to the opposite trend - a decrease in coolant in production engines.

Modern engines have an automatic ignition angle control system, which allows the internal combustion engine to operate on “non-native” fuel - for example, 92 instead of 95, and vice versa. The OZ control system helps to avoid detonation and other unpleasant phenomena. If it is not there, then, for example, if you fill an engine with high-octane gasoline that is not designed for such fuel, you can lose power and even fill the spark plugs, since the ignition will be late. The situation can be corrected by manually setting the OZ according to the instructions for a specific car model.

Compression ratio in a car engine

Calculation of compression ratio and engine volume

Engine calculation

Calculation of compression ratio and engine volume

The compression ratio in a car engine is the ratio of the volume of the piston space of the cylinder when the piston is positioned at bottom dead center (BDC) (total volume of the cylinder) to the volume above the piston space of the cylinder when the piston is positioned at top dead center (TDC), that is, to the volume of the combustion chamber.

b = cylinder diameter;

Vc = volume of the combustion chamber, that is, the volume occupied by the fuel-air mixture at the end of the compression stroke, immediately before ignition by a spark; often determined not by calculation, but directly by measurement due to the complex shape of the combustion chamber.

Increasing the compression ratio in a car engine requires the use of fuel with a higher octane number (for gasoline internal combustion engines) to avoid detonation. Increasing the compression ratio generally increases its power, and also increases the efficiency of the engine as a heat engine, that is, it helps reduce fuel consumption.

The compression ratio in a car engine, denoted by the Greek letter E, is a dimensionless quantity. The amount of compression associated with it depends on the degree of compression, on the nature of the gas being compressed and on the compression conditions. During the adiabatic process of air compression, this dependence looks like this: P=P?*?^?, where

?=1.4 - adiabatic index for diatomic gases (including air),

P? — the initial pressure, as a rule, is taken equal to one.

Due to the non-adiabatic nature of compression in an internal combustion engine (heat exchange with the walls, leakage of part of the gas through leaks, the presence of gasoline in it), gas compression is considered polytropic with a polytropic index n=1.2.

At ?=10 the compression in the best case should be 10^1.2=15.8

Detonation in an engine is an isochoric, self-accelerating process of the transition of combustion of the air-fuel mixture into a detonation explosion without performing work on the transition of the energy of fuel combustion into the temperature and pressure of gases. The flame front propagates at the speed of an explosion, that is, it exceeds the speed of sound in a given environment and leads to strong shock loads on the cylinder parts - the piston and crank groups and thereby causes increased wear of these parts. The high temperature of the gases leads to burnout of the piston bottoms and burning of the valves.

The concept of compression ratio should not be confused with the concept of compression, which means (at a certain structurally determined compression ratio) the maximum pressure created in the cylinder when the piston moves from bottom dead center (BDC) to top dead center (TDC) (for example: compression ratio - 10 :1, compression - 14 atm.).

Complex of operations of an engineering calculator

The built-in mathematical calculator will help you carry out the simplest calculations: multiplication and summation, subtraction, and division. The online degree calculator will quickly and accurately raise any number to the degree of your choice.

The presented engineering calculator contains all possible variations of online programs for calculations. Kalkpro.ru contains a trigonometric calculator (angles and radians, degrees), logarithms (Log), factorials (n!), calculation of roots, sines and arctangents, cosines, tangents online - many trigonometric functions and more.

You can work with the computing program online from any device; in each case, the size of the interface will be adjusted to your device, or you can adjust its size to your taste.

Numbers can be entered in two ways:

- from mobile devices – input from the display of a phone or tablet, program interface keys

- from a personal computer - using an electronic interface display, or through a computer keyboard using any numbers

Chip tuning (reprogramming)

The method is simple: you don’t need to open the engine and you don’t need to buy anything either. If you entrust this matter to a specialist, the power plant will fully reveal all its capabilities that the automaker hides in order to increase the life of the car. The increase in engine power will be 10-15%! Most often, tuners increase the amount of fuel supplied.

The engine will become stronger, and emissions into the atmosphere will be more harmful. You can also unlock the crankshaft speed limiter. For example, Honda once produced 160 hp without turbocharging. With. with a cylinder volume of only 1.6 liters. This was achieved by spinning the engine up to 8 thousand rpm.

Counting example

This is what the generally accepted calculation formula for an automobile internal combustion engine looks like: “SSD = (RO+OKS)/OKS.” The compression ratio here is o, the working volume of the cylinder is “RO”, and the volume of the combustion chamber is “OKS”.

To calculate “PO,” you must first decompose the single engine volume or displacement into the number of cylinders used. For example, the displacement of the “four” engine is 1997 cm3. To determine the capacity of one cylinder, you need to divide 1997 by 4. You get about 499 cm3.

To calculate the “OCS” parameter, specialists use a tube or pipette calibrated in cm3. The chamber refers to the place where the fuel ignites directly. The chamber is primed and then the volume is measured using a liquid burette. If you don't have a graduated tube, you can pump out the liquid with a syringe and then measure it in a measuring cup or on a scale. In this case, it is advisable to use clean water for calculations rather than gasoline or diesel fuel, since its specific gravity is more related to the volume in cm3.

Calculation of compression ratio

Calculation of compression ratio

Posted by spamer » Mar 23, 2009, 9:58 pm

In general, I installed copper head gaskets of 1-1.5 mm (I don’t remember exactly) on my JUP. So, according to the manual, it should have an SG of 6.7-7.0. But I think that with such a gasket it doesn’t even have 6.5. Please help me calculate. Here's how I did it, assuming that the gasket thickness was 1 mm: V=D^2h*0.785 We get: Cylinder volume 62*62*58*0.785=175 cubic meters. The volume of the gasket is 62*62*1*0.785=3017.54 cubes, that is, 3 cubes. So?? How I calculated the volume of the CS based on the fact that the SF should be, for example, 6.7: we divide the volume by the ratio of the total (175) by the ratio with the compressed (that is, the SF) we get 175:6.7 = 26 cubes. And I have a gasket of 3 cubic meters, therefore I have KS 29 cubic meters and SJ 175_29 = 6 (not enough).

Method No. 2. Power increasing blocks

The popularity of using blocks to increase the power of a diesel engine is explained by their versatility, quick installation and ability to significantly save fuel.

Among the disadvantages, it is worth noting a decrease in the service life of the cylinder block, injectors and injection pump and the rapid depletion of the particulate filter. Also, the modular method, in contrast to properly carried out chip tuning, increases the emission of harmful substances.

Block for improving the operating modes of the ECU CPU

The unit is included in the high-pressure fuel system and its computing module controls engine operation, bypassing the ECU, without underestimating sensor readings. By diagnosing the pressure in the fuel system, and when it increases, it sends a command to the control unit to increase the injector timing within the permissible range.

Injector control module

Installing the module allows you to control and change injector control pulses. The module is connected to the injector wire gap and regulates the operation of the fuel injector by changing the opening time of the injector needle. As a result, the fuel injection angle changes and combustion efficiency increases.

Module for changing the fuel injection pump operation scheme

Installed on diesel engines with a mechanical injection system. The block increases the power of a diesel engine due to changes in the functioning of the fuel pump. The module adjusts the fuel sensor data to lower values. As a result, pressure increases in the fuel pump housing using a solenoid valve.

The positive aspects of this method include inexpensive equipment and ease of installation. The disadvantages include floating engine speeds and reduced fuel injection pump life.

Module for converting fuel rail pressure sensor data

The equipment connects to the wires of the rail pressure sensor and sends data about a decrease in compression in the fuel rail to the electronic control unit. The ECU changes the intensity of the injectors, the power of the internal combustion engine increases, and fuel consumption decreases.

Module for reducing fuel accumulator pressure

The fuel pump is responsible for regulating the pressure level in the fuel accumulator. By installing an additional unit in the electronic circuit of the fuel system, information about the loss of fuel injection pump power is supplied to the ECU. The ECU will give a command to increase the injection timing.

Method number 3. Turbocharging

Engine performance is increased by installing a turbine, which supplies a large amount of air into the combustion chamber. The fuel system control unit gives a command to increase fuel injection and engine power increases.

The disadvantage of this method is the increase in fuel consumption and the short service life of the turbine. At the same time, turbocharging prevents the engine from stalling when you press the car's stop pedal.

2016-03-08 Reducing and increasing the compression ratio

Each owner has his own requirements for the car. Some tune it, others, on the contrary, reduce its performance. There are various ways to make this a reality.

Possible options for calculating engine volume

Increasing engine compression ratio

This is the most common way to increase productivity. As a result, engine volume and consumption remain the same, but power increases. However, not everything is so rosy. It is not for nothing that manufacturers at factories do not increase power to maximum values.

The bottom line is the physical properties of gasoline. The greater the compression, the higher the likelihood of detonation. To do this, you need fuel with a high octane number (a value that characterizes the detonation resistance of the fuel). There is also a positive aspect. Since the power has increased, fuel consumption will decrease under standard engine operating conditions.

An example with the most common brands of gasoline - AI-92 and AI-95. When switching to fuel with a higher octane rating, consumption decreases. But the cost per liter increases, so there are no significant savings.

Ways to increase compression ratio

There are two common methods:

1. Reducing the thickness of the engine gasket. This creates a risk of pistons colliding with the valves, so accurate calculations are necessary. It would be more rational to use valves with deep recesses. They will ensure smooth operation. It is imperative to re-adjust the valve timing, as they will change significantly.

2. Boring of cylinders. The engine displacement increases, which leads to an increase in the compression ratio. The combustion chamber remains the same. The result is more fuel and more power. The disadvantage is that all pistons need to be replaced.

The increase in power is relevant for engines that initially have a low compression ratio. The lower it is, the stronger the effect will be.

Reducing engine compression ratio

It is used for exactly the opposite purposes. Engine performance decreases for a simple reason - this creates the opportunity to fill in with cheaper fuel.

Previously, AI-76 gasoline was available. To transfer the car to it from a more expensive one, the compression ratio was reduced. A thick engine gasket was used. To do this, we took two thin layers of paronite and added aluminum between them. The gasket could be made at home using simple improvised means.

The combustion chamber became larger, which made it possible to use fuel with a low octane number.

It is not recommended to use methods of increasing and decreasing the compression ratio on modern cars. They have a large amount of electronics installed that are responsible for the required values of engine operation. Trying to upgrade the engine yourself, you can bring it to a state where only a major overhaul will help.

Let's sum it up!

The right approach, the presence of special equipment and straight hands can do almost anything, without exaggeration. Make the suspension harder or softer, improve handling or increase engine efficiency - all this can be done by specialists

It is important to understand for yourself what goal you are pursuing and what such tuning will cost. After all, after all the above modifications, you will get a completely different car with different characteristics and it’s not a fact that you will like it

Over time, you may regret the work done and time wasted. So, for example, in addition to improved handling and stiffer suspension, you will get a decrease in comfort due to new shock absorbers, springs and silent blocks, and increased fuel consumption due to large and wide wheels. In addition, you will no longer be able to calmly and carefreely fly over bumps on the road; you will have to get used to slowly overcoming them due to the fact that you have low-profile tires and a very stiff suspension. Do not rush to redo everything at once, start small, change the wheels and tires, then if this is not enough, replace the springs, and only then everything else until you achieve the required result.