The problem of shifting gears while the engine is running is common, especially in cars with a manual transmission. The malfunction can occur either completely unexpectedly, or gradually, making itself known by the appearance of a characteristic grinding sound and difficulties when shifting gears. In any case, without eliminating the cause of the malfunction, you will not be able to operate the car.

Gears are difficult to engage with the engine running: possible reasons

At the very beginning, it should be noted that the inability to engage a gear with the engine not running may indicate a serious gearbox malfunction, which consists of failure of the synchronizers. The second reason may be wear or breakage of the gears. It is also possible that the components and mechanisms responsible for transmitting force from the lever in the cabin to the gearbox when selecting a gear may become jammed.

To accurately determine the causes, in the first case it will be necessary to remove the box for disassembly and subsequent troubleshooting; in the second case, it is necessary to identify and replace broken components. In some cases, it is enough to carry out their prevention: removal, lubrication and careful adjustment.

As for problematic switching when the internal combustion engine is running, then the list of the most common faults includes:

- lack of gear oil in the gearbox;

- problems with the clutch mechanism;

The smell of burning

Take a sniff. You may smell burning oil and feel heat coming from the gearbox (this is especially noticeable with a longitudinal engine, when the gearbox is directly under the gear selector). A burning smell indicates that your transmission is overheating due to excessive load or a critical drop in the oil level in the unit. Don't forget that oil not only reduces friction losses, but also removes excess heat from the gears. Be that as it may, this malfunction indicates the need for an urgent inspection of the level and quality of the oil, as well as its subsequent topping up or replacement. A low level of lubrication quickly damages the bearings and gears of the gearbox, after which it becomes beyond repair.

Common causes of gear shifting problems

There may be many reasons why you cannot move the gearshift lever to the working position. And they are not always associated with a malfunction of the box itself - in some cases the culprit is the clutch, sometimes the engine. In any case, to find out the cause yourself, you must have the appropriate knowledge and experience - otherwise there is a high risk that you will not be able to do this or that as a result of your actions you will have to carry out more complex and expensive repairs.

If the gears do not engage with the engine running due to a malfunction of the gearbox, it will require dismantling and troubleshooting - an operation that requires great care. The same can be said about the clutch. However, it is better to proceed to a more detailed description of possible problems and ways to eliminate them.

VAZ 2109 does not engage reverse gear

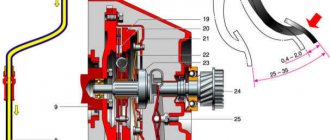

Placing the rear speed in the extreme position most often leads to its refusal to engage. Since several models have exactly the same boxes, the VAZ 21093 does not engage reverse gear for the same reason. It may be a short lever and the rocker is not enough to reach the desired position.

Just look at the photo of the gearbox below to determine the cause. Repairs should be carried out in the pit, since everything will have to be done from below. You need to loosen the slide. Align the gears with the reverse gear and tighten the bolt. The lever should be in the reverse gear position.

Why don't the gears turn on when the engine is running?

The clarity of gear engagement and the operation of the entire shift mechanism often worries owners of cars with a manual transmission. A common problem is that after starting the engine, one or more gears are engaged with great effort or not completely, it is not possible to change gears, at the moment of switching on, extraneous noise is heard, unnecessary vibrations appear, etc.

Such malfunctions appear unexpectedly, and difficulties when shifting gears can increase gradually. Speeds may be difficult to switch on “cold” and/or “hot”. It is noteworthy that gears in a manual transmission often shift normally when the engine is turned off.

Automatic transmission won't shift gears

Although the automatic transmission is maintenance-free, that is, it is designed for the entire life of the vehicle, it is also susceptible to breakdowns. However, here the reasons why gears are not changed when the engine is running are partly different. Let's look at them:

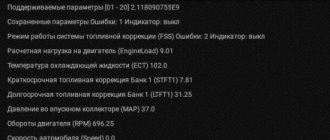

Those malfunctions that are caused by internal reasons cannot be eliminated independently. Moreover, not all car services will undertake such work. In any case, if you have problems with shifting on a car with an automatic transmission, you should first perform computer diagnostics of the box.

Source

VAZ or foreign car - is there a difference?

To begin with, we note that the operating principle of the main components is the same for all cars. And such a malfunction can happen to anyone, be it a foreign car or a domestic car. The only difference is the type of drive. On rear-wheel drive vehicles, the lever is connected directly to the gearbox.

On front-wheel drive cars, the engine is located transversely relative to the body. Therefore, to operate the box, a rocker or cable drive is used. The latest VAZ models (including Kalina and Vesta) use the latter type of drive. It is more reliable, but it also has problems. If the gears do not engage with the engine running (including Niva), do not panic and take the car to a service center. Perhaps the reason lies in trivial malfunctions that can be fixed on your own.

Problems with switching to automatic transmission

Shifting problems with automatic transmissions are not uncommon. Problems with the automatic machine arise for several reasons.

- backstage malfunction. This mechanism is the most problematic in old-type automatic transmissions. To eliminate the malfunction, the unit will need to be replaced. In most cases, it will be necessary to dismantle the gearbox for these purposes;

- insufficient oil level. The presence of lubricant leaks on the automatic transmission housing may indicate wear of the sealing gaskets, which are not difficult to replace yourself. After this, you need to change the oil in the box. Also, owners of cars with an automatic transmission are recommended to visually inspect the gearbox for oil leaks at least once every 2000 km;

- problems with the transmission control unit can ultimately cause the automatic transmission to completely lock up. To fix the problem, you will need to replace the failed mechanism and thoroughly inspect the electrical part of the gearbox.

Traction and link

If you have a front-wheel drive domestic car (nine, Priora, etc.), and the gears are difficult to engage with the engine running, you should pay attention to these two details. Often, when starting from a standstill, the gearbox lever begins to rattle convulsively (this is especially true for the Lada Samara family of the first and second generation). The link flies out of its fastenings. As a result, gears are difficult to engage when the engine is running. The way out of the situation is to replace the elements with new ones. But this should only be done if you are really convinced that it is the rocker that is faulty by looking under the bottom of the car.

Troubleshooting gearbox

Possible gearbox malfunctions, their causes and solutions

Troubleshooting the gearbox is carried out by removing it from the car, disassembling it, and troubleshooting parts if it is found that some of them are badly worn

Particular attention should be paid to the condition of the sliders and clamps. If burrs are noticed on the sliders, they must be removed with a file.

You also need to check the condition of the springs and retainer balls. The springs must be intact, and the latch must move without problems in its seat. If necessary, worn or damaged elements must be replaced.

You should also carefully inspect the power forks for bending. Even a slight bend can affect the ease of gear engagement.

After assembly, gear shift adjustment must also be performed. To be precise, the position of the scenes is set.

Low gearbox oil level

An insufficient amount of oil in the box makes the process of shifting gears extremely difficult, but the speeds must be engaged. When switching in this way, a metallic crunch is heard, and when driving in a gear, the transmission begins to make a lot of noise and “howl.”

A complete lack of lubrication in the gearbox will not allow you to change gears, since without oil the synchronizers will not be able to work properly, and the gears in the gearbox will not engage.

Any manifestation of these symptoms requires immediate cessation of operation of the vehicle and checking the transmission oil level in the gearbox. It is also necessary to inspect the gearbox for damage to the housing, oil leaks through the seals and gaskets.

It should be noted that for manual transmissions of many cars, the oil in the gearbox is filled from the factory for the entire service life. In practice, replacement is recommended every 60-80 km. mileage

It is imperative to fill only with lubricant recommended for viscosity and other characteristics. As for adding oil to the transmission, it is necessary to separately take into account the issue of compatibility with the already filled lubricant.

Possible malfunctions of the UAZ-469 gearbox and ways to eliminate them

Details Category: Transmission UAZ-469

Possible malfunctions of the G6BA engine, their causes and solutions

Noise in the UAZ-469 gearbox

| Probable cause of the malfunction | Remedy |

| The fastening of the gearbox with clutch housings and transfer case is loose | Secure loose connections |

| Oil contaminated with solid particles | Change oil with crankcase flush |

| The oil does not comply with the instructions in the Lubrication Card or its level is low | Change the oil or add to the level in accordance with the Lubrication Chart |

| Worn or damaged parts | Disassemble the gearbox and fix the problem |

Difficulty shifting gears of UAZ-469

| Probable cause of the malfunction | Remedy |

| The clutch “drives”, as a result of which the synchronizer blocks gear engagement | Adjust the clutch and its release drive as described in the “Clutch” section |

| The synchronizer parts are worn out or the ball comes out of the socket | Replace worn parts |

| The first gear gear jams on the secondary shaft due to scuffing of the seating surface by burrs formed at the ends of the gear splines from engaging the second gear with impacts on the teeth | Disassemble the gearbox. Clean any burrs on the secondary shaft. Remove burrs from gear splines. When assembling, align the gear splines that were not previously seated with the seating surfaces of the shaft. Replace the secondary shaft/first gear kit if necessary. |

| Forks and other parts of the shift mechanism are deformed | Straighten or replace deformed parts |

Self-switching off of the UAZ-469 transmission when the vehicle is moving

| Probable cause of the malfunction | Remedy |

| Loose fit on the centering surfaces due to wear or crushing of parts | Replace parts. Select the synchronizer hub with the coupling, as shown in Fig. 59. Select the first gear gear according to the secondary shaft with minimal clearance and easy movement |

| Worn gear bushings | Replace bushings or gears with bushings |

| Parts are distorted due to bent shift forks | Align the forks to the dimensions shown in Fig. 60, or replace with new ones |

Rice. 59. Completing and selecting parts for the UAZ-469 synchronizer: 1 - synchronizer hub; 2 — synchronizer clutch.

Note. When the parts move mutually by 14 mm, the misalignments in the splines measured at points T1 and T2 should not exceed 0.35 mm (as shown).

Rice. 60. Control dimensions of UAZ-469 gear shift forks: A - first and second gear forks; B - third to fourth gear forks.

Manual transmission: What you need to know when shifting gears

The result is premature wear of the clutch disc. In order to keep the car from rolling on an incline, you need to depress the brake pedal. In order to start, of course, you will have to press the clutch and smoothly press the gas, releasing the clutch. In this case, you will reduce the load time on the clutch basket and release bearing. You can also hold the car by maintaining certain engine speeds, catching a certain moment when you release the clutch and press the gas.

Surprised? But in fact, this advice is really very important, because having a habit of leaving your hand on the gear shift knob can lead to premature transmission failure. If you most often leave your hand on the gearbox when stopped in a traffic jam or at a traffic light, then the first gear of the manual transmission suffers the most. Remember that by placing your hand on the gearshift knob, you create extra pressure on it, which is transferred to the gearbox. As a result, excess pressure on the handle can lead to unfree shifting of the desired gear. This can damage the gear shift knob as well as the transmission itself.

Clutch basket

Over time, the clutch basket fails on all cars with a manual transmission. Sometimes it’s due to wear and tear, sometimes the petals or the so-called “spider” break. Let me start, perhaps, with the “spider”, this is a mechanically fixed release bearing on several extensions (done like this on some VAZs), if the extension breaks, then it cannot be effectively fixed to the basket - the gears do not engage.

Next, the petals of the box break, or they become weakened. This leads to the fact that it is very difficult, almost impossible, to release the clutch disc. Therefore, the “speeds” do not switch – we just change the basket.

Well, the last wear and tear is the basket disk. It has a metal disk inside, and over time, especially from high mileage, wear forms there. When starting, the car will shake, and if the wear is very large, the gears may not shift.

In any case, we need to change the clutch basket.

Cable

If you have a more modern car, then the problem may be with the cable drive.

On such machines, the gearbox lever does not have a linkage and is not inserted into the transmission. If the cable breaks, the gears will not engage either with the engine running or with the engine turned off. This is the main sign of a breakdown. The solution is to completely replace the gearbox cable. Luckily it's inexpensive.

Fork

Now let's look at more complex malfunctions due to which the gears do not engage when the engine is running. UAZ is also susceptible to this breakdown, so you should not neglect the fork. Thus, on most rear-wheel drive and all-wheel drive vehicles, the gears are engaged hydraulically. When the driver presses the clutch pedal, the release piston is activated, which pushes the fluid under pressure. As a result, the fork is moved to the side and the disk is disconnected. Inspect the condition of the plug itself and check the tightness of the system. If the level in the reservoir constantly drops (by the way, a “brake fluid” is used for the clutch), the clutch slave cylinder boot may have torn. Because of this, we get incomplete compression of the fork. The latter also sometimes breaks off, especially on GAZelles. This thing looks like this:

This indicates that the plug was not of the best quality and should be replaced. When purchasing such critical items, it is not the price that is important, but the quality. You should not give preference to cheap analogues. Repairs can take a lot of your time and effort. On front-wheel drive vehicles, replacing the fork requires dismantling the gearbox.

Engine mounting cushion

Oddly enough, this malfunction can significantly affect the quality of the gearbox. Moreover, due to bad airbags, gears are not engaged when the engine is running, both with a manual transmission and an automatic transmission. On some cars, separate supports for the box are installed. Check their integrity and replace if necessary. It is very simple to check - the engine should not jerk from side to side when increasing speed and idling. If the cushions “sag,” the motor will break the linkage or the input shaft will jam.

Typical gearbox malfunctions and possible causes

| GENERAL INFORMATION |

| SYMPTOM OF MALFUNCTION | POSSIBLE REASONS |

| Knocking noise at low speed | Wear of the inner or outer constant velocity joint (CV joint) |

| Wear of differential bearing seats | |

| Increased noise when cornering | Differential gear noise |

| Knocking noise when accelerating and decelerating the car | Loose engine mounts |

| Wear of the inner CV joint | |

| Wear of the pinion axle and mounting holes in the differential housing | |

| Wear of differential bearing seats | |

| Knocking sound when turning | Wear of outer CV joint |

| Vibration | Bearing vibration |

| Axle shaft bent | |

| Out of roundness of tires | |

| Wheel imbalance | |

| Wear of the CV joint of the axle shaft | |

| Significant angles in the CV joint (violation of the static suspension travel) | |

| Self-switching gears | Worn or misaligned gear shift drive |

| Shift drive sticking | |

| Breakage or loosening of the locking washers of the input shaft bearings | |

| Worn or deformed shift fork | |

| Increased noise in neutral in the gearbox when the engine is idling | Wear of the bearings of the input shaft gear block |

| Worn clutch release bearing | |

| Wear of input shaft gears | |

| Worn 1st gear or bearing | |

| Worn 2nd gear or bearing | |

| Worn 3rd gear or bearing | |

| Worn 4th gear or bearing | |

| Worn 5th gear or bearing | |

| Wear of secondary shaft bearings | |

| Increased noise only in 1st gear | Breakage, chipped teeth or wear of 1st gear gears |

| 1st and 2nd gear synchronizer wear | |

| Worn 1st gear or bearing | |

| Worn differential gears or bearings | |

| Wear of the main drive driven gear | |

| Wear of the lever and rods of the shift mechanism | |

| Increased noise only in 2nd gear | Breakage, chipped teeth or wear of 2nd gear gears |

| 1st and 2nd gear synchronizer wear | |

| Worn 2nd gear or bearing | |

| Worn differential gears or bearings | |

| Wear of the main drive driven gear | |

| Wear of the lever and rods of the shift mechanism | |

| Increased noise only in 3rd gear | Breakage, chipped teeth or wear of 3rd gear gears |

| 3rd and 4th gear synchronizer wear | |

| Worn 3rd gear or bearing | |

| Worn differential gears or bearings | |

| Wear of the main drive driven gear | |

| Wear of the lever and rods of the shift mechanism | |

| Increased noise only in 4th gear | 3rd and 4th gear synchronizer wear |

| Breakage, chipped teeth or wear of 4th gear gears | |

| Worn 4th gear or bearing | |

| Worn differential gears or bearings | |

| Wear of the main drive driven gear | |

| Wear of the lever and rods of the shift mechanism | |

| Increased noise only in 5th gear | Worn 5th gear synchronizer |

| Breakage, chipped teeth or wear of 5th gear gears | |

| Worn 5th gear or bearing | |

| Worn 5th gear or bearing | |

| Wear of the main drive driven gear | |

| Wear of the lever and rods of the shift mechanism | |

| Increased noise only in reverse gear | Breakage, chipped teeth or wear of the reverse gear intermediate gear, wear of the primary and secondary shaft gears |

| 1st and 2nd gear synchronizer wear | |

| Main gear drive wear | |

| Wear of the main drive driven gear | |

| Worn differential gears or bearings | |

| Increased noise in all gears | Insufficient oil level |

| Bearing wear | |

| Breakage, chipped teeth or wear of the gears of the primary and/or secondary shafts or wear of the shafts | |

| Oil leak in the clutch area | Transmission housing |

| Clutch release bearing lever | |

| Oil leak in the middle of the transmission housing | Transmission housing |

| Switching mechanism | |

| Reversing light switch | |

| Oil leak on the left side of the transmission housing | Crankcase cover |

| Oil leak from main gear | Bearing caps and final drive seals |

| Final drive pan | |

| Final drive pan | |

| Gear grinding when shifting gears | Clutch release bearing lever |

| Clutch release drive | |

| Input shaft or gear block | |

| 5th gear synchronizer | |

| 5th gear or bearing | |

| 1st gear or bearing | |

| 1st and 2nd gear synchronizer | |

| 2nd gear or bearing | |

| 3rd gear or bearing | |

| 3rd and 4th gear synchronizer | |

| 4th gear or bearing | |

| Reverse gear |

Gear does not engage when the engine is running reason

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

Help me out, I got caught again with my VAZ 21103. A week ago, all gears stopped turning on when the engine was running, but when it was turned off everything was fine. Afterwards, I had difficulty getting to the service station: with the engine off, I put it in 1st gear, depressed the clutch and let’s start it – it started, only while the starter was running, the car began to move jerkily while the clutch pedal was depressed. The service was already closing, I left the car on the street until the morning. When I come in the morning, everything is fine as if nothing had happened - everything switches back to normal. But I decided that I still needed to open it and see what was there. At the same time, I drove into the service center on my own with excellent gear shifting. In general, we took off the box and changed the clutch fork and release fork, because the old release fork had ground 0.5-1 mm into the mounting points on both sides. The basket and disc are fine - they ran half of them until they started replacing them. Now a week has passed and today has come and everything has been covered with a copper “basin” - it won’t switch again when it’s running. The repair was then provided by the best service in our city, according to reviews on local forums. Now I really need your advice, what could it be and how to treat it? Has anyone encountered something similar? I would like to understand if I ended up having to repair the box itself?

PS I wouldn’t be surprised if I come to her this evening, and she has repaired herself and can go anywhere again... until morning comes again, like today.

It happened like that. The clutch basket petals are bent.

Source

Clutch faults

Simply put, the clutch is a mechanism that serves to transmit the torque of the internal combustion engine to the transmission, and also opens the engine and transmission so that gear can be changed. Failure of individual components of this unit may make it impossible to shift gears while the engine is running.

Brake fluid leaks

The design of many modern cars assumes that the working fluid for the clutch is brake fluid. If there is not enough fluid in the clutch drive hydraulic system, then the clutch will not engage fully.

In this case, the gears will engage slowly or not engage at all. For an initial check, you should look at the fluid level in the reservoir. If the level is low, it is necessary to check for leaks, eliminate defects and bleed the clutch.

If the fluid level is normal and no other reasons have been identified, you will need to remove the gearbox to inspect the clutch elements. Usually, when you try to turn on the speed and this mechanism breaks down, no loud grinding metallic sounds are heard from the gearbox itself.

Release bearing

Gears may not engage or may not engage fully if the fault is related to the clutch basket. The release bearing may also be the cause. If the specified bearing does not move freely along the input shaft or is jammed, then replacement of the part is necessary.

It is necessary to separately add that the primary sign of problems with the release valve is the appearance of a rustling or distinct hum when the car is running. The noise appears only when the clutch pedal is pressed to the floor. Such extraneous sounds can be present both on a cold car and on a warm one. After releasing the clutch pedal, the noise should disappear. A jammed release lever will not allow the clutch to engage, which complicates gear shifting and can also lead to rapid wear and destruction of other elements of the clutch mechanism.

Clutch basket and disc

Basket malfunctions are often associated with critical wear of the petals. Wear means that the basket stops performing its functions as it heats up. An increase in temperature leads to the fact that the clutch basket cannot completely remove the pressure plate. The result is very difficult gear shifting after the engine has warmed up a little.

After removing the box, it is necessary to inspect the basket for deformation, signs of overheating and other defects. If found, the element must be replaced.

Another reason why the gears do not engage when the car is running or engages with effort may be a worn clutch disc.

After disassembly, it is necessary to inspect the friction linings on the disk. They should not be critically worn, burnt or damaged, and the disc should not be deformed. Additionally, during the clutch inspection process, a check of the diaphragm springs is required. After replacing failed clutch elements, the box must be well centered during subsequent assembly, and the clutch must be pumped.

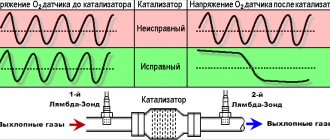

Noise in neutral

Start the engine and listen. You may notice a strange noise that changes in character when you depress the clutch. Did you notice? The noise may come from excessively worn input shaft bearings. This may also indicate a low oil level or the wrong type, or severe wear on the release bearing. A malfunction of the latter can be detected by pressing the clutch pedal all the way. When the bearing is worn out, you will hear a strong rustling or humming sound. When you release the pedal, the noise becomes muted again.