Functional load of Lada Largus suspensions

- Comfort during movement is achieved through the interaction of mechanisms focused on smoothness, muffling unevenness and eliminating unwanted vibrations.

- Handling is characterized by an adequate response to all steering commands from the driver. Moreover, accuracy and convenience of maneuvers become important aspects when increasing or switching speed.

- The suspensions of the Lada Largus contain actively moving parts, so the safety of the entire vehicle largely depends on them.

Front suspension

One of the main tasks of this element of the chassis is to ensure smooth movement. When the front wheel encounters an uneven road, the body continues its movement along the previously traversed trajectory, “damping” all vibrations.

Its design is much more complex than the rear variation, since it provides the ability to change the position of the front wheels, thereby providing effective control of movement in all directions. This is justified by a number of design features that are subject to additional loads.

It is worth noting that the front part of the Lada Largus, like any other car, is heavier than the rear, because the weighty units of the power and chassis are concentrated there. Undoubtedly, this causes a large load, which contributes to its rapid wear. Thus, the condition of the front suspension is directly related to the safety of driving the car.

Rear suspension

As a rule, the rear suspension of the Lada Largus is much simpler than the front: the wheels of the same name are not required to change the angle of rotation, and their orientation is focused only on vertical movement. But, despite this, the condition of this unit is also related to the safety of movement and the corresponding level of comfort.

In relation to it, semi-dependent and dependent varieties are considered. In the first case, the suspension consists of two levers fixed between the body and the wheels, which provides optimal kinematics. The dependent suspension is connected by a rear axle beam, which is attached to the body by trailing arms.

labavto.com

The suspension of the Lada Largus ensures comfortable movement. It is recognized by many motorists as unkillable. This is especially true on domestic roads. This detail is completely borrowed from Renault Logan. It is energy-intensive, soft and reliable. But sometimes problems arise with it. You can solve them yourself.

Design and characteristics of suspensions

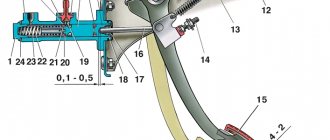

The front suspension is a simple, comfortable and inexpensive MacPherson strut design, but with some modifications. It is mounted on a subframe. The front arms are attached to it. At the ends of the levers there is a ball joint, through which the lever is connected to the steering knuckle. Vibrations are dampened by shock absorber struts with coil springs. To avoid lateral rolls, a torsion stabilizer is installed.

If in old VAZ models the lever was changed separately from the ball joint, then on Largus the ball joints are changed simultaneously with the lower lever, as on Renault Logan. Largus also differs in that the stabilizer is secured to a lever located below. Due to the simplicity of the design and maintainability, you can find faults yourself at home.

The main part of the rear suspension is a semi-independent beam, in the cavity of which there is a stabilizer, rigidly connected to the lower arms. The rear shock absorbers are attached to the lever at their lower end; its springs rest against the lever bracket through a gasket. The difference between the largus suspension is that the shock absorber and spring are separate parts that are not combined into a single unit. Each lever is attached to the body using silent blocks. The rear suspension is a reliable unit; it rarely breaks, but is easy to repair.

Diagnostics and signs of suspension malfunctions

One of the advantages of the Lada Largus is its reliable and durable suspension. But despite this, over time the elements wear out. If proper maintenance is carried out in a timely manner, faults are identified and corrected, you can extend the life of the suspension and prevent failure of its parts.

The subframe is the main element of the front suspension, so timely diagnostics will avoid problems with the chassis and unit failure. The levers, rear part of the engine and exhaust system cushions are mounted on it. Subframe malfunctions should be looked for in the places where the hanging elements are attached. Typical symptoms of malfunctions are a knocking sound in the front suspension, and wheel alignment changes.

To maintain a smooth ride, dampen road irregularities, ground clearance and level the vehicle while driving, shock absorber struts are installed. They limit body sway. The following signs indicate the presence of malfunctions:

- The body sways when driving on uneven roads;

- oil smudges;

- knocking, vibration and creaking when moving;

- poor handling;

- When hitting even small potholes, impacts and jolts are felt.

When some of the coils of springs break off, the ground clearance decreases, and body roll is noticeable if you place the car on a flat surface.

The function of the anti-roll bar is to prevent the body from swaying and maintain vehicle stability on the road. Problems with the node are determined by the following symptoms:

- when driving on an uneven road, a metallic knock appears;

- if you brake sharply, the body sways strongly;

- On sharp turns there is a noticeable roll.

Using levers, the angle of rotation of the wheels is adjusted. Structurally, the lever is a metal pipe; thanks to a ball joint, it is connected to the steering knuckle. Problems are possible due to wear of the fixing silent blocks.

Malfunctions manifest themselves in the form of a knocking sound that occurs when the car hits an uneven surface, the drive wheels become unbalanced, the vehicle pulls in different directions while driving, and play in the steering wheel is felt. If the hub wears out, the steering knuckles fail. The malfunction can be determined by the uneven wear of the tire tread; when you turn the steering wheel, you can hear a creaking sound, and the car pulls to the right and then to the left.

Diagnostics of suspensions is carried out only on a flat plane. It makes it possible to determine which parts and assemblies need to be replaced. The suspension is checked in stages:

- First, we inspect the shock absorber strut supports. There should be a distance of no more than 1.5 cm between the glass and the top of the support.

- The steering wheel should rotate easily both left and right, and there should be no play or extraneous sounds in the form of crackling or squeaking.

- Check for play by rocking the balls, arms and rods from side to side.

- Try to rock the car. If the shock absorbers are working properly, after a few vibrations the body will return to its previous position.

- Make a visual inspection of the silent blocks. If defects are found on them, they must be replaced.

Front suspension diagnostics.

Most suspension elements, excluding shock absorbers, cannot be repaired. If they are faulty, they must be replaced with new parts.

Restoring the suspension

Suspension repair work includes dismantling and replacing worn and faulty elements.

To do this you will need to prepare the following tools:

- Screwdriver Set:

- a set of keys;

- set of heads;

- jack;

- hammer.

Malfunctions and ways to eliminate them

During its operation, the suspension can cause not only all sorts of sounds in the form of knocks and squeaks, but also direct problems with the steering. If this part behaves suspiciously, it should be immediately fully diagnosed.

Noise and knocking while driving

The main reasons for the suspension failure of the Lada Largus are related to uneven roads. For example, a knocking sound in the front suspension of a Lada Largus begins after the car falls into a hole or hits a bump.

In addition, the inexperience of the car owner is not the last circumstance that leads to repair of the chassis. Having noticed a pothole belatedly, the brake pedal is pressed, which only increases the load several times and aggravates the situation.

The problem may be faulty shock absorbers, worn ball joints, loose fastening bolts, or lack of lubrication. If worn parts need to be replaced, this should be done immediately. When a malfunction of the suspension is associated with the fixing force or lack of lubricant, tightening them and appropriate lubrication will correct the situation.

If there is noise or knocking in the rear suspension, in addition to rubber seals and torque rods, attention should be paid to the condition of the exhaust pipe. A detailed analysis of the entire mechanism allows you to accurately determine the cause of the breakdown and eliminate it in a timely manner.

Departure of a vehicle from straight-line motion

Most often this is due to different tire pressures, incorrect wheel alignment or incorrect bearing clearance. These problems are resolved by checking and adjusting the characteristics to suit normal operation.

In some cases, even disassembling the suspension using specialized equipment is required. For example, if the front suspension arm of a Lada Largus is severely deformed, then the entire axle will need to be replaced.

It is worth noting that tire defects may not be immediately noticeable, so you should swap the wheels of the front of the car. If the direction of care changes, then the problem is in the condition of the rubber. When the loss of strength of one of the springs is to blame, it will immediately compress, affecting the visual tilt of the car body.

Vertical oscillation of the front wheels

This situation most often develops during braking or accelerating to maximum speed. The passenger car begins to tilt, and under the influence of road unevenness it makes oscillatory movements. This is justified by a possible imbalance of the wheels, settling of the suspension springs or failure of the shock absorbers.

In this case, the anti-roll bar may simply not work during acceleration and braking. Here you should check the condition of all parts and, if they are worn, replace them by securely tightening the fixing bolts.

Such vertical vibrations are unacceptable, since the chassis and steering perceive them as natural dynamic loads, which ultimately leads to loss of controllability.

Front and rear unit malfunctions

Lada Largus is considered one of the most popular domestic cars. The first of its main advantages is its “indestructible” suspension. But despite its high reliability and durability, the system will sooner or later need maintenance and repair. Thanks to this, it will be possible to extend the life of the suspension and prevent failure of other elements. You can avoid unpleasant consequences and costly repairs by identifying faults correctly and in a timely manner.

Signs of problems with the subframe on Largus

In the case of this element, you need to understand that it serves as the basis of the front suspension. And identifying its malfunctions in a timely manner means avoiding more serious problems, including replacing a failed unit. Not only the suspension arms, but also the exhaust system cushions, as well as the rear part of the power plant are attached to the subframe.

Wear or damage to the suspension subframe can be easily determined independently by some characteristic signs. For example, the main indicator is the play in the places where attachments are attached. In addition, a knock from the front will indicate a malfunction (a knock is generally a characteristic sign of problems with the suspension).

Problems with the subframe can also be indicated by wheel alignment/camber problems.

Signs of faulty shock absorber struts

These parts are designed to level the car while driving. And also to ensure smooth suspension movement when hitting various obstacles and uneven surfaces. Shock absorbers and springs prevent the body from swaying too much and also provide vehicle clearance.

Malfunctions of shock absorbers and springs can be easily recognized by the following symptoms:

- oil leaks;

- strong body swaying when hitting obstacles;

- vibration, squeaks and knocking when moving;

- controllability decreases;

- strong shocks and impacts (suspension breakdown) when falling even into small holes.

An equally important role in the suspension is played by springs, which have their own characteristic symptoms of malfunctions. These include reduced ground clearance, jolts and strong swaying when hitting obstacles. When the coils of springs break, you can notice how the body tilts in one direction or another when the car is standing on a level surface.

Signs of a malfunctioning stabilizer bar

This element is designed to maintain vehicle stability in a flat plane and prevent the body from swaying. The stabilizer functions together with levers, with the help of which it is attached to shock absorber struts and hubs. The part is quite durable, but due to natural wear and tear, the time comes to replace the suspension stabilizer.

The malfunction of this element can be diagnosed by a number of general signs and some special symptoms.

| What's happening: |

In what situations:

An important part of the suspension is the levers, with their help the angle of rotation of the drive wheels is limited. The lever is connected to the steering knuckle through a ball joint. This element itself is a metal tube bent in a certain way. Accordingly, it fails very rarely.

Malfunctions associated with suspension arms will most often be the result of wear or damage to the silent blocks with which the arms are secured.

Malfunctions can be identified by the following signs:

- imbalance of the drive wheels;

- knocking when hitting obstacles;

- While driving, the car pulls to the left or right.

Thumping knock in the front suspension on a LoganMachine

Welcome dear reader of the blog AAuhadullin.ru.

Today marks exactly one year since Renault Logan's front suspension arms were changed.

In this video I showed already worn out original front suspension arms installed at the AutoFramus factory.

Please see the video below to see how the factory’s products look:

In terms of metal weight, the original levers are heavier compared to the German company TRW.

My Logan car is currently experiencing knocking noises on small bumps, sometimes on the right side, sometimes on the left. A preliminary diagnosis is that the silent blocks have sagged and there is a dull knock in the front suspension, and at times a small knock comes from them.

Scheme of work to eliminate knocking in the suspension

Before starting work, it is necessary to place rolling shoes on both sides under the rear wheel of the car. Then the front left wheels are removed to gain access to the levers and their mounting. An additional support is placed under the car body for insurance during work.

Next, the lever fasteners are pulled in the area of the silent blocks. After broaching, you will need to drive it to determine whether the dull knock has disappeared or whether everything remains the same. If the slight knocking on bumps does not go away, then you will have to look further in the front suspension for the cause of the malfunction.

To work, we use the key set to “18”. I started tightening it and there was indeed a slight slack, and the nut pulled out easily. We stretch the silent block nuts on both sides onto the mounting axis, as well as the rod bolt, which is attached to the car body. For work it is convenient to use a spanner wrench or a socket with a wrench.

Similar work is done on the right side of the car. An additional support is also installed under the car body and the silent block fasteners and the upper link bolt are also pulled through.

Before tightening the silent block fastening nuts, we first treat the connection with a VD40 rust converter or a similar compound.

Along the way, I turned my attention to the front pillar, where you can see small drips, not even drips, but fogging, but this is not critical and you can use the car for now. The racks hold up well and do not allow impacts on speed bumps.

On the opposite side of the machine, one nut also had some slack and was tightened. So, for the purpose of prevention, I recommend tightening the nuts securing the levers and the tie rod bolts to the car body when knocking noises appear.

This concludes writing this article. Loganovod leave comments, like and ask questions.

Causes of extraneous noise and knocking

There can be plenty of reasons for extraneous noise and knocking in the front suspension. When parts wear out, the brakes, steering system, and engine can rattle. However, the greatest amount of noise in the presence of defects occurs in the suspension and shock-absorbing units; read more about the Renault Logan front suspension design here.

In order to carry out an independent inspection, and, if necessary, repairs, you will need a lift or inspection hole.

Support stand

For comparison: old and new support strut on Logan

Before you begin inspecting the suspension under the car, first assess the condition of the front strut supports. To do this, you need to open the hood and evaluate the gap on the spring stop cup.

If the gap exceeds 1 cm or it differs relative to the opposite side, this indicates that the supports have sagged and they do not absorb impacts on small bumps, therefore, they need to be replaced.

Shock absorber struts

The presence of a dull knock in parts of the front suspension may indicate defects in one of the shock absorber struts. The easiest way to diagnose is to alternately rock the car on the left and right sides. If there are working shock absorbers, the car will smoothly return to its original position, already on the first or second free play.

The presence of smudges and unsatisfactory condition of the bumpers will also indicate that the rack should be replaced.

Anti-roll bar link

This chassis element is checked when the vehicle is under load. By rocking the car, you should pay attention to the movement of the cup relative to the lever itself. If this element malfunctions, it will jump and make a characteristic knock, which in turn, undoubtedly, is observed when driving on an uneven road.

Inspection and replacement of the stabilizer bar link

The same goes for the anti-roll bar bushings. When they wear out, play and free movement will be felt in the places of contact with the rod itself. Diagnostics and replacement of stabilizer bushings can be carried out both on the ground and with the car suspended.

Unpopular reasons for knocking

It would be a good idea to check the anti-roll bar bracket. This part consists of bushings based on metal and rubber, which are turned in different directions and connected by a thin isthmus. Most often it is he who breaks down. On rough roads, on small bumps and on turns, you can hear a knocking sound.

For a correct diagnosis, you need to pull the end of the stabilizer with one hand. This will work better if the wheels are turned to the right.

It happens that the motor mounts wear out. The engine moves actively at increasing speeds and on uneven surfaces. At certain moments, he reaches the body with the generator and oil pan. The result is a knock. This source of knocking is rarely guessed at. Many people change the suspension, but replacing the front suspension does nothing in this case.

Additional noise sources

Let's consider additional sources of extraneous noise!

Steering rack

Failure of the steering rack (especially on the left side) is not a rare occurrence for Renault Logan.

The price for a new steering rack for Renault Logan is very steep

It is necessary to check the serviceability of this element by rocking the lever itself. When it is faulty, a slight play will be felt.

Engine mount

In order to find out the condition of the engine mount, you just need to visually look at it; with a high degree of wear, tears will be visible.

On the left is the old mount, on the right is the new engine mount. The service life of rubber seals is about 100,000 km

In order to conduct such a full, detailed inspection and find a fault on the Renault Logan front suspension, it may require a lot of effort and time. However, when the problem is found and solved, noise when driving on any, even the worst roads, will no longer bother and cause a lot of discomfort to its owner.

Remember that timely repair of even small faults guarantees the durability of the entire suspension as a whole.

Knocking in the suspension: causes and troubleshooting

The greatest loads when moving over uneven surfaces are taken by the suspension and steering elements. For heavy SUVs, this is of particular importance: both the solid mass of the vehicle itself and frequent off-road driving have an impact. Off-road means not only impacts, but also a much larger amount of dust and dirt compared to asphalt roads. That is why, in standard and even more so in tuning suspension units, special attention is paid to the strength and reliability of seals. Pay attention to the Tough Dog off-road shock absorbers: a rod dirt collector and an effective oil seal, created for Australian dust, work great in Russia too.

Dust and dirt inherently work as an abrasive: once inside the hinge, they accelerate its wear several times over, which leads to an increase in gaps. As a result, characteristic knocking sounds begin to be heard in the suspension when driving over uneven surfaces. Impact loads further accelerate wear, so knocking in the suspension is a direct indication for immediate repair, and any detected play must be eliminated even before extraneous sounds are heard.

Checking the rack supports

The task of the strut supports is to connect their rod to the body, providing it with the necessary freedom of movement. The fact is that when the suspension moves, the shock absorber or strut changes not only its length due to the stroke of the rod, but also its position relative to the vertical axis. If the rod is fixed rigidly, it will begin to bend, quickly wearing out the shock absorber seals.

For SUVs, where even stock suspensions have more travel than conventional passenger cars, this operating feature is of particular importance. If it is lifted, then both the angle of installation of the rod and the amplitude of its oscillations in the vertical plane may change. The causes of suspension knocks due to wear of the supports begin to come out noticeably faster. Therefore, when modifying the suspension, installing tuning supports is used very often: pay attention to the parts from SteelStaff.

Increasing loads accelerate the wear of the support - its rubber element, which connects the rod mounting sleeve with the outer race, begins to crack and lose elasticity. When crossing obstacles, this immediately makes itself felt with characteristic dull knocks in the suspension. The reason for this is the damping properties of rubber.

It is not difficult to determine excessive wear of the support: while rocking the car, you need to keep an eye on the rod securing nut. When moving, it will begin to oscillate both vertically and horizontally, clearly indicating excessive freedom of the inner frame of the support. If you put your hand on the clip, then in addition to the knocks of the suspension, simultaneous blows to the palm will be felt.

Rack diagnostic methods

There are a lot of methods. The classic one is to swing the body down, and it should smoothly rise to its normal position and stop. If everything is so, then the rack is working.

It happens, although quite rarely, that the strut makes extraneous sounds due to its internal problems, for example, the nut that holds the piston has become unscrewed. However, this does not cause knocking. When driving, the car sways and controllability decreases. In this case, replace the strut and repair the suspension.

Various shock absorber breakdowns are the consequences of its improper use. The oil in these systems must have a special specific viscosity, which also depends on the air temperature. Having warmed up the engine, the driver immediately takes off, but the oil in the rack has not warmed up. If it’s frosty outside, then the viscosity in the stand is too high. In this case, thin and very fragile parts fail.

Thick oil may also not be related to the weather. Sometimes excessively thick liquid is poured into shock absorbers. This is done to increase the resistance force and so that the oil does not “run away”. But as a result, stability and controllability deteriorate, because hard does not mean good.

Steering check

The steering elements perceive not only the forces from the vertical movements of the wheel, but also their lateral component. When crossing a track or constantly steering, the load on the hinges is especially strong.

The knock in the suspension is noticeably louder and harsher. In addition, it already manifests itself when driving over small irregularities: the wheels, which have gained a certain freedom due to the increase in play, begin to walk from side to side on an uneven road, constantly choosing steering play in opposite directions. The causes of suspension knocks in this case are worn-out hinges of the steering tips and rods, which directly perceive the vibrations of the steering knuckles. Due to the relatively small areas of contact between the balls and the races inside these joints, their wear progresses quite quickly, which becomes the reason for the constant replacement of cheap consumables. Tuning parts are further strengthened: just put the “native” steering rod and a part from companies like SteelStaff next to each other to see the difference.

Checking the support bearing

Both shock loads and dirt are equally harmful to support bearings. The increase in gaps in them reveals itself not only as a clearly localized knock on bumps in the front suspension on the right or left side, but also as a certain deterioration in handling. Reactions to the steering wheel are dulled, and with a noticeable dependence on which direction the steering wheel is turning in relation to the faulty bearing. The front wheel on the side of the worn unit additionally “breaks” in the vertical plane, changing its camber angle.

To determine if the support bearing is faulty, the car must be rocked in the transverse direction, keeping your palm on the support. In this case, excessive movements of the strut rod will look the same as when the support itself is worn out, but the knocking will be much sharper, and the impacts will clearly be felt in the palm.

How to check silent blocks?

A flat mount will be required for diagnosis. This will allow you to determine how badly these parts are worn. Using the mount, the lever will move in the longitudinal and transverse directions. If there is play or damage, then the front suspension silent blocks are to blame for the knocking.

Sometimes the levers can be collapsible. Then you can replace it with a silent block. To do this, the lever is dismantled, and then, using a special mandrel, the part is squeezed out. It is advisable to lubricate the new silent block before installation. The seating surface must also be cleaned. After installation, the knocking should stop.

Checking ball joints

The ball joints of the levers take on very heavy loads, and their destruction often leads to the vehicle becoming untransportable. When a pin flies out of the body or the ball self-presses out of the lever, the chassis simply folds and the wheel loses its rigid connection with the body. For primitive McPherson-type designs, where the steering knuckle is held only by the lower ball and upper strut support, this is especially dangerous. In multi-link systems, shock loads are distributed over a larger number of elements, but this does not mean that the condition of the ball joints and every small knock in the suspension requires less attention.

With increasing play in the ball joints, the knock of the suspension on bumps is quite harsh, and is not clearly localized vertically by the ear. The simplest but most obvious method of control is to sharply rock the suspended front wheel in a vertical plane, while the force from the steering knuckle will first select play in the ball joints and only then be transmitted to the levers.

Checking the chassis and transmission

We check the condition of the chassis and transmission every 15 thousand kilometers. The parts of the chassis (wheels, suspension arms, anti-roll bar, front suspension subframe, rear suspension beam, shock absorbers and suspension springs) and transmission (front wheel drive shafts) must be free of deformations, cracks and other mechanical damage affecting the shape and strength of parts. Alternately hanging the front and rear wheels (while the car must be securely fixed on stands), we check the condition of the wheel hub bearings.

Use only factory-made stands. The wheel should rotate evenly by hand, without jamming or knocking.

Holding the wheel in a vertical plane, we alternately sharply pull the upper part of the wheel toward ourselves, and the lower part away from us, and vice versa. We make sure there is no play (knock). If there is a knock on the front wheel, ask an assistant to press the brake pedal. If the knocking noise disappears, then the wheel bearing is faulty, and if the knocking noise remains, then the ball joint is most likely worn out. The hub bearings of the front and rear wheels are not adjustable and must be replaced if there is play. To check the serviceability of the ball joint, insert a mounting blade between the steering knuckle eye (which includes the ball joint pin) and the suspension arm.

By pressing the lever away from the steering knuckle with a mounting blade, we monitor the movement of the ball joint housing relative to the steering knuckle eye. If there is play in the connection, replace the ball joint.

We check the condition of the protective covers of the front suspension ball joints. We replace ball joints with torn or cracked covers. To check the silent block of the front suspension arm...

... we alternately insert the mounting blade between the subframe and the end of the outer bushing of the silent block (on one side) and the subframe and the lever head (on the other side of the silent block) ... ... and try to move the lever head along the axis of the bolt, first into one, and then into the other side. If the lever head moves freely, without effort, it means that the silent block of the lever is badly worn or damaged and needs to be replaced. Ruptures, cracking and swelling of the rubber bushing of the silent block are unacceptable. Similarly, we check the condition of the other silent block of the lever.

Checking the racks

A telescopic strut, unlike a shock absorber, is also a guiding element for wheel movement - it’s not for nothing that the rods on them have a noticeably larger diameter. An increase in lateral loads requires an increase in the rigidity of the upper part of the strut cup, where the seals and rod guide bushing are located.

A characteristic sign of wear is not only a knock in the front suspension on small bumps, but also oil leakage from under the rod. Since its seals are designed exclusively for its vertical movements, as soon as it begins to oscillate relative to the vertical at the worn front strut, the oil is no longer retained inside. Each compression of the suspension is accompanied not only by an impact, but also by the release of some oil outward. Because of this, the strut loses its ability to dampen vibrations. The car begins to “float” more and more noticeably, rolls in turns increase, and the car falls towards the worn-out strut. The thud of the suspension becomes harder and louder.

Checking the stabilizer and its struts

The anti-roll bar is essentially a torsion bar that twists each time the spring is compressed on only one side. Simply put, when the car body begins to fall inward during a turn, the stabilizer simultaneously counteracts compression on the inside of the turn and additionally presses the wheel on the outside to the ground, preventing the car from falling over and hanging out the wheels. In this case, the cause of suspension knocks is excessive freedom of the stabilizer - it gains vertical freedom of movement and hits the mountings instead of twisting.

So that the stabilizer can twist, it is connected to the body loosely, through cushions, and to the levers or steering knuckles - through double hinges (stabilizer struts, “bones”).

The sounds also differ noticeably when different components wear out: when the cushions wear out, the knocking in the suspension when driving over uneven surfaces is dull, heard primarily on large bumps, and is heard clearly from the bottom. The stabilizer struts make themselves felt already on small bumps, the knock of the suspension on bumps is harsher, and it is more difficult to distinguish it by ear from the knock of the steering tips. However, manually rocking the stabilizer struts immediately reveals play in them; the stabilizer itself (both front and rear) is more convenient to move with a mount if deep cracks in the pads are not immediately visible.

Installation of wheels with a larger radius

Largus comes standard with 15R wheels. Many motorists choose the 16 or 17 radius option instead of the one proposed by the factory. Additionally, this makes the car's exterior more attractive. However, this option also has a significant drawback, namely the unstable position of the car when driving, as well as malfunctions in the ABS system and some related sensors.

Installation of spacers

The most budget option (and popular) is to install special spacers, which are sold at any auto parts store. The only thing that is required from the car owner is the removal of the suspension struts. The parts themselves are unified and suitable for many VAZ cars. Spacers are installed between the rack and the body bowls (as an option - between the beam and the rack).

Replacing strut parts

One of the best methods for increasing ground clearance is to install stiffer springs and longer shock absorbers. As a rule, such racks are approximately 20 mm longer than standard devices. In combination with reinforced springs, they are able to significantly increase ground clearance, and the car does not sag all the way when transporting the maximum permissible weight of cargo. The only drawback is the higher price of such kits.

Repairing the suspension yourself and increasing the ground clearance on the Lada Largus is easy to do if you have at least minimal car repair skills. If you have never done this before, it is still recommended to carefully study the instructions. And if you are unsure of your own abilities, it is better to turn to qualified car service specialists.

| metallic knock; | when driving over uneven surfaces; |

| big roll; | when passing sharp turns; |

| the body sways strongly; | during sudden braking. |