The mass air flow sensor is a special sensor that monitors the mass air flow of the power plant. Where is this control device located? In the fuel system of the engine, or rather, directly in the intake tract. Experts call it the most important element that ensures proper fuel injection into the engine. This sensor, like any other component, can fail.

This article describes how the mass air flow sensor operates on the VAZ-2115 and the possible problems that arise when it fails. We will also tell you about ways to eliminate them.

Why do you need a mass air flow sensor?

This monitoring device is designed to determine the volume of air entering the combustion chambers of the power unit. As you know, without this the engine, in principle, will not be able to work. The manufacturer installed it near the air filter.

During operation, the engine receives 1 part gasoline and 14 parts air. As a result, the most optimal mixture is formed, allowing the power plant to operate as efficiently as possible.

If this proportion is not respected for one reason or another, the following begins to happen:

- excessive gasoline consumption;

- power drop.

Therefore, correct air mass flow is one of the basic conditions for the proper functioning of the vehicle. This parameter is calculated in the ECU based on the MAF readings.

Depending on how hard the driver of the car presses on the accelerator, the air is supplied more intensely. For its part, the mass air flow sensor measures its incoming volumes, and the data is sent to the on-board computer. The latter regulates the flow of gasoline accordingly.

We learn how to check and clean the mass air flow sensor on a VAZ 2114

To ensure more efficient and stable operation of any modern engine, many different devices are used. One of these is the mass air flow sensor (MAF), in particular, we will talk about VAZ 2114 cars. Read more about the functions, malfunctions, diagnostics and cleaning of the controller below.

Functions of mass air flow sensor

What is the VAZ 2114 mass air flow sensor and what functions does it perform? The primary task of the regulator is to create arrogance from air and fuel vapors.

The regulator can measure two interconnected parameters, namely:

- reaction time;

- volume of air used.

In accordance with the information received, the correction device determines the required volume of components to create the mixture. If incorrect data is provided, the mixture will not be able to correspond to the operating mode of the power unit; accordingly, its power may decrease and fuel consumption may increase.

Operating principle of the air flow sensor

The sensor is based on a platinum wire only 70 micrometers thick. It is hidden in a special tube located in front of the throttle valve. When air hits it, the wire cools. To restore normal temperature, a certain charge of electricity passes through it, according to the size of its ECU, and finds out exactly how much fuel the engine needs at the moment.

Due to the fact that air comes directly from the atmosphere, dirt regularly settles on the wire. It is this that, for the most part, contributes to the fact that the sensor becomes unusable. The latest models of mass air flow sensors, however, have an automatic cleaning system.

A significant drawback of the described design is its inability to repair. As a result, sooner or later, the expense of money becomes inevitable.

Price

We remind you that this sensor is the most expensive of all sensors, its cost ranges from 1500 to 4000 depending on the model.

The mass air flow sensor is a special sensor that monitors the mass air flow of the power plant. Where is this control device located? In the fuel system of the engine, or rather, directly in the intake tract. Experts call it the most important element that ensures proper fuel injection into the engine. This sensor, like any other component, can fail.

This article describes how the mass air flow sensor operates on the VAZ-2115 and the possible problems that arise when it fails. We will also tell you about ways to eliminate them.

DMRV failure - how to identify

If this control element fails, a lamp lights up on the dashboard, signaling the need to check the car’s power plant.

The main signs of failure of the mass air flow sensor:

- power is lost;

- the speed also drops;

- a lot of fuel is consumed;

- the engine starts poorly.

There are several ways to determine the performance of the mass air flow sensor:

- by turning off;

- multimeter;

- upon inspection.

In the first case, replacing the sensor is not difficult. Just disconnect the connector (pinout is not required here) and turn on the engine. The ECU must go into emergency mode. In this case, the supply of the combustible mixture is regulated only by the throttle valve. At the same time, at idle, the power unit produces 1.5 thousand revolutions. Next, you will need to drive a certain distance. If the car accelerates faster than usual, we can confidently say that the mass air flow sensor has broken down.

It is also worth pointing out that the multimeter is useful only if the car is equipped with a sensor manufactured by.

The check goes like this:

- The scale on the tester is set to 2 volts of DC voltage;

- the red probe is attached to the yellow wire, the black one to the green;

- turn on the ignition.

If the readings are within:

- 1.02 volts - then the sensor is working;

- 1.03 – acceptable value;

- 1.05 is the limit.

In cases where the measured voltage is higher, a breakdown should be considered. In order to determine from the appearance of the control device whether it is working, you will need to carefully examine the tubes leading to it from the inside. They are easy to dismantle using a Phillips screwdriver. First of all, unscrew the clamp securing the corrugated sleeve. The surface of this tube must be clean, without oily films.

The presence of dirt inside the sensor is a clear sign of its malfunction. As a rule, the problem occurs when the car owner forgets to change the air filter on time.

Oil leaks are usually evidence of excess lubricant in the system or improper operation of the shut-off valve. Such contamination significantly reduces the service life of the mass air flow sensor.

Then it is necessary to dismantle the sensor itself. To do this, you need to use a 10mm socket wrench. After the control device is removed from the filter, it will need to be inspected. In a situation where the rubber gasket of the sensor remains in place, then we can speak with almost one hundred percent certainty about a breakdown of the mass air flow sensor.

Idle speed control

A sensor that keeps the engine idling. It is a DC motor with a worm gear; there is a metal wedge on the shaft, which, if necessary, opens or closes the air channels of the throttle assembly. Installed on the throttle valve, secured with two screws to the body. Quite often it fails due to contamination of the shaft or aging of the sealing ring.

Signs of malfunction:

- Uneven idle speed;

- Long start of the internal combustion engine;

- Spontaneous engine stop;

Cleaning the air flow sensor

As noted earlier, the mass air flow sensor cannot be repaired. But some craftsmen manage to clean it, thus extending the service life of the monitoring device in question. Moreover, some claim that they have done this more than once.

In reality, it is worth recognizing that the chance of repair is quite low. However, if you take into account that the cost of a new sensor is quite high, and an attempt to revive the old one generally requires nothing but time, then you should try.

To clean the air flow sensor you will need:

- composition for cleaning carburetors;

- soft brush;

- Phillips screwdriver.

The sensor is disassembled and the inside of the tube and the platinum wire itself are carefully cleaned. Next, all parts must be left to dry. During this time, remove the throttle entirely and also clean it of any plaque inside. Do not remove the cable from the gas pedal. The assembly is placed on a clean rag and washed with carburetor fluid. You will also need to clean the idle speed regulator and the surrounding area from dirt. If you manage not to damage the wire in the mass air flow sensor, then eventually the problem will become less acute for some time. It is important that the sensor is not damaged mechanically.

Finally, it is worth noting that to increase the service life of the sensor, first of all, it is necessary to replace the air filter on time.

Fuel level sensor

Indicates the remaining amount of fuel in the tank. Installed directly in the tank on the fuel pump glass. It fails when the graphite contacts on the electrical board are rubbed. When replacing, you should pay attention to its type number, which is indicated on the board, since all types of FLS have different resistance. If an unsuitable sensor is installed, large errors in readings may occur.

Signs of malfunction:

- Incorrect readings about the presence of fuel in the tank;

What does a faulty air flow sensor cause?

Operating an engine with an inoperative/faulty flow meter causes detonation of the fuel mixture in the combustion chamber. This affects the operation of the crank mechanism (crank mechanism) and destroys the piston surface, which can cause a “wedge” in the engine.

What indications should a working mass air flow sensor give?

The voltage of the analog-to-digital converter (ADC) of the flow meter when the engine is not running should be 0.996 V. Indicators of 1.016 and 1.025 V are acceptable, but if they reach more than 1.035 volts, it means that the sensing element of the mass air flow sensor is clogged.

IT IS IMPORTANT TO KNOW . To accurately determine the degree of deviation of the operating flow meter values from normal values, it is necessary to evaluate the engine operation at different speeds.

For example, for an injection 1.5-liter VAZ 2111 engine, if it is in good condition, at idle (860–920 rpm) the correct readings are 9.5–10 kg/hour, and at 2 thousand rpm - 19 –21 kg/hour. If the flow meter at 2 thousand rpm shows about 17–18 kg, then the car will drive stably. If the values are from 22 to 24 kg/hour, then the vehicle will move steadily, but the fuel consumption per 100 km will be approximately 10–11 liters. In addition, the car will have difficulty starting in cold weather due to fuel overflow when the engine warms up.

Principle of operation

The principle of operation of the air flow sensor on a VAZ consists of two parameters:

- Amount of air consumed.

- Reaction time.

Different controllers react differently to these parameters, for example, If the sensor slightly overestimates or underestimates its readings, then the January -5.1 controller, due to the oxygen sensor, detects the error in the readings of 1 mass air flow sensor and adjusts the injection duration. But if the Sensor has a long reaction time, then the controller will not cope with the adjustment, and you will feel failures at the time of acceleration. The Bosch MP7.0 controller reacts more sensitively to this error, which leads to unstable idle speed, but failures during acceleration will be less noticeable than on January -5.1.

Symptoms of a problem

The mass air flow sensor is located in the air duct near the air filter. It is designed to determine the amount of incoming air. Depending on its readings, the control unit will show how much fuel is needed to form a high-quality fuel mixture. The normal ratio is 1:14. Therefore, the quality of the fuel-air mixture depends on the correct readings of the flow meter.

The high-quality operation of the mass air flow sensor depends largely on the cleanliness of the air filter. Therefore, if symptoms of a malfunction of the mass air flow sensor appear, you should first check the air filter before making repairs. The flow meter is usually beyond repair. If it is faulty, it is replaced with a new device. But its cost is quite high, so you should first make sure that the causes of the problems are in the sensor and not in other malfunctions of the machine.

The signal for diagnosis is the following symptoms of a malfunction of the mass air flow sensor:

- Check Engine appears on the instrument panel;

- an error is displayed indicating a low level of the mass air flow sensor signal;

- the engine is bad, accelerates very slowly, stalls, its power drops;

- high level of fuel consumption;

- the engine is unstable at idle;

- the engine stalls when changing gears;

- The rpms are either high or low.

There are other symptoms of a “dying” sensor. For example, it may have cracks in the corrugated hose that connects the throttle body to the sensor. If the engine stalls, there may be a power problem or damaged wiring. This is a signal to check the electrical wiring. If malfunctions are detected, the machine's electrical system must be repaired.

In addition to the above possible signs of failure of the mass air flow sensor, you should diagnose the sensor signal level.

A low signal level may mean the following:

- Mass air flow sensor is not connected;

Disconnected sensor connector

- open circuit in the sensor connection circuit;

- the mass in the chain breaks, oxidation appears;

- signal wires are broken or incorrectly connected;

- Engine control unit malfunction.

You should not draw conclusions about a malfunction of the mass air flow sensor, relying only on the symptoms listed above. A complete diagnosis of the engine and machine should be carried out, since signs of a flow meter failure may appear if other devices malfunction (for example, due to a clogged air filter). Then you need to repair these devices to restore the car's functionality.

DMRV error code

The following errors may indicate a malfunction in the operation of the mass air flow sensor:

- P0100 - damage to the electrical circuit connecting the sensor. To eliminate the breakdown, you need to check the wiring for integrity, since accidental disconnection of the connector or damage to the electrical contacts is possible.

- P0102 - the vehicle control unit began to receive a low signal, which was recorded at the input of the mass air flow sensor power line. To eliminate the cause of the breakdown, it is necessary to check the electrical wiring and the insulating layer of the cable; oxidation of the contacts of the wiring connector (the so-called chips) is possible.

- P0103 - critically high signal detected at the input of the mass air flow sensor power line. If the cause of the malfunction is not the wiring, then a visual inspection and cleaning of the flow meter will be required or it will have to be replaced with a new one.

Mass air flow sensor (MAF) for Kalina E-GAS

- Manufacturer: ITELMA

- 0 reviews

- Description

- Characteristics

- Video

- Reviews 0 ? '(' + product.reviewsCount +')' : »>>

Dear customers, in order to avoid errors when sending a mass air flow sensor (MAF), indicate your car model, year of manufacture and number of valves in the “Comment” line.

The mass air flow sensor (MAF) VAZ 1118 is a hot-wire anemometer type.

Structurally, this type of sensor has a sensitive element, a thin mesh (membrane) based on silicon, which is installed in the intake air flow. The grid contains a heating resistor and two temperature sensors, which are installed before and after the heating resistor.

The accelerator pedal position is transmitted to the engine control unit via two accelerator pedal position sensors (variable resistors), which are connected to the accelerator pedal.

The position of the accelerator pedal (depending on the driver's actions) is the main input variable for the engine control unit.

The throttle valve is driven by an electric motor (throttle servomotor) in the throttle valve control module, namely over the entire speed and load range.

The throttle valve is actuated by a servo drive based on signals from the engine control unit. With the engine off and the ignition on, the engine control unit controls the throttle servomotor, exactly matching the data from the accelerator pedal position sensor. This means that when the accelerator pedal is depressed halfway, the servo opens the throttle valve equally; in this case, the throttle valve will also be open approximately halfway.

When the engine is running (under load), the engine control unit can open and close the throttle valve, independent of the accelerator pedal position sensor.

For example, the throttle valve may already be fully open, although the accelerator pedal is only depressed halfway.

The advantage of this scheme is that throttling losses at the throttle valve are prevented.

In addition, at certain loads there are noticeably better emissions and fuel consumption figures.

The engine control unit, analyzing the required torque for various components (e.g. air conditioning, automatic transmission, ABS/ESP..), calculates the optimal throttle opening angle for a given situation.

The mass air flow sensor is installed between the air filter and the throttle pipe.

Other article numbers of the product and its analogues in catalogues: 1118011300100.

Product features: Mass air flow sensor (designation according to the catalog of NPP "ITELMA" 1118-1130010), designed to convert the air flow entering the engine, the signal output is frequency. The sensor information allows you to determine the engine operating mode and calculate the cyclic filling of the cylinders with air at steady engine operating conditions, the duration of which exceeds 0.1 seconds.

VAZ 1117-1119, VAZ 2113-2115, VAZ 2170-2172; VAZ 2190.

How to identify a problem with the VAZ 1118 mass air flow sensor (E - GAS)?

How to replace the VAZ 1118 mass air flow sensor (E - GAS) yourself?

With the online store Discounter AvtoAzbuka, repair costs will be minimal.

Just COMPARE and BE SURE.

Don't forget to share the information you find with your friends and acquaintances, as they may also need it - just click one of the social networking buttons below.

Checking and repairing at home

There are eight ways to independently check amplitude and frequency mass flow sensors.

Method No. 1 - disabling the air flow meter

The method consists of disconnecting the sensor from the fuel system of the car and checking the functionality of the system without it. To do this, you need to disconnect the device from the connector and start the engine. Without a mass air flow sensor, the controller receives a signal to switch to emergency operation mode. It prepares the air-fuel mixture only based on the throttle position. If the car moves faster and does not stall, it means that the device is faulty and requires repair or replacement.

Method No. 2 - flashing the electronic control unit

If the standard firmware has been changed, then it is unknown what reaction of the controller is programmed in it in case of an emergency. In this case, you should try to insert a 1mm thick plate under the throttle stop. The turnover should increase. Now you need to pull out the chip from the air flow meter. If the power unit continues to work, then the cause of the malfunction is the firmware.

Method No. 3 - installing a working sensor

Install a known good part and start the engine. If after replacement it begins to work better, the motor does not stall, then replacement or repair of the device is required.

Method No. 4 - visual inspection

To do this, use a Phillips screwdriver to unscrew the clamp holding the air collector corrugation. Then you need to disconnect the corrugation and inspect the internal surfaces of the air collector corrugation and the sensor.

Inspection of duct corrugation

There should be no traces of oil or condensation on them, the surfaces should be dry and clean. If you do not take care of the air filter and change it rarely, then dirt can get on the sensitive element of the sensor and cause it to break. This is the most common malfunction. Traces of oil may appear in the flow meter if the oil level in the crankcase is high, or if the oil sump of the crankcase ventilation system is clogged. If necessary, you need to clean the surfaces using special cleaning products.

Method No. 5 - checking the mass air flow sensor with a multimeter

To do this, you need to turn on the tester in a mode in which constant voltage is checked. The limit value for measurements should be set to 2V.

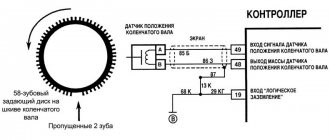

DMRV operation diagram

Sensor pinout:

- The yellow wire is located closer to the windshield. It serves as an input for a signal from the flow meter.

- The white-gray wire is the sensor voltage output.

- The black and pink wire leads to the main relay.

- The green wire is used to ground the sensors, that is, it goes to ground.

The wires may have different colors, but their location is unchanged. To check, you need to turn on the ignition, but do not start the car. The red probe from the multimeter must be connected to the yellow wire, and the black one must be connected to ground, that is, to the green wire. We measure the voltage between these two outputs. Multimeter probes make it possible to connect without disturbing the insulation of the wires.

On the new device, the output voltage ranges from 0.996 to 1.01 V.

During operation, this voltage gradually increases and by its value one can judge the wear of the flow meter:

- if the sensor is in good condition, the voltage is from 1.01 to 1.02 V;

- in satisfactory condition - from 1.02 to 1.03 V;

- the sensor resource ends if the voltage is in the range from 1.03 to 1.04 V;

- a value in the range from 1.04 to 1.05 indicates a near-death state; if there are no contraindications, then you can continue to use the sensor;

- if the voltage exceeds 1.05 V, the mass air flow sensor requires replacement.

ADC flow meter readings

Diagnostics of the mass air flow sensor "Tseshkoy" is not difficult and can be done with your own hands.

If there is dirt on the removed sensor, you can clean it yourself. You can use WD-40 to wash it. To clean the mass air flow sensor, you must first remove the pipe from it, and then dismantle the device itself. Inside the device there is a mesh and several wires - sensors.

They need to be sprayed with cleaning agent and washed. Then let the liquid dry. If dirt remains, the procedure should be repeated. You need to clean the pipe with the same product. It must be free of dirt and oil stains. After replacing the air filter, all parts must be returned to their place. After the cleaning procedure, the functionality of the device can be restored to 80%, the error about the reduced sensor signal level disappears (the author of the video is “24 hours”).

Flushing the sensor will help avoid costly repairs.

Method number 6 - checking with a scanner

Test method:

- Install a diagnostic program on your phone (smartphone), tablet or laptop computer (for example, Torque Pro, Opendiag, BMWhat, OBD Auto Doctor).

- Connect your mobile device or laptop to the diagnostic connector located on the vehicle's electronic control unit using a special cable, Bluetooth channel.

- Launch the diagnostic utility on your phone (smartphone) or computer.

- Wait until the program finishes scanning all vehicle components. As a result, the utility will check the serviceability of each vehicle unit.

- Decipher the error codes that the program will show after the diagnostics are completed.

To perform this method, testers are used:

- K-Line 409/1;

- Scanmatic;

- ELM (ELM) 327;

- OP-COM.

Method No. 7 - checking by Vasya the Diagnosticist

To identify a malfunction of the mass air flow sensor without removing it from the car, you need to:

- Install a program called “VASYA diagnostician” on your laptop (laptop) and run it.

- Connect the adapter to the vehicle's diagnostic port.

- Select the item “Electronics 1” or “01 – Engine electronics” from the “Control unit” tabs to connect to the vehicle’s control unit.

- Go to “Custom Groups”.

- Select 211, 212 (passport value) and 213 (current value).

- Compare current indicators with passport data. If the deviations are high, then it is necessary to replace the mass air flow sensor.

Method No. 8 - using a motor tester

GOOD TO KNOW

This method is used to test frequency-type flowmeters.

To check the mass air flow sensor with a motor tester (oscilloscope), you need to connect it to the sensor (depending on the car brand) and start the engine.

Mass air flow sensor check parameters:

- transient time when the ignition is on;

- air consumption readings at idle and a sharp increase in engine speed;

- voltage in the sensor network.

IT IS IMPORTANT TO KNOW

The output data is individual for different types of engines. Before diagnosis, you should check the current indications with an official representative.