What is caster angle

Correct adjustment of headlights on a Lada Granta

Caster angle, or simply caster, is the deviation of the wheel's turning axis from the vertical. The need for its existence is due to the desire to obtain a self-centering steering system. This parameter affects the car's steering ability in various conditions:

- during acceleration;

- braking;

- coasting.

The higher the caster angle, the better the wheels are centered, but this also reduces the vehicle's steering ability, increases the turning radius, and reduces traction on uneven or slippery roads. As it decreases (the less the wheel's turning axis deviates from the vertical), the grip of the front wheels with the surface improves, but a phenomenon called oversteer occurs.

When tuning a racing car's suspension, engineers base it on the road conditions the race will be in. If the track is uneven, slow, with a lot of hairpins, the angle is reduced, but if you have to drive on a high-speed track with an even surface, the angle is increased.

Caster - what is it?

In technical language, the definition of caster is “the angle of the steering axis of the wheel to the longitudinal section of the car.” On most modern cars, this parameter is inherent only to the front controlled pair. It is determined by the inclination of the stabilizer link relative to the vertical.

Setting up castor

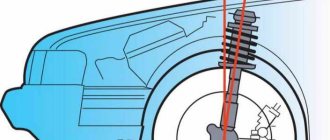

You can see the caster angle by removing the wheel. In this position, you can see that the shock absorber is not located strictly vertically, but at a slight deviation. The term is more clearly presented on two-wheeled vehicles - motorcycles, bicycles. The angle of the fork clearly displays the caster.

What does it affect?

How to remove the rear wheel hub with your own hands? how to change the front and rear wheel bearings with your own hands how to disassemble the rear wheel hub

Like other wheel alignment adjustments, caster angle is responsible for the car's handling. Namely, the level of self-alignment of wheels when turning depends on its value. The higher the value, the faster the steering response, but more effort is required.

A knocked down castor is the reason the car pulls to the side

That is why the value can only be adjusted on sports cars. The settings are especially relevant for drifting, where it is necessary to quickly change the angle of movement of the car when moving from one turn to another in a skid. Therefore, for adjustment, the upper fastener of the stabilizer link is carried out on special supports with a movable mechanism.

What is castor on a car?

On Wikipedia, caster is defined as Caster angle, the angle of the wheels in the longitudinal direction. Sometimes it is also called "castor". To be fair, it should be noted that Word underlines the word “caster” in red, but castor does not. The caster of a car wheel is determined by the angle of inclination from the vertical axis to the line connecting the upper and lower suspension points of the car wheel. The figure shows the main angular characteristics of the wheel suspension.

Why do they use positive caster in a car, and not negative caster as in airplanes? At first, airplanes also used a positive angle, but as speeds increased, a rattling effect began to appear and they switched to a negative angle. In addition to handling, positive caster in a car adds a few centimeters to the length of the wheelbase, and this contributes to greater longitudinal stability.

Video - what does wheel caster affect:

Who and how determines the caster angle of a car's wheels?

Grant fret wheel size

The Caster angle of the wheels is calculated at the vehicle design stage. In this case, many technical parameters of the vehicle are taken into account:

- maximum curb weight;

- drive arrangement (front, rear, all-wheel drive);

- maximum and most probable (assumed for specific driving conditions) vehicle speed;

- acceleration and deceleration;

- aerodynamic characteristics.

This list is far from complete, so you can imagine how difficult it is for designers to choose a specific value. It's even more difficult to do this when designing a sports model. It is necessary to take into account the personal characteristics of the driver and the characteristics of each route. That's why there are special adjustable upper strut mounts on the car conversion market.

Professional racing car mechanics adjust the caster of the wheels before each track, taking into account its features:

- elevation changes;

- number of “studs”;

- coating and other specific parameters.

If the track has a large number of turns, hairpins, uneven spots, and does not allow much acceleration, the caster angle is reduced. On a smoother and more predictable track, the angle is increased.

Too much angle can cause the vehicle to become uncontrollable when entering a turn at high speed on slippery road surfaces.

Let's come down to earth and move on to specific examples of domestic cars.

Frequent front suspension malfunctions

Maintenance and repair of the front suspension in Priora involves identifying the exact cause of the breakdown:

- If there is extraneous noise or a distinct thud is heard, the struts may need to be replaced. Check the tightness of the bolts securing the stabilizer hoses, tighten if necessary. If the cushions are worn out, replace them with new ones. If the supports at the top of the suspension strut are loosened to the body, tighten them. Assess the condition of the rubber component of the strut mount, ball joint, spring device, and compression motion buffer. If they are damaged or defective, replace them. Alternatively, check the wheels for imbalance.

- Liquid may leak from the strut, for one reason - the rod seal has worn out and collapsed. This will be indicated by the appearance of burrs on the rod, damage to the chrome surface, and mechanical defects in the sealing ring located on the strut body. Replace the old telescopic stand with a new one.

- If the suspension in the Priora breaks, you will have to replace the spring device and telescopic strut.

- It has become difficult to drive the car, it constantly skids to the side - it’s time to check the air pressure in the tires and normalize it. If the wheel alignment angles leave much to be desired, perform a wheel alignment. It may be necessary to replace the rubber lining in the suspension mounts or springs.

Read more: New fog lights on Priora

Effect of Caster Angle on Handling

The size of the tire contact patch with the road depends on the wheel camber. The purpose of camber adjustment is to achieve maximum contact area. Wheel camber affects mainly the wheels located on the outside of the turn, which bear the main load. The caster angle provides a change in the camber of the wheels during a turn. The wheels lean into the turn and are in better contact with the road, counteracting the buoyant centrifugal force.

The smaller the deviation of the wheel's turning axis from the vertical, the more pronounced the car's steering is; the maximum possible steering is achieved at zero caster angle. This is explained by the fact that when the steering wheel is turned, the wheel turns to a larger angle. At the same time, the suspension works as efficiently as possible, because all the levers move up and down in a vertical plane. The shock absorbers also operate at maximum efficiency, better absorbing road imperfections.

With a small caster, there is a possibility of the car's front axle drifting when accelerating out of a corner. This happens because the center of gravity shifts back during acceleration, the front axle is unloaded, and the wheels grip the road worse. Also, a low caster angle impairs wheel self-centering because the force forcing the wheels to remain straight is reduced.

Large caster threatens to demolish the front axle when coasting or braking at the entrance to a turn, since the wheels deviate less to the side. At the exit of the turn, on the contrary, the understeer improves, because The wheels lean more towards the inside of the turn, increasing the contact patch with the road.

What should the collapse be like?

Ideally aligned wheels (zero camber) are good as long as the car is driving in a straight line and if it has a stiff suspension.

Classic textbooks on automotive engineering say that wheels need to fall apart. They say that the load is redistributed between the outer and inner wheel bearings, the running shoulder is reduced, and wheel displacement is compensated when the axle load increases. The last point has the right to life, because As the axle load increases, the camber angle decreases. And in order for the wheels to still have good traction with the road, they should first be disintegrated.

However. The design of the roadway is critical. If the road is built according to all standards and looks like a convex arc in cross section, it is logical to slightly camber the wheels so that when turning they remain perpendicular to the surface.

Nevertheless, car designers are faced with the task of making cars as controllable as possible and the wheels as grippy as possible. That's why modern automakers "knock off" the wheels a little.

However, it is not advisable to excessively “dump” the wheels (as on racing cars) on a regular car: the contact patch decreases, this makes it unstable when moving in a straight line, it becomes more difficult to accelerate and brake, and the tires wear out heavily on the inside.

Do-it-yourself wheel alignment on a VAZ 2110

You can check and adjust the appropriate angles on the vehicle in the garage or on any flat, flat surface, for example, asphalt. Before starting, you should measure the tire pressure; its value must correspond to the norm:

- For 13 inch tires – 1.9 bar;

- For 14 – 2-2.1 bar.

You need to remove all heavy objects from the car and unload it. To work you will need a basic tool and several auxiliary items.

Equipment

To carry out the work you will need:

- Set of wrenches;

- Short building level;

- Roulette (3-5 m);

- Vernier calipers (can be replaced with a steel ruler);

- Chalk;

- Plumb line with cord;

- A special device is a ruler for checking alignment (you can make a homemade device from two tubes, one of which goes into the other).

To check the toe-in, it is recommended to use a pit (an overpass will also work).

Camber Angle Adjustment

The following numbers appear in the car owner's manual: 0 degrees ±30 minutes.

- With chalk, 2 lines are placed on the surface of the rim - at the top and bottom of the wheel.

- A string with a plumb line, attach (you can use a magnet) to the fender of the vehicle. Now you should measure the interval from the wheel to the lace in the area from the top and then from the bottom mark. The values should differ by no more than ±1 mm.

- Since the geometry of the wheels cannot be absolutely ideal, you should roll the car forward so that the lines (marks) move by 90. Now you should make two additional marks and take measurements again.

- Points 2,3 and 4 will have to be repeated for the second wheel.

- Next, you need to place the vehicle 180° compared to the previous position and repeat the measurements.

- Using a wheel wrench and a car jack, remove one of the wheels. Using a pair of 19mm wrenches, loosen the 2 bolts that hold the shock absorber strut bracket to the steering knuckle.

- Using a 19 key, move the steering knuckle the required distance inward or outward, moving the eccentric of the bolt head. This will allow you to change the camber angle.

- Then you should fasten the counter-bolts, put the wheel back in and rock the car, pressing 3-4 times on the corresponding front fender. Repeat angle measurements.

- Check measurements and make adjustments until an acceptable result is achieved.

On most domestic front-wheel drive cars (including the VAZ 2110), a camber of -1/+1 mm should be installed.

Adjusting the toe angle

Although this parameter is sometimes adjusted using a thread, a more accurate option is to use a special device (ruler). To begin with, we drive the car onto an overpass or pit, and set the steering wheel straight. Next you need to perform the following sequence of actions:

With chalk, draw two lines on the tires - on the inside and next to the rims. Using a ruler, set it so that its tips touch the lines. Other parts of the line should not touch anything other than the wheels. If you are using a factory measuring device, you need to look at the moving scale, align 0 with the pointer, and then fix it. When using a homemade ruler, you will have to perform all manipulations manually - that is, use a tape measure to measure the ruler each time and write down the values. Pull the vehicle forward to move it a few tens of centimeters; the ruler should move (if the ruler was made independently, you just need to take the measurements again). Check the value on the ruler scale. The distance between the wheels on the rear axle and the similar distance between the front wheels are not the same, although they should have equal values. Most likely, it will be necessary to adjust the length of the tie rods, plus or minus (make them longer or shorter). Using a 27mm wrench, loosen the tie rod locking nuts. Using a 24mm wrench, you can change the length of the tie rod (you should turn it exclusively by the clutch). Now you should set the factory scale so that it is possible to adjust the toe to 0, then slightly move the vehicle back. When the readings are -1/+1 millimeters, the installation is considered complete

It is very important to move the vehicle forward again and check the measurements. Particular attention should be paid to the steering wheel. If suddenly it turns out to be shifted to the side, it means that the length of the rods is set incorrectly, and some of them are currently displaced. To correct it, you will have to change the length (for example, increase) one (any) rod by a certain number of revolutions, and change the second (for example, reduce) by the same number of revolutions

If the steering wheel returns to its normal position, the problem is solved.

When to do it

It is recommended to check and adjust angles in the following cases:

- The car has traveled about 10-15 thousand km (for domestic models) or 20-45 thousand (for imported brands).

- The vehicle became difficult to drive, and the tires began to wear out quickly and unevenly.

- The steering wheel does not return to the neutral position on its own after the vehicle is pulled out of a turn.

- After repair work related to the suspension, steering elements and load-bearing parts of the body, namely: replacing the CV joint (constant velocity joint), installing new steering tips and ball joints, replacing the front side members.

- If the vehicle has been in an accident, it is also recommended to check the camber and toe angles.

It should be noted that before starting work on measuring and setting angles, it is necessary to find out:

- Are the steering components in good working order?

- Should the wheel bearings be replaced?

- Are there any problems with the front suspension elements?

You should also definitely balance the discs (if there is any runout).

Computer wheel alignment allows you to most accurately set wheel angles

Castor adjustments

Caster angle is the angle between the steering axis of the wheel and the vertical in a side view. It is considered positive if the axis is tilted backward relative to the direction of movement.

Camber is the inclination of the wheel plane to the perpendicular restored to the plane of the road. If the top of the wheel is tilted outward of the car, then the camber angle is positive, and if it is tilted inward, it is negative.

Toe-in is the angle between the longitudinal axis of the vehicle and the plane passing through the center of the steering wheel tire. Toe is considered positive if the planes of rotation of the wheels intersect in front of the car, and negative if, on the contrary, they intersect somewhere behind.

Below are experiments to understand how wheel adjustments affect the behavior of the car. The Samara VAZ-2114 was chosen for testing - most modern foreign cars do not burden the owner with a range and choice of adjustments. All the parameters there are set by the manufacturer and it is quite difficult to influence them without structural modifications. The new car has an unexpectedly light steering and slurred behavior on the road. The wheel alignment angles are within the tolerance range, with the exception of the longitudinal angle of inclination of the left wheel (caster) axis of rotation. In relation to the front suspension of a domestic front-wheel drive car, setting the angles always begins with adjusting the caster. It is this parameter, on the one hand, that is decisive for the rest, and on the other hand, it has a lesser effect on tire wear and other nuances associated with the rolling of the car. Moreover, this operation is the most labor-intensive - I think that is why they “forget” about it at the factory. Only then, having dealt with the longitudinal angles, does a competent master begin to adjust the camber, and then the toe-in.

How is this implemented in reality?

It’s easier for racing car designers: here the suspensions have high angular rigidity and a short stroke. In this case, the static and dynamic indicators are approximately the same.

But on ordinary cars there are soft, elastic, comfortable suspensions with long travel. And the greater the suspension travel, the more the dives, lateral rolls, and bumps into obstacles are reflected on it and, accordingly, the camber changes.

Therefore, in order to achieve maximum controllability combined with comfort, designers of consumer cars have to conjure up the suspension kinematics.

Convergence

This is the position of the wheels relative to the longitudinal axis of the car when viewed from above. It can also be positive (the front parts of the wheels “look” at each other), negative (the front parts of the wheels tend to move apart) and zero (the wheels are parallel to each other).

Wheel alignment

What is toe-in responsible for?

There is a theory (in quite authoritative sources, too, by the way) that toe-in is needed to compensate for the side effects of camber and keep the wheels in the desired position. They say that broken wheels inevitably tend to roll to the sides, while knocked down wheels tend to fall on top of each other. This theory assumes an unambiguous connection between camber and toe: with negative camber, the wheels should diverge, and with positive camber, they should converge.

The reality is, of course, different.

The camber traction helps keep wheels with negative camber from falling into a heap when moving. There is no point in compensating for it with toe-in. With positive camber, the thrust also tends to increase toe-in - this is due to the design of the controlled suspension.

How is castor calculated?

Angles are calculated during the vehicle design stage. For this, various technical characteristics are taken into account:

- Limit weight.

- Drive type.

- Average and maximum car speeds.

- Acceleration during acceleration and braking.

- Aerodynamics of the vehicle.

All these characteristics are considered in detail by the designers, and on their basis the castor deviation is compiled. The process is labor-intensive, especially for calculations when designing sports models that have unique characteristics.

Auto mechanics working in the sports industry adjust different sizes for each track, taking into account the terrain:

- Height difference.

- Number of studs.

- Road surface and its parameters.

If there are a large number of required maneuvers on the highway, the castor angle is reduced. At calmer distances, castors, on the contrary, increase.

If the castor value is too high, the car may not be able to take turns at high speeds and on wet road surfaces.

How to remove a chip on a car windshield

Curiosity towards technology is characteristic of both motorists with an innate reverent attitude towards the car, and those who do not waste extra rubles, being confident in their abilities. In general, the economics of such an undertaking are tempting: for treatment at a service station they will charge you at least 1,500 rubles, while a very decent glass kit from Done Deal will cost only 400 rubles. Looking at such dissonance, the temptation to do everything with your own hands only increases.

Technologically, chip repair is similar to dental treatment: cleaning, drilling, filling with polymer, drying. You need to be extremely careful with drilling. Generally speaking, at home it is recommended to avoid it, limiting yourself to only cleaning the damage. This operation is included in the checklist of professional services by default: an experienced master is well versed in drilling modes, which reduces the risk of damaging the glass to a minimum.

As for the very essence of the masterful approach, everything is serious here:

- Cleaning and purging. It’s rare that a car owner, having experienced a chip, immediately takes action to fix it. Usually there is a pause between the appearance of a defect and repair, albeit a short one, say, 2-3 days. This is enough for the microstructure of the chipped glass to become saturated with contaminants. They need to be deleted, since restoring them will be of no use.

- Drilling. The procedure helps to bring a beam of refracted light to a common denominator so that the driver does not get blinded at night. The drilling process is closely monitored by the master, for which he installs a mirror in the salon. As soon as the chip rays in the mirror return to normal, the operation is completed.

- Filling the chip with polymer. The damage is masked by a transparent substance. The impeccability of the result is guaranteed by a special device capable of distributing the polymer to all the cracks and microcracks of the defective area. However, sometimes this is not enough, which is why craftsmen take a risky move - heating the glass.

- Drying. The final stage of polymerization is sealing the chip with thermal tape and drying under an ultraviolet lamp.

- Polishing. Finishing with a special compound gives the repaired area a laconic appearance. Thus, the visible transition zone disappears and the defective area, together with the conditioned area, looks like a single whole.

A commendable gesture towards the master would be the careful concern for the cleanliness of the insides of the newly appeared chip. To do this, fresh damage must be covered with at least ordinary stationery tape. The highest point of attention to the sterility of the chipped area is considered to be a napkin placed under adhesive tape. This will prevent the glue from getting into the microscopic insides, which will provide the basis for an excellent result of repair measures.

Home cooking fully follows the principles of professional technology. The analogy can be traced down to the smallest detail - a high-quality result is unthinkable without thorough cleaning, complete filling of the chip with substance and proper drying. Here, as expected, simple and affordable devices are used that work on the principle of professional equipment, and drying, in general, occurs naturally. However, the instructions for the sets describe the entire process from A to Z:

- Defect cleaning.

- Arrangement of a site for vacuum filling with polymer. A funnel with a fitting for a medical syringe is glued to the windshield.

- Filling the defect with a repair substance. The syringe is connected to a funnel and the composition is pumped under the funnel. After filling, it is necessary to ensure that the polymer is distributed throughout all microcracks. To do this, fix the syringe in a compressed position for 10 minutes.

- Drying. For complete polymerization, the repaired area should be left in the sun. In summer, hardening time is about two hours.

- Finishing work. At the end of drying, remove excess polymer from the surface of the glass. A blade can be used as a tool.

Self-adjustment

On VAZ cars, you can adjust the caster angle yourself. More precisely, not an adjustment, but a change in value, since it is impossible to accurately measure the angle yourself. Adjustment is made by adding (removing) washers on the suspension, as shown in the figure.

One puck is about 19 minutes, in degrees, of course. An infinite number of washers cannot be installed, 4 at the rear and 2 at the front are allowed

. You can first go to the stand, measure the corresponding angles, then figure out what to add or subtract, and perform this procedure in the garage.

Some tuning enthusiasts install SS-20 supports on the Priora, increasing caster to 3 degrees. They say the effect is amazing. This may be true, but it is better not to experiment unnecessarily.

In a similar way, you can adjust the caster angles of the wheels on other cars, but before doing this, you need to find their value in the technical descriptions of a particular car. Usually in imported high-speed cars with front-wheel drive it is in the range from 2 to 4 degrees, in rear-wheel drive cars - from 4 to 10.

Video - adjusting caster on Lada Granta:

May be of interest:

Scanner for self-diagnosis of a car

Compare the cost of MTPL for your car

Choose a DVR: an indispensable gadget for the driver

Some drivers prefer a DVR in the form of a mirror

The unknown about the known. Caster wheels

Stas [stas90]

29.09.2017,

From an early age, most of us rode a bicycle, first for children, then a three-wheeler. Back then we didn’t think about why you could ride a bicycle “without hands.” With a certain skill, you can ride a bicycle in a straight line, even turn small angular distances, without applying any effort to the steering. And now many people don’t realize that the “caster” wheels are to blame. In technical terms, this is the angle of inclination between the vertical line through the wheel axis and the inclination of the steering column.

If the axle is inclined towards the driver, then the caster of the wheel is considered positive; if in the direction of travel, the caster is negative. By the way, in technical terminology the term “castor” is allowed, which for some reason WORD does not emphasize as a spelling error. In general, this terminology came, of course, from English. Anyone who has been to the circus has probably seen how famously the circus tightrope walkers ride their bicycles. And all because for special tricks they use bicycles with zero caster wheels, that is, strictly vertical suspension.

Caster wheels are also used in aircraft manufacturing (where wheels with negative caster are often used), and even in wheels for furniture and carts. Thanks to him (the caster), the office chair, if pushed, will go straight and not wander chaotically around the office.

Caster concept

Caster

angle in the automotive industry refers to the angle of the wheel suspension in the longitudinal plane. We are more familiar with such concepts as camber and toe; they often have to be adjusted when replacing suspension elements, since handling and tire wear depend on them. But we rarely adjust caster, sometimes never. But controllability depends no less on it, and so does wear. Basic angular parameters.

The positive angle was chosen from the point of view of the larger wheelbase of the car. Negative caster is often used in aircraft manufacturing, as it reduces the longitudinal “bounce” of the wheel at high speeds. In general, the dynamics of wheel motion are very complex; many dissertations are devoted to its description and calculation.

How to install caster

The amount of caster is determined at the stage of car development and modeling. To calculate a specific caster value, most of the dynamic and static characteristics of the car are taken into account:

- weight;

- drive wheels (front, rear or all-wheel drive);

- aerodynamic parameters;

- speed characteristics of the car;

- expected values of braking and acceleration accelerations.

The most difficult tasks in this regard are for designers of sports cars. They have to take into account the individual driving style of racing drivers and the parameters of the track. Therefore, in the market for converting vehicles into sports cars, there are adjustable strut mounts.

Before each race, the team mechanics adjust the caster of the wheels based on:

- differences in absolute heights along the route;

- distance and number of hairpins on the route;

- speed limit;

- coating condition;

- weather conditions.

The caster angle is made smaller when it is necessary to increase the car’s handling in the presence of a large number of “hairpins” and irregularities. If the track is more predictable, the caster angle can be increased, making the steering easier for the racing driver. If the caster angle is increased above the limit value, the car may “lead” off the track when turning on a slippery surface.

I'll leave the professionals alone. Caster adjustment is also important for regular drivers.

Caster angle values for real cars

In rear-wheel drive VAZs, the wheel caster value is approximately 3 degrees and thirty minutes. As a matter of fact, no one controls this boat when the car is released from the production line. I will say more, caster deviation is allowed by plus or minus 30 minutes. That is, on a car that has just rolled off the assembly line, there may be 3 degrees on one wheel, and all 4 on the other. Manufacturers believe that when installing high-quality new parts, caster should be within normal limits. And there, as God willing. As far as I know, on imported cars, caster adjustment is not included in the pre-sale preparation program.

On front-wheel drive VAZs, the caster value is approximately half as much, that is, about 1.5 degrees. On foreign cars the same trend continues: on front-wheel drive 2 – 4 degrees, on rear-wheel drive 4 – 10 degrees. Considering that the caster angle of front-wheel drive cars is small, an error of just half a degree will be more significant in terms of handling. Imagine one of the wheels moves slightly ahead of the other. Accordingly, the car will be pulled towards the driven one.

Conclusion:

When buying a new car, it would be a good idea to check the caster of the wheels, if, of course, there is a stand near the parking lot.

Caster adjustment

If you like to drive fast and tinker with your car unnecessarily, you can independently adjust the wheel caster. I'll tell you how to do this on VAZs. First, you need to go to a service station and measure the caster of each front wheel. If they are very different, you can change the values by adding or decreasing the number of washers on the suspension.

Removing and installing one washer corresponds to approximately 19 minutes of caster. Remember: the maximum number of washers is 2 in front and 4 in back.

For example, you can remove one washer from the front and add it to the back. The angle will change to minus 38 degrees. After adjusting the caster, you will again have to go to the stand and adjust the wheel alignment and check the caster at the same time. It's a troublesome task, but sometimes it's worth the candle.

On the Internet you can find recommendations for installing supports on the Priora SS-20. In this case, the caster increases to approximately 3 degrees. I checked it myself - the effect is not bad.

In conclusion, I would like to remind you that the normal condition of a car’s suspension is one of the main conditions for traffic safety. Don't waste your money on this.

Installation angles

All installation geometric angles are measured in degrees, with the exception of the toe angle, which is most often measured in millimeters in European countries.

Vehicle suspension parameters are measured from several angles:

- toe-in;

- camber (Gamber);

- caster;

- longitudinal angle;

- transverse angle;

- kingpin angle.

The main setting angles are the first three, that is, toe, camber and caster angles. Changing any of these angles significantly affects the geometric parameters of the wheels. In order to understand what a wheel alignment is, it is worth examining each corner separately in detail.

Toe-in

Toe-in is translated from English as wheel toe-in and generally has a positive meaning; traditionally, Subaru models have zero toe-in, and negative settings are used exclusively on sports racing cars.

Positive toe is considered when the front part of the tire is directed inward towards the longitudinal central axis of the car, and negative when it deviates outward. The deviation of this angle affects:

- for increased tire wear;

- handling when turning;

- vehicle rolling distance.

On rear-wheel drive vehicles, positive toe-in is considered to be within 1 to 2 millimeters, and on front-wheel drive vehicles, from 0 to 1.5 mm. The adjustment units are located on the steering rods.

Camber (Gamber)

The camber angle can be either positive or negative depending on the design features of the vehicle suspension. On rear-wheel drive vehicles, positive yaw deflections are usually used in the range from 0 to +1 degrees. Front-wheel drive vehicles generally have negative camber from 0 to -1 degrees. Significant deviations affect handling and contribute to wheel tread wear.

The main reasons for violation of the Gamber angle are:

When these malfunctions occur, the wheel begins to deviate towards negative camber, while the toe-in of the wheels changes, quite often the initial position of the steering wheel changes, the car is felt to pull away, and wear marks appear on the tread on one of the sides.

It is worth noting that not all cars, especially cars with MacPherson strut suspension, have adjustment units for this angle. On earlier models, eccentric bolts were installed on the lower arms or shock absorbers for adjustment. So, for example, on the VAZ 2108 model, the upper bolt securing the shock absorber strut to the axle is eccentric, which allows adjustment work. Gradually, the engineers abandoned this idea. Therefore, if the camber deviates from the factory parameters, the reason should be sought in the elements of the chassis or body geometry.

Caster

A very important and responsible angle, violation of the parameters of which leads to the car moving away from straight-line motion; in fact, the front axle of the car’s wheels shifts in relation to the rear axle. Caster stabilizes the vehicle's handling at high speeds and ensures that the steered wheels return to their original position when turning. The angle is always positive, and the higher it is, the more stable the car is at high speed. On ordinary cars the range is from two to five, and on sports cars the tilt reaches nine degrees or more.

Reasons for changing caster tilt may include:

- the lever is deformed due to hitting an obstacle;

- silent blocks destroyed;

- spring is broken;

- the shock absorber strut is deformed (MacPherson system);

- deformation of the front subframe or body.

Almost all SUVs have units that allow you to adjust the angles of the wheels, which are located at the point where the levers are attached. Two adjustment methods are used:

- eccentric bolts;

- adjusting plates or washers.

On the VAZ 2121 the unit is located on the upper arm; washers are used, by installing or removing which adjustment work is carried out. Imported SUVs have special eccentric bolts located on the lower or upper suspension arms.

What happens?

The unit of measure for caster is degrees. Depending on the location of the shock absorber, the angle can be:

- Zero. The stand is positioned vertically;

Positive castor

- Positive. The stabilizer is deflected towards the interior;

Positive castor

- Negative. Tilt towards the headlights.

Negative castor

On modern cars, a small positive value is set. This is explained by the best controllability conditions and low rolling resistance. This position provides an optimal ratio of torque to steering force.

Zero caster was used on early models. Over time, this arrangement of wheels has been proven to be inappropriate due to dynamic changes in geometry during braking or acceleration.

Installation and repair of VAZ cars (2110 and Lada Priora)

To ensure good stability and controllability of the car, the front wheels are installed at certain angles relative to the body and suspension elements. Three parameters are adjusted: toe-in, wheel camber angle, and the longitudinal inclination of the steering axis.

The casting angle of the steering axis (Fig. 1) is the angle between the vertical and the line passing through the centers of rotation of the ball joint and the bearing of the telescopic strut support, in a plane parallel to the longitudinal axis of the vehicle. It helps stabilize the steered wheels in the direction of straight motion. This angle is adjusted by changing the number of shims on the extension ends. To decrease the angle, washers are added, and to increase it, they are removed. When installing/removing one washer, the angle changes by approximately 19′. Symptoms of deviation of the angle from the norm: the car pulls to the side when driving, different forces on the steering wheel in left and right turns, one-sided tread wear.

Wheel camber angle (Fig. 2) is the angle between the plane of rotation of the wheel and the vertical. It promotes the correct position of the rolling wheel during suspension operation. The angle is adjusted by turning the top bolt securing the telescopic strut to the steering knuckle. If this angle deviates greatly from the norm, the vehicle may deviate from straight-line motion and cause one-sided wear of the tread.

Wheel toe (Fig. 3) is the angle between the plane of rotation of the wheel and the longitudinal axis of the car. Sometimes this angle is calculated by the difference in the distances between the edges of the rims, measured from the rear and front of the wheels at the level of their centers. Wheel toe ensures the correct position of the steered wheels at various vehicle speeds and turning angles.

Toe is adjusted by rotating the adjusting rods with the tie rod ends loosened. Before adjustment, the steering rack is set to the middle position (steering wheel spokes are horizontal). Signs of toe deviation from the norm: severe saw-tooth wear of the tires in the transverse direction (even with small deviations), squealing tires when cornering, increased fuel consumption due to high rolling resistance of the front wheels (the vehicle's run-out is much less than expected).

It is recommended to check and adjust the angles of the front wheels at a service station. The car is placed on a horizontal platform and loaded in accordance with the manufacturer's recommendations (see below). (Checking and adjusting the angles on an unloaded vehicle is acceptable, but gives less accurate results. Before doing this, make sure that the tire pressure is correct, the tread wear on the left and right wheels is approximately the same, there is no play in the bearings and steering, and the wheel rims are not deformed (radial runout - no more than 0.7 mm, axial runout - no more than 1 mm).

Checking the wheel alignment angles is mandatory if suspension parts that affect these angles have been replaced or repaired. Due to the fact that the installation angles of the front wheels are interconnected, first of all the caster angle of the turning axis is checked and adjusted, then the camber and, lastly, the toe-in.

For a run-in vehicle in running order and with a payload of 320 kg (4 people) in the cabin and 40 kg of cargo in the trunk, the wheel alignment angles should be within the following limits: camber angle……………………………………………………………… …………..0°±30′ toe……………………………………………………..0°00'±10′ (0±1 mm) pitch angle rotation axis…………1°30'±30′

Angles of vehicle wheels in running order: camber angle……………………………………………………………..0°30'±30′ toe…………………………… ………………………..0°15'±10′ (1.5±1 mm) pitch angle of the turning axis…………0°20'±30′

Caster angle (steering axis pitch angle)

Increasing the caster angle improves cornering and return of the steering wheel to its original position, and also increases its information content.

A positive caster angle is when the stance is tilted back, as in the picture.

A negative caster angle is the opposite, but this rarely happens.

Factory setting for front wheel drive vehicles is +1° 30′ ± 30′. In tuning, values of +3 are used. 4°, a caster angle will cause poor handling during hard acceleration, meaning it will be difficult to hold the steering wheel.

Adjusting the caster angle involves changing the number of washers on the suspension braces. To increase the angle, the number of washers is reduced in the front or rear part; to decrease the angle, they are added.

When changing the number of washers on the extension, you need to ensure that the chamfers on them are facing towards the thrust end of the extension; this also applies when installing the internal thrust washer of the rubber-metal hinge, when all the washers have been removed.

The number of adjusting washers should not be more than 2 at the front and 4 at the rear. Installing or removing 1 washer corresponds to a change in caster by 19′ (minutes).

On rear-wheel drive Vases, the factory caster value is +3° 30′ ± 30′ without load, 4° ± 30′ with load, for tuning it is set to 4. 10°.

Adjust by placing washers on the axis of the lower arm. Increasing the angle - installing washers on the side towards the interior, decreasing - on the side towards the front bumper.

It is better to carry out adjustments on special stands where wheel alignment is done.

If your car is in service, but you really need to go. You may need to rent a car. In some cases, this turns out to be cheaper and more convenient than a taxi.

Source