Any car contains a significant number of moving components and connections from the outside and under the hood. This is especially true for front-wheel drive cars, steering and suspension.

Long-term and trouble-free operation of mating parts and connections depends on lubrication and cleanliness of the rubbing surfaces. If third-party objects in the form of sand, dust and dirt get into the lubricants used to lubricate the rubbing elements, as well as on their surface, then they act as abrasive materials that lead to intense wear of the rubbing elements. Any structural element that has associated parts from exposure to polluting particles very quickly fails.

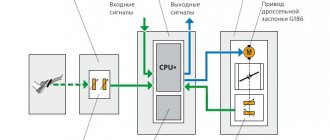

CV joint design

For example, consider a constant velocity joint (CV joint). This element of the drive design not only transmits torque from the gearbox to the wheels, but also allows the wheel to turn.

This hinge operates under significant loads. It consists of cages - external and internal and balls that transmit force from one cage to another and allow you to change the angle of the clips relative to each other. In this case, the balls are constantly in contact with the surfaces of the clips. This hinge design is very reliable, but under one condition - the absence of contaminating elements. The presence of sand and dirt inside the hinge wears out the surfaces very quickly. At first, the hinge begins to “crunch”, and then it may even be destroyed due to severe wear of the working surfaces.

What is a car boot?

Interconnected parts of the car require constant protection.

The presence of various lubricants in the units (interaction points) requires the use of covers that prevent the leakage of lubricant, as well as the ingress of various microparticles (dust, water, dirt, etc.). These protective special covers are made of rubber and are called anthers. They can be of completely different sizes and shapes, for example, elongated or bell-shaped, but they all have only one purpose - to protect any rubbing joint (hinge or any other). Any damage to the boot is a fairly serious nuisance, because even the smallest crack will lead to moisture and dust getting into it. This creates an abrasive that can lead to faster wear, corrosion, and operational problems.

Since the anthers are subject to various influences, it is necessary to constantly check their condition. This is necessary so that you can replace them with new ones in time, thereby preventing disruptions in the operation of the unit protected by the anthers.

For the boot to do its job perfectly, it must have the following characteristics:

- The material used for manufacturing must be elastic;

- The boot must be adapted to function under a wide variety of temperature conditions and be resistant to aggressive environments;

- There should be no reaction to fuels and lubricants.

Wear resistance

The material used in the production of the boot must withstand very heavy loads.

- High temperatures, should not melt or crack at extreme positive temperatures.

- Low temperatures, should not “tan” in frosts

- Should cope well with wear, i.e. protection against friction

- Breaking work. Must withstand torsion and fracture

Previously, anthers were made mainly of rubber, but this material was far from perfect, so it could dry out in the summer and could also become tan in the winter. Small cracks or even breakthroughs appeared.

Therefore, then the production technology was changed a little; now new rubber compounds with improved characteristics or more advanced silicones are used. In any case, the boot must be very durable to withstand high loads, because its service life is calculated to last many thousands of kilometers.

CV boot

CV joint is a part of every car with front-wheel drive. Its design provides for 2 “grenades” (the second name for CV joints) on each side (one internal and the other external), each of them is protected by an external CV joint boot and an internal CV joint boot, respectively. They are usually made of silicone or neoprene to provide protection even under the most difficult conditions.

In appearance, the CV joint boots resemble a cone, which is folded like an accordion. This shape was chosen for a reason - thanks to it, the part can be protected from pinching when the angle changes. The boot is fixed on both sides with clamps, which help to reliably protect the hinge from dust.

If the drive is regularly inspected, any damage to the boot can be noticed in time. If you find the slightest crack or other defect that could break the seal, you must immediately replace the boot with a new one.

Replacing the boot is not such a difficult task, but it is quite troublesome. The first step is to dismantle the drive. Next, after completing this process, the damaged boot is cut and then the grenade is removed. Before putting a new boot on the hinge, you need to wash it and then apply lubricant. If everything is done, you can return the parts back to their place.

Clamps, as well as a damaged boot, must be replaced and cannot be reused. You can find out more about replacing the CV joint boot in the article “Replacing the outer CV joint and CV boot.”

Symptoms of breakdowns

And it’s worth talking a little about the obvious signs that the grenades are out of order. This is not a very pleasant moment, as it can hurt your wallet. For example, owners of domestic cars will have to pay at least 3,000 rubles just for a set of spare parts for repairing drives. What can we say about the happy owners of prestigious Nissan and Ford models, the CV joint boot (internal or external) of which costs the same as a joint on a “nine”.

The first sign of a mechanism malfunction is the appearance of extraneous sounds, especially when driving away with the steering wheel turned to the side. When I straighten the steering wheel everything disappears. But you can confuse the breakdown of a grenade with a malfunction of the ball joint - it also crunches when the play in it increases. Therefore, before making a final diagnosis, it is worth checking the entire suspension to identify the maximum number of defects.

Tie rod boot

Anthers are also used in the steering. Their shape, as well as their fastening, are determined by the specific design. The difficulty of replacing the boot directly depends on where they are attached:

- If the boot is located in the place where the steering rods are attached to the rack, as, for example, in the “nine”, then you will have quite a difficult time, since to replace it you need to perform a number of procedures, which include disassembling the steering mechanism.

- In VAZ cars, the anthers are usually located at the ends of the rack. To replace any of them, you will only need to remove the clamps, then unscrew the nut that secures the rod, disconnect it and remove the boot.

- Among the many types of anthers you can find some very interesting ones. For example, in one of the Volkswagen models they are made in the form of elastic caps, which are put on the body and secured with clamps. Such boots protect the steering mechanism from dirt and are quite easy to change.

Anther and its features

Any self-respecting motorist knows what a boot is - it is an elastic rubber product that protects against the unwanted entry of various particles - dust, water, oil, etc. - into the mechanism. Under the grenade boot (to be specific) there is a special lubricant made on the basis of graphite. It's called "CV joint lubrication".

Ball joint boot

This type of anther differs from the models described above in that their design resembles a mushroom, where the narrow part fits tightly to the finger, and the wider part is located on the body of the support itself. A retaining ring is used to secure the boot.

Replacing a damaged ball joint boot is quite easy. You just need to disconnect the hub and support, and then carefully pry up the retaining ring with a screwdriver. After you have done this, you can safely remove the boot from the support. Before installing a new boot, it is necessary to wash all surfaces as thoroughly as possible and also lubricate them.

The same boots are used for tie rod ends - they are absolutely identical (both the design itself and the method of replacement). Size is the only thing that makes them different.

Signs of boot failure

As mentioned in one of the previous sections, the boot has become something of a consumable item for car enthusiasts. If he “walks” for at least a year, this can already be called an excellent result. It is very easy to identify a defect in the boot - just inspect the boot properly. A sign of product failure is:

- Rupture in one or more places;

- The presence of grenade lubricant on the outer surface of the boot;

- The appearance of a large number of small cracks.

Although it is recommended to inspect the boot every 10-15 thousand kilometers (and even more often in the case of a cheap consumable), often the car owner receives a signal about the need to replace it without a visual inspection - when a grinding and crunching sound begins to be heard in the lower part of the car.

Shock absorber boot

These boots are used to protect shock absorbers; they are usually made in the form of a corrugated rubber cover and quite often are not secured at all. They are held in place due to a good fit, and their purpose is to protect the rod from dust and dirt. As always, there are exceptions - the VAZ “classic”, where a metal cover is used. It, of course, provides longer-lasting protection, but is less effective than its relatives made of rubber.

Thanks for subscribing!

The requirements for the material from which the anthers are made are very high, because in order to function as needed under overload conditions, it must withstand a fairly wide temperature range. In addition, it must be durable and not be destroyed when it gets exposed to oil or salt, which is used to treat roads in winter.

What are we talking about?

The constant velocity joint, which is usually called a CV joint (abbreviated by letters) or a grenade, is one of the most important and at the same time the most mysterious elements of an automobile chassis. Why mysterious? The fact is that car enthusiasts encounter the problem of failure of these joints very often. And since the vast majority of front-wheel drive and many all-wheel drive cars are equipped with a grenade, this problem is very acute. Hinges are internal and external . They have an almost identical device. In general terms it is:

- Housing with clip;

- Separator;

- Clip;

- Balloons;

- Shaft;

- Retaining ring;

- Cover (boot) with a clamp.

It is this hinge that ensures normal transmission of torque even when rotated up to 70 degrees relative to a certain axis. In the case of a car, this means that the drive axle, while remaining rigidly fixed, can normally transmit torque to the joint, which in turn can rotate. This makes it possible to create a complete wheel drive system in vehicles with independent suspension. However, grenades have many disadvantages: a tendency to overheat (almost completely resolved in some types of hinges), the need for lubrication, a tendency to self-jam (solved in “Tripoid” type models), and capriciousness in operation. Regarding the latter: grenades quickly fail when water, sand, small stones, etc. get inside the separator. A high-quality boot can solve this problem .

Brake caliper boot

There are two types of caliper boots - one of them is intended for the guide, and the second protects the piston. They differ in shape, but both are made of a springy material that can withstand overloads and protect the caliper from dust.

Quite often, a car boot is changed during scheduled repairs. If you find any damage, it is best to immediately replace the worn part with a new one. A replacement that is not carried out on time can very well lead to very sad consequences.

Where is it used?

Basically, the anthers are installed on the moving elements of the front and rear suspensions, for each unit they are different and differ in design, as can be found on:

- Shock absorbers, many will now say that these are not anthers, but covers, but essentially the function is the same, so you can attribute them here. In fairness, it is worth noting that sometimes they are plastic, not rubber.

- CV joints Front grenades are also protected by rubber covers

- Steering rack. There are only two of them here

- Ball joints and steering ends

- On the clutch fork (manual transmission)

- Some stabilizer models

To be honest, in various modifications of the car there can be quite a lot of different ones. For example, many automakers even protect door pulls with such covers. I once read information that there can be about 40 - 60 dust boots in a car, but only 10 - 20 perform really important tasks.

Flywheel boot

This boot especially stands out among the rest. Metal is used to make it - this is its main difference from other variations. The flywheel boot is designed to reliably protect the part itself from the ingress of third-party liquids or particles, which is why it has a second name - the clutch housing cover.

Of course, just like other parts, it can be mechanically damaged or worn out. If it is not possible to restore its working condition, then it must be replaced.