Symptoms of a faulty fuel pump

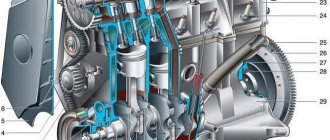

Fuel pump for VAZ

Actually, these are rather two stages of the same malfunction, although it happens that malfunctions in the operation of the fuel pump do not lead to its complete failure. Especially when these failures are caused by some extraneous factors. And so, the fuel pump either simply fails or does not work at all. These are all his breakdowns. Another thing is that there are many breakdowns of other elements, which in their symptoms are very similar to fuel pump breakdowns.

How to determine if a fuel pump is faulty

Be that as it may, most of the signs indicating a fuel pump malfunction may indicate problems in other systems and components of the machine. The car is malfunctioning - maybe the spark plugs, maybe the ignition, maybe some sensor is acting up. Extraneous noise in the engine can generally be caused by various breakdowns. Even when the engine stalls immediately after starting, you cannot blame only the fuel pump. For example, without readings from the crankshaft position sensor, the ECU can stop the pump, which is quite a normal car reaction to such a problem. And even a decrease in pressure in the system can be caused by leaks in the fuel lines, breakdown of the bypass valve and other failures.

What can you do right away? First of all, you can check the operation of the fuel pump before starting the engine. To do this, open the fuel tank cap and have someone turn on the ignition without turning the starter. In the first seconds after turning on the ignition, you should hear a specific noise from the fuel pump. If it is missing, most likely the pump will have to be replaced, although it is possible that the reason for the failure is the power supply to the device.

Measuring the pressure in the fuel rail is another way to check the fuel pump. Normal pressure readings, as well as the correct procedure for installing a pressure gauge, should be found in the documentation for your car.

Most often, in modern cars, when the fuel pump fails, it is replaced. But there is no need to rush into this. Perhaps the cause of the failure is not the fuel pump itself, but, for example, a coarse filter that is simply clogged. In this case, simply cleaning this mesh will help and you won’t need to change anything. It is also worth checking the wiring, fuse, as well as the fuel pump relay; perhaps the reason for the failure of the device lies here. Again, checking the fuel lines, the bypass valve, and even the injectors themselves will also not be superfluous.

What are the main advantages and disadvantages of the pump?

Initially, the design features of this unit will seem simple. However, in order to understand in detail the principle of operation of the unit, it is necessary to proceed to an explanation of the following aspects.

The situation is interesting in that the fuel tank in the Lada Kalina is placed by the developers under the bottom in the rear of the car. It is connected to the fuel rail under the hood via lines. To be able to supply gasoline at a given pressure parameter, you will need an efficient and high-performance gasoline pump.

The main feature of this unit is that it operates on an electric drive. This allows the pump not only to efficiently supply fuel to the elements of the injection system, but also to have enviable reliability.

The main advantages of the fuel system pump unit are considered to be:

- timely provision of injection elements with the required volume of fuel, regardless of the engine operating mode;

- simple design and decent resource;

- high safety, because the fuel pump stops functioning as soon as the engine stops.

Next, let's look at the main disadvantages that this unit has acquired:

- noise during operation;

- need for constant cooling;

- sensitivity to fuel quality indicators.

It is the use of substandard gasoline in combination with untimely replacement of the filter that can guarantee the failure of this expensive unit. There is a situation when the engine does not pump. In this case, you need to know how to check it and, if necessary, how to remove it.

Preventing fuel pump malfunctions

What should you pay attention to so that the fuel pump runs as long as possible? First of all, this is the quality of the fuel and, of course, timely replacement of the fuel filter. If the gasoline you fill contains various foreign inclusions, this will most likely negatively affect the condition and service life of the fuel pump, and not only it. Therefore, it is not worth saving on the quality of fuel, since such savings then result in very significant expenses for car repairs.

Monitor the fuel level in the tank. The fact is that the fuel pump is cooled by the same gasoline that it pumps. Accordingly, if there is little fuel, or the pump runs idle, it may overheat and therefore fail. Knowledgeable people also advise cleaning the gas tank at the appropriate time and not neglecting this procedure. This is, perhaps, all the prevention of problems with the fuel pump.

Replacing the fuel pump on Kalina

Welcome! Fuel pump - is responsible for supplying fuel from the tank to the car engine; if it fails, fuel stops being supplied to the engine and therefore the car will not start, or over time it may simply start to work worse and in this case the car will twitch when driving and it will lose dynamics (the fuel pump in such a situation will still pump fuel into the engine, but it will do it very much), besides this, the fuel pump no longer serves anything, although if you think about it, it goes first together with the Fuel Level Sensor , secondly, there is still a mesh on it that cleans gasoline from dirt, so we can say, thanks to the gas pump, we also find out how much fuel is left in the tank and even before this fuel goes into the engine, it is cleared of small particles of dirt, by the way, we will give advice, If you don’t want to change the fuel pump very often, then try never to bring the gasoline in the tank to the very minimum and especially do not drive the car until it runs out of gas (Only do this in rare cases or because of the situation), otherwise such trains will not lead to anything good and soon the fuel pump (this is its second name) will become unusable.

Note! To replace this pump on a car, you will need a set of tools in which: Screwdrivers will be lying around, a hammer and a drift, but in principle, the help of screwdrivers will be enough (But this is only if you don’t have a hammer with a drift, if you do, be sure to take them)!

- Replacing the fuel pump

- Additional video clip

How to check the fuel pump

Regardless of the type of fuel for which the car is designed, it must be supplied to the engine uninterruptedly. Its reliability and stable operation directly depend on this. The quality of domestic gasoline traditionally leaves much to be desired - most engine mechanisms and systems suffer from this, primarily the fuel pump. To prevent it from breaking down at the most unexpected moment, you need to know the signs and causes of the malfunction, and also adhere to preventive measures to maximize the life of the gas pump.

The need for fuel purification

To prevent malfunction of the pump unit in Lada Kalina, it is necessary to purchase fuel only from trusted suppliers, and also promptly replace the filter element of the system.

Impurities must be filtered not only through the specified consumable component. They are also neutralized:

- in a mesh located on the suction pipe of the pump unit;

- in the filter module for fine fuel purification, which is “embedded” directly into the line;

- using the mesh located near the pressure level regulator in the ramp;

- mesh until it gets inside the nozzle.

The aspects reflected in the first two paragraphs have a significant impact on the correct functionality of the pumping unit.

It is necessary to replace the filter in a Lada Kalina car after an interval of 30 thousand km. Owners systematically forget about the need to clean or replace the mesh on the pump nozzle. This is not surprising, since the manufacturer did not regulate this type of work and did not indicate the frequency of actions. They begin to “move” only in situations where the fuel pump exhibits characteristic malfunctions.

However, there are recommendations based on the experience of the owners. They hint at the need to clean or replace the mesh (if it is damaged) every 60 thousand km (or earlier).

Purpose and principle of operation of the fuel pump

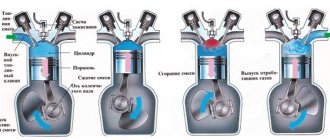

The fuel pump is designed to pump fuel from one point to another. In a car, the role of the first point is played by a fuel reservoir - the tank, and the second - by the engine, where the pumping takes place. This process occurs at a certain pressure, which is maintained by the pump reducer, which is a very important point.

Fuel pumps are divided into 2 types according to the type of drive: electric and mechanical. Inside the first there is an electric motor with a mini-pump, which operates from the mains and uninterruptedly pumps fuel into the engine. The second type is becoming increasingly rare, as it is installed on carburetor cars, and operates due to the reciprocating movement of the lever.

Signs of a fuel pump malfunction

Mechanical fuel pumps

In a mechanical fuel pump, malfunctions most often occur due to wear of the sealing gaskets and the formation of leaks between parts of the housing. As a result, the tightness of the structure is broken, air gets in, fuel stops getting into the carburetor and the engine stalls. A similar consequence is caused by membrane rupture and valve failure. At the same time, the car begins to move jerkily until the fuel supply stops completely.

Electric fuel pumps

On cars with mechanical and electronic injection, the signs of a fuel pump malfunction are slightly different, but they can be classified into certain groups:

- The engine does not start. Rotation of the starter with dry spark plugs does not cause flashes in the cylinders. There is no pressure in the fuel line, or it is extremely low; the buzzing of the pump is not heard when the ignition is turned on or the starter is operating.

- The engine does not start, although occasional flashes occur in the cylinders. There is pressure in the fuel line, but without a pressure gauge its value cannot be determined. The candles are dry.

- The engine starts and idles normally, but pressing the accelerator causes it to stop. If you want, it is possible to raise the speed to medium, but attempts to start lead to the engine stalling. There is a black coating on the spark plugs, the operation of the fuel pump is characterized by a changing sound.

- The engine starts, holds idle speed normally, and picks it up easily at neutral speed. When driving at medium and high speeds, a “twitching” is observed. It happens that after a certain mark on the tachometer the speed does not pick up, and the engine stops producing the required power under load. At the same time, the spark plugs are white, and by their appearance it seems that the car is ignited too early or has a lean mixture.

It is worth noting that the above symptoms of fuel pump malfunctions are also typical for other engine breakdowns, and they cannot be used to unambiguously diagnose a fuel pump malfunction. For example, speed also fluctuates if there is a problem with the air sensor, throttle valve, clogged injectors or poor quality fuel.

Possible causes of fuel pump malfunction

Mechanical fuel pump disassembled

A mechanical fuel pump may fail for the following reasons:

- If the integrity of the diaphragm is damaged.

- After dirt accumulates under the valves.

- When the filter is clogged.

- When the spring loses its elasticity.

- If the seal of the housing is broken.

- Due to natural wear and tear of parts during operation.

The electric fuel pump of a modern car is quite reliable. Malfunctions in it arise only due to the influence of certain factors, among which the most common are the following:

Burnt contacts inside the fuel pump

1. Faulty wiring in the form of dirty, rusty, melted or damaged wires in the fuel complex interferes with the operation of the device and also limits the required current parameters, making it difficult to pump fuel.

2. Debris and foreign impurities in the fuel tank in the form of rust, dirt, water, mechanical particles that penetrate the fuel pump and cause its breakdown.

Video with instructions for replacing the fuel pump

Replacing the fuel pump on a Ford Focus 2

To access the Lada Kalina fuel pump, you need to fold back the rear seat, remove the insulation (if any), and then begin dismantling the device.

Step-by-step work order

- Disconnect the negative terminal from the battery.

- We open access to the protective cover.

Raise the rear airbag up

Then unscrew the four bolts from the black metal cover located under the rear seat.

To avoid losing, we put the bolts in one place.

When the bolts are unscrewed, remove the cover to the side.

Under the decorative cover you can see the fuel pump and DUST!

When the cover is removed, you will see a picture where the upper part of the fuel pump is visible, as well as the fittings that are connected to it. Now you can begin the dismantling itself, and first of all, disconnect the power wires. To do this, remove the plastic clamp on the block and pull it to the side. The next step is to disconnect the fittings; in order to remove them, you need to press on the metal clamp with one hand, and use the other hand to pull the fittings to the side using pliers.

The block is marked with a red arrow, and the fittings with a green arrow.

When dismantling the second tip, note that its retainer is made of green plastic, and in order for the fitting to leave the place of fixation, you need to press on it, and then pull the tip itself to the side with your other hand. Before you begin removing the fuel pump, you should thoroughly clean everything of dust and dirt to prevent any debris from getting into the fuel. When everything is clean, you can begin to dismantle the retaining ring that secures the fuel pump to the housing. To perform these manipulations, you can use a special puller, or using a flat screwdriver and a hammer, knock it counterclockwise from the mounting points. Use a hammer and screwdriver carefully so as not to damage the ring or fuel pump housing.

Strikes should only be made on the ring.

Then, when the ring clip has popped out of its seat, you can take it out. Now is the time to start removing the fuel pump itself; to do this, you need to grab it by the top part and pull it up. In this case, you should be extremely careful so as not to bend the structure. Please note that the fuel pump is equipped with a special float indicating the amount of fuel in the gas tank, and in order not to knock it down, the fuel pump should be removed so as not to touch the body of the fuel tank. Here is a photo example of when the fuel pump has been successfully dismantled.

Successfully dismantled fuel pump.

All installation work should be carried out in strict reverse order, similar to the removal procedure.

Replacing the fuel pump mesh

Fuel pump mesh close up

When the fuel pump is removed, you can inspect the filter mesh. This is the so-called coarse filter. To do this, you need to disassemble the fuel pump and replace the filter element.

On the left is the new one, on the right is the old fuel pump mesh.

Checking the fuel pump

Checking the mechanical fuel pump

The operation of a mechanical fuel pump is checked by disconnecting the hose from the manual pumping outlet, after which the lever on the pump pumps fuel, which, if there are no breakdowns, should be supplied in a stream in time with the movement. During the procedure, place a rag under the pipe to prevent gasoline from spilling in the engine compartment.

Checking for faults in the electric fuel pump is carried out in the following ways:

Checking the filter on the electric fuel pump

1. Check the filter. Most often, problems with the operation of the device arise when the coarse filter is clogged, which is characterized by the appearance of the following symptoms:

- Decrease in engine power;

- Weak traction at high speeds;

- Difficulty starting the engine;

- Unstable operation at idle and low speeds.

Checking the fuel rail pressure

2. Checking the pressure in the fuel line, based on the results of which you can more accurately determine the problem with the pump:

- At idle speed the pressure should be 0.23-0.25 kPa;

- When starting the engine, the pressure should reach 0.3 kPa;

- In transition mode – 0.28-0.3 kPa.

If in transition mode the pump does not produce the required pressure, then there is a high probability of clogging of the coarse filter mesh. If the pressure in the fuel line when the return pipe is pinched does not reach 0.4 kPa, this means that the degree of wear on the pump is quite high.

3. Check the pump for mechanical damage. If the pump mechanism is significantly worn or dirt gets into it, a characteristic noise will be heard. When the ignition is turned on, the fuel pump works, but with obvious signs of a malfunction of the mechanism.

Problems with the fuel pump - what to do?

To avoid the risk of a sudden engine stop on the road and the inability to start it, it is necessary to diagnose and repair it at the first sign of problems in the fuel supply system.

You should contact the service center in the following cases:

- The appearance of noise from the fuel pump installed directly in the tank or near it, in the rear of the car.

- If with each cold start it takes more and more time to start the engine.

- A drop in engine power, an uncharacteristic sound of its operation.

- “Floating” speed of the power unit, deterioration in its responsiveness when pressing the gas pedal.

Repair

Mechanical fuel pump repair

Repairing a mechanical fuel pump consists of installing a new repair kit (diaphragm and valves) and, if necessary, a worn pusher with a spring. A deeper repair of this device is impractical, since the costs of purchasing and repairing worn parts are close to the cost of a new product. If the pump housing is deformed or damaged, it must be completely replaced.

Electric fuel pump repair

The electric fuel pump is equipped with a non-separable housing, and if it breaks down, the product is replaced with a new one. Without special skills, equipment and spare parts, opening and repairing it is impossible. But some workshops undertake similar work, the price of which is lower than buying a new pump. The main failures of the device are as follows:

- Damage to brushes and motor commutator. Repair involves replacing them with new ones.

- Breakage of the plastic coupling connecting the rotor and the motor armature shaft. The clutch is replaced with a new one.

- Anchor failure. The repair involves rewinding this part.

The described actions allow us to eliminate the gas pump malfunction on all models of the VAZ: 2101, 2102, 2103, 2104, 2105, 2106, 2107, 2108, 2109, 21099, 2110, 2111, 2112, 2113, 2114, Niva, Priora, Kalina, Grant, Vesta and most foreign cars.

Preventing fuel pump breakdowns

The best prevention for long-term operation of the fuel pump is its careful and proper operation, as well as compliance with the following rules:

- All scheduled vehicle repairs must be accompanied by the replacement of all fuel filters.

- It is necessary to monitor and ensure the cleanliness of the fuel tank and filters, as well as monitor the quality of the fuel being refilled (the absence of water, sand and other impurities in it).

- Eliminate the possibility of water getting into the fuel tank.

- Protect the fuel pump housing from mechanical stress that causes dents and cracks that contribute to the development of corrosion processes.

Source