Elastic coupling for driveshaft VAZ 2107

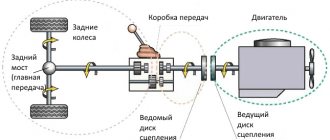

The driveshaft of the VAZ 2107 consists of two parts (front and rear), connected to each other by a articulated coupling (cross). This design allows you to avoid loads on the shaft while driving, when the body and chassis of the car begin to “play.”

The VAZ 2107 cardan consists of front and rear shafts connected by a cross

The end of the rear shaft is connected to the axle gearbox, and the end of the front shaft is connected to the gearbox shaft. The connection to the gearbox is made through an elastic coupling, which is a kind of buffer for leveling shock and dynamic loads on the driveshaft and gearbox shaft.

The elastic coupling acts as a buffer, smoothing out dynamic loads

Flexible coupling location

The elastic coupling is located in the lower front part of the car on the rear side of the gearbox. You can see it if you remove the engine protection and climb under the car. The coupling is easily recognizable due to its hexagonal shape.

The clutch is located on the rear side of the gearbox in the lower front part of the car

Coupling design

The basis of the coupling is a cushion made of especially durable rubber. Along its circumference there are six steel bushings fused into rubber, through which the bolts connecting the cardan flanges and the gearbox secondary shaft pass. The coupling kit also includes a special tightening clamp, which is put on it during installation or dismantling.

The elastic coupling consists of a rubber base and six steel bushings located around the circumference

Diagnostics of elastic coupling faults

The coupling may fail as a result of:

- wear of metal bushings;

- body wear;

- rupture of the body.

In each of these cases, the malfunction will manifest itself in the form of body vibration and extraneous sounds coming from the gearbox.

The condition of the coupling can only be checked by inspecting it and assessing the size of the play between the flanges of the gearbox and cardan shafts. This is done as follows.

- The car is driven onto an overpass or inspection hole;

- The engine protection is removed;

- The coupling body is inspected and the condition of the bolted connection is assessed.

- By loosening the cardan, the presence or absence of play is determined.

If signs of wear or mechanical damage are found on the coupling body (the body is partially or completely torn), the part must be replaced. A slight play (provided the body is intact) is eliminated by tightening the nuts of the connecting bolts. If the play is large, the elastic coupling will have to be replaced with a new one.

Criteria for choosing a new coupling

Driveshaft couplings for the VAZ 2107 in Russia are produced under catalog numbers 2101–2202120 and 2101–2202120Р. The retail price of the part, depending on the manufacturer, ranges from 400 to 600 rubles.

Table: technical characteristics of the elastic coupling of the VAZ 2107 driveshaft

| Characteristics | Indicators |

| Length, mm | 140 |

| Width, mm | 140 |

| Height | 35 |

| Weight, g | 780 |

| Bending rigidity, Nm/deg | 3,14 |

| Torsional rigidity, Nm/deg | 22,5 |

| Rigidity during axial displacement, N/mm | 98 |

| Breaking load (not less), N | 4116 |

| Cyclic durability, cycles | not less than 700000 |

MAZ suspension bearing design

1 5337-2201006-20 Cardan shaft 2 5337-2202010 Shaft 3 53361-2202090 Clamp 3 53361-2202090 Clamp 4 201540 Bolt M12-6gx30 5 250514 Nut M12-6gx30 6 252137 Washer 12 FROM 7 5337-2202087 Bracket 7 5337-2202087 Bracket 8 5432-2201010-10 Cardan shaft 9 250688 Nut М10х1-5Н6Н 9 250688 Nut М10х1-5Н6Н 10 252136 Washer 10 FROM 10 252136 Washer 10 FROM 11 371264 Bolt М10х1-6gх40 11 371264 Bolt M10x1-6gx40 12 5336-2202084-10 Bearing race 13 200272 Bolt М8-6gх65 14 250510 Nut М8 15 252155 Washer 8L 16 5336-2202050 Flange 17 5337-2202015 Shaft 18 374964 Nut М42х2-5Н6Н 19 258086 Cotter pin 20 5336-2202059-10 Oil seal 21 264072 Oiler 1.1.Ц6хр. 22 5336-2202081-10 Cover 23 5336-2202085 Pillow for the intermediate support of the propeller shaft 24 6.312-A Bearing 25 250560 Nut М16-6Н 26 252017 Washer 16 FROM 27 5336-2202062-10 Plate 28 5337-2202088 Bracket 29 202123 Bolt M16-6gх50

Suspension bearing for propeller shaft VAZ 2107

The suspension bearing (or idler bearing) is designed to ensure uniform rotation of the driveshaft while driving. In addition, it is an additional point for attaching the cardan and is included in the design of the intermediate (suspended) support. In fact, it itself is a support, since it comes complete with a bracket, with which it is attached to the bottom of the car through a transverse bracket.

The bearing design is based on the outer and inner races and seven steel balls

Outboard bearing location

The bearing is installed in front of the spider at the end of the front of the driveshaft. It can be seen from the inspection hole in the axial recess of the bottom behind the exhaust pipe at its junction.

The VAZ 2107 suspension bearing is located in front of the crosspiece on the front of the driveshaft

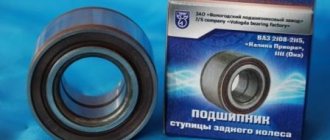

Hanging bearing design

The hanger bearing is an ordinary closed type ball bearing. It consists of an inner and outer race and seven steel balls. For mounting on the bearing housing there is a steel bracket with holes for bolts.

The suspended bearing is equipped with a special bracket for ease of fastening

Diagnosis of outboard bearing faults

The causes of outboard bearing failure are usually wear or mechanical damage. The service life of the bearing is about 150 thousand km. However, exposure to moisture, dirt, as well as stress caused by poor road conditions can significantly reduce it.

Signs of bearing wear are:

- slight vibration;

- hum emanating from the place where the cardan is “suspension”;

- shaft play.

It is quite difficult to accurately diagnose bearing failure; this will require dismantling the driveshaft.

Outboard bearing selection criteria

Suspension bearings for the VAZ 2107 in Russia are produced under catalog numbers 2101–2202080 and 2105–2202078. The requirements of GOST 6–180605 apply to them. Imported analogues must comply with the requirements of ISO 62305.2RS. If there are no such markings on the packaging of a new part, it is most likely a fake, and it is better not to purchase it. The average retail price of a VAZ 2107 suspension bearing is 450–500 rubles. When choosing a manufacturer, it is better to give preference to the Vologda Bearing Plant. Bearings produced at VPP are considered to be of the highest quality and most durable.

Table: technical characteristics of the VAZ 2107 suspension bearing

| Characteristics | Indicators |

| steel grade | ШХ 15 |

| Outer diameter, mm | 62 |

| Internal diameter, mm | 25 |

| Height, mm | 24 |

| Rated rotation load, rpm | 7500 |

| Load capacity static/dynamic, kN | 11,4/22,5 |

| Ball diameter, mm | 11,5 |

| Weight, g | 325 |

How to determine the faulty condition of the outboard cardan bearing of your own car?

The presented bearing serves as an additional support and dampens possible vibrations during rotational movements of the cardan shaft. If you do not systematically lubricate the bearing, then after twenty to thirty thousand kilometers you may need to replace it with a new one.

Sometimes during a coasting trip a strange sound appears, reminiscent of a hum, coming from somewhere unknown. This noise may be a sign that the bearing is faulty.

It is important to distinguish between the knocking of the cross and the bearing hum. Usually, a knock occurs when you touch the structure - a harsh, dull steel sound. And the hum, which resembles the grinding of wheels on a snowy surface, is accompanied by trembling, and is felt only at speed.

After driving the car onto the lifting device, you will need to make sure that extraneous noise comes directly from the area of the suspension cardan bearing. The noise may accompany the shaking.

When the car owner makes sure that beating, shaking and various kinds of twitching come from this area, it is necessary to unscrew the fastening bolts and lower the cardan shaft onto the ground surface. But you need to be careful - the CV joint of the cardan shaft should emerge from the transfer case and oil fluid will begin to flow from there. After this, you need to check the bearing for the presence of play. If the mechanism is in good condition, then there should be no play.

Balancing the driveshaft VAZ 2107

After disassembling and replacing any element, the driveshaft must be balanced. This is done on a special stand, so for balancing it is easier to contact the nearest car service center. The balancing itself consists of measuring and eliminating the imbalance on the three shaft supports. Its permissible value at a shaft rotation speed of 5500 rpm should not be more than 1.62 N*mm. The imbalance is eliminated by welding small weights (metal plates) onto the surface of the front driveshaft.

If vibration appears after repairing the driveshaft, you can try to balance it yourself. Naturally, there can be no talk of any accuracy here, and the balancing itself will be only temporary. This is done as follows.

- Drive the car onto a viewing hole or overpass.

- Inspect the driveshaft.

- Conventionally divide the front universal joint into four sectors (if you imagine it in cross-section).

- Find a small weight weighing 30-50g and attach it to the front of the shaft using tape or tape.

- Drive along a flat section of road, paying attention to your choices.

- If the vibration does not disappear or increases, move the weight to another sector and repeat the checking process.

When the load is in its place, the vibration should stop, unless, of course, it is caused by an imbalance of the shaft.

How is a bearing replaced?

In addition to reading the article, we recommend watching the video:

VAZ “5-ka”, “6-ka” and “7-ka” have a similar chassis structure, therefore the rules for installing and replacing bearings apply to all of the listed models.

First, you need to put the vehicle on the inspection hole and remove the cardan shaft, and at the same time dismantle the crosspiece (thanks to the 27 key, the bolt is unscrewed). Do not forget that the nut does not need to be completely removed - you need to leave a little space directly on the thread in order to later press out the plug.

After this you will need a puller. It can be of different devices - when selecting this part, you must ask the dealer about the specific model of vehicle it is intended for. Thanks to the puller, the cardan shaft fork is pressed into place. It is quite possible that such a part may jam and not come out. A hammer is used for this. There is no need to knock too hard, otherwise both the fork and the puller will become faulty. After this, the required part is pressed out, and the support plate is removed.

Next, the bearing is directly pressed from the shaft. To do this, you need to find two corners (50x50) and with their help, simultaneously with support on the cardan, press out the spare part that is worn out. If necessary, you can take a steel extension and easily hit it with a hammer. That's it, the bearing is removed.

After removing the suspension cardan bearing, you need to remove the retaining ring and mud washers. Now you can begin installing the new replacement part.

Installation is done in a similar way. But here you need to take into account one feature - for a quality replacement it is necessary to lubricate the new part. Otherwise, an extraneous sound will appear after replacing the cardan outboard bearing. Usually, manufacturers lubricate the part in advance, but this is not quite enough to prevent sound from appearing after changing the cardan outboard bearing. To ensure the car has good rotational movement of the propeller shaft, it is necessary to carefully pry off the bearing cap (wall) using an awl and process it. After this, the new part is ready for installation. If it is noticed that this spare part rotates with hooks, then it needs to be replaced with another one, since the part is either defective or counterfeit.

By following these instructions, the car owner can easily replace a worn-out spare part with a new one, guaranteeing long-term and uninterrupted operation of his own car.

Useful tips

To increase the service life of the VAZ 2107 driveshaft, you need to follow a number of simple recommendations.

- Avoid excessive contamination of the driveshaft couplings.

- Systematically check the tightness of the fastening elements and the presence of lubricant in the connecting units.

- If shaft malfunctions are detected, do not delay repairs.

- When purchasing spare parts for a cardan, pay attention to the manufacturer and compliance with GOST or ISO requirements.

- After repairing the driveshaft, be sure to have it balanced at a service station.

Diagnosing a malfunction, repairing and replacing the suspension bearing and elastic coupling of the VAZ 2107 propeller shaft with your own hands is quite simple. This requires minimal plumbing skills, a standard set of tools and careful adherence to the recommendations of professionals.