What is the pressure in the engine cooling system?

During operation, the internal combustion engine heats up to a high temperature. The engine cooling system must cope with the heat removal function. This is necessary for the efficient operation of the power unit. If there is no coolant circulation, the internal combustion engine will very quickly overheat with all the ensuing consequences. Let's talk about what the pressure in the cooling system should be and how to fix typical problems on your own.

Removing air pockets from the VAZ-2114 stove

Airing of the heating system on VAZ-2114 cars is a fairly common phenomenon. When faced with an air lock problem, you can solve it yourself. The main thing here is to find the reason, and then use one of the three most effective methods.

- Cooling system features

- Causes of traffic jams

- Methods for solving the problem

- First method

- Second method

- Third method

Briefly about the main thing

The first step is to decide why there is pressure in the cooling system. It would seem that the banal circulation of coolant should be enough to remove heat. This used to happen when water was poured into the radiator. But it was also common to come across a car on the side of the road with steam pouring out from under the hood. This happened because the water did not have time to cool, and since its boiling point is 100 degrees, it boiled very quickly.

Modern antifreezes, most of which are alcohol-based, boil at approximately 115 degrees Celsius. But it’s worth remembering the school physics course, where you can learn that an increase in pressure leads to a shift in the boiling point of the liquid. This also applies to antifreeze that circulates through internal combustion engine systems.

Why is pressure needed?

It would seem that there is no need for pressure in the cooling system, because all that is required is to ensure continuous circulation of antifreeze so that it heats up as it passes through the water jacket of the cylinder block and is cooled in the radiator by the flow of oncoming air when the car is moving, or by air forced by the fan.

At first it was like this: water was poured into the radiator, and the car set off. About eighty years ago there was nothing unusual in a car standing on the side of the road with steam pouring out from under the hood, and the phrase “the engine was boiling” evoked understanding among everyone. The driver could continue driving either by pouring cold water into the radiator, or by waiting for the water poured into the cooling system to cool down.

The reason is simple: the boiling point of water at atmospheric pressure, as is known, is 100 degrees Celsius, antifreezes made on the basis of alcohols boil at a temperature of 110–115 degrees. The coolant, passing through the cooling system, does not have time to cool down and, as a result, boils. Moreover, the higher the load on the motor, the faster.

So, in a VAZ-2110, the pressure in a working cooling system should be about 1.2 atm.

What pressure in the engine cooling system is considered normal?

Much depends on the design features of the car. But usually it is 1.2-1.4 atm. for passenger cars. For example, on a VAZ-2110, 1.2 atmospheres can be considered normal. Critical pressure in the system is achieved when the antifreeze heats up and reaches its boiling point. At this time, the pressure in the system should be released. This is done so that the radiator or any other weakest point does not tear.

The expansion tank cap is responsible for releasing pressure. Its device is extremely simple. There is a metal case with two holes. Inside there is a ball with a diameter larger than the holes. When it reaches a certain temperature it rises. This results in air being vented into the atmosphere. On many cars 1.5 atm. is the pressure at which the release occurs.

What should normal blood pressure be?

The pressure in a car's engine cooling system cannot be increased indefinitely, since too high will eventually lead to rupture of its weakest elements. Normally it should be 1.2–1.4 atm. As the antifreeze heats up and reaches its boiling point, the pressure reaches a critical value. At this moment it must be reset in order to avoid failure of the cooling system first, and then jamming of the pistons in the cylinders, and as a result, breakdown of the latter.

To maintain pressure within acceptable limits, an air valve is installed in the cap of the expansion tank (for VAZ-2110) or radiator.

It has a simple device:

- inside the case, which has identical holes at the top and bottom, there is a ball slightly larger than the holes.

- The weight of the ball is selected in such a way that when a pressure reaches 1.5 atm, it rises, opening the lower hole and releasing air from the cooling system into the atmosphere.

- At the same time, while the coolant is not heated, the ball closes the lower hole, and the upper one remains open, providing an influx of atmospheric air and ensuring faster heating of the antifreeze.

Nowadays, the most common version of the lid is one that has two valves (inlet and outlet). As the pressure rises, the release valve opens and the excess is discharged from the system. When it falls below atmospheric pressure, the intake begins to work.

Often, due to malfunction of the valves, the system ceases to function correctly. Moreover, even a new cover does not guarantee that everything will work as expected. Car owners often complain that the expansion tank bursts. This can be caused either by improper operation of the lid valves or by a defect in the tank itself (thin walls).

Valve performance check

Until the antifreeze heats up, the ball inside the lid closes the bottom hole, while the top one remains open. This is necessary for the flow of air from the atmosphere and rapid heating of the coolant. I would like to note that it is periodically necessary to check the functionality of the lid. After all, it often happens that it gets wedged in one of the positions. Because of this, the engine either takes a long time to warm up or does not hold pressure.

Checking the cap of the expansion tank of the VAZ-2110 is extremely simple. To do this, just unscrew it and shake it. If you can hear the ball dangling inside the housing, then the system is working and it is not jammed. Excessive pressure in the engine cooling system, as noted above, can lead to fatal consequences. Therefore, on modern cars the cover has two valves: inlet and outlet. Nowadays you can find lids on sale that operate at a certain pressure. But it is strongly recommended not to change the parameters set by the manufacturer.

Articles

- 21110-1008650-00 – plastic screen (only for 11183);

- 21120-1008658-00 – rubber screen pin;

- 21080-1311065-00 (-01, -03) – expansion tank plug;

- 21080-1311067-00 – gasket for the plug.

Do you only need distillate?

We tried to expel air from the system, but on the VAZ-2114 the entire “plug” takes up 100-150 ml. This means you don’t have to add anything at all to the tank. You can also add regular distilled water.

It is easier to find a 100 ml package of distillate at a pharmacy or battery store.

High blood pressure and methods of control

The cooling system is designed in such a way that the expansion tank cap is responsible for the pressure in it. Although there are various design options. For example, on some American cars, the expansion tank serves as a sump, and the cap itself is installed on the radiator tee. However, the essence of the work remains the same.

The pressure in the VAZ-2110 engine cooling system should be in the range from 1.2 to 1.5 atm, while a drop or exceeding of these values can already be considered a serious deviation. Quite often, motorists are faced with high blood pressure. The reason will be the same lid, the valve of which is stuck in the closed position. In this case, the system will warm up, the pressure will increase, but it will not be released. Because of this, steam-air plugs form, preventing the normal circulation of coolant through the system.

Articles

- 21110-1008650-00 – plastic screen (only for 11183);

- 21120-1008658-00 – rubber screen pin;

- 21080-1311065-00 (-01, -03) – expansion tank plug;

- 21080-1311067-00 – gasket for the plug.

Do you only need distillate?

We tried to expel air from the system, but on the VAZ-2114 the entire “plug” takes up 100-150 ml. This means you don’t have to add anything at all to the tank. You can also add regular distilled water.

It is easier to find a 100 ml package of distillate at a pharmacy or battery store.

Replacing a failed unit

The cooling system cap can last longer than the car engine, or you can buy a new one, which will be defective. It's hard to guess here. But in any case, you should not try to repair it. It costs a penny for most models and is non-repairable. In case of malfunction, it is simply replaced with a new one.

At the same time, it is strongly recommended not to shorten the springs by changing the moment of operation of the cover. After all, many motorists do this, which in most cases does not lead to anything good. Of course, if you have tuned the cooling system and engine, then it is quite possible that you need to achieve more pressure in the system or, conversely, less. In other cases, it is worth buying only the original or a worthy analogue with the same parameters. Remember that high pressure in the engine cooling system can lead to local overheating of the internal combustion engine and failure of certain components.

Signs of an airlock. why is it dangerous?

In addition to the engine running intermittently due to uneven cooling, there are several other signs of problems with the ODS:

- Rapid engine overheating.

- Non-working stove.

- The gas pedal falls off when driving slowly.

But even if you do not notice its presence based on the signs described above, the engine will soon inform you of its presence more clearly, for example with a wedge. The fact is that if its operation is disrupted, the SOD ceases to perform its main task - maintaining the temperature of the internal combustion engine and lubricants in it in the operating range.

Violation of this process significantly increases engine wear and subsequently leads to a violation of the mechanical integrity of its parts.

System leakage

An even more popular problem among motorists is lack of pressure. This may happen due to:

- stuck air valve;

- presence of leaks in the cooling system.

Accordingly, identifying the problem will not be difficult. The first thing you can do is look at the antifreeze level on a cold engine. If it does not change from trip to trip, then there are no leaks in the system. The second step is to replace the air valve with a new one. After this, the pressure should normalize and the antifreeze will not overheat. Very often, increased pressure in the engine cooling system causes it to then drop. This is partly due to the wedging valve. Sometimes it works, sometimes it doesn't. As a result, pressure builds up, which can cause a leak to form in a weak spot, and then the seal disappears.

Determining the cause

Video: Second car with a problem: the stove does not heat - there is air in the system!

The main indicator of the appearance of an air lock is that the stove is not working or is not working well. But this can also happen due to the fault of the same thermostat. If it gets stuck in the open position (the antifreeze constantly moves in a large circle), then the engine simply will not reach operating temperature and the stove will not heat up.

Therefore, if you decide to fix problems with the cooling system, first check the operation of the thermostat. This is easy to do; let’s look at the steps using the VAZ-2109 as an example.

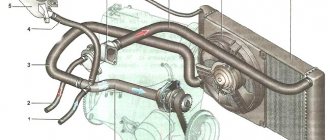

Start checking with the engine cooled down. We start the engine, open the hood, find the upper large pipe going to the radiator - it is a supply pipe and comes from the thermostat, we test its temperature with our hands. If the thermostat is working properly, the pipe remains cold until the engine warms up to operating temperature. As the engine reaches temperature and the thermostat opens, the pipe will begin to heat up.

If the thermostat is functioning normally, but the heating system is not working, there is likely an air lock in the system that needs to be expelled. But before that, eliminate the cause of its appearance. To do this, carefully inspect the connections of the system pipelines to see if there are any leaks.

Inspect the water pump and motor where the cylinder block meets the head. Traces of antifreeze leakage indicate damage to the gaskets. Eliminate the cause of the air lock, and only then solve the issue of airing.

A common cause of a plug is a violation of the technology for replacing and adding antifreeze; the problem with a non-heating stove is associated with it.

Video: How to avoid air in the cooling system when filling with antifreeze.

How to find a leak?

The first place to start is with a visual inspection. If you look under the car, it is likely that there is a puddle of antifreeze underneath. But even here you need to understand that often a gap appears only when a certain pressure is reached, so it will not be possible to find it when it is cold. However, there are special devices for pressurizing the system, and the engine must be cold to avoid burns.

As such a device, you can use a conventional pump and pressure gauge. Everything can be done in a garage. First of all, disconnect the upper pipe connecting to the expansion tank. It is advisable to insert a bolt of suitable diameter into the hole. Next, we connect a pump with a pressure gauge to the pipe and build up pressure. When reaching 1.5 atm. the air valve should operate. At the same time we are looking for a leak.

How to detect leaks

You can start with a visual inspection of the elements of the cooling system, however, if the leak is not severe, the inspection is unlikely to yield results. The most reliable way to identify a weak point is to create increased pressure and watch where the antifreeze comes from. To avoid burns, the car engine must be cold.

In garage conditions, this will require a pump with a pressure gauge or a compressor. From the expansion tank you need to disconnect the pipe coming to it from above and connect the pump hose instead. The disconnected pipe must be plugged with a bolt of suitable diameter and the bolt must be secured with a clamp. After this, you can build up pressure and see where the leak appears. By the way, when the 1.5 atm mark is reached, the air valve should operate.

Let's say there are no obvious coolant leaks, which means you should check the floor in the cabin; antifreeze may be escaping through a leaky heater radiator. If there are also no traces of coolant in the cabin, all that remains is to inspect the cylinder block and, last of all, the inside of the cylinders, having first removed the spark plugs. It would also be a good idea to check the engine oil level: with internal leaks, it increases as antifreeze enters the engine crankcase. » alt=»»>

The car's cooling system is designed to create and maintain a certain thermal regime for optimal operation of the engine, which gets very hot during operation. Its operating principle in most modern cars is based on heat transfer due to the circulation of a liquid coolant (antifreeze or antifreeze).

Nuances of the cooling system

Much also depends on the coolant used. For example, there is no need to pour water even into old cars; it is better to buy inexpensive antifreeze, there will be fewer problems. However, modern engines require high-quality cooling. The manufacturer indicates in the manual the recommended brands of coolant. It is advisable to follow these tips and not dilute the antifreeze if you do not have a concentrate.

Modern coolants have different service life and boiling points. For example, G12 boils later than G11, and G12++ has an increased resource, but it is also more expensive. In any case, to avoid engine boiling, it is recommended to fill only high-quality coolant.

Original spare parts

Very often, high pressure in the engine cooling system is formed due to a malfunction of the air valve, we have already dealt with this. Another thing is that this valve has an insufficient resource, or even a new one may not work. This also applies to other elements of the cooling system, such as a thermostat, water pump, pipes, sensors, radiators, etc. To sleep peacefully, it is better to get the original, the service life of which is often quite long. Of course, such spare parts cost several times more, but they almost 100% guarantee the proper operation of the unit as a whole. After all, the failure of such a seemingly insignificant element as a cover can lead to a major overhaul of the engine.

As for Chinese components, this is a lottery. Some of them can be quite high quality, while others do not travel even 100 kilometers. It’s better not to take risks, because the stingy pays twice.

Methods for eliminating air lock

To avoid wasting energy, first diagnose the entire system. Diagnostics will help to identify whether there are any leaks in the system, various defects and blockages. In addition, it is worth checking the operation of the thermostat. If it malfunctions at least partially, the entire system will work ineffectively, no matter how much air is expelled from it.

There are several options for getting rid of an air lock in the cooling system.

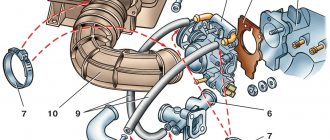

Before starting the elimination procedure, it is extremely important to completely change the antifreeze

The first way to remove an air lock in the VAZ 2114 engine cooling system is to remove the hose on the throttle assembly. You need to let the engine run. Take a container and place it under the hose that you will unscrew. A container is needed for the leaking liquid. After which the hose is screwed into place. And don't forget to add antifreeze. When using this method, the air comes out on the first try, but if you do all the steps again, the air lock will be completely eliminated. The next method of removing an air lock from the cooling system of a VAZ 2114 is in many ways similar to the first. The fundamental difference in this case is that the engine must remain cold. We begin to unscrew the already familiar hoses, as in the first method. Noticing that the antifreeze does not flow out, we take out the prepared tube to help it with this. You need to bring the tube to the tank, create a tight seal with your fingers and blow into it properly. We also place a container under the antifreeze flowing from the hose. Then we return the hose back and add antifreeze. Problem solved. In both the first and second methods, it is better to place the container under both the pipe and the hose, since you will never guess where the liquid will come from. And the last method, which does not require disassembly, but requires an assistant. It is necessary to drive the car onto the overpass. The top of the radiator should be higher than other parts. Then pour antifreeze to the edges of the expansion tank. After which the assistant starts the engine to warm up the system. Periodically you need to add gas up to about 3500 rpm

It is very important that the antifreeze does not boil. You also need to add coolant at the same time.

Add until bubbles stop appearing on the surface. The principle of this method is simple. A steam exhaust hose is connected to the radiator, which conducts air into the tank. In this case, the antifreeze level drops abruptly and then it is necessary to add fluid.

Now VAZ 2114 car owners know how to remove air from the cooling system. Everyone can choose the most suitable method for themselves. By the way, not all experts recommend the second option for performing the work. This is due to the fact that due to the inexperience of the car owner who decided to get rid of the airlock, antifreeze, which is toxic to humans, can enter the body. The work of expelling an air lock from the cooling system is not very complicated and does not require special equipment. All that is needed in this case is thick rubber gloves, rags, and containers.

Serious consequences

We have already discussed that pressure is created in the engine cooling system. It's quite normal. Another thing is that very often there is a malfunction that is extremely difficult to determine. For example, the antifreeze goes away, but there is no visible leak. In this case, it is quite possible for coolant to enter the engine crankcase. It is recommended to check the oil level regularly. If the coolant actually goes into the engine, the level will increase. Most likely, this indicates a broken cylinder head gasket, changing which is tantamount to rebuilding the power unit.

Any part has its own specific resource, upon reaching which there is no guarantee that it will continue to work properly. There are often cases when even a new expansion tank cap turns out to be inoperative. And now we are not talking about Chinese spare parts, but about original ones. Unfortunately, there is no escape from this.

Causes of poor-quality stove operation

Based on the complex structure of the stove, it becomes clear that it may not work correctly for many reasons. A malfunction of at least one of the components and components of the heating system can lead to a malfunction of the stove. In this case, a malfunction may occur due to the driver’s fault, or it may be a consequence of aging or incorrect operation of other vehicle systems.

Problems with the stove can manifest themselves in the following ways:

- Poor interior heating.

- Cold air from the stove.

- Variable temperature of air supplied from the stove.

- Weak flow of hot air from the stove.

- The heater in the car does not turn on.

Knowledge of the structure of the stove itself and possible breakdowns will make it possible to avoid large expenses when repairing a car. Let's look at the most common causes of poor-quality stove operation below.

Fan doesn't work

A fan malfunction can often be one of the problems with heating the interior. The cause of this failure is usually damage to the bearings or graphite brushes, which may require complete fan replacement. Also, the fan may be faulty due to the blown fuse or relay in the electrical power circuit, which is also a reason to contact a car service center.

If the fan makes a whistle during operation, and its rotation speed changes from minimum to maximum and vice versa, then the cause of the problem may be a failure of the fan motor. In such conditions, the radiator may remain hot, but it will not be possible to warm the interior to the desired degree.

Insufficient coolant level

A malfunction of the stove can be caused by a coolant leak, as a result of which heat stops flowing into the cabin radiator in the required volume. This in turn leads to a decrease in the volume of antifreeze in the expansion tank. To fix the problem, you need to find the location of the leak, add antifreeze to the expansion tank, and sometimes it may be necessary to replace the coolant supply valve.

Engine pump faulty

The pump is used to circulate antifreeze and to ensure proper functioning of the stove. If such a pump breaks down, a malfunction may occur in many engine components, including the vehicle interior heating device.

A malfunction of this part can be caused by wear on the inside of the impeller, a broken crankshaft belt, or even jamming of the pump itself. It is better to eliminate this kind of problem by completely replacing the pump, and to avoid such breakdowns, it is recommended to regularly check the hose leading to the pump, and also listen to sounds under the hood.

Blown engine head gasket

The head gasket is designed to connect the block and the car engine head itself, ensuring tightness and preventing coolant and fuel from mixing with each other. Burnout of the gasket in the engine cooling jacket leads to the generation of exhaust gases, which can enter the cooling system through the pipes. In this case, the heat exchanger becomes airy and the efficiency of its operation decreases, the coolant can heat up, and malfunctions are observed in the operation of the stove.

Thermostat malfunction

The thermostat is a device directly involved in the circulation of coolant, so its malfunction will affect the air temperature in the cabin. Since the thermostat can be in an open or closed position, its failure is characterized by jamming in one of these positions.

If the thermostat is stuck in the closed position while driving in city traffic, the temperature of the antifreeze may increase, and subsequently the engine may overheat. When stuck open, the interior temperature will be low when driving in high gears, while the temperature will remain normal at low speeds.

Heater core blockage

The heater radiator can become clogged for various reasons, and this can happen both from the outside and from the inside. For example, the outside of the radiator may become clogged due to dust, leaves, and insects entering through the protective casing. On the inside, clogging occurs due to dirt and deposits that can form in the engine cooling system.

Cabin filter clogged

A heavily contaminated cabin filter is one of the common causes of stove malfunctions. Many drivers treat it quite dismissively and do not replace or throw away the old one for a long time.

It should be remembered that a clogged filter is an obstacle to the flow of heated air into the cabin. In addition, when the filter is clogged, dust and mold spores can enter the cabin and accumulate in the filter itself.

Let's sum it up

So we figured out why there is pressure in the engine cooling system, why it can be excessively high or, conversely, low. There is often nothing complicated about checking it yourself, although a lot depends on the car. For example, it happens that the coolant temperature sensor fails. It can provide incorrect data to control devices, thereby misleading the driver. It can show both a high temperature of the power unit and, conversely, a low one. But this will not mean that the system is not working correctly.

If there are any breakdowns in the cooling system, they must be repaired as soon as possible. It is advisable not to operate a vehicle with a stuck cover or thermostat. After all, for some engines overheating is fatal, and major repairs are not cheap at all. In general, it is worth regularly checking the coolant level in the system to ensure that there are no leaks or other defects. It is also recommended to periodically clean the radiators from dirt, as this can cause increased engine temperature.

Didn't find the information you are looking for? on our forum.

Causes of air locks

Air is characterized by relatively low thermal conductivity, and by itself it is rarely used as a cooling agent (the exception is radiator blowing, but the reasons here are prosaic - the complete absence of energy costs). But its danger when mixed with technical fluids lies not so much in the reduction of heat capacity, but in the formation of air pockets, which, accumulating at the highest points of the line, prevent the free flow of coolant.

When does air leak into a sealed engine cooling system? There may be several reasons:

- depressurization of the system is a violation of the integrity of the connections of pipes, tubes, hoses at the point of their attachment to the fittings, which leads to such a phenomenon as suction of outside air. This can happen as a result of overheating, accidental mechanical impact, inept driver actions, or due to natural wear and tear. Separately, it is worth mentioning cases where loss of tightness occurs due to prolonged exposure to low pressure in the system, observed at the surface of the pipeline walls during coolant movement;

- Many drivers don’t even realize that when replacing or adding antifreeze, if done quickly, a large funnel is formed that does not allow air to escape. As a result, a noticeable amount of air enters the system, which threatens the formation of traffic jams with all the ensuing consequences. Therefore, the recommendation to pour antifreeze in a thin stream, regardless of time, remains relevant for a significant part of car owners;

- problems with the functioning of the air valve. A pump is used to circulate coolant in the system, but the pressure created is not static: due to the heating of the liquid, the pressure increases in certain sections of the line, and decreases in the area of the radiator. This is, in principle, normal. But in some cases, the area of high pressure reaches the expansion tank, the air in which is compressed, and the valve in the tank lid bleeds it out. At reduced pressure, the reverse process occurs - air is sucked in. But if the valve is stuck, then it only works in one direction. This is fraught with the accumulation of air mass, which is simply forced to move on through the pipelines, mixing with the coolant;

- air can penetrate into the CO through a leaky pump seal, as well as through the fiber if it has end-to-end mechanical defects;

- antifreeze leaks through the connections of hoses, pipes and both radiators may not lead to air entering the system through them, but in such cases the volume of coolant decreases, which automatically leads to an increase in air volume (through the expansion tank). If the radiator is clogged, the engine begins to overheat, and collectively this leads to the formation of traffic jams;

- Violation of the integrity of the cylinder head gasket is another common cause of antifreeze leakage penetrating into the cylinders, as a result of which the volume of coolant decreases, and you already know the consequences of this phenomenon.

By the way, when antifreeze gets from the cylinders into the crankcase and accumulates there, checking the oil level with a dipstick may show its increase. If coolant enters the exhaust system, this can be detected by a change in the color of the exhaust from transparent to white.

This problem should not be treated as a minor issue. Troubles if airiness and the causes of its occurrence are not eliminated may be too serious. A change in the normal circulation of antifreeze along the main line is only the first sign, but this is where problems with heat removal from the power unit begin.

Since coolant does not enter the radiator due to air locks, it does not cool and flows into the engine while still hot. The latter begins to overheat, worsening its dynamic performance.

A secondary manifestation of CO airiness is deterioration in the performance of the cabin heater, since antifreeze does not reach it, and the operation of the fan does not improve the situation - cold air continues to flow into the cabin

Most often, drivers pay attention to traffic jams not because the engine is overheating, but because they are cold

In the warm season, this reason also becomes unobvious. Meanwhile, the abnormal temperature conditions of the engine will sooner or later result in thermal shock - the worst thing that can happen to it at all. And then you cannot avoid spending a lot of money on restoring the engine, and you will have to do without a vehicle for quite a long time - such malfunctions cannot be repaired in a day or two.