Cause of valve knocking

Not a single mechanism, including internal combustion engines, can operate without timely maintenance. It is important to carry out preliminary diagnostics and routine repair work, regardless of whether the power unit is working properly or not. All sorts of foreign noises from under the hood are sure signs of malfunctions, which, if not promptly intervened, can result in very significant costs for the car owner.

Perhaps the knocking of valves cannot be confused with another sound source. In terms of noise level, only a motor that troits can compete with the clatter of valves. The problem under consideration is typical for engines that have traveled more than one hundred thousand kilometers, were untimely and poorly serviced, or were subjected to loads that exceed the rated load. In the latter case, valve knocking can occur even on a new car that is still under warranty.

As for the cause of the knocking, it is quite obvious and is characterized by an increase in the gap between the camshaft cams and the levers. A metallic clatter appears when the gap set by the manufacturer exceeds the permissible limits. Such a malfunction cannot be ignored, since the unpleasant sound itself is just “flowers”.

ENGINE KNOCKING IN FRONT WHEEL VAZ CARS

In front-wheel drive VAZ cars, the engines may have different digital indices, since the engines are installed on different car models. But basically all power units have the same circuit diagram, but they may differ:

- 8-valve or 16-valve cylinder head;

- Piston diameter;

- Carburetor or injection fuel system;

- Minor design features (different sensors, collector configuration, etc.).

In particular, the VAZ 2114 car is equipped with an 8-valve 4-cylinder engine with a volume of 1.5 liters of the VAZ 2111 model, with a fuel supply system of the “injector” type (distributed injection). Exactly the same internal combustion engine (ICE) is equipped with the VAZ 2115 and VAZ 2113.

Various knocking noises can occur in an internal combustion engine, and it is not necessarily the valves that are knocking. Knocks can occur:

- In the piston group,

- In the crank mechanism;

- In the gas distribution system;

- In attachments (water pump, generator, etc.).

Why does the engine knock, what could be causing the knocking:

- insufficient amount of oil in the oil system crankcase;

- wear of parts due to long-term use;

- manufacturing defects;

- engine overheating;

- operation of the motor at constant maximum loads.

Knocking in the VAZ 2114 engine has a different character; determining the cause is sometimes difficult even for technicians who have some experience in repairs. But there are characteristic sounds that are identified quite easily:

- a sharp “dry” metallic sound, clearly audible when you sharply press the gas pedal. This is how the crankpins (bearings) of the crankshaft knock. This is a serious knock, at a minimum, it requires crankshaft grinding;

- the sound is medium in tone; when the speed increases, it seems that something is rolling around inside the internal combustion engine. This is how the pistons usually knock;

- single clicking sound. As the speed increases, it seems to merge, and is similar to the sound of a working sewing machine. This is how parts of the gas distribution mechanism (camshaft, pusher) usually knock.

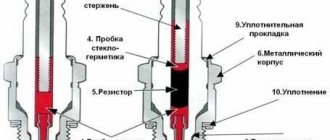

How do valves knock, how to determine it? The valve knock is usually quite sharp, clicking, and high-pitched. He can knock not just one, but several at once. To understand the cause of various noises in the gas distribution mechanism (GRM), you need to have at least a little idea of its structure. The VAZ 2114 timing belt consists of the following elements:

- camshaft.

- timing gear.

- Timing belt.

- Pushers.

- Adjusting washers.

- Inlet and exhaust valves.

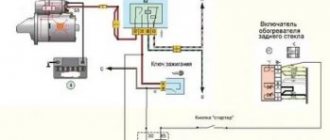

Basically the scheme works as follows:

- From the rotating crankshaft, movement is transmitted through the timing belt to the camshaft gear;

- The gear is rigidly fixed to the camshaft (fixed with a key and secured with a bolt), so the shaft is also driven;

- The camshaft cams press on the adjusting washer located in the outer part of the bottom of the pusher.

- The pusher presses the valve, the valve opens and closes when the crankshaft moves, the working mixture is filled into the internal combustion engine cylinders, and the working cycle is completed.

The cause of the knock can be any link in the gas distribution mechanism. But there are the most common reasons:

- Large gap between the camshaft cam and the pusher;

- Wear of camshaft bearings;

- Wear of the seat in the cylinder head (cylinder head) under the camshaft;

- Worn uneven surface of the adjusting washer;

- Breaking of the seat for the pusher in the cylinder head.

Why do engine valves knock?

- When an engine operates for a long time with a faulty gas distribution system, this cannot but affect its performance characteristics and service life. In particular, there is increased wear of all working components, due to which the engine may even fail. The car owner must understand that for each car model the valve clearances are individual, so adjusting them “at random” will not bring the desired result.

- If the clearances are adjusted incorrectly and their value is less than the normalized value, the valves will be constantly clamped during operation. Operating valves under these conditions may cause them to stop closing completely over time. The consequence of interruptions in the operation of the gas distribution system is frequent overheating of the engine and a decrease in compression in the cylinders.

- If valve knocking begins to be heard when the engine is warm, most likely the oil pressure in the system does not meet the required standard. In any case, to avoid problems, the valves should be adjusted every 15-20 thousand kilometers.

- Also, the knocking of valves or one valve when the engine is cold when warming up can be heard with faulty hydraulic compensators; when the engine warms up, the noise from the valves usually goes away, in this case you can still wait for repairs, this is not critical, in this mode the engine can still run for a very long time time and 10 and 20 thousand kilometers

The need to replace hydraulic compensators on the cylinder head occurs when knocking from the valves occurs both on a cold and on a warm engine. In this case, it is recommended to completely overhaul the cylinder head.

What to do if valves are knocking

Extraneous noise in the engine appears most often on cars that the owners do not take care of, and if they do, it is from time to time, and the breaks in these cases are usually very long. An illustration of this can be an analysis of the reasons why valves knock.

The most common reason is increased clearance between the arms and the camshaft cams. And this reason can be eliminated simply by adjusting the valves. And, again, an elementary thing that every driver should know - the valves must be adjusted every fifteen thousand kilometers. This is a mandatory rule.

Careless drivers have had cases when they remembered the valves after 70 thousand miles, and then the car mechanic could not do anything with them, they could not be adjusted.

Car owners often worry about valve knocking on a cold engine. That is, when the engine is cold, there is a clear knocking sound, but as the engine warms up, these sounds disappear. Experienced automobile mechanics explain this by saying that on a car with a fairly high mileage, parts wear out, and this especially happens with parts of the power plant. Small gaps appear between them, which generally do not affect the operation of the systems for the worse, but manifest themselves in a cold state. It is because of these resulting gaps that such annoying sounds appear for drivers. When heated, the metal expands, the gaps disappear, and along with this the unpleasant sound disappears.

However, this does not mean that one should be indifferent to extraneous noise in the engine when it is cold, especially if the owner monitors the timeliness of all adjustments. After all, on a cold engine, at idle speed, the main or connecting rod bearings of the crankshaft can make noise, and this is already very serious. You should definitely contact a specialist for diagnosis.

Every driver heard the valves knocking when hot. Especially with a sharp increase in speed. The most common reason for this is low-quality gasoline. But there may be other reasons, for example, a knock sensor has failed. Or the oil pressure has dropped.

In addition to increasing the clearance, the causes of noise produced by valves can be:

- wear of the camshaft cams - in this case it is necessary to replace the entire camshaft;

- valve spring failure - if this is detected, a new spring must be installed;

- the guide bushing may need to be adjusted or replaced;

- Valve knocking can be caused by completely different reasons, for example, a poorly tensioned timing belt or poor flow of oil through the camshaft to the fingers due to clogged channels in the valve.

It is very difficult for an inexperienced person to determine by ear that the valves on a VAZ 2114 are knocking. Nevertheless, experts recommend some folk remedies, recalling that the camshaft rotates twice as slow as the crankshaft and, accordingly, the sound of the valves should not be frequent. For better sound perception, they suggest placing an empty metal mug to your ear and placing it on the hood. In this case, the sound becomes clear and easy to hear.

When operating a car, the driver must remember that extraneous noise in the engine can be avoided by constantly monitoring the condition of all systems, promptly replacing spare parts that have been used under warranty, and making all necessary adjustments.

Source

How to avoid valve knocking

It is important to understand that during routine maintenance, both intake and exhaust valves are subject to adjustment. As for the decrease in oil pressure in the system, a similar nuisance occurs when it thickens and is not replaced in a timely manner.

It is difficult for thick oil to penetrate through thin oil channels; therefore, some components do not receive adequate lubrication, which leads to their premature wear. Perhaps the most terrible consequence of untimely oil changes can be the failure of the crankshaft main bearings.

Valve adjustment should be carried out by professionals at a specialized service station. In fact, this procedure is not too complicated and inexpensive. To work, the master only needs a probe, which is installed between the top point of the rod and the rocker arm. The adjustment will not take much time and will allow the car owner to remain calm about the condition of his vehicle.

Valve knocking: main reasons

At the very beginning, we note that valve knocking is a problem that is more typical of engines without hydraulic compensators. In other words, these elements can knock on engines that structurally require the need to adjust the valves at a certain frequency. As for engines that are equipped with hydraulic compensators, in units of this type it is often not the valves themselves that knock, but the compensators mentioned above.

We also recommend reading the article about what a hydraulic compensator is. From this article you will learn about the design of this element, as well as how hydraulic compensators work to automatically adjust the valve clearance.

Valve knocking usually appears on engines in two cases:

- natural wear and tear of the power unit as a result of impressive mileage;

- the valves are not adjusted or this procedure was performed incorrectly;

In other words, the mechanism can knock both on an old engine and on a relatively new engine that has only traveled a few tens of thousands of km. The main reason for this knocking is a strong increase in the gap that is present between the camshaft cam and the lever. An increased gap between these elements means that the camshaft cam hits the rocker. The result is a general increase in noise during operation of the engine and timing belt; the engine runs “hard”. The appearance of a distinct ringing metallic sound was also noted, which is clearly audible and localized in the area of the cylinder head and valve cover.

It should be understood that the valve thermal clearances initially set at the factory tend to get lost after several tens of thousands of kilometers traveled. It is for this reason that the owner needs to adjust these gaps from time to time. The setting is carried out taking into account a strictly defined value for a specific type and model of engine, which is prescribed in the operating instructions for a particular vehicle.

Let us immediately note that the generally accepted recommendation for valve adjustment intervals is a mileage of 15-20 thousand km. Before making adjustments, especially on older engines, it is necessary to eliminate the possibility of problems with oil pressure in the lubrication system. The gap adjustment itself is carried out using feeler gauges. These probes are inserted into the slot, which is located between the pusher and the cam on engines with an overhead camshaft. On other types of motors, the gap is located between the upper edge of the rod and the rocker arm. When setting the gaps, it is also advisable to take into account the outside air temperature. The valves are optimally adjusted at a temperature of +20 degrees Celsius. If adjustments occur, for example, at negative temperatures, then this nuance should be taken into account and a certain correction should be made for it.

Reducing the gap (the valves are clamped) is also unacceptable. The fact is that in the case of clamped valves, the following happens: after a relatively short run, they stop closing completely. If these elements cannot close completely, then the compression in the cylinders drops due to depressurization of the combustion chamber, hot gases break through the gap between the valve and the chamfer, engine overheating, valve burnout, etc. occurs. In this case, the engine starts poorly, loses power, consumes too much fuel, suffers from trouble, etc. The result is the impossibility of further normal operation of the internal combustion engine and the need to eliminate both the problem itself and the likely consequences of driving with clamped valves. Please note that the degree of increase or decrease in the gap directly affects the wear of not only the timing belt, but also the entire engine. Long-term operation of the power unit with obvious knocking in the gas distribution mechanism leads to serious damage and rapid failure of the entire power unit.

We also recommend reading the article on how to determine valve burnout yourself. From this article you will learn by what signs and in what ways you can find out that the timing valve has burned out.

Valves are knocking - why not come visit the engine

Owners of modern cars sometimes notice some kind of unnatural ringing knock coming from under the hood. It's the valves knocking. Many people are surprised by this fact. According to the general opinion, valve knocking is typical only for old cars, where the thermal gap is adjusted using a bolt or selecting washers. Mechanical wear of the working parts of the camshaft cams and other parts contribute to an increase in clearances. This is all clear.

How to explain the origin of the knocking if the thermal gap is adjusted automatically by such newfangled devices as hydraulic compensators? It turns out that in this case, valve knocking can occur very often. The reasons for the appearance of such an unpleasant sound are much greater than those of other types of valve thermal clearance regulation.

A little theory about valves

It is believed that the hydraulic compensator is the most reliable system for regulating valve thermal clearances. In fact, if all engine systems are in full working order, the driver should not worry at all about adjusting the gaps. A hydraulic compensator, consisting of a housing and a plunger, is installed between the camshaft cam and the valve. The clearance is adjusted automatically each time the cam is pressed due to the oil pressure in the lubrication system.

The main sources of extraneous sounds in the engine

You must understand that not every extraneous sound is a signal of engine malfunction. This primarily concerns knocking noises in the outer parts of the engine. But everyone has a reason that must be found. For example, the flagellum that holds together the bundle of electrical wires has broken. The wires fell apart and when the engine was running, some of them began to muffledly hit some surface. Will this lead to serious consequences? At first, no. If measures are not taken, then after a long time the insulation on the wire will wear out and a short circuit may occur, which, through the combustion of a fuse, will de-energize some part of the on-board network. Parts that have loose fastening bolts often knock. This is also an unpleasant, but not critical situation. It is enough to take the keys and tighten the loose threaded connections yourself.

Types of extraneous noise in the power unit

Here are the most common extraneous sounds in the engine that should alert the car owner:

Hissing . This specific sound under the hood of the car while the engine is running may indicate air leaks in depressurized vacuum systems or in the cooling system. The consequences can be severe. In the first case, the brake system may fail, in the second, the engine may overheat due to an antifreeze leak. Therefore, you urgently need to go to a car service center to diagnose and eliminate the cause of the hissing sound.

A squealing or sharp whistling sound most likely indicates a weakened drive belt of some component: timing belt, generator, water pump, air conditioning compressor. The belt begins to slip in the drive pulleys and at the same time emit a characteristic squeal. If timely measures are not taken, the belt may break with unpleasant consequences.

Knocks of different tones inside the engine in the area of the crankshaft, pistons, and valves give rise to diagnosing the operation of the engine as a whole to identify the cause of extraneous sounds. Unusual knocking inside the engine is a cause for the most serious concern. Their appearance may signal the possible high costs of eliminating them. If the liner rattles, you will need to disassemble the engine with grooving or even replacing the crankshaft. A knocking sound appeared in the middle of the block - the connecting rod and piston group was worn out. You will need to completely disassemble the engine, bore the cylinder block, change pistons, rings, pins. If the sound is clearly audible in the upper part, then perhaps the valves need to be adjusted, or perhaps the piston reaches the cylinder head due to a large gap in the connecting rod bearings.

Reasons for the appearance of extraneous sounds in the engine

The reasons and circumstances under which knocking appeared are different. Extraneous noise can be clearly heard both outside the engine and inside it. Internal ones are more dangerous than external ones. The cylinder block contains the crankshaft, pistons, connecting rods, and parts of the gas distribution mechanism. If the knocking comes from this group of mechanisms, then this is always associated with partial or complete disassembly of the engine to eliminate the malfunction. Often the sounds are sharp in nature, which intensifies when the throttle is opened smoothly. If the sounds are loud, with a “light tinkling” of iron and appear with a rapid increase in the speed of rotation of the flywheel, then this indicates detonation - a violation of the fuel ignition regime.

Video: Mercedes 126, found the cause of the knocking in the engine

Knocks from detonation

If the knocking is strong with a ringing “metallic” tint and occurs when the gas pedal is sharply pressed, or under load, then this is the result of detonation - explosive combustion of fuel in the cylinders. Moreover, detonation occurs differently in different types of engines. Gasoline engines have the expression “knocking fingers.” This is not entirely correct. In fact, during abnormal fuel combustion, the piston skirt knocks when it passes top dead center. Gasoline detonation is the result of refueling with poor fuel with a low octane rating, incorrect valve timing adjustment, and prolonged engine operation in an overheated state. To eliminate detonation, it is enough to cool the engine, adjust the fuel injection and ignition systems, and fill the tank with gasoline in accordance with the technical regulations of the car.

Diesels also have fuel detonation, but their reason for its formation is different. This is an early injection of diesel fuel or a lean fuel mixture, which arises from improper operation of the pressure valve in the high-pressure fuel pump (HPF). Moreover, the sound will be loud, ringing, similar to the blows of a piston on the surface of the cylinder head. In such cases, they say that the diesel engine operates “hard”. This impression arises because the compression ratio of diesel engines is much higher than that of gasoline engines, so in normal operating condition the distance between the piston and the block head is microscopic. You can get rid of detonation by restoring the operation of the pressure valve on a special stand in a service station.

Even in diesel engines, at idle speed, the knocking of the plungers is clearly audible. This is a design feature of almost all engines of this type. These sounds do not pose any threat. Diesel engines have been used with them for more than one year. In engines with gasoline injection, an experienced ear hears the “clicks” of fuel injectors, which are also inherent in most engines of this type. They do not pose any serious threat to the engine, and in no way affect its performance characteristics.

Valve knocking on cold and hot engine

Valve train problems can cause all kinds of problems with your car's engine, including:

- High oil consumption

- Blue smoke

- Cylinder head noises

- Misfires

Problems can arise, for example, when:

- You allow the oil level to drop

- Don't forget to change your oil regularly

- Operating the engine when it is very overheated

- Or work for a long time without maintenance or without correcting engine problems

Why do engine valves knock?

But problems with the valve train can occur even if you regularly maintain your engine and make the necessary repairs, especially if it has a high mileage.

Whatever the cause, this guide will help you diagnose the most common valve train problems and their potential sources. Diagnose the problem sooner rather than later to avoid costly repairs.

To make this easier, the following sections are divided into symptoms that can be caused by different types of valve problems. Look at the index below. If one or more of these symptoms are similar to what you are dealing with, go to this section. Reading the additional sections will give you more ideas about the types of problems that may arise and will help you with your renovation project.

Before you begin, however, keep in mind that while we're focusing on valve train problems here, none of these symptoms are exclusive to the cylinder head. Therefore, try to get as many clues as possible during the diagnostic phase and, if necessary, troubleshoot suspected components. You will find some troubleshooting tips in the relevant sections.

What's wrong with them

Now we will describe common reasons explaining why valves knock. In modern engines, the camshaft is located on top, its cams push the valves through rods - a simple, best mechanism. The rods are called pushers.

- There is always a minimum gap between the tip of the pusher and the cam, regulated by the manufacturer. An increase in the gap is one of the reasons why the valves began to knock. As the gap decreases, knocking will also appear, and the valve may eventually stop closing tightly.

- Another possible cause of monotonous valve song could be a knocking engine, for example, due to bad gasoline.

- If valves knock only during acceleration, this is most likely due to increased engine speed and insufficient oil pressure.

- The malfunction may occur due to a poorly tensioned timing belt.

- Finally, it is simply wear of parts or shaft cams.

With all this, it is necessary to distinguish between two main types of the problem being analyzed. Valve knocking sometimes occurs only on a cold engine or, on the contrary, only on a warm one. Let's look at these varieties separately. If the valves knock only when cold, then the essence of the phenomenon is as follows:

- the engine is a bit old, worn parts show themselves with large gaps when starting up, gradually, when warming up, the iron expands, the gaps decrease, the sound disappears, this is the main answer to the question why valves knock only on a cold engine;

- The gap between the pusher and the cam is no longer normal, but on a warm engine it still does not produce an extraneous sound.

If the problems with the valves are only hot, then the possible prerequisites are as follows:

- the bolt securing the camshaft to the bed is not tightened well; when warming up, the cam seems to move away from the pusher;

- insufficient oil level in the engine, severely clogged oil filter - because of the latter, for example, there is no longer enough oil for the valves when it’s hot;

- hydraulic compensators are knocking.

About hydraulic compensators and more

Let's talk about them separately now. If they are not there, for example, when a VAZ 2109 (which does not have them) has a valve knocking somewhere, then the last reason from the above list immediately disappears... So, if they are not there, the valve clearances are adjusted using special washers, and if they are there are... They perform a self-regulatory function.

In general, a hydraulic compensator includes a housing and a plunger. Both are located just between the cam and the valve. When the cam moves, oil from the engine enters the housing, pushing out the plunger. It fills the entire thermal gap between the cam and the end of the valve stem when the valve opens, and when it closes, the oil leaves. This solves the problem.

It is precisely because of this design of hydraulic compensators that insufficient oil pressure causes a distinct knocking of the valves. By the way, such disadvantages of hydraulic compensators as complicated design, loss of some power, increased wear of the camshaft forced Toyota engineers to abandon this system when designing.

However, many modern engines of VAZ cars have hydraulic compensators installed. Therefore, you need to be careful about the valve knocks of these cars when the engine warms up.

By the way, you should not confuse the sound of a different nature with valve tapping, when the adsorber valve on a Priora or Kalina simply knocks - this is a typical problem for them. It can be treated simply: remove this unit from the air filter housing, find an adjusting bolt slightly filled with epoxy-type material, and rotate it.

Why do my fingers knock in the engine?

| Index |

| I. Blue smoke comes out of the exhaust pipe |

| II. My engine won't idle |

| III. My engine is making shots from the exhaust system |

| I can hear the crash |

| V. I hear a rumbling noise |

| VI. I hear a knock |

| VII. My engine has no power |

| VIII. Preventing problems |

Problems with the valves can lead to exhaust pipe smoke.

How to Replace a Worn Rod Seal

It is often possible to replace worn rod seals without removing the cylinder head.

Some shops fill the combustion chamber with compressed air to hold the valve in place while replacing seals. You may not have compressed air at home, but you can use a flex cable or similar soft, thick cord instead.

- Place the transmission in Park (automatic) or Neutral (manual), and set the emergency brakes (Handbrake).

- Remove the spark plug from the cylinder you need to work on.

- Rotate the piston you will be working on to BDC (bottom dead center). Rotate the crankshaft using the socket and jumper on the front crankshaft bolt. If necessary, remove all spark plugs to make it easier to turn the crankshaft.

- Fill the cylinder with about 5 feet of cord. Use a large screwdriver to push the wire through the spark plug hole. The end of the cord should hang in the spark plug hole after filling the cylinder so that it can be pulled out later.

- Raise the piston to TDC (top dead center) by turning the crankshaft by hand. This allows the cord to press against the valve and hold it in place.

- You can now use a spring compressor to replace the valve seal.

- Install a new seal.

- Reinstall the remaining components.

- Turn the piston towards bottom dead center and remove the cable.

If necessary, consult your vehicle's repair manual.

A dirty spark plug due to oil leaks can cause a misfire.

ADJUSTMENT

In any case, if a characteristic valve knock occurs in the engine, it is necessary to check the condition of the valves. In this case, adjustments should be made. To adjust the valves of the VAZ 2114, factory-made adjusting washers with a thickness of 3 to 4.5 millimeters are provided, the thickness changes every 0.05 mm. We make the adjustment as follows (you will need a special shim remover and washers themselves of varying thickness):

- Disconnect the throttle cable bracket from the valve cover;

- Remove the valve cover (two bolts);

- We dismantle the timing belt casing;

- We set the top dead center in the first cylinder of the internal combustion engine (there is a mark on the timing gear). How to align the marks can be found in the repair and operation manual. You can turn the camshaft clockwise using the camshaft bolt. But this must be done carefully and without unnecessary effort;

- We check the gap with a set of automotive feeler gauges between the pusher and camshaft cams 1 and 3 valves according to the timing belt. The intake valve should have clearance

0.2 mm, at graduation it is larger on average

0.35 mm;

- We remove the adjusting washer and look at the markings (thickness is indicated in three numbers). Using mathematical calculations, we determine the required thickness to adjust the gap and install the new washer in place. We immediately check the resulting gap;

- We turn the camshaft a quarter turn clockwise and adjust valves 2 and 5. After another quarter - 6 and 8, the last ones to adjust are valves 4 and 7, also after ¼ turn.

- After adjustment, we put everything back together in the reverse order, start and listen to the engine.

My engine won't idle

Extremely high temperatures in combustion chambers can damage the valve surface or seat. These high temperatures can be caused by a stuck EGR valve or carbon deposits. If heat chips away at the surface of the valve face or seat, it can cause:

- Combustion pressure leak

- Misfire, usually at idle

- Noisy valve

How to Diagnose a Burnt Valve

- If compression pressure is leaking through the intake valve, you may hear a chugging sound from the carburetor or throttle body.

- If pressure is leaking through the exhaust valve, you may hear a puffing sound from the exhaust pipe. Watch the following video for an example of bad exhaust valve noise coming through the exhaust pipe.

To confirm a compression leak and its likely source, perform a compression test, cylinder leak test, or vacuum test.

If it is burnt out, you need to remove the cylinder head, process the seats and replace the burnt ones (or all).

Cotton from a car exhaust pipe

Cylinder head problems can also be caused by a floating valve. A float valve condition occurs when the valve fails to close and seal the combustion chamber tightly. This is usually due to a weakened or broken valve spring.

A weakened spring is more common on high mileage engines. After miles of service, the spring loses strength, allowing it to float.

The valve may also float due to a broken spring. Usually the gap between the valve stem and rocker arm widens, which also causes noise.

Any of these conditions can lead to:

- Tapping noise

- Cotton from a car exhaust pipe

While mechanical problems are the main cause of a floating valve, excessive engine speed can also prevent the valve from closing properly, leading to engine performance problems.

How to diagnose a sound coming from the cylinder head:

- Remove the cover

- Set the engine to idle speed

- Watch valve movement

- Press your thumb on a suspicious valve lever to calm it down

- If the noise stops or changes significantly, you have found a faulty one.

If you suspect a worn spring and other valve system components are in relatively good condition, remove the spring for inspection.

There are two basic measurements used to test a spring. If the spring is not broken:

- Check the height of the installed springs

- Use a valve spring tester to check the spring tension (you may need to take the spring to the machine shop for this test).

Compare your results with the specifications. Refer to your vehicle's repair manual.

VAZ 2109 valves are knocking

- Registration

- Entrance

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

- List of forums AUTOLADA.RU

- Family "Samara"

- 1

- 2

- >

Source data: 21083, carb. The engine is normal, the compression is high, it doesn’t consume oil, the valves have just been adjusted (they did a good job, we know someone who has a good service).

Problem: when accelerating hard (not even on the gas), up to 3000-3300 you can clearly hear the knocking of valves. When passing 3300 it subsides and disappears (as far as possible for 083). There are no failures during overclocking.

What I did: 1) I moved the advance towards a later one - it doesn’t help 2) I removed the vacuum accelerator hose - it’s still knocking 3) I checked the marks on the camshaft and crankshaft - they match, it hasn’t slipped

What else am I thinking of trying: 1) Fill in 95 2) check the operation of the distributor 3) check if the mixture is lean (although I really don’t fully understand what the mixture might have to do with it)

Question: how to check it (distributor)? what to look at? How to make sure that the ignition is set late and make sure that the problem is due to its incorrect setting or distributor malfunction? Otherwise I’ll change the distributor, but the problem is different - maybe there’s something wrong with the head itself?

Please help me with advice. Thank you!

OK, I'll try tomorrow, although it's strange - I used to drive 92 before and there were no problems (((.

For me, the ignition is taking it far beyond reasonable limits. Just now.

OK, I'll try tomorrow, although it's strange - I used to drive 92 before and there were no problems (((.

Almost sour and fresh were mixed.

With incorrect OZ and bad gasoline, the piston pins knock.

Valves knock only from incorrectly set gaps. There is also a knocking sound of some kind of crap (it flew out of the head, glasses or something) in the timing belt, eliminating which is a difficult task, the result of which is just stopping the knocking.

Almost sour and fresh were mixed.

With incorrect OZ and bad gasoline, the piston pins knock.

detonation occurs, and not the fingers knock

If the mileage of the head is over a hundred, then the valve guide bushings may knock due to wear, which can only be solved by repairing the cylinder head. If the valve clearances are normal, then there will be no knocking, but the oil may also be to blame. What kind of oil is it fake?

Can you tell me more about oil? What could oil have to do with it?

Please help me with advice. Thank you!

There may be some banal carbon deposits on the pistons and you will be turning the distributor for a long time to no avail.

If all of the above dancing with a tambourine does not help, take off the head and clean the piston.

when I run in

20 thousand soot was 2 millimeters

and this despite the fact that I only fill up with 95 and at trusted gas stations.

Damn, they actually stopped knocking at 95.

What is the trick, can anyone explain clearly?

13 in all 4 cylinders.

to Murphy, whatever you call it, a knock is a knock. The most interesting thing is that I moved the distributor both earlier and later - it still knocks. as then?

Does detonation occur with late ignition? Well, let’s say I actually have detonation (with, let’s say, late ignition). how did changing from 92 to 95 help? Has detonation resistance increased?

agree. and how and why the OZ affects detonation.

I read an article here.

everything is very beautifully described, but the conclusions are somehow opaque

How can detonation be reduced during operation?

The occurrence of detonation, in addition to the chemical composition of the fuel and the design features of the engine (mainly the compression ratio), is somewhat influenced by operating conditions. The occurrence of detonation is promoted by fuel combustion at an excess air coefficient close to unity. When the combustible mixture is enriched, oxygen becomes insufficient for the formation of peroxide compounds. When the mixture becomes leaner, heat is spent on heating excess air, and the tendency to detonation decreases.

A common technique for reducing detonation is to reduce the ignition timing, when the time to prepare the combustible mixture for ignition is reduced, and combustion and the formation of oxygen-containing substances occurs in less time. Increasing the crankshaft speed also reduces the tendency to detonation because the time available for the cycle is reduced. By closing the throttle valve, the portion of the combustible mixture is reduced, which also reduces the intensity of detonation.

Can valves knock due to oil?

Low oil level can cause noise in the valve system.

I can hear the crash

Problems with a hydraulic lifter (hydraulic lifter) are similar to problems with a worn valve guide or rocker arm (see following sections). A stuck, worn out or failed lift can also cause a knocking noise.

However, identifying a problem with one or more athletes can be difficult. Do these preliminary checks:

- Check that the oil level is correct.

- Examine the condition of the oil.

- Adjusting the test valve.

- Check the condition of other system components (rocker arms, pushers, springs).

If none of these components seem bad, you may be dealing with a sticking retainer.

Before you begin disassembling the valve system components, you may want to try an engine oil detergent additive if your vehicle uses hydraulic lifters. The additive can help restore the lift if it gets stuck; otherwise you may need to replace the hydraulic compensator.

How to Find a Noisy Valve Trim

On some cars, removing the valve cover to find a noisy lifter isn't that difficult. You can use a mechanic's stethoscope to determine the problem, but a piece of rubber hose may also work fine.

- Remove the cover.

- Set the parking brake and transmission to neutral (manual) or park (automatic).

- Start the engine and let it idle.

- Place one end of the hose against your ear and the other end over the spring area of each valve.

- A noisy lifter will sound louder when you put a hose on a valve with a faulty lifter.

You can use this method to find valve noises also coming from a specific cylinder.

Rockers can also suffer from lack of oil.

Engine valves knocking - I hear a rumbling noise

Like worn guides, rods and springs, worn rocker arms are rare unless they have been used for quite some time, the lubrication system has problems, or the system has been neglected.

While a worn rocker likely won't affect engine performance, it can cause system noise. You may hear light tapping or rattling sounds coming from one or more of the affected rocker arms.

To diagnose the problem:

- Check the condition of the engine oil.

- Check for proper oil circulation around the valve system.

- Identify the noisy rocker arm using a mechanic's stethoscope or rubber hose as described in the previous section.

- Remove the rocker arm and check for dents or roughness where it contacts the valve or, if applicable, the pushrod.

Any of these problems can shorten the life of the rocker arm if they cause insufficient lubrication or increased clearance between the rocker arm and the rod.

Too much clearance can cause noise and accelerate valve stem and rocker arm wear.

PERIODICITY OF ADJUSTING VAZ 2114 VALVES

Car owners have a question: how often is it necessary to adjust the valves on a VAZ 2114 if they do not knock, and is it necessary to make adjustments in this case? According to the factory settings, the valves should be adjusted every 20 thousand km during vehicle operation.

Why carry out adjustment work if the valves of the VAZ 2114 do not knock? The fact is that over time, seat saddles wear out over time. The valve becomes higher and the clearance decreases. And too small a gap threatens loss of power and burnout of the exhaust valves. Before the due date, the clearance in the valves should be checked if knocking occurs and if it is suspected that they are clamped.

I hear a knock

A worn valve guide or stem is more common in high mileage engines. Wear increases the clearance between the rod and guide. With a wider gap, oil will flow along the guides and drop into the combustion chamber.

Common symptoms include:

- You can hear the sound of valves clicking

- Spark plug fouling

- Abnormal oil consumption

If engine oil contaminates the end of the spark plug electrode, it can also cause the cylinder to misfire.

The fingers of the VAZ-2109 are knocking

15 October 2015, 19:47 #1

And here’s another question: 2109, when driving, I press on the gas and it feels like my fingers are about to fly out, from turning the distributor + - there is practically no change, what do you recommend? dv. They also did a complete overhaul, this didn’t happen before the renovation.

October 15, 2015, 20:39 #2

Who did the overhaul? . The locksmiths were conscientious.

October 15, 2015, 20:56 #3 + 1

Well, the guy was a smart guy who repaired diesel engines, but this was his first time doing a VAZ.

October 15, 2015, 21:38 #4

Podarok, 15 October 2015, 19:47, #1

. what do you advise? dv. They also did a complete overhaul, this didn’t happen before the renovation.

. redo the overhaul. . or install another engine.

October 15, 2015, 21:51 #5

VAZ 2109 Lada Granta Sedan

October 15, 2015, 11:11 pm #6 + 2

Check the RV marks, and the automatic ignition timing in the distributor, sometimes it jams on the axle.

October 16, 2015, 21:21 #7

Change the gasoline and check the ignition timing and the operation of the vacuum and centrifugal ignition timing regulators using a strobe light.

October 21, 2015, 11:52 #8 + 1

I changed the ignition timing vacuum and everything was back to normal. Thanks everyone.

Lada Vesta MTZ-1221

October 21, 2015, 2:09 pm #9 + 1

fingers tapping -

A man runs into a car shop - sell me the most expensive imported synthetic oil. bought it and ran away...

the seller decided to look where he would pour it - and around the corner he poured oil on his hand and jerked off.

- Why did you buy something expensive?

My engine has no power

Timing belt problems:

The most common timing belt failure is a belt failure due to extended life or failure of the associated component.

However, a worn timing belt can also stretch too much, or a faulty component can cause the belt to skip a sprocket tooth. These problems can cause engine performance problems such as:

- Engine knock

- Increased fuel consumption

- Ignition delay

- Loss of engine power

If you have a broken timing belt it can cause damage to your engine. The best preventive measure is to replace the belt at the interval recommended by the manufacturer.

Timing circuit problems:

A worn timing chain is not common, but it can happen on high mileage engines. However, some timing chain assemblies use a hydraulic tensioner and nylon guides.

For a hydraulic tensioner or guide, problems are most often caused by dirty oil, low oil, or low pressure in the system. Although low pressure can also cause noise along the valve row. Additionally, the guides may become worn to the point that the tensioner cannot keep the chain tight.

Any of these problems will cause the chain to become slack between the camshaft and the crankshaft sprockets. In addition to the rattling noise, this will disrupt the timing of the valves and pistons and cause a loss of engine power.

How to Check for Slack in the Timing Chain

In addition to diagnosing the rattling noise coming from the front engine cover, you can perform the following check.

For this test, you will need to remove the valve cover to access the valve block, or if your model has a distributor, remove the distributor cap.

- If your vehicle has a distributor, remove the distributor cap; otherwise, remove the valve cover.

- Remove the spark plugs to make it easier to turn the crankshaft if necessary.

- Using the appropriate size socket and jumper, rotate the crankshaft back and forth a few degrees using the crankshaft bolt at the front of the engine.

- If the crankshaft rotates several degrees without moving the rotor or distributor valve, the timing chain, hydraulic tensioner, or guide is faulty.

A broken timing belt can cause serious damage such as bent valves.