Weight of VAZ 1111 Oka

The curb weight of the three-door hatchback VAZ 1111 Oka 1111 0.7 MT with an empty fuel tank is 614 (kg).

Hatchback weight:

Curb weight of modifications:

- VAZ 1111 Oka 1111 0.7 MT (1990 - 1996): 635 (kg) 975 (kg).

- VAZ 1111 Oka 11113 0.8 MT (1996 - 2006): 645 (kg) 975 (kg).

The value of the permissible gross vehicle weight is indicated in parentheses.

Scheme for calculating the weight of a car without fuel:

For example, it is necessary to determine the curb weight of a VAZ 1111 Oka 1111 0.7 MT hatchback with an empty fuel tank.

First, the fuel mass (MT) in the tank is determined (at maximum filling):

- MT = PT x OB, where PT is the density of the fuel (for gasoline - 710 (kg)/m3); OB is the volume of the fuel tank (30 l, indicated in the car’s passport); the resulting result is rounded to a whole number.

- MT = 710 x 0.030 = 21 (kg).

The curb weight of a car with an empty fuel tank is determined as the mathematical difference between the total curb weight and the fuel weight:

Important: the hatchback of the first group of the especially small class VAZ 1111 Oka was produced by the Russian company AvtoVAZ from 1987 to 2008, possible layout: front-engine or front-wheel drive, seats - 4.

Other names:

Other designations for the passenger car of the first group of the especially small class VAZ-1111: Astro Oka 11301, SeAZ 1111 Oka, KamAZ-1111.

Subtleties of the model range:

The engine of the model is two-cylinder, developed on the basis of the middle two cylinders of the VAZ-2108 engine (11113 - based on 21083) and is widely unified with it.

Years of production Years of production: 1987-2008.

Cylinder block

Cylinder block 1 is the basic part of the engine and is used for installing and fastening mechanisms, devices and auxiliary units of the engine. The block is cast from special low-alloy cast iron.

Coolant passages are made along the entire height of the cylinders, which improves cooling of the pistons and piston rings and reduces block deformation from uneven heating.

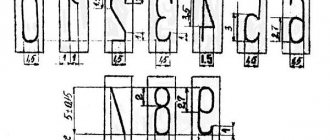

To increase rigidity, the lower plane of the block is lowered 53 mm below the axis of the crankshaft. The block cylinders by diameter are divided into five classes through 0.01 mm, designated by the letters A, B, C, D, E:

| Class | Engine cylinder diameter 1111, mm | Engine cylinder diameter 11113, mm |

| A | 76,000. 76,010 | 82,000. 82,010 |

| IN | 76,010. 76,020 | 82,010. 82.020 |

| WITH | 76,020. 76,030 | 82,020. 82,030 |

| D | 76,030. 76,040 | 82,030. 82,040 |

| E | 76,040. 76,050 | 82,040. 82,050 |

The cylinder class is indicated on the bottom plane of the block opposite each cylinder.

The cylinder and the piston mating to it must have the same class. During repairs, the cylinders can be bored and honed to accommodate an increased piston diameter of 0.4 and 0.8 mm.

News from manufacturers

03/20/2021Lada Largus 2021 – what’s new? AvtoVAZ did not dare to radically change the car this time either. The B0 platform has been tested, it is reliable and unpretentious, and what is important is that it is not so expensive (this platform was created back in 1998). But, unlike the 2021 LADA Largus facelift, where the radiator grille and...

more details

09/10/2020Prices for the new Land Rover Defender have become known. In the fall of this year, Land Rover car dealerships will go on sale with a new generation Defender. There are five trim levels in total: Standard, S, SE, HSE and the top-end X. The minimum cost of a “short” Defender in the Standard trim starts from…

more details

08/10/2020Skoda Rapid 2021 – has changed, but has not increased in price Already in the basic configuration, the Skoda Rapid is equipped with LED headlights, this has never happened in the compact car segment. In more expensive trim levels, cornering lights and a high-beam control function appear. Among the new options, it is worth noting a distance control system with an auto-braking function.

more details

Cylinder head

The cylinder head 22 is cast from aluminum alloy and has wedge-shaped combustion chambers. Guide bushings and valve seats made of cast iron are pressed into the head. The intake valve seat dimensions are larger than the exhaust valve seat dimensions. The seats, pre-cooled in liquid nitrogen, are inserted into the sockets of the heated cylinder head. This ensures a reliable and durable fit of the seats in the head. The working chamfers of the seats are ground after installing them in the head, concentrically with the holes in the valve guides. A special non-shrink gasket on a metal frame is installed between the head and the cylinder block.

The head is centered on the cylinder block with two bushings and secured to it with six bolts. To uniformly compress the entire surface of the block gasket, to ensure a reliable seal and to avoid tightening the bolts during subsequent vehicle maintenance, the cylinder head bolts are tightened evenly without jerking in four steps and in a strictly defined (shown on sheet 10) sequence:

- Method 1 - tighten the bolts to a torque of 2 kgf m;

- Method 2 - tighten the bolts to a torque of 7.08. 8.74 kgf m;

- Method 3 - turn the bolts 90°;

- Method 4 - turn all the bolts again by 90°.

In the upper part of the cylinder head there are three supports for the journals of the camshaft 12. The supports are detachable. The upper half is located in the bearing housing 15, and the lower half is in the cylinder head. The camshaft bearing housing installation bushings are located at the housing mounting studs. The holes in the supports are machined together with the bearing housing, and therefore the cylinder head can only be replaced assembled with the bearing housing.

A KLT-75T type sealant is applied to the surfaces of the cylinder heads mating with the bearing housing in the area of the outer camshaft supports.

Install the bearing housing and tighten its fastening nuts in two steps:

- 1st step - pre-tighten the nuts in the sequence indicated on sheet 10 until the surfaces of the bearing housing contact the cylinder head. The mounting bushings of the housing must fit freely into their sockets;

- 2nd step - finally tighten the nuts with a torque of 2.2 kgf m in the same sequence.

At the top of the head there are four sockets with a diameter of 35.320. 36.345 mm for valve tappets.

From above, the cylinder head is closed with a cast aluminum cover 16 with a gasket.

The housing of auxiliary units 19 is attached to the rear end of the cylinder head.

The engine, complete with clutch and gearbox, forms a power unit, which is mounted on the car's subframe on three elastic supports. The supports support both the mass of the power unit and the loads that arise when the vehicle starts, accelerates, and brakes. The supports reduce body vibration when the engine is running, ensure minimal engine vibrations, and also protect the engine from shock loads when the vehicle moves over uneven roads. The location of the supports, taking into account the center of gravity of the engine and power unit, helps reduce the transmission of vibration to the body. The design of the engine mount eliminates the possibility of direct contact of engine parts with the body, which significantly reduces the transmission of noise and knocking from a running engine inside the body.

Suspension, steering, braking system

The front of the car was equipped with a MacPherson-type suspension, with telescopic shock absorbers, wishbones and a transverse stabilizer bar. At the rear, a suspension was used, consisting of shock absorbers, coil springs, trailing arms and a transverse beam.

Steering "Oka" ...

injury-proof, made of the “rack and pinion” type. The transmission of force from it to the wheels was carried out by two steering rods.

The front wheels were equipped with disc brakes...

the caliper was movable. The gaps between the caliper and the pads were adjusted automatically.

The rear wheels had drum mechanisms; the gap between the shoes and the drum was adjusted automatically. The drive of the service brakes was hydraulic, while the parking brake had a cable drive.

Article on the topic - OKA suspension: diagnostics and malfunctions

On-board electrical network…

the car was single-wire, the negative pole was the body itself. The nominal voltage in the network was 12 V. The voltage in the network was maintained by two sources - the battery and the generator.

In general, the Oka car was very interesting, but the unprofitability of production and lack of competitiveness with foreign cars of this class led to the curtailment of its production.

cylinder head

The cylinder head is solid cast aluminum. Since the engine has a timing belt with an overhead camshaft, the cylinder head is equipped with beds for the shaft. To install the camshaft, three beds with covers were made. There are no shaft bearings; their role is played by the working surfaces of the bed and cover (therefore, if the bearings are heavily worn, the entire head must be replaced).

The cylinder head also houses timing valves (2 for each cylinder). As usual, the intake valve, to ensure better filling of the cylinder with the combustible mixture, has a larger diameter than the exhaust valve.

Article on the topic - Removal and repair of the cylinder head of the Oka car

The cylinder head is fixed to the block with 6 bolts. When tightening fasteners, a certain pattern is used, which eliminates the possibility of the head being “skewed.”

Bolts require gradual tightening with increasing tightening torque. The force on the cylinder head mounting bolts has strictly defined values, so tightening must be done with a torque wrench.

Engine

The power unit is a two-cylinder engine. Many parts are interchangeable with the VAZ 2108 engine, but this does not mean that the power units are identical. To remove the strong vibration inherent in a two-cylinder engine, there is a special balancing shaft on which counterweights are installed to dampen vibrations. The shaft has a rigid drive in the form of gears. This is the cause of the rumbling noise of an engine that is not warmed up to operating temperature.

As it warms up, the noise disappears, but not completely. This is a serious irritant for drivers who have just started operating an Oka car. The technical characteristics of this mechanism play an important role in the operation of the entire unit. And after a short period of time, addiction develops, and other advantages of a small machine begin to dominate this disadvantage.

The car's ignition system is one of the most reliable in the world. The weak point in a contactless electronic system can only be the ignition coil. Otherwise, the system is very reliable; it is enough to monitor the condition of the high-voltage wires and promptly replace the spark plugs.

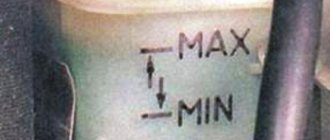

Another feature of the engine: for reliable and long engine service, it is necessary to maintain a strictly average oil level. Overfilling or lack of lubricant will very quickly lead you to a repair shop. And the cost of repair work will be the same, regardless of the model, be it a Lada Kalina or a VAZ 1111 Oka.

Basic faults

In the early days of the 1111/11113's existence, Oka owners often complained about increased annoying vibration and noise from the engine compartment. The noise was especially loud when the engine was warming up; the balancer shafts mentioned above were to blame for it. This phenomenon worries car owners, but is not considered a malfunction. The engine may also be noisy due to too large valve clearances. The problem is eliminated by adjusting them. Vibration is a design feature, since the engine only has two pistons. A fairly common problem with engines is burnout of the cylinder head gasket. Its main reasons:

- factory production flaws, when the gasket was manufactured with inaccuracies;

- Incorrect tightening of the cylinder head, in which the gasket is not fully compressed.

If the motor is repaired, the seal is replaced and cannot be reused.

Important: if there are burrs on the new gasket, it is also not recommended to install it in the engine.

The Oka 11113 engine may have difficulty starting “hot” after a short stop. The reason for this is the layout of the engine compartment and problems with the fuel pump diaphragm. In a hot VAZ 11113 engine, fuel vapors are formed, including in the cavities of the fuel pump, and this unit is not intended for pumping gases and can “fail” when starting the engine before it cools down. The aperture can be changed.

Important: if a problem with the motor occurs on the road, you can simply place a damp cloth on the pump as a temporary measure. This will cool the unit somewhat and allow you to get to the place where the diaphragm can be replaced.

Other possible problems:

- Loss of engine spark.

The ignition coils are located in such a way that water can enter them, for example, when the car crosses puddles. Water causes the voltage booster module to fail, and as a result, the engine cannot be started. There may also be general wiring problems associated with poor build quality and poor-quality wires, which are typical for VAZ engines in general.

- Damage to the engine cooling system.

Most often the pump fails due to poor assembly and low quality components. If the pump fails, the engine overheats and breaks down, so you need to monitor the temperature of the unit and change the pump promptly, if necessary. The engine thermostat is also not of high quality and may fail, with subsequent replacement.

- Electronic sensor failures.

Oka engines use domestically assembled electronics, which are not of the best quality, and sensor failures are not uncommon. In addition, they are not always properly secured to the unit body due to poor production standards.

Despite these problems, many repair operations, with the exception of complex specific breakdowns, can be performed by the car owner independently or in a “garage” car service. Spare parts from motors 21083, 21093 are suitable for repairs.

Specifications

It’s not difficult to calculate the Oka’s fuel consumption if you know what kind of engine is installed inside. This is a carburetor engine with a capacity of 649 cc, 30 l/s. This is half of the V8 engine (VAZ-2108). Some other components were taken from another model, VAZ-2105, for example heating fittings, faucet, radiator. This partially solves the problem with spare parts, but some parts (for example, the crankshaft) are original, so, given the small scale of production, the price for them may exceed the cost of similar parts for other domestic cars. This is worth taking into account when purchasing, since the low fuel consumption of the Oka will bring savings, but perhaps only until the first major repair.

Cylinder-piston group

The piston is made of heat-resistant aluminum alloy; the part is subjected to additional heat treatment during the manufacturing process.

The piston bottom is flat (which makes the engine “plug-in”), but it is possible to install pistons from a VAZ-2108 with grooves on the bottom for the valves.

Number of rings – 3. The top two are compression, the 3rd is oil scraper. A hole is made in the groove for the oil scraper ring to drain the lubricant removed from the cylinder walls.

Compression rings ensure sealing of the combustion chamber (the necessary compression is created in the cylinders). Additionally, they participate in heat exchange - they remove heat from the top of the piston and transfer it to the cylinder walls. The oil scraper ring is equipped with a radial expander to increase the area of contact with the walls.

The finger is a round piece, hollow. The finger is “floating”, that is, during operation it rotates in the bosses.

THIRD ATTEMPT

The new prototype, codenamed “Oka-3” (), is modestly hidden in the corner of the showroom of the AVTOVAZ Scientific and Technical Center. The car was not shown to a wide audience. What about the outside public - even the majority of VAZ workers don’t know that work is being done in this direction! It is clear that these are difficult times for the company. Not long ago it was officially announced that work on “Project C” would be temporarily stopped. But, unlike this development, Oka-3 is based on an existing platform, it uses serial units, so the path to the assembly line can be very short. And the existing prototype is not plasticine, but a running one. They even gave me a ride. You feel like you’re driving a full-fledged car, but it’s unusual to back up - it seems that you can reach the glass of the third door with your hand. In general, the same “Kalina”, only a little shorter.

Around town

In city mode, the fuel consumption of the Oka ranges from 5 to 7 liters, and the car itself performs excellently in the city. The car handles well (if you don’t overload it) and is economical; you can find a parking space almost everywhere: where a full-size passenger car won’t fit, the Oka will fit in without any problems.

But the age of the car probably takes its toll. The older it is, the noisier it becomes in the cabin, however, if you want to drive with a little more comfort, you can add additional sound insulation. In the front seats, the seating position is comfortable even for people with taller than average height, but the pedals are located further to the right than the standard location in a passenger car: for a driver accustomed to the usual position, the clutch will be exactly under the right foot.

Another drawback is the stove. It is only warm enough for people in the front seats.

Some of the shortcomings were eliminated in production over time: in models older than 1900, a rear window heater, fabric inserts on the seats, and a shelf on the trunk appeared.

In 1996, modification “11113” appeared. Its engine was already 750 cc, and its power was 36 hp. Compared to its predecessors, it was more dynamic and economical: the fuel consumption of the Oka (VAZ-11113) of this modification is 6 liters per 100 km (urban mode), which was facilitated by a lower operating speed.

In 1999, twenty-eight thousand of these machines were manufactured, and a year later another thirty-two thousand units of equipment were being prepared for production. Production growth is significantly limited by supplies of various components from AvtoVAZ.

Reviews

I read reviews on the Internet about OKA cars of various modifications. I'll tell you briefly. Many people don’t like this car because of its appearance, but many are happy with the fact that it is simple, easy to repair, an internal combustion engine of two cylinders with two valves. Another disadvantage is that it is light, and when driving along the highway next to an oncoming truck, the Oka is almost blown away by the wind. Another downside is that the distance between the wheels is smaller than that of standard cars, so in winter it doesn’t fall into a rut and gets tossed around. Some people call it the “mad stool.”

As for me, you can take it if you don’t travel long distances, for example, to a postman to deliver a newspaper. Fuel consumption is low.

Safety of passengers and driver

"Oka" is a car whose technical safety parameters are simply absent. It is better not to get into an accident with this car. In a frontal collision at a speed of 50 km/h, the living space of the front passengers ends in the area of the backs of the front seats. It simply doesn't exist. The steering will pose an additional threat to the driver. Given this circumstance, seat belts in this car look like a mockery of common sense.

The rigidity of the body is indicated by the following: if the car is parked on an uneven surface, then the deformation of the body does not allow the trunk or door to be closed normally. The rigidity of the body can protect only from a small push. You can't count on it in case of an accident.

This is the harsh cost of the affordable price of the VAZ Oka car. The technical characteristics of a small, nimble car are negated by a complete lack of a sense of safety. Each owner has to make this choice himself. Just don’t forget that in addition to your own life, the life and health of your passengers are always in your hands.

Is it worth exposing them to such danger? This is a rhetorical question. After all, if a manufacturer has produced such a car, then there is a demand for it. The decision is always yours.

Tank dimensions from OKA vehicles

Moderator: User buggy

Tank dimensions from OKA vehicles

Post by Tavrovod » Sun Aug 26, 2012 3:28 pm

Can anyone tell me more or less exact dimensions of the Oka tank?

I was building a quad, and suddenly it turned out that the existing tanks did not fit into the frame, or rather into the space that was left for it.

Re: Tank dimensions for OKA vehicles

Post by Dimas » Tue Sep 04, 2012 9:19 pm