Characteristics of VAZ 21102

You shouldn’t expect miracles from a car plant that hasn’t been able to develop a coherent line of engines in its 40 years of existence, but thanks for what it has. The owners of the VAZ 21102 car initially considered themselves somewhat deprived of fate, because they received fewer valves than the owners of the same dozen, only with an index one more - 21103. The same engine, almost the same characteristics. But 21103 costs $300 more. Does it make sense to overpay, or to safely drive a VAZ 21102? We have listed the technical characteristics in the table, and we will explain everything that does not fit in the table in words.

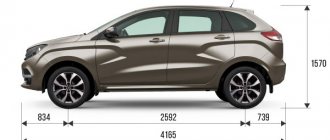

Dimensions and features of modification 21102

Let's look at the technical characteristics of the VAZ 21102: overall dimensions, engine, transmission, suspension. Let's start with the dimensions.

| Aspects | Indicators |

| Length | 4.265 m |

| Width | 1.676 m |

| Height | 1.42 m |

| Wheelbase length | 2,492 m |

| Front track width | 1.41 m |

| Rear track | 1.38 m |

| Clearance | 16.5 cm |

The body type of the car 1102, like the entire line, is a sedan. The car is front-wheel drive, has 4 doors and 5 seats. The luggage compartment volume is 430 liters. The fuel tank holds 43 liters of gasoline. The curb weight is 1020 kg, and the total weight is 1495 kg.

Modification 21102 is the second oldest among all the “ten”. The opinion that this version is a successor to car 21101 is erroneous. In 1996, AvtoVAZ launched the first model of the VAZ 2110 into mass production. The pilot version of the “ten” was experimentally equipped with a carburetor fuel supply system. But a few months later, the company's leading engineers introduced a new version of Lada. It was decided that a modern car, which is the Lada 110, should have the injection principle of gasoline injection.

In the same 1996, an engine with an injector was introduced into the next version of the Lada - 21102. However, the number of valves was not increased from 8 to 16. This modernization “overtook” only the VAZ 21103 in 1997. But model 21101 is the youngest of the entire line. The version went on sale in 2004. It is a copy of the first “ten”, but has undergone restyling and modifications to the engine.

In the case of the VAZ 21101, repairs are less urgent, because the car is newer than 21102.

VAZ 21102, price

Engines of this format, multi-valve, began to be installed on middle-class cars only in the early 90s. In some ways, such engines certainly win, so it is not surprising that there are practically no live production models with eight-valve engines left abroad. And we still have it. Don't throw it away. Let's try to find advantages in this motor, and we have already found the first thing - price. Since cars of the tenth family are no longer produced, you can find 21102 on hand for an average of 80 thousand. This will be a car with average mileage without capital. The 16-valve version will cost 120-140 thousand. The difference is significant.

Coolant temperature indicator

Antifreeze or coolant is used to cool the engine. To ensure proper operation of the power unit, the coolant also has its own controller. In its functionality, this regulator is vaguely reminiscent of the choke that is equipped with 8- and 16-valve carburetor engines of the “ten” and other vehicles. The sensor itself is designed to monitor the temperature of the consumable.

Installing a new antifreeze sensor

In fact, this device also provides fuel regulation. If the power unit is running cold and has not yet warmed up, it will receive more gasoline for normal operation. Readings about the coolant temperature are displayed on the control panel in the vehicle interior. In accordance with these indicators, the driver will always be able to find out about the overheating of the unit by the way the sensor arrow on the dashboard begins to move into the red zone.

The antifreeze temperature sensor periodically fails; it is characterized by the following malfunctions:

- Loss of electrical contact inside the controller, resulting in its inoperability.

- The device is installed in such a way that it may be exposed to moving elements, particularly the accelerator pedal cable. It would be even more correct to say that the cable does not act on the sensor itself, but on its wires, which in fact can lose insulation as a result of long-term use.

- Often the regulator breaks down if the ventilation device starts to function on an engine that is not warmed up.

- If the motor is overheated, it may be difficult to start.

- If the fuel temperature controller fails, it can lead to increased gas mileage. If you encounter one of these problems, then to ensure normal operation of the car engine, you need to replace the controller. Detailed replacement instructions are presented in the video below (author - REPAIR VAZ 2110, 2111, 2112).

VAZ 21102, engine injector

The advantages of 16 valves are obvious, and it’s even more prestigious to drive a ten with the Gli 16V nameplate and, while checking the oil, admire the plastic mug covering the engine. Just like in a foreign car. But there is no need to rush to conclusions. Dozens were completed regardless of the engine. The same power windows, the same interior amenities and central locking. It turns out that the difference between 102 and 103 is only in the engine, and, as we have seen, it is quite significant. And the 77 horses of the 102 model compared to 90 of the 103 look unconvincing. Stop. Is 90 horsepower for a one and a half liter engine convincing? Hardly. Here is the first contradiction. The price is twice as high, the power is only 13 horsepower. What's the point of paying more?

We look at the passport and see that the 102nd has a stated maximum speed of 170 km/h, and the 16-valve car is 185, and the difference in acceleration to hundreds is about 2 seconds. But there is one important detail here. That detail that makes our planet a little cleaner. Catalyst. The 103rd engine is already prepared for Euro 3 standards, which means that the 40-kilogram increase and the design of the catalyst itself will eat up at least 7% of the power. It turns out that the 13 horses won by 16 valves and a complex timing drive system are driven only by a catalyst. But that's not all.

Mass air flow sensor: air regulator

The tens electronic system needs information about the amount of air required. This is necessary to create the optimal volume of the warm-air mixture.

Considering the sensors of the VAZ 2110 injector 8 valves , it should be noted that the mass air flow sensor is the most sensitive of all devices.

A small amount of moisture or dust can cause damage. This must be taken into account during the car repair process. So, the sensor determines the volume of air before entering the system. The disadvantages of the device are:

- sensitivity to moisture and dust;

- malfunctions during operation of the power unit at idle speed;

- increased fuel consumption;

- difficulty starting the engine;

- at increased speeds and significant loads, the power unit may stop abruptly.

All of the above reasons are due to the fact that a mixture that is too lean (or rich) gets into the cylinders. The operating principle of the device in question is quite simple. There are several heating elements inside the structure, which “lose” temperature as air passes through. The more electricity used to heat these components, the more air enters the system.

Thus, the change in electrical power is directly related to air flow. The information is transmitted to the system, which turns on the appropriate modes and controls air flow.

Fan sensor

This tool is necessary for measuring temperature and then turning on a fan designed to cool the engine. Unlike other devices, it is reliable and has a long service life. The sensor is filled with a solid substance that expands as the temperature increases. By purchasing high-quality products, owners of the VAZ-2110 model will be able to forget about the need for replacement for a long time.

The task of the device in question is reduced to transmitting a signal to the computer as a result of pressing the gas pedal. Thus, the amount of fuel injected increases. The design of the regulator is quite reliable. Failure is indicated by jerking when pressing the accelerator pedal. Also, sometimes “failures” occur. A regular tester is used for testing.

If the damper is closed, the voltage is about 0.5 Volts. When you press the pedal as hard as possible, the voltage increases to 4 volts.

Knock sensor

The device is mounted on the cylinder block. Its function is reduced to transmitting information about detonation to the electronic control unit. As a result of increased detonation, the ECU (in accordance with the software) changes the operation of the power unit. Dozens of recent series have piezoceramic devices installed. Functionality testing is performed using a tester. To do this, you need to connect the meter to the contacts of the device and lightly knock. The measuring device should record voltage drops, which indicates proper operation.

There are other sensors, such as valve timing and a lambda probe, that can be installed on cars with 8 and 16 valves. To study the features of each device, it is recommended to use the instruction manual for the VAZ 2110 car.

Any modern car is equipped with many different sensors that allow the driver to know about the condition and performance of certain components. And the VAZ 2110 car is no exception; in this article we will talk about what sensors are used in it and what their location is.

As you know, the VAZ 2110 injector with 8 or 16 valves is significantly superior to the carburetor version in many ways. At least because in this case the supply of gasoline, as well as the combustible mixture, is regulated by electronics. Accordingly, the use of electronics implies the use of many different regulators and controllers. Their breakdown can lead to certain consequences, so the car owner should always know what certain regulators are responsible for. Below we consider almost all VAZ sensors that are in the top ten.

The power unit of the "tens" is controlled using the ECM - an electronic system. This system must always know how much air needs to be supplied for a certain volume of gasoline. These two parameters are closely related to each other, since with their help a combustible mixture with the required density is formed in the engine power unit. After the system determines the required volume of air, it begins to select the appropriate amount of gasoline. As for the regulator, it is responsible for the suction volumes.

Natural habitat VAZ 21102

Summarizing this small study, we can say with confidence that the 16V nameplate will cost significantly more than a standard one and a half liter eight-valve engine. If you look at consumables and maintenance, the picture is quite impressive. The capricious engine of the 103rd Lada will not always put up with low-quality fuel, while the 21102 will gladly gobble up what it is given at any gas station, unless, of course, it is an outright surrogate. The design of a dozen with 16 valves increases the cost:

- only high-quality leaded gasoline;

- expensive timing drive system;

- replacement and maintenance of an expensive catalyst;

- increased fuel consumption at lower levels.

Consequently, for small cities with an average level of service and inconsistent quality of gasoline, it is better to choose 21102. Here, the pursuit of maximum speed is unlikely to justify the significantly higher costs of maintenance and the starting cost of the car itself. Therefore, the number of valves is not the main thing here. The main thing is to choose the right engine for its future habitat, which is what we sincerely wish for everyone.

Production of Bogdan VAZ 2110 and VAZ 2110

Despite the similarity of the cars, the Lada 2110 Bogdan and the VAZ 2110 are produced in different countries. The Volzhsky Automobile Plant began producing such a car as the VAZ 2110 in 1995. One of the main features of the car was its original external design, as well as the presence of all-wheel drive. Production of the sedan ceased in 2007.

Production of Bogdan VAZ 2110 and VAZ 2110

Production of Bogdan began after the cessation of production of the VAZ 2110 in Russia. The first licensed Ukrainian sedan was produced in the city of Cherkassy. It was he who became a full-fledged analogue of the VAZ 2110. This vehicle became a partial copy of the famous vehicle.

Idle speed control

Today, in urban environments, drivers simply cannot do without idling. Therefore, every car, including the VAZ 2110, is equipped with an idle speed sensor. Incorrect operation or failure of this regulator will significantly complicate driving, because it will cause the engine to stop even during the shortest stops. So if the controller fails, and this is not uncommon in VAZ 2110 cars, it needs to be changed as quickly as possible.

Removing the idle air control

The main purpose of this type of regulator is to support the speed required for normal operation of the power unit. Thanks to the device, the driver can always make a short stop as a result of changing the incoming air volume. As for the location, this controller is installed on the throttle line. In particular, we are talking about an anchor stepper motor, which is equipped with two windings.

When a corresponding signal is received on one of the windings, a special needle moves forward one step and backwards one step. Thanks to the worm gear, the device rotates, which is produced using a stepper motor, thus converting this movement into translational. The rod itself, namely its conical part, is located in the line through which the air flow is supplied.

Thanks to the functioning of the rod, the system adjusts the idle speed of the power unit. The rod from the device, as mentioned above, can be retracted or extended. In this case, it all depends on what kind of pulse will be supplied from the regulator. The controller itself allows you to adjust the frequency at which the engine crankshaft will rotate when the machine is stopped for a short time.

In addition, the controller controls the incoming air flow, which bypasses the throttle in the closed position. When the engine is warmed up, the regulator, by controlling the movement of the rod itself, at idle speed allows you to maintain the required crankshaft speed. In this case, the load and condition of the power unit do not play a role.