We all know that basic “native” noise insulation is of little use and only the naive will expect much from the basic “Noise” sound. At least this rule applies to “our” cars. Experienced drivers have learned from their own experience that until you make good noise insulation on a VAZ, driving in it on our roads will be more like torture than moving in comfort.

VAZ Repair has many articles on the topic of sound insulation. Today the list will be replenished with one more, I will tell you how to soundproof doors on a Lada Granta at home.

What is the danger of noise?

The basic configuration of the Lada Granta car has everything you need, but the level of comfort of the vehicle is average. Unnecessary sounds can be removed only through comprehensive sound insulation. It will give the following results:

- will reduce the negative impact of noise on some organs;

- will allow the driver to clearly react to situations on the roads and quickly take the necessary actions;

- will protect against the development of dangerous diseases, including mental ones (high noise levels negatively affect the nervous system).

For example, a large number of unpleasant sounds leads to a narrowing of the lumen of blood vessels, activates the work of the heart muscle, causes a sharp jump in blood pressure, angina pectoris. Therefore, noise becomes a source of chronic stress.

Causes of increased noise

Soundproofing of Grant doors is done to eliminate all types of noise:

- Intermittent - they are created by a faulty heater motor, less often cooling or air conditioning.

- Constant - here we are talking about external noise that enters the cabin from the outside, causing problems with the suspension, tires, and transmission.

- Pulse ones are creaks, knocks, clicks.

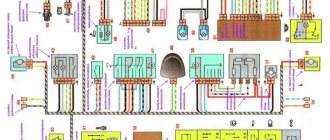

It is impossible to exclude sources of noise, but it is possible to minimize their negative manifestations. To do this, it is enough to soundproof Grant's doors according to the diagram below.

Distribution methods

Soundproofing Granta doors, if done correctly, will remove all unnecessary noise. It is necessary to work comprehensively, since there are many channels for the penetration of extraneous sounds into the cabin. The first method of noise transmission is airborne. The volume in this case depends on the presence of obstacles on the way - if there are many of them, the intensity of the waves will be low, and vice versa.

The structural diagram of noise progression involves the transmission of waves to various body parts that generate vibrations. Metals transmit vibration effects best.

When soundproofing the doors of Grant's cars, two types of materials need to be used - sound absorbers will eliminate noise transmitted through the air, and vibration absorbers will cope with vibrations.

Do-it-yourself surgery technique

As you know, sound insulation on Grant is carried out in stages. First one part of the car is processed, then the others.

Doors

How to properly soundproof Granta doors

As a rule, the soundproofing process begins with the doors. Some, after completing the “noise” of the doors, stop there and do not continue, others carry out complete sound insulation. If you treat only the doors, this will be called partial sound insulation, but it gives a good result, especially in terms of improving acoustic properties.

Note. Thus, the doors of Lada Grants often become the location for installing the front speaker. And in this regard, this part of the car must first of all be soundproofed. The untreated door itself makes a poor speaker enclosure. On the other hand, a well and correctly processed door does not “sing along” with the dynamics, but is “silent”.

- The minimum option, when only the outer panel and door card are processed with materials;

- Standard version, which will be described in detail below;

- The maximum version of execution, which is of more competitive interest. More dense and thick materials are used here.

Recommendations from manufacturers

Door insulation reduces external noise and increases vehicle comfort. When working with Granta doors, special attention should be paid to the clanking and ringing parts of window regulators and locks. They can be treated with special materials to eliminate the problem.

Work should begin by disassembling the interior - use plastic spatulas and clip lifters. You can replace the tool with regular screwdrivers. Cutting is done using a stationery knife or scissors; after application, the material is rolled using a metal roller.

The doors are treated in 4 layers. The first is a vibration isolator 2 mm thick. To increase work efficiency, the foil is rolled with a roller. The second layer is a sound absorber with a moisture-resistant sealant, the third covers the holes on the door body. The fourth, when soundproofing doors (cards, frames), Grant absorbs unnecessary sounds. Visually, it looks like a foam-like substance that is applied to the plastic door trim from the inside.

Let's sum it up

In general, the insulation event allows you to take the LADA Granta to a new level in terms of comfort, as evidenced by multiple reviews from owners who carried out this action. Do not despair if the maximum insulation is not capable of 100% efficiency. Sometimes it is enough for car owners to have the doors soundproofed. In any case, driving in the car will become more enjoyable, which will be the best reward for the owner for his work.

Tools and materials

For vibration insulation of rear and front door areas, stp plates and other materials are used. A complete set of tools and raw materials for work includes:

- set of acoustic plugs;

- a couple of sheets of insulators 460*700 mm;

- bitoplast sheet 1000*700 mm;

- 50 cm corrugations for wires;

- 3 sheets of Visalis 460*700 mm;

- industrial dryer;

- degreaser;

- gloves;

- knife;

- screwdrivers;

- keys.

If the old vibration isolation pad is very worn, it is recommended to install a new one. Visalis is cut into equal pieces, the fragments are laid out in piles and heated using a hairdryer.

• floor soundproofing Grants

Do-it-yourself noise insulation in Grantu, what materials are required: a hair dryer; degreaser, spatula, soft small roller, set of keys, screwdriver, utility knife.

If you have everything you need at hand, then you can begin preparing the soundproofing of the floor, namely:

– dismantling the front and rear seats;

– dismantling the rear passenger air ducts;

– removal of the standard Shumka (rags and vibration material).

It is worth noting that complete removal of the carpet is not possible, since it is crushed by the torpedo and the stove. All that can be done is to carefully cut it with a stationery knife in those places where it borders on the plastic. After the carpet is removed from the car, the floor soundproofing process continues:

– the working surface must be cleaned and degreased;

– cutting out sound insulation sheets of a suitable size;

– heating the bitumen side of Shumka sheets with a technical hairdryer;

– gluing “vibration” onto the cleaned metal of the body.

All subsequent sheets of vibromaterial must be applied overlapping, which will prevent the appearance of seams.

If, from the owner’s point of view, a second layer of sound insulation makes sense, then it can be implemented using an accent or BiPlast, the practical application of which is what Granta sound insulation is known for.

Vibration isolation

Vibration-absorbing materials (vibration for short) are applied to the iron parts of the body of a Grant or other car. The transmission, power unit, suspension elements - all this and uneven road surfaces, a certain air resistance, cause the parts to creak and make other sounds that are not particularly pleasant to the ear.

The operation of vibration is explained by the laws of physics, which determine the parameters of internal friction. As a result, the vibration energy is converted into heat. The basis of the compositions is mastic or bitumen.

How to apply correctly

Soundproofing of Grant doors is done in stages, first one part of the car is treated, and then all the rest.

The first stage is door processing. It can be the only one or the main one - noise on the doors is required, but it alone will not be enough to achieve optimal performance. The treated door space will make a good enclosure for the speaker. Work options:

- processing of the door card, outer panel;

- sheathing with dense thick materials;

- The standard scheme is the most popular.

When performing work using standard technology you need to:

- Provide access to work surfaces that will be soundproofed.

- Prepare surfaces for applying sound insulators - first of all, degrease and clean.

- Cover the panel with a vibrating layer of materials.

- Place an air absorber on top to serve as a heat insulator.

- Treat the frame with or without sealing the holes. The first option is preferable, but not always possible. Cover the holes with materials from the “Viek” set, cutting them according to the shape and size of the windows.

- Treat the door trim, coat the joints with sealant or hot melt adhesive. When choosing a composition, it is not so much the price that is important, but the characteristics and their compliance with the specified parameters.

To eliminate vibrations, it is recommended to use Bimast or Vibroplast M1 plates. Ideal sound absorbers - Accent and Splen. It is better to lay the material overlapping in horizontal stripes - this will increase the degree of rigidity of the working panel.

Application rules

To remove interior parts, all visible screws are unscrewed. The element is pryed off from one edge and then along the entire perimeter to snap off the plastic or metal clips. To remove load-bearing elements such as seats or seat belts, you have to use wrenches and sockets. The surface to be treated is thoroughly cleaned of dirt and anti-corrosion coatings, dried and degreased.

Many people strive to cover the entire surface of the metal with vibration insulation. This is a pointless waste of time and expensive material. It is necessary to paste over extended flat surfaces that are capable of resonating. By default, 70% of the surface is covered. Never seal service or ventilation openings. They allow moisture to escape and air to circulate. The plugs must be left open; they will be needed to perform technological operations.

It is always better to cover a smaller area, but with thicker material. An exception must be made for vertical and ceiling surfaces. There, material that is too thick may not adhere well. Horizontal surfaces are covered with vibration insulation with a thickness of about 4 mm, for vertical and ceiling surfaces - 1.5-2.5 mm. Thin steel surfaces, being weighted by an amorphous material that does not have its own rigidity, cease to resonate.

After removing the protective film or paper, the vibration insulation is carefully pressed against the metal from the middle to the edges and rolled with a roller. It is imperative to get all the air out from under it. In most cases, porous sound insulation sheets are glued over vibration insulation and bare metal. Such technology should be treated as a necessary measure. On surfaces with complex terrain, a fairly thick material is springy and does not hold well, blocking drainage and circulation holes.

Cutting them out is a dubious matter. For Shumka, continuity of coverage is key. It is better to glue Shumka onto mats, factory soundproofing mats or plastic cladding. An example would be the trunk area. Shumka glued to the raised floor will give a better effect and will be cheaper than a continuous pasting of the spare wheel niche and the sides around it.

For the most part, they use Shumka with a thickness of 6-8 mm. On surfaces with complex terrain you have to go to 4 or even 2 mm. Sometimes it is necessary to glue 2-3 layers of thin insulation, since thicker ones spring back and come off.

The sealant is glued along the joints of mating parts to prevent mutual friction and beating. They can be used to wrap rods and bundles of wires. Clamps provide additional fixation of the wiring. There is no need to get rid of factory sound insulation. You've already paid for it, and it does its part to suppress noise. Reassembling the interior is done in the reverse order. It is convenient to use mastic to treat arches. It can be applied to the surface under the fender liners in 2-3 layers. This increases the corrosion resistance of the metal.

Comparison of treatment zones

When soundproofing Granta doors, a number of points need to be taken into account. Basic:

- the side parts of the body are processed in a similar way to the doors;

- Hard, not soft, slabs are laid on the floor - Bimast is the best option;

- Shumka can be of 3 types, as is the case with doors;

- the partitions of the engine compartment and wheel arches are covered with Barrier-type materials; ordinary vibrations are powerless in this case;

- The ceiling is usually large, the metal on it is thin - Vizomat is used for sound insulation.

You need to work with the ceiling carefully so as not to get the opposite effect. Be sure to improve the rigidity of the panel by gluing B-polystyrene strips or a special profile.

• external sound insulation of Granta arches

Sound insulation of Granta wheel arches can be implemented depending on the preferred material.

At the moment, only two materials can provide simultaneous protection and noise insulation, namely: – liquid Vibroplast from the company StandardPlast;

Necessary tools: spatula; brush.

– sheet material (vibration isolator sheets).

Necessary tools: hair dryer; large and small rollers.

If we are talking about the first material, then it is worth noting the need to apply it to an exceptionally clean and dry surface of the wheel arches.

The consumption of liquid vibroplast is calculated relative to the mass to the area being processed. Thus, 1 kilogram is enough for 0.3 square meters.

Vibration isolator sheets are much more economical in relation to the price category, and are also simple in the process of pasting over wheel arches. All that is necessary is to heat the sheets with a construction hairdryer and roll them out onto the pre-prepared surface of the arches.

Do-it-yourself high-quality sound insulation of the Lada Granta video will provide a more detailed description of the process of sound insulation of external arches through the use of one or another material.