Old style injector ramp (16 V) for VAZ 2110, 2111, 2112

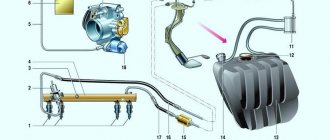

Fuel rail of the VAZ 2112 (l.5i) engine assembled with injectors:

1 — fuel supply tube to the fuel rail; 2 — fuel pipe for draining fuel into the tank; 3, 4, 5 and 6 - nozzles; 7 — diagnostic fitting (for checking fuel pressure, closed with a threaded cap); 8 — fuel rail; 9 - fuel pressure regulator

Fuel rail VAZ 2112-1144010 old model. Used on VAZ 2110-2112 cars from 1997 to 2004. Can be installed on any 16-valve VAZ engine. For organizing a fuel system with a return line and an external fuel pressure regulator.

The injector ramp VAZ 2110-1144010-10 is most often replaced by the following terms: fuel rail, injector block. Therefore, if you hear these terms, then know that we are talking about the same thing.

The injector ramp 2112-1144010 of the old model is designed to supply fuel to the injectors on an engine with distributed fuel injection and fix them.

The engine fuel rail 2110-1144010 serves to supply fuel to the injectors and is mounted on the intake pipe. On the opposite side of the fuel pressure regulator at the end there is a fitting for monitoring fuel pressure.

Original old style fuel rail 2110-1144010, box type with pressure regulator and return drain pipe. Injection is carried out using four nozzles. It is possible to install BOSCH 0 280 150 996 (green) or SIEMENS 6238 (gray) injectors or other types with the appropriate parameters.

The pressure regulator, attached to the rail, changes the fuel pressure in the rail from 2.8 to 3.2 bar (280–320 kPa) depending on the vacuum in the receiver, maintaining a constant pressure difference between them. This is necessary for accurate dosing of fuel by injectors.

Ignition control is assigned to the electronic engine management system. This system controls the amount of air and fuel supplied to the cylinders, controls the operation of the fuel pump, controls the supply of high-voltage pulses from the ignition coil to the spark plugs and adjusts the ignition timing, regulates the crankshaft speed at idle. Fuel rail 2110-1144010 is designed to work as part of a microprocessor control system for an internal combustion engine with controllers “M1.5.4”, “JANUARY 5.1” from “BOSCH”, or their analogues.

The injector ramp (fuel) VAZ 2110-1144010 of the old model is installed on cars of the tenth VAZ family with a 16-valve engine manufactured by AVTOVAZ OJSC, and is also supplied as spare parts for them.

Other article numbers of the product and its analogues in catalogues: 21120114401000.

VAZ 2110, VAZ 2111, VAZ 2112.

How to independently replace the fuel rail on fuel-injected 16-valve cars of the tenth VAZ family?

Don't forget to share the information you find with your friends and acquaintances, as they may also need it - just click one of the social networking buttons below.

Dear visitors and customers, we would like to draw your attention to what methods can you pay for your orders?

Source

Signs of regulator malfunction

Prolonged operation of the vehicle, without inspection and minor repairs, causes a more serious malfunction in the operation of its systems. As for the fuel pressure regulator, most often after a certain period of time its spring begins to sag, which accordingly does not create the required force and the fuel returns back to the tank. In turn, this process helps to reduce the pressure in the fuel rail and leads to a loss of engine power.

We recommend: Tread depth of winter and summer tires - permissible height

Moreover, this is not the only problem that may arise. Very often, when idling, engines stall, losing power, and when changing gears, the car refuses to accelerate. Also, often, when jerking occurs (while driving), the engine seems to choke, not responding to the gas pedal. Another reliable sign of a breakdown in the fuel pressure regulator is a sharp increase in fuel consumption and, believe me, you definitely won’t miss this indicator.

Simply put, there are the following possible indicators of a fuel pressure regulator failure:

uneven operation of the motor;

stopping idling;

a sharp increase (or decrease) in crankshaft rotation speed;

loss of engine power;

complete or partial lack of response to the gas pedal;

poor vehicle acceleration when changing gears;

frequent jerks during movement;

rapid increase in fuel consumption.

If you notice at least one of the described factors, it is worth checking whether everything is in order with the fuel pressure regulator.

Among the types of its breakdowns, the main ones are:

weak valve holding the required pressure,

the fuel begins to move freely throughout the system, thereby reducing its pressure, and ultimately returns to the tank. As a result, when the speed increases, the engine lacks fuel and its power drops significantly;

complete blockage of the regulator or limited fuel supply.

Leads to the engine stopping while the car is moving, and fuel begins to pour out of all accessible cracks;

valve malfunction

(they say “the valve is sticking”) happen due to pressure changes, which results in the car “jerking.”

But the most common problems with the fuel pressure regulator, nevertheless, are expressed in mechanical damage to its parts or their clogging. In addition, often the reason lies in the wear and tear of the materials used to create the mechanism, and even after eliminating the problem that has arisen, you will no longer be able to achieve the original standard indicators.

Also, there are some other subjective reasons that affect the proper operation of the pressure regulator - low-quality fuel (diluted with water), prolonged absence of vehicle operation, valve malfunction. We called them subjective because problems can be avoided through each driver’s responsible attitude towards his car, including timely repairs and quality service.

What injectors are installed on VAZ 2110–2112 cars

The main advantage of injectors for VAZ cars of the tenth family is that they are interchangeable. There are only two types of sprayers - produced by Bosch and Siemens. And each of them, regardless of marking and year of manufacture, can be replaced with another.

Bosch injectors are traditionally manufactured in black housing

When selecting, there is only one limitation - engine size. 1.5 injectors are not suitable for 1.6 liter engines.

The Siemens injector has a blue tip

Both Bosch and Siemens injectors of any marking can be installed on 8-valve and 16-valve engines.

Table: how to select injectors for VAZ 2110–2112 by marking

| Siemens | Bosch |

| Injector DEKA VAZ 6238 | 0 280 150 996 and 0 280 158 110 |

| Injector DEKA VAZ 6393 | 0 280 158 502 |

| Injector DEKA VAZ 20734 | 0 280 158 017 |

| Injector DEKA VAZ 20735 | 0 280 158 022 |

| Injector DEKA VAZ short 20734 | 280158017 |

| Injector DEKA VAZ short 20735 | 0 280 158 022 |

When is it time to change injectors?

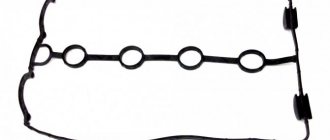

Many car enthusiasts are confident that it is necessary to clean the injector only within the period specified in the user manual. But the manufacturer, when indicating the mileage, did not take into account all the details. As a rule, not all of us fill in fuel that meets the requirements of the European standard, so the injection system in the car suffers, or more precisely, the nozzles in the injector. Replacing the injectors will help save the situation. Important! When dismantling the injectors, it may be necessary to replace the seals along with the ramp. And this procedure is long and difficult.

Procedure for removing oil injectors

Before you begin removing injectors from any car of the tenth VAZ family, you will need to relieve the pressure in the fuel system. Removing any element that is under pressure in any way can result in personal injury.

How to get rid of excess fuel

To relieve the existing fuel pressure, you need to turn off the fuel pump and exhaust the remaining gasoline:

After this, start the engine and wait until it stalls. It is recommended to turn the ignition on several times to ensure that there is no gasoline left in the system.

Next, you can begin to remove the injectors. It is recommended to prepare the necessary tools in advance:

All elements of the repair kit are usually at hand for any driver

How to remove parts from the engine

To install a new injector, the socket is first thoroughly cleaned of dirt and fuel, and only then can the product be screwed in. It is better to drop a few drops of gasoline onto the rubber ring before installation - this will make the nozzle fit into the mounting hole more easily. All work is then carried out in reverse order.

The process of checking the pressure in the fuel system

You will need: an air (or preferably a water) pressure gauge, onto which you need to put a hose with a diameter of 12 mm and tighten it with a clamp. The engine should be cold and the generator covered with a rag.

- Unscrew the cap of the control fitting on the fuel rail (fitting). Near the timing belt (on the right in the direction of travel), or on the left near the oil filler neck (for the VAZ 21129 engine);

- Unscrew the spool from the fitting using the wheel valve cap. At this moment, due to the residual pressure in the rail, gasoline will splash out (you can first relieve the rail pressure by removing the fuse from the fuel pump with the engine running and wait until it stalls).

- We put the pressure gauge hose on the ramp fitting and secure it with a clamp;

- Turn on the ignition. The fuel pump will turn on;

- We check the readings on the pressure gauge.

What pressure should be in the fuel rail? On VAZ 2110, 14-15, 99 models it should be in the range of 2.8 - 3.2 bar. On modern engines (Priora, Granta, Kalina, Vesta, XRAY, etc.) the pressure should be 3.6–4.0 bar. The process is also shown in the video:

https://youtube.com/watch?v=QaJwthsYi3Q

Features of injection wiring

The appearance of an injection engine power system was marked by a real breakthrough in the automotive industry. Not only have cars with internal combustion engines begun to consume noticeably less fuel, but it has also become possible to fine-tune them to a specific operating mode by adjusting the injectors. However, this state of affairs also affected the complexity of building vehicles. More precisely, the number of different electronics in the design of an injection car has become noticeably larger, and the wiring diagrams have become much more complicated.

This is due to the fact that the injector is a fine-tuning unit that requires broad information about the operation of many vehicle components. This aspect of the functioning of the injection system affected the addition of many sensors to its structure, working in conjunction with the head unit (electronic control unit). To clarify this point, we highlight the following new devices in the design of injection machines:

Measuring pressure using improvised means

Homemade design for measuring pressure in the fuel rail using a conventional tire pressure gauge

It’s easy to measure the pressure using available tools; you just need to have a regular tire pressure gauge on hand (which is used to monitor tire pressure - approx.). All you have to do is follow our instructions exactly. We will tell you how to carry out this operation correctly, and what the correct pressure should be in the fuel rail of the VAZ-2112.

Repair of injectors VAZ 2110–2112

Repairing injectors means cleaning the product and replacing the O-rings. Simple measures to restore the functionality of the injectors can significantly increase the car’s power and make cold starts easier. Injector repair is possible in the following cases:

In all other cases (cracks and deformations, long service life), it is recommended to replace the nozzles with new ones.

How to blow out and clean oil molds

On cars of the tenth family, injector cleaning may be necessary after 40–50 thousand kilometers. In this case, it is best to carry out the procedure yourself, since you can always observe for yourself the true condition of the motor and its elements, and also save a significant amount on service station services.

Many drivers prefer to use the simplest method of cleaning injectors - fuel additives. Special liquids, along with gasoline, are poured into the tank and pass through all elements of the fuel system, cleaning them. This measure is justified for new cars in which the degree of pollution is at a minimum level. But additives will not be able to properly clean injectors and other elements of the system.

Video: a simple way to clean injectors using a repair kit

Injector VAZ-2110

The fuel that is poured into a car cannot be called clean. In any case, it contains various impurities and dirt. Practice shows that after 40 thousand kilometers, a car needs to clean the injector nozzles. It’s worth noting right away that during normal operation of your car, it is strongly not recommended to carry out such an operation.

But if signs of contamination are obvious, there is no need to hesitate. Determining the need for such a procedure is very simple.

A sign of a malfunctioning injector (nozzles) may be the following:

Scheme for checking and replacing an injector in a VAZ-2110 car

1. The wire must be disconnected from the battery terminal

2. Remove air filter 1 together with the intake pipe hose 2 (see photo).

3. Disconnect the vacuum hose from the fuel pressure regulator.

4. Disconnect the block with wires from the throttle position sensor, after first pressing out the plastic latch.

5. Also, by squeezing the plastic latch, the block with wires must be disconnected from the idle speed control.

6. Disconnect the injector harness connector from the wiring harness.

7. Remove the bolts securing the fuel rail. Pay attention to the presence of flat washers under the bolt heads (it will be more convenient to remove the bolts, for example, with tweezers).

8. Unscrew the screw securing the fuel pipe holder. Remove the holder. Please note that there is a special spring washer installed under the screw head.

9. Carefully move the fuel rail in the direction of the injector axis so as to remove all injector elements from the holes in the engine intake pipe.

10. Carefully remove the ramp under the receiver so as not to damage the injector.

Low pressure in the fuel rail of the VAZ 2110

If the electrical circuit in a VAZ 2110-2112-2170 car is obviously in good working order, and the pump hums as usual, this does not mean that gasoline is supplied to the injectors as normal. No! There may be some problems here. Let's start with the most basic.

First, remove the protective cap of the fitting (as shown in photo 1), be sure to place a cloth underneath so as not to splash the engine compartment with fuel, and use the tip of a thin slotted screwdriver to press the spool of the fitting. If the stream of fuel is thin or weak, this means low pressure in the fuel rail; you need to look for the cause. If gasoline sprays with strong pressure, then there is hope that the pressure is within normal limits (2.8-3.2 bar), but to be sure, you need to measure it with a pressure gauge. At the service center this is done using fuel pressure gauges with adapters.

We will use a simple one from a tire pump. The only main thing is that the measurement limit is at least 4 bar. You will also need a part of a gas-resistant hose, the length of which should be 150 millimeters, the internal diameter of which should be 10-12 mm. , as well as 2 more clamps. Use the wheel valve cap to unscrew the spool valve from the fuel rail fitting. We put the pressure gauge hose on the fitting and tighten it with a clamp.

We turn on the ignition, without starting the engine: after 2 seconds, the gasoline pressure in the rail should increase to 2.8-3.2 bar and remain at this level (photo 3). If it is significantly lower (about 1 bar) and remains at this level for a long time, you need to check the supply line 4; most likely, it is clogged. There are 2 problem areas: fuel pump mesh 2 and fuel filter 5. First, let's check the filter. It is located under the underbody next to the gas tank (photo 4). If it is ok, you need to look at the pump grid.

We take the fuel pump out of the tank, remove the screen and wash it. Before installing the fuel pump, it would be a good idea to check it for leaks and the reliability of the connection of its tube (arrow in photo 5) to the fuel line. You will certainly ask what to do if the supply line is clean, the pump is humming, and the pressure is still below normal. In this case, you need to change the pump itself; it has exhausted its service life! P Or it may happen that the pump seems to be functioning normally, but there is no pressure in the rail! This can happen in winter if there is a lot of water at the bottom of the fuel tank.

P When the grid freezes, it interrupts the flow of fuel to it. What should I do? Lighting a fire under a gas tank, heating it with a blowtorch or some other source of fire should not be done under any circumstances. It is preferable to remove the fuel pump and clear it of ice. The second option for those in no hurry: roll the car into a warm room and wait. Then it would be a good idea to empty the water from the fuel tank. It's a troublesome task, but a rewarding one.

Now we have made sure that the pressure in the ramp is within normal limits. Does fuel enter the engine cylinders? This is not a fact! The injectors may become clogged, the supply of gasoline decreases, and maybe even stops completely. However, sometimes a control signal is not sent to the injectors, although they themselves are in good condition. Control should begin with inspection of the spark plugs.

If the spark plugs are wet, then gasoline flows. Dry? In this case, you need to check the signal at the harness connector of the mechanical liquid or gas atomizer (injector) with a probe (as shown in photo 6). Did you do it, but the spark plugs are still dry? Then you will have to unscrew the screws securing the ramp and lift it under the intake manifold so that the injector nozzles can be seen. We turn on the ignition and turn the engine crankshaft with the starter. If there are no streams of fuel, you need to remove the injectors and most likely replace them with new ones.

True, almost every serious service will recommend that you wash them. Ask about prices: if the price of a new set of injectors is slightly higher than flushing, then you should choose a replacement. After all, old injectors also experience age-related problems. Taken from: https://autoshas.ru.

On the VAZ 2110, the fuel pressure regulator is designed to maintain constant pressure in the fuel system in any operating mode.

The RTD is a diaphragm valve that is installed in the fuel rail. On one side, gasoline pressure is exerted on it, on the other, springs and air from the intake manifold.

Fuel system diagram for VAZ-2112 injector 16 valves

The fuel hose of the Lada Priora is the main artery that ensures a reliable supply of gasoline to the internal combustion engine. The fuel system consists of several component hoses. Some of them are made of metal, others of plastic, and others of rubber of very low quality, which ultimately leads to significant wear of such products when exposed to sub-zero temperatures.

Unfortunately, it is impossible to completely avoid the use of elastic materials such as rubber. The thing is that the parts that are located on the engine are subject to some vibrations. In order for displacements to be damped, elastic materials are used when transferring fuel from one unit to another. A good example of this is the Priora’s rubber fuel hose.

Detailed diagram of the fuel system

Detailed diagram of the fuel system.

1 — nozzles; 2 — fitting plug for monitoring fuel pressure; 3 — injector ramp; 4 — bracket for fastening fuel pipes; 5 — fuel pressure regulator; 6 — adsorber with solenoid valve; 7 — hose for suction of gasoline vapors from the adsorber; 8 — throttle assembly; 9 - two-way valve; 10 - gravity valve; 11 - safety valve; 12 - separator; 13 — separator hose; 14 — fuel tank plug; 15 - filling pipe; 16 — filling pipe hose; 17 — fuel filter; 18 — fuel tank; 19 — electric fuel pump; 20 — fuel drain line; 21 - fuel supply line.

Below we will look at the main elements of the fuel system separately.

Fuel tank

Dismantled VAZ-2112 gas tank.

The filled gasoline is supplied from the tank, which is located in the rear of the car, in the area where the sofa is located . The tank is made of steel and assembled by welding two stamped parts. Gasoline is supplied to the tank through a special neck, from a gas-resistant hose made of rubber, secured together with clamps.

Gasoline pump

Fuel pump VAZ-2112 1139009

A gas pump is an electrical functional device, submersible, installed directly into the gas tank itself. This pump is started by a signal from the ECU controller, which is responsible for fuel injection, through a relay when the ignition is turned on. If the fuel pump doesn't pump, the engine won't start! The operating pressure of the pump is at least 2.8-3 bar (atmospheres - approx.). In order to get to it, just lift the rear sofa and unscrew the technical hatch.

Fine filter

The new filter is ready for installation.

From the fuel pump, through a flexible steel hose, gasoline passes under pressure to the fine filter. The filter is made of steel and cannot be disassembled. A special paper filter element is installed inside. On the housing cover there is a special arrow, created for visual indication during installation, showing the direction of movement of gasoline in the system.

Fuel rail

Through steel fuel pipes, after filtration, gasoline passes directly to the fuel rail. It is designed to transfer gasoline to atomization and is mounted on the “outlet”. On one side of the fuel rail there is an RTD, on the other there is a fitting for controlling gasoline pressure. The pressure in the ramp in operating condition should be from 2.8 to 3.2 bar ( 2.8-3.2 atmospheres - approx.) - this indicator depends on the stabilization in the receiver, indicating constant differences in them. This is necessary in order to dose the optimal amount of gasoline into the injectors.

Fuel pressure control

Be careful when dismantling.

An RTD is a special device with a valve, assembled with a special diaphragm with a spring retainer. Under the influence of this element, the working position is in the locked type. It is also designed to divide the internal space of the regulator itself into two closed cavities - air and fuel.

The cavity for air is connected to the hose and receiver, and for fuel it is connected to the structure itself on the ramp.

During operation of the motor, the vacuum overcomes the resistance created by the spring and tries to tighten the diaphragm, thereby opening the valve. And from another position, at this time, gasoline presses on the diaphragm, also influencing the spring. As a result of this action, the valve opens slightly and part of the fuel flows back into the gas tank through the fuel line.

When the gas is pressed, the vacuum behind the throttle valve (throttle valve - approx.) becomes less, and the diaphragm, under the influence of a spring, closes the valve, increasing the fuel pressure. And if it is closed, the vacuum pulls the valve as far as possible - reducing fuel pressure.

The total pressure drop in the sensor is determined by the stiffness of the spring and the size of the hole. It cannot be adjusted, it is a non-separable element, and when it fails it must be replaced.

Fuel rail with injectors

An injector is a special solenoid valve that is needed to transfer gasoline to the manifold when current is applied to it, and close under the influence of a return spring when the power is turned off. They are mounted in place of fixation through special rubber rings and held there with a metal bracket. It is controlled by the ECU from the injection system. If a break or short circuit occurs in the injection wiring, the injectors should be replaced.

Injection system

An injection system in which feedback is provided and a fuel evaporation trap is installed. It consists of an adsorber, a separator, connection hoses and valves mounted under the hood. Its action is as follows:

- Some of the fuel vapor that accumulates in the tank is condensed in the separator and then drained back into the tank. And the rest pass through two-way and gravity valves.

- A two-way valve prevents excessive decrease and increase in pressure inside the fuel tank, and a gravity valve prevents fuel from leaking out when the vehicle rolls over.

Vapor recovery system

This is what the adsorber looks like on a VAZ-2112.

Afterwards, fuel vapors go through one fitting into the engine compartment - namely into the adsorber, where coal is installed to absorb them. The second fitting of the adsorber is connected to the throttle units using a tube, and the third is directly connected to the atmosphere. However, when the engine is not running, the 3rd fitting is closed by a valve and in this state the remaining elements are not associated with air. And when starting the engine, the controller of the system responsible for injection sends a signal to the valves with a frequency of 15-16 Hz , communicating the adsorber itself with the atmosphere. During such work, if the air flow rate is higher and the intensity of the pulses passes through more, then the blowing will be much more efficient.

And where this feedback does not exist, fuel vapors are “caught” only by a separator and one check valve.

Air intake system

When installing a new filter, follow the installation instructions.

The air filtration element is installed in a special plastic case and mounted on three rubber elements (supports - approx.). This filtration device is made mainly of a paper base, and during installation, its numerous corrugations must be located according to the arrows, that is, parallel to the machine itself.

Fuel circuit under the hood - adsorber and air filter housing

Bypassing the filtration element, the air passes through the sensor (mass air flow sensor - approx.) and enters the intake hose and then straight to the throttle assembly. The throttle valve assembly is mounted on the receiver, and when you press the gas pedal, it opens slightly, thereby changing the rate of air entering the system, while simultaneously regulating the addition of the fuel mixture. After all, fuel distribution directly depends on the amount of fuel consumed.

Cleaning Priora injectors

There are two options for washing injectors: with and without removing them from the car. The removed injectors are washed on special stands using ultrasound, under the influence of which even the oldest contaminants disappear. Ordinary drivers do not have such stands, so below we will consider a more popular option for washing injectors without removing them from the Priora. Here's what you'll need for this:

Flushing sequence

Ordinary car nipples are inserted into the holes of a plastic bottle

Priora injectors are washed using a filter and a plastic bottle

The green button is clearly visible on the Priora fuel hose

The main fuel hose of the Priora is connected to the fuel filter for flushing

The device for washing Priora injectors is assembled and ready for use

A car water pump plays an important role in the operation of a car engine. It is possible to recognize its malfunctions using the following article: https://vazweb.ru/desyatka/pitanie/zamena-forsunok-vaz-2114.html

Causes and Troubleshooting

If the above symptoms are detected, you should check the performance of the RTD using one of the suggested methods:

- measure the pressure in the fuel rail, its value should be at least 3 bar;

- find the return hose and carefully press it with pliers while the engine is running;

- disconnect the vacuum pipe leading from the manifold from the regulator.

The most reliable way is to measure with a pressure gauge. The device is connected to the fitting on the fuel rail, the test is performed with the engine running. If the pressure is below 3 Bar, additionally check the fuel pump - the unit may have lost performance. For diagnostics, you will need a tee with a pressure gauge embedded in the supply line. If the pump produces 3 Bar or more, change the RTD.

The reasons for valve failure look like this:

- the spring has lost its elasticity and allows the membrane to bypass fuel at low pressure;

- pollution with low-quality gasoline;

- rod jamming.

Due to the design features (the element body is rolled), repairing the fuel pressure regulator is impossible in most cases; the part will have to be replaced. The option of washing and blowing helps only with blockages inside the element.

Squeezing the return line is done at idle speed of the engine, preferably “cold”. If engine performance stabilizes, there is a problem with the RTD or pump. To determine the “culprit”, you will still need to measure the supply pressure. Try removing the vacuum tube from the manifold at higher speeds - if the valve has become unusable, the behavior of the power unit will not change.

Signs and Symptoms of a Malfunctioning Fuel Pressure Regulator

All these problems arise due to the fact that the regulator becomes clogged or completely clogged over time. Another common cause of failure is weakening of the spring, leading to a strong decrease in pressure. In the absence of normal pressure, fuel supply decreases, power decreases and controllability deteriorates. Such problems are especially common on Ladas - Kalina and Priora, as well as on cars of the 2110, 2112, 2114, 2115 series.

To check the part, you need to carefully inspect it itself, the vacuum hose and all connections. Any leaks found must be corrected. It is also recommended to check the membrane. Disconnect the tube that goes from the RTD to the receiver and shake it. If no gasoline comes out from inside and there is no strong odor, then the membrane is in order.

RTD in diesel engines

Diesel vehicles running on the Common Rail system are also equipped with a pressure regulator. It fits into the fuel rail or is located on the high pressure fuel pump housing. The principle of operation is approximately the same. A special valve diverts unused fuel into the return line, preventing excessive loading.

In diesel engines, the regulator has a slightly different structure than in gasoline engines. It consists of a solenoid and a rod, which rests against a ball to shut off the return line. The design protects the engine from hydraulic vibrations and, as a result, from rapid wear.

Signs of breakdown

If for some reason the fuel pressure regulator does not perform its functions, then this can be understood by the following signs:

- The engine's operation has become unstable, it may begin to stall when idling, although it would seem that the fuel level is sufficient and all systems are in working order;

- The crankshaft at idle speed has increased or, conversely, decreased speed;

- The engine, as they say, “loses throttle response”;

- While driving, dips and jerks occur in a running engine;

- Gasoline consumption increases compared to what it was before;

- The content of CO and CH in the exhaust increases;

- The engine starts with difficulty. Although this property does not always appear.

If the regulator has become completely unusable, then an increase in fuel pressure is observed. Instead of the norm for the VAZ 2110, which ranges from 2.5 to 3.3 kg/cm2, it reaches 4 – 5 and even more.

Consequently, the fuel pump supplies more gasoline by volume, which is not completely burned, and overconsumption is guaranteed. Of course, such a regulator needs replacement, and the sooner the better.

If the fuel pressure regulator does not provide the required pressure, or simply does not hold, then the lack of fuel pressure leads to the fact that normal supply does not occur, and the VAZ 2110 “chokes” when you need to increase the speed.

In addition, the starter cannot quickly spin the engine; it has to be turned on many times.

It is quite clear that we first learn about excessive consumption of gasoline by readings from the level sensor. However, sometimes the FLS also starts to lie, and then the true consumption cannot be known.

There may be a situation when you still have half a tank of gasoline, but the FLS says that the fuel is almost empty. That is, the flow sensor itself may confuse you, and before rushing to replace the regulator, make sure that the FLS is working properly, remember that the VAZ 2110 has problems with it very often.

If you notice that it is lying, the fuel sensor may need adjustment or even replacement.

Modifications of the VAZ-2112 car

VAZ-21120 . Modification with a 16-valve injection engine with a volume of 1.5 liters and a power of 93 horsepower. 14-inch wheels were installed on the car. This modification has a problem with valves bending when the timing belt breaks. The problem can be solved by increasing the depth of the grooves in the piston bottoms.

VAZ-21121 . The car was equipped with a VAZ-21114 8-valve injection engine with a volume of 1.6 liters and a power of 81 horsepower.

VAZ-21122 . Budget modification with an 8-valve injection engine VAZ-2111. The car was produced without electric windows, the wheels were 13 inches in size, and the brakes were unventilated from a VAZ-2108 car.

VAZ-21123 Coupe . Three-door, five-seater hatchback. The only two doors for entering the car are 200 millimeters wider than those of the five-door hatchback, and they are mounted on new, durable hinges. The rear arches of the car have become wider. The engine was installed with a 16-valve injection engine with a volume of 1.6 liters and a power of 90 horsepower. The car was produced from 2002 to 2006 in small quantities, the reason for this was the high cost of the car.

VAZ-21124 . Modification with a 16-valve injection engine VAZ-21124 with a volume of 1.6 liters. Produced from 2004 to 2008. For this type of engine, the problem with valve bending was solved. To do this, the depth of the grooves in the piston heads was increased (up to 6.5 mm). In addition, the design of the cylinder block was changed to achieve a working volume of 1.6 liters, for which its height was increased by 2.3 mm, and the radius of the crankshaft was increased by 2.3 mm accordingly. There were also a number of other minor changes.

VAZ-21128 . The luxury version of the car, produced by Super-auto JSC, was equipped with a 16-valve VAZ-21128 engine with a volume of 1.8 liters and a power of 105 horsepower.

VAZ-2112-37 . A racing modification of the VAZ-2112, prepared for the “ring” in the Lada Cup qualifying group. The car was equipped with a 1.5-liter VAZ-2112 engine with a power of 100 horsepower. The racing car was equipped with a safety cage, an external aerodynamic kit and a front extension of the strut support cups.

VAZ-2112-90 Tarzan . All-wheel drive modification with a VAZ-2112 body on a frame chassis with transmission and suspension parts from a VAZ-21213 Niva. It was also equipped with a 1.7 or 1.8 liter engine from the Niva.

How to check on VAZ and foreign cars

To determine a breakdown, the following procedures are performed:

You can check the performance of the RTD yourself, even without tools. To do this, just pinch or disconnect the valve and study the intensity of the stream. A pressure gauge will give a more accurate result. It should be connected between the fitting and the fuel hose, having first disconnected the vacuum hose. The measurement is taken at idle speed. The information obtained depends on the car model - for example, in a VAZ 2110, the pressure indicator should start at 0.3 and gradually increase to 0.7 Bar.

Fuel pressure regulator with connected pressure gauge

Has your blood pressure changed? You may have connected the pressure gauge incorrectly. Check the connection. If everything is correct, it means the regulator has become unusable.

Where is the fuel pressure regulator located and how does it work (video)

How to check the operation of the fuel pump?

First, you should check the fuse. To do this, check the instructions for its location. Next, you should check the voltage at the pump. Before doing this, be sure to check if everything is in order with the battery. The voltage at the fuel pump terminal must be checked using a multimeter or tester. The instruction manual always indicates the required voltage.

Using a tester, check the voltage supply to the fuse. Often this is where the electrical circuit breaks.

If the search does not yield results, then the voltage should be checked on the contacts themselves. All contacts must be in place and connected to ground. A broken contact or its oxidation leads to failure of the fuel pump system. If no broken contacts are detected, but the voltage drops by more than 1 volt, then the problem is in the wiring or oxidation of the contacts. There should be no short circuit in the wiring.

If, after checking the voltage, contacts and fuse, you do not find any problems, then the problem lies in the fuel pump itself. In this case, the fuel pump will most likely require replacement. In practice, it most often turns out that replacement is a last resort. First, you should try to restore and test the fuel pump again.

Before you check the fuel pump, you need to remember that, as mentioned above, pressure is the most important characteristic of the fuel pump, so it is worth measuring its level.

How to check the pressure in the fuel rail?

You will need a pressure gauge that measures pressure in the range from 7 to 10 atmospheres. If you choose a pressure gauge with a large margin, you risk getting less accurate measurement results. Specialized stores sell a kit for measuring pressure, but you can also design your own device.

If you want to assemble the device yourself, you will also need a hose with an internal diameter of 9 millimeters. You will also need plumbing tow, with which you can seal the connection between the pressure gauge and the tube. All parts are connected and tightened using a clamp. You will also need a car spool. Next you need to perform a series of actions:

- Place the car on a level surface that is prevented from rolling, turn off the ignition and open the hood.

- Check that the injection nozzles have access to the fuel rail.

- Find the fuel pressure plug and remove it. Then you should unscrew the nipple using the spool.

- Prepare an empty container (a regular bucket will do) and a clean rag. This is necessary to collect residual fuel, which under pressure can splash out in different directions. Therefore, take care of the safety of your skin (especially your face and eyes).

- Connect the device to the fitting and begin checking the mechanism.

Checking the pressure in the fuel rail should occur in four operating modes of the power unit:

- when the ignition is on;

- at idle engine speed;

- code the fuel pressure regulator tube is reset;

- when the drain tube is compressed.

Fuel rail pressure measurement results

The results may vary slightly for different car models, but in general they should be as follows:

- when the ignition is turned on, the pressure must be at least 3 atmospheres,

- at idle engine speed - at least 2.5 atmospheres,

- when the pressure regulator tube is reset - at least 3.3 atmospheres,

- when squeezing the drain tube - at least 7 atmospheres.

Fuel rail pressure fluctuates slightly during preparation. When you press the pedal, it suddenly takes on a value of 3 atmospheres; when you release the pedal, it drops to 2.5 atmospheres. When fuel enters the fuel system, turn off the ignition and begin observing the pressure gauge. The pressure in this case should drop to 0.7 bar and remain unchanged.

If the pressure drops to zero, there may be a problem with the fuel pressure regulator. In this case, the regulator must be replaced immediately. The cause could also be the fuel pump check valve.

It is necessary to observe the behavior of the pressure gauge even at 3,000 engine speeds. A drop in pressure will indicate a faulty fuel pump. Sometimes the fuel pump cannot reach the required pressure for a long time. In this case, the problem lies in a clogged fuel filter, which needs to be replaced, or in a dirty fuel pump mesh (read more about where the fuel filter is located).

If the above methods do not reveal a malfunction of the fuel pump, you will have to diagnose other units (DPZD, IAC, mass air flow sensor, compression in the engine and some other indicators and parts).

What are the consequences of malfunctions in the operation of RDTs?

Over time, the engine starts more and more poorly. Fuel begins to come out of the cracks, which leads to a strong increase in its consumption. When the pressure changes unevenly, the dynamics of movement are disrupted, surges occur, and the car jerks during acceleration.

Is it possible to repair a failed part? In most cases, no, you have to completely change it. Repair units are almost always non-separable. Some experts suggest repairing the component, but this is dangerous. It is better to buy a new regulator - fortunately, it is inexpensive.

Determining violations in the operation of RTDs is not a very difficult task, which can be handled independently. Remember that this part of the machine needs to be checked periodically. By detecting the problem in time, you will protect important car components from rapid wear.

Important nuances

There are a few things to keep in mind when cleaning your injectors. Here they are:

Replacing injectors is a long procedure. Nevertheless, it is quite within the power of a novice driver if he has at least a vague understanding of the structure of an injection engine. When cleaning the injectors, the situation is much simpler: you just need to be able to use a drill and know where the main fuel hose is located.

Carburetor cars are slowly but surely becoming a thing of history. Float chambers and diffusers have been replaced by injectors and distributed fuel injection, the quality of which is controlled by the car’s on-board computer. On the one hand, injectors have made life much easier for motorists. On the other hand, even these reliable devices periodically fail. Fortunately, the driver can replace them with his own hands. The main thing is to know how it's done.

Causes of fuel pump failure on a VAZ-2110

Contamination of the fuel tank leads to premature failure of the fuel pump.

Incorrect operation of the unit can also lead to unit malfunction. Experts advise that when starting the engine, initially turn on only the ignition for 2-3 minutes and do not turn on the starter. During this time, the pump will pump the required amount of fuel into the system and create a certain pressure there.

The pump may also fail due to natural wear and tear. It usually lasts for a mileage of 150,000 kilometers. This is 4-5 years. But the timing may be different. It all depends on the conditions of its operation.

Burnt contacts of the fuel pump terminal block.

Sometimes a pump failure can be caused by a breakdown in the electrical network, failure of a relay or fuse. Such malfunctions can be quickly eliminated on your own. It's not expensive.

There are craftsmen!