Replacing the Lada 2109 engine (VAZ 2109)

- What to put?

- Underwater rocks

Tuning is not just about changing the appearance of a car, as many people think.

In fact, revisions often concern the technical component. Someone makes changes to the exhaust system, changes elements of the factory engine. But there is a more drastic, expensive and interesting option - change the engine. With the new engine you get different technical characteristics, increased power, increased maximum speed, better acceleration.

What's under your hood?

Replacing a motor is a fairly serious step that requires thinking through every stage, from choosing a new motor to the consequences that such work may result in.

Oil change features

Filter and plug position

Changing the oil in a VAZ 2109 engine is not the most common process, but you can handle this task as needed. If you buy a used car from another person, you need to change the lubricant in the engine as quickly as possible. Repairing the steering rack on a VAZ 2109 with your own hands (video) The steering rack in front-wheel drive cars is fully responsible for the functionality of the entire steering mechanism. With all this, it is recommended to flush the engine with a special liquid, because it is not clear to you exactly what was filled in earlier.

It is also recommended to change the oil if you have not used the VAZ 2109 for a long time. Similar posts. Replacing the rear light of a VAZ 2115 with your own hands - step-by-step instructions. When the engine is not started for a long time, condensation accumulates in it and mixes with the lubricant, causing a deterioration in its performance and ultimately increasing wear on all internal parts of the unit.

Without removing the gearbox

In short, it is quite possible to remove the engine from your “nine” without removing the gearbox. To do this you will have to follow these steps:

- Place bricks or other reliable supports under the gearbox;

- Unscrew the left crab, move the stretcher aside;

- Remove the generator, crankshaft pulley, and camshaft gear from the engine;

- The pump, tensioner pin, distributor, and exhaust pipe are also dismantled;

- If a major overhaul is planned, then you can also remove the head;

- Then the engine mount is removed;

- The motor is moved from the box and lowered to the floor. To remove the engine, the front part is raised higher using a jack and the volume is removed;

- Or you can pull it out through the top using a winch.

In practice, all experts recommend dismantling the engine along with the gearbox. Especially if you plan to replace the engine or increase the power of the standard engine. In this situation, the box itself is often changed so that it can clearly interact with the new motor.

Gearbox from nine

How to remove an engine from a car

At home, there is usually no professional lifting equipment, so you will have to rent it or make it yourself.

Do-it-yourself goose for removing the engine

This is a simple mechanism that resembles a gooseneck. It makes it possible to move the engine away from the engine compartment. It may have a rotating design that allows you to remove the engine without moving the machine.

The heavy internal combustion engine is simply transferred to a workbench located next to the car. In fact, it is a universal garage crane. The rack rests on long “legs” located under the engine compartment to prevent it from tipping over. A cable and a winch are used for lifting.

The gander is used both in garage conditions and in small services.

DIY engine removal lift

As a rule, this is a rolling crane, the lower part of which is placed under the front bumper. A smooth platform is required; on uneven ground, removing the engine using such a device is problematic. The lift operates using hydraulics or a tensioning mechanism like a winch. The device is simple: a stand with rolling supports, and a movable boom on which the motor is suspended. You can make a lift with your own hands from a channel or a square professional. pipes.

If there are strong wheels on supporting legs, you can quickly roll out the lift with the motor and move it to the repair area.

Do-it-yourself winch for removing the engine

Applicable if the car is being repaired in a solid stone garage. The most inexpensive tool that can be used to remove an engine. A chain or cable is used to pull it out.

There are two design options:

Features of removing various motor designs

Longitudinal arrangement.

As a rule, such internal combustion engines are removed without a gearbox, although exceptions are possible. The radiator needs to be removed.

Transverse arrangement.

The motors are compact and easy to lift vertically. The gearbox remains on the engine.

Hybrid systems and electric vehicles.

Internal combustion engines in such machines take up little space or are absent altogether. Electric motors can be built into the wheel drive or integrated into the transmission. Due to their small size, their dismantling is not difficult.

All types of internal combustion engines are installed on supports. In frame structures, the attachment points are located on the frame; in cars with a monocoque body, there is usually a subframe.

Actions requiring increased caution

Remove the muffler and camshaft pulley last. Further actions are taken taking into account the actual situation. If the star bolts are covered with a layer of dirt and oil, then there is no need to unscrew them. Remove everything together with the camshaft. It is better to unscrew them if the motor has been used recently.

The front crankshaft pulley will help you remove the engine correctly. To do this, it is recommended to use a folding key. It is installed through the top, not through the bottom. Before using it, it is recommended to switch to speed 4-5. After this, the VAZ engine is more easily subject to normalized physical impact. If the above recommendations do not help ease the movement of the key, you must use the services of an assistant.

One of the assistants gets into the car and presses the brake pedal. In this case, it is easier to remove the front crankshaft pulley. After this, the pipe and the generator bolts located on top are dismantled.

If the transmission bolts show signs of physical wear or significant contamination, it is better to replace them.

In this case, removing the engine will reduce the likelihood of failure in the future. After all, no one knows when the next time a car owner will look under the hood.

When removing the wires from the generator, it is necessary to gradually loosen the fastening of the device itself. The more accurately your hand moves, the less likely it is to get damaged. After this, the “crab” is removed with no less care. It is secured with two bolts, which we remove using a wrench. Before unscrewing the last bolt, the device is slowly moved to the side.

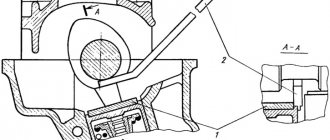

Photo. Head removed from engine

Next, unscrew the pipe, the upper bolts of the generator and the gearbox bolts (three bolts and one nut), they are indicated by arrows in the photo.

Photo. Engine, bottom view

Unscrew the wires from the generator and the generator mount itself is indicated by an arrow in the photo, and remove the generator.

Unscrew the crab, it is shown in the photo, I almost unscrewed it, there is only one bolt left, and loosen the rear link bolt.

Photo. Unscrewed crab

Place the unscrewed crab to the side as shown in the photo.

Photo. Fixed motor

Next, fix the engine as shown in the photo, you can use the timing belt and, in order to avoid scratching the car, place a rag under the brick, as shown in the photo. Loosen the engine mount and unscrew the mount from the engine itself, grab the belt and pull out the pipe that fixed the engine, lower the engine.

Removing a VAZ 2110 engine, step by step procedure:

1. First, you need to remove the battery from the car.

2. The next step is to remove the hood.

3. After this, remove the oil from the engine crankcase by unscrewing the drain plug, and remove the coolant from the cooling system by unscrewing the drain plugs of the cylinder block and radiator with the expansion tank cap removed.

4. Now you need to remove the air filter with the intake pipe hose, not forgetting to then close the carburetor on top with the technological cover.

5. Then we take and disconnect the exhaust pipe with the bracket from the engine, lower it slightly down so that the flange can come off the intake valve studs.

6. The next movement is enough to turn the throttle valve drive sector to the stop torque.

7. After this, you need to unscrew the two bolts securing the throttle valve drive rod bracket and move it to the side without disconnecting the rods from it, but so that it does not interfere with further work.

8. Next, having unscrewed the fastening nut, carefully remove the tip of the engine “mass” wire from the stud.

9. Finally, loosen the next two fastening nuts and remove the tips of the “mass” wires from the studs securing the rear cover of the cylinder head.

10. Carefully disconnect the block with wires from the coolant temperature sensor by slightly releasing the clamp.

11. Then gradually loosen the clamps and remove the radiator outlet hose from the thermostat and the radiator inlet hose from the cooling jacket pipe.

12. Now disconnect the wire from the coolant temperature indicator sensor.

13. Slightly loosen the clamp and remove the heater supply hose from the water cooling jacket pipe.

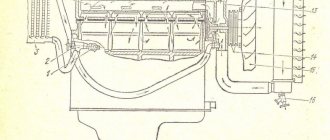

14. The next effort is to disconnect the block (No. 1 in the figure above) with the wires from the detonation sensor (No. 2 in the figure) (or remove the sensor, but to do this, unscrew the nut of its fastening and remove the sensor from the stud, but be sure to leave it on wiring harness).

15. Now it is important to disconnect the block with wires from the low-voltage terminal of the ignition module by pressing the latch holding it.

16. Then carefully disconnect the block with wires from terminal “D” of the generator, carefully move the rubber boot and unscrew the nut in order to then disconnect the wires from the contact bolt (terminal “B+”) of the generator.

Types of major repairs and cost differences

An engine is a complex mechanism in which any of the components can break. Major repairs may be required if the part breaks in several places. In pricing policy, the relationship is simple - the more damage, the more money you will have to pay. The complexity of the repair is often determined by the number of breakdowns and the general condition of the part.

If sand is already falling from the engine due to age, oil is leaking and the shaft is knocking, then you need to prepare for a serious financial blow. If something happens to the cylinders, even if nothing else is damaged, a major overhaul will still be needed.

Reinstalling the head

Now you can carefully install the cylinder head in its place, making sure that at this moment the gasket does not slip out or move to the side. Of course, the guides fix it, but you should still be extremely careful.

Next, we will need a torque wrench, since the bolts will have to be tightened with a certain torque. It is also worth keeping in mind that the tightening order must be observed. The diagram below shows the sequence in which to twist:

Now regarding the force with which it is necessary to tighten the bolts. This should be done in 4 steps:

- First, a torque of 20 Nm

- Second reception with a torque of 75-85 Nm

- Tighten each bolt another 90 degrees.

- Finally turn it 90 degrees.

In what cases is it necessary to change the earbuds?

1. The main reason is simple physical wear and tear. As the liners wear, free movement of the crankshaft will appear, as well as a reduced degree of lubrication due to a drop in oil pressure.

2. Rotating the liners. The most common causes of this malfunction are the following:

- the lubricant has become extremely viscous, abrasive compounds have entered it, and it may be that it has disappeared altogether;

- the bearing caps are not tensioned sufficiently;

- excessively liquid consistency of the engine oil, as well as operation of the power unit at extreme conditions.

Removing the head and replacing the cylinder head gasket

Burnout of the gasket under the cylinder head on VAZ 2109-2108 cars is the most common reason why the head has to be removed from the engine, and accordingly with further repairs, or rather, replacement of the gasket. If this problem is not noticed in time, it can lead to quite sad consequences, since the engine can overheat and even jam.

The procedure itself for removing the cylinder head and replacing its gasket is not complicated, but at the same time it requires certain technical skills and a small number of tools, the list of which is given below:

- Hex or similar bit with adapter for use with wrench

- Torque wrench - in this case I used the Ombra model with a range from 10 to 110 Nm, which is quite enough

- Flat screwdriver

- Extension

- Gasket Remover

Auto repair school – DIY car repair

This article will describe the process of replacing the rear engine mount on a VAZ-2109 car . On VAZ 2108, 2109, 2109 and VAZ 2113-2115 cars, replacing the rear airbag is similar. But first, I will list the reasons why you should think about replacing the pillows or engine mount. Wear, breakage and destruction of the rubber or metal component of any engine mount leads to vibration and itching while driving, and shocks when starting and stopping the car. Therefore, if the above symptoms appear in your car, then pay attention to the condition of the airbags or, as they are also called, engine mounts. If large cracks, breaks or peelings of the rubber part of the cushion are detected (photo 1), replace the part. If the metal part of the pillow bursts or breaks, replace the part as soon as possible. I think there will be problems in this part. But questions regarding work related to replacement may arise! Right? Therefore, we continue to read further and at the end of this material the answers to the questions will be found)))

Spare parts . The rear engine mount for VAZ 2108, 2109, 2109 and VAZ 2113-2115 cars can be found on the Internet and purchased using the catalog number - 2108-1001033-10. According to the manufacturer, everything is simple - we buy a pillow from BRT or SEVI. Other options are not options...

Tools required for replacing the rear engine mount : a 17 socket wrench, a pair of 19 socket wrenches, a trapezoidal jack for fixing the engine. We carry out the replacement work in an inspection pit.

The procedure for replacing the rear engine mount (support) on a VAZ-2109 car:

We drive the car into the inspection hole. Remove the engine protection, if any.

Place a jack under the gearbox and slightly lift the gearbox up (photo 2)

Preparatory stage

Before starting work, it is strongly recommended that you familiarize yourself with the structure of the “heart” of the iron horse. This will help avoid many problems associated with incorrect connection of individual system elements, such as:

- right front support;

- generator;

- engine;

- gearbox - it is necessary to remove the gearbox only if the engine is overhauled or replaced;

- starter;

- system for turning on the lights for reversing marks VAZ 2109;

- stretching;

- left front support;

- a plug that secures the hole for draining oil from the engine;

- front wheel drives on the right side;

- rear support-fix;

- hole for draining oil from the gearbox;

- left-hand front wheel drive;

- gearbox shift drive rod.

Beginners are advised to take photographs of the listed parts in assembled form. In order to successfully dismantle the VAZ engine, it is necessary to use the tools recommended by the manufacturer. A list of these can be found in the vehicle operating instructions. Regardless of the reason that prompted the need to carry out removal and diagnostics, you must adhere to the following scheme:

A carefully removed car ignition module will help you remove the engine correctly. Due to the fragile nature of the device, do not use excessive physical force. After this, the plug located on the block is dismantled. Only after all the liquid has been drained is the next element removed.

All plugs from the drive are disconnected in random order. The same thing happens with the throttle and hose cables. Before starting this stage, it is better to use a camera to record the initial position. The photo will be useful when the installation of the VAZ engine begins.

Literally, pinpoint precision is required when it comes to removing the hose leading to the gas line. To do this, you need a key set to “17”, which will not break the rather fragile system. Here, as in the case described above, it is necessary to carry out recording using a photo.

When returning the VAZ engine to its rightful place, the photograph will help to correctly connect all the elements. There is no room for error here. Only after you have completed removing all the tubes on the “head” can you move on to those parts that are directly attached to it.

Purpose of crankshaft bearings

These parts are sliding bearings that ensure acceptable operation of the connecting rods when they rotate the crankshaft. At this very point, during the operation of the power unit, colossal loads arise on the parts. Imagine, the piston, after igniting the fuel-air mixture, gains a simply monstrous speed and at the same time, at the lowest point of its stroke, it encounters an obstacle in the form of a shaft elbow, which provides it with a reciprocating maneuver. It is this “return” that puts the greatest load on the connecting rod bearings.

Of course, no one has yet canceled the laws of physics, therefore, due to friction, sooner or later the liners will fail, that is, they will no longer provide the contacting parts with minimal friction. As they wear out, the oil pressure will decrease and the so-called oil film will no longer provide the proper degree of protection.

It is also worth knowing that liners are divided into two groups: connecting rod and main. To see the difference between them, look at the image below to see which ones are located and where:

What to put?

Indeed, the most important issue among VAZ 2109 owners is the range of engines that may be under the hood of their car.

Let's look at several popular solutions that are most often found among those who decide to change the engine on their VAZ 2109.

Option

Peculiarities

Gas is a cheaper alternative to gasoline, which will allow you to save big in the future at gas stations. This replacement is called the easiest. But you should take into account the fact that such a replacement will pay off only if the car is used frequently, and you will have a gas cylinder in the trunk. Such work can only be done by specialists with appropriate qualifications and permits.

VAZ injector 1.5 liters

A good alternative that will allow you to extract more power from your improved car. The injector is more powerful, it requires less fuel, and provides better dynamics. But in practice, changing engines from VAZ to VAZ is not the best solution, since there are many options among more reliable, powerful imported cars

Engine tuning options

VAZ 21093 engine tuning

As mentioned above, engine tuning involves several methods. They all have both their advantages and disadvantages.

Engine modernization in the first way

This option involves installing and replacing the following components:

- Lightweight connecting rods, which fit the size 121 mm.

- A lightweight crankshaft, the piston stroke of which should be 78 mm.

- Lightweight piston rings.

- Cylinder head borrowed from Lada Kalina.

- Forged pistons having a diameter of 82.5 mm.

- Camshaft size 11.3 mm.

Note. This modification of the engine gives considerable power, which in l/s is equal to 98. This also makes it possible to reach a maximum speed of 183 km/h.

Easy tuning of the VAZ 2109 engine

Method two

This method involves upgrading the engine by interfering with the operation of the transmission and carburetor. In this case, such modernization will not require too high financial costs, unless, of course, the work is carried out on its own. So:

- The first step is to install a new filter, which should have a diameter of 70 mm. This filter must have a direct-flow outlet device. This will make it possible to increase engine power by 10 l/s.

- We install a 5-speed transmission.

- We install a new oil cooler.

Option three

This method of engine modernization involves the installation of the following parts:

- New oil nozzles.

- Lightweight pistons.

- Lightweight crankshaft.

- New gearbox.

- Lightweight flywheel.

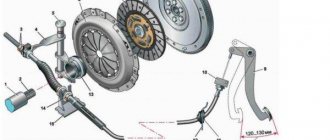

- Improved grip.

In addition to the above, a lot of new components are installed on the car, including a non-contact ignition system, a sports muffler (see: We do high-quality replacement of the muffler on a VAZ), a copper radiator, and so on.

Carburetor

This part of the car is given special attention when improving the engine. In particular, the carburetor is replaced along with other parts:

- First of all, the spring is removed from the vacuum drive of the second chamber damper. This gives a good increase in power.

- You can also modify the vacuum drive by inserting a homemade wire ring into the design.

- The diffuser is being replaced.

- The pump nozzle is being replaced.

Removing the engine, VOLGA AVTOMOTIV-TOMIX

The engine is removed from the car upwards. To remove the engine, a lifting device with a lifting capacity of at least 300 kg is required. The car must be installed on a lift, inspection ditch or overpass. Before removing the engine, it is necessary to prepare a reliable stand on which the engine must stand steadily. It is easier to remove the engine if you remove the hood.

Before disconnecting hoses and electrical wires, we recommend that you mark them so as not to mix them up during assembly.

1. Disconnect the fuel supply and drain lines.

2. Remove the battery.

4. Remove the engine splash guard.

5. Drain the engine cooling system.

6. Drain the oil from the engine crankcase.

7. Remove the radiator of the cooling system with the electric fan and fan shroud.

8. Disconnect the wire terminals from the ignition coils. Remove the ignition coils.

9. Disconnect the phase sensor connector from the wiring harness.

10. Remove the screws and disconnect the wires from the oil pressure indicator 1 and emergency oil pressure 2 sensors. Loosen the clamp and remove hose 3 to the expansion tank from the thermostat fitting.

11. Disconnect the connectors from the engine temperature sensors 3, coolant temperature indicator 2, coolant overheat indicator 1.

12. Loosen the tightening of clamp 1 and remove hose 2 from the fitting to the check valve of the vacuum brake booster. Disconnect connector 3 from the throttle position sensor. Loosen the clamp and disconnect pipe 4 of the air supply from the throttle assembly. Move the pipe along with the mass air flow sensor to the side.

13. Unscrew the nut and remove the blue ground wire 2 from the stud at the front end of the receiver. Unscrew nut 1 and remove accelerator cable 3 from sector 4 of the air throttle valve drive.

14. Slide the cable gland 3 from the threaded end 2 of the cable shell, unscrew the nut 1 securing the cable end and remove the end 2 from the bracket fixed to the engine intake pipe, sliding it back. Then lift the accelerator cable upwards from the bracket.

15. Bend the accelerator cable holder and remove the cable from it. Move the accelerator cable away from the engine.

16. Disconnect the plug block, speed sensor and crankshaft synchronization sensor located between the engine intake pipes from the wiring harness.

17. Disconnect the wires from the generator...

19. Disconnect connector 1 from the idle speed control. Unscrew nut 2 and remove the ground wires from the stud at the rear end of the receiver.

20. Disconnect plug 1 from the air temperature sensor. Loosen clamp 2 and remove the coolant supply hose from the heater tap fitting.

21. Unscrew the nut and disconnect the oil supply hose to the oil cooler from the tap.

22. Loosen the clamp and remove the heater outlet hose from the heater radiator fitting.

23. Unscrew nut 1, remove knock sensor 2 and move it along with the wire away from the engine.

24. Disconnect the connectors from the injectors. Unbend the wire harness holders and remove the harness from the holders. Route the wiring harness away from the engine.

25. Remove the accessory drive belt.

26. Unscrew the fastening bolt and disconnect the “mass” wire.

27. Remove the two bolts securing the power steering pump and remove the pump from the engine without disconnecting the hoses.

28. Attach the lifting hooks to the lugs on the exhaust manifold and generator bracket.

29. Unscrew the nut and disconnect the oil drain hose from the oil cooler from the fitting on the crankcase.

30. Remove the exhaust system.

31. Remove the gearbox.

32. Remove two bolts on each side securing the clutch housing amplifier to the cylinder block, unscrew the two nuts from the bolts securing the clutch housing to the amplifier and remove the bolts. Then lift the rear of the engine and remove the booster from behind the center linkage linkage.

33. Remove the clutch housing.

34. Remove the bolt securing the engine mount bracket to the mount on each side.

35. Check that all hoses and electrical wiring are disconnected from the engine.

Carefully lift the engine up

37. Install the engine in reverse order. When installing the engine on the mounts, make sure that the mounting pins on the mounts fit into the holes on the engine brackets, and the bolt holes on the brackets and mounts should line up.

Preparation

At the preparatory stage, short but very important, it is worth completely de-energizing the car by disconnecting the battery. You also need to remove all hoses, speed and clutch sensors. Be sure to drain the oil from the engine crankcase and the liquid that cools the radiator. Removing the engine without removing the gearbox:

- first of all, you need to put a reliable support under the car, preferably wooden stumps;

- unscrew the left crab, move the stretcher to the side;

- remove the generator from the engine;

- remove the tensioner pin, pump, distributor and receiving pipe;

- do not forget to remove the head if you are planning a major overhaul;

- the motor must be removed from the box and lowered to the floor;

- in order to get the engine, you need to raise the front part higher (this is done using a jack);

- you can also just pull everything through the top.

Removing an injection engine from a car without disassembling

To remove the injection engine from the car, you need a lifting device with a lifting capacity of at least 300 kg and slings (chain).

Installing the injection engine on the car

Install the engine and all removed parts in the reverse order

On these machines, VAZ 2101 to 2107, the principle of engine removal is the same. If you decide to remove the engine yourself at home, without any equipment, and don’t know how to do it correctly, then this article is for you.

The engine has to be removed to overhaul it, or to replace it with another engine.

You look at the engine and the first feeling is that it is difficult to remove the engine from the car, but in fact everything is very simple, two men can easily remove the engine themselves at home and also put it in place. I will give an example of removing an engine from a VAZ 2106, although this principle is suitable for VAZ2101 to 2107.

The engine can be removed entirely, but this is much more difficult, or you can remove it without the head, this is much easier. If you decide to repair the engine yourself, then the second option is preferable, since you have to disassemble the engine anyway and why drag out the extra weight. I will describe the removal of the engine with its partial disassembly, in the engine compartment of the car.