After several years of active use, the throttle assembly becomes seriously dirty and requires immediate cleaning; under the negative influence of crankcase gases, as well as small particles of oil and dust, the operation of the carburetor becomes unstable. Cleaning of the throttle valve (DZ) should be done every 50-60 thousand km, in addition, it is necessary to carry out preventive maintenance from time to time with mandatory partial disassembly of this unit.

SYMPTOMS OF THROTTLE VALVE CONTAMINATION:

1. It is difficult for the engine to switch from high speeds to idle when the accelerator pedal is suddenly released. For example, when you brake or coast in neutral. Instead of a smooth return to speed, they rapidly drop to 400-600 per minute, after which, as a rule, the engine stalls with characteristic shaking or with great difficulty is restored to the required speed.

2. Also, an engine with a dirty throttle assembly has difficulty with “cold” starting, and in some severe cases, “hot” starting. Before starting such an engine, you have to turn the starter for a long time, and the characteristic smell of gasoline can be heard from the exhaust. However, as soon as you slightly open the throttle several times by briefly pressing the gas pedal, the engine “comes to life” and starts.

CAUSES OF THROTTLE VALVE CONTAMINATION

A mixture of air and oil, as well as microscopic dust particles that pass through the air filter from the crankcase ventilation system. When used on a car, this substance slowly covers all internal surfaces, especially in places where there is strong air turbulence, that is, behind the throttle valve, as well as on the idle air control rod. From long-term operation, the thermal gap itself becomes “overgrown” with dirt, and the cross-section of the bypass channel of the idle air regulator in the throttle valve decreases.

Today I will talk about how to clean the throttle valve of a VAZ 2112 with your own hands with a detailed description of the entire process.

CLEANING THE THROTTLE VALVE

This work is carried out on a “cold” engine to avoid burns and other troubles.

From the tool you will need:

- Tortseva at "13".

- Screwdriver Set.

- Fluid for flushing the throttle body; as an option, I can recommend a time-tested cleaner for carburetors - Abro, it is highly effective and is very inexpensive.

HOW TO CLEAN YOUR THROTTLE VALVE - STEP BY STEP GUIDE

1. First of all, you need to remove the plastic (decorative) engine cover.

2. Then you need to unscrew the expansion tank cap in order to reduce the pressure in the cooling system.

3. You need to loosen the clamps (see photo, they are indicated by arrows)

4. Remove the forced ventilation hose from the air pipe. Carry out a visual inspection if you find traces of oil in the air pipe - most likely the thin forced ventilation channel in the throttle assembly is clogged. If this is so, then all crankcase gases, together with oil particles, go through a large ventilation branch.

5. Take a screwdriver and loosen the two clamps, then remove the throttle body heating hoses, they can be plugged for a while with something like bad spark plugs.

6. Remove the hose of the gas tank ventilation system; to do this, you need to unscrew the clamp.

7. All that remains is to remove the cable and unscrew the two fastening nuts of the throttle assembly.

NOW DIRECTLY ABOUT HOW TO CLEAN THE THROTTLE VALVE OF A VAZ 2112

1. Take the previously prepared cleaner and thoroughly clean the throttle valve, including all channels of the assembly. Pay SPECIAL attention to the calibrated positive crankcase ventilation duct; as a rule, it is so coked that you have to use a needle or a steel spoke to clean it.

2. Unscrew the two bolts and remove the idle air control (IAC). Properly rinse its channel in the throttle body, pay attention to its condition, the service life of the IAC is approximately 100 thousand km. If during the inspection you find that the idle air control rod is very dirty, sticks, has a lot of play or wear, I recommend replacing it with a new one.

3. If the gasket in the throttle assembly has a “human” appearance, there is no need to change it, but if it is damaged, replace it.

For those who like photos in the “before and after” style, I specially compared two images for greater clarity and demonstration of the work done.

Assembly is carried out in reverse order. That's all there is to cleaning the throttle valve, put everything back together and check the result. The result will be incredible, I can say from personal experience that after I cleaned the throttle valve the car seemed to have been replaced, everything changed, the engine performance, idle speed and sound changed so much that it seemed to me that the engine of my car had been replaced, or I had done something wrong "in the adjustments.

While driving, an unprecedented throttle response and sensitivity came from somewhere, the engine began to gain speed faster and “eat” less fuel. The idle speed has stabilized, in short, the result is simply stunning. I hope your throttle valve cleaning also did not go without a trace... Thank you for your attention, take care of yourself and your car.

Consequences of throttle valve contamination

The throttle valve contains a sensor that transmits information about its opening to the electronic engine control unit.

After this, the ECU regulates the supply of fuel to the combustion chambers. Many VAZ 2112 owners are thinking about increasing the power of their car by improving or replacing this engine unit. After a year or two, the car begins to behave less quickly, the idle speed disappears, and small vibrations begin to spread throughout the body. Symptoms of a clogged mechanical regulator are immediately noticeable - the engine takes a long time to switch from high speed to idle, even when the gas pedal is suddenly released. This is most felt when you switch to neutral speed or simply coast. This is usually followed by a smooth stop of the engine instead of the standard return to idle. There are also problems with cold starting or, conversely, an engine that is too “heated” will require turning the starter for a long time, which is fraught with consequences in its own way.

Often it is the condition of the throttle valve that affects this. How? The fact is that after 50–60 thousand kilometers, the patch on the damper becomes dirty, and this leads to improper operation of the engine. So before you think about completely replacing or upgrading your throttle body, maybe you should try just cleaning it?

Throttle position sensor (TPS). Replacing TPS

Thanks to the fact that in our century cars are equipped with injection engines and have, so to speak, brains. They are equipped with many different sensors that are responsible for most processes. This is of course very good and convenient, BUT... If at least one fails, the operation of the entire car is disrupted, and this is what affects: consumption, power, dynamics, etc. In this section we will look at what a throttle position sensor (TPS) is, what it looks like, what it does, and how to change it (there is nothing complicated about it).

Type of sensor and its functions. So, this sensor is shown in the photo:

Why is TPS needed? Everything is simple here, it is needed to control the injectors (supply more or less fuel), depending on how much the throttle valve is open.

Like all parts of a car, this sensor has a service life and tends to fail. Of course, you can go to a car repair shop and pay extra money. In general, replacing the TPS is not a difficult task and you can do everything yourself; if you have all the tools, you will spend a maximum of 5 minutes.

This sensor can be classified as a variable resistor - it has three contacts: 1) Power (5 V) 2) Ground 3) Controller

By pressing down the gas pedal, the TPS looks at the output voltage and determines the quality of the mixture, taking into account the position of the DPS (angle).

If this sensor fails, the mass air flow sensor takes over its responsibilities.

TPS malfunctions. 1) The first thing you can feel when the TPS breaks down is a floating speed. Moreover, there are situations when the engine runs stably, and then, for no reason at all, it starts accelerating (even when the car is warming up). 2) The next trouble is the car jerking at start-up or at low engine speeds. Moreover, at 1500 rpm you already need to switch to a lower gear, otherwise it seems that the car is about to stall. 3) The dynamics leave much to be desired (well, there’s no need to describe anything here, I think you’ll feel it for yourself in your car). 4) When you move at speed and switch off the gear, the engine may stall (not a very common occurrence, but it happens a couple of times per 100 km, or even more often). 5) The check light comes on 6) The consumption increases (if during normal operation of the car the average consumption on a VAZ 2110 is 7-7.5 liters, then when the sensor is not working it reaches 10 liters).

I think we've sorted out the nasty stuff. Now let's move on to diagnosing the sensor, because the above things can happen for other reasons. First of all, measure the voltage at the output of the slider (the ignition should be on). To do this, we throw a voltmeter to the contact of the slider and to the minus. A sensor malfunction will be indicated by a voltage greater than 0.7 volts. We do all this at idle speed. To be convincing, you can open the damper completely (“turn it on”), the output voltage should be less than 4 volts. Plus, you can check the resistance. Let's use an ohmmeter, connect it to the output and to the power supply. If you slowly change the throttle angle, the resistance should also change smoothly. If you have identified one of the fault points, then you need to replace the TPS. It is not expensive: 150-400 rubles, depending on the company and quality, I would not recommend saving.

Replacing the sensor. I think even novice car enthusiasts can replace the TPS, because all that is required is to unscrew 2 bolts. Here you may need a screwdriver with a short handle; with a long one it won’t be convenient - you won’t be able to get it.

We unscrew the bolts, remove the sensor, pay attention, there is a gasket there. When replacing the sensor, it is also better to replace it

We put on a gasket. We put the new sensor in place (nothing can be confused here). We tighten the bolts to the end, but don’t be too heroic, since our sensor is plastic and can burst.

Snap the wiring harness block. That's it, the repair is complete, there is no need to configure anything additional. The only BUT. If your check light comes on during a breakdown, then when replacing the TPS, you need to reset the error, otherwise the sensor may continue to work incorrectly (since this error is stored in the brain). However, do not rush to computer diagnostics. Everything is much simpler. You can reset the check error yourself.

(votes: 3, average: 5.00 out of 5)

Do-it-yourself damper cleaning

After a long period of use, the throttle valve becomes dirty under the influence of crankcase gases and small particles of engine oil, which negatively affects the operation of the entire engine.

On average, preventive cleaning of the damper needs to be done every 40–50 thousand km, but ideally every second cleaning should be carried out with complete disassembly of the unit and washing of all its components. The procedure for cleaning the throttle valve itself is not difficult; the main thing is to remove it when the engine has cooled down so as not to get burned.

To do the work at home, you will need a 13mm wrench, a set of screwdrivers and cleaning fluid. After removing the assembly, and this will not be difficult if you have the preparation, take the liquid and thoroughly clean the throttle valve, also pay attention to the forced ventilation duct. Sometimes it gets coated with a thick layer of plaque, so feel free to use a needle or a steel knitting needle for a perfect clean. Pay attention to the gasket in the throttle assembly; if it is defective, replace it. After this, reassemble and install the part in reverse order.

If done conscientiously, you will feel the forgotten power of your car and responsiveness to the commands of the accelerator pedal. If this does not seem enough, then you can think about updating the throttle valve on your VAZ 2112.

Cleaning the remote control

Cleaning the throttle body will cost much less than buying a new throttle body for a VAZ 2110. The price of a new unit is several times higher.

To clean the throttle unit with your own hands, you must use the following materials and tools:

- screwdriver;

- set of tools with keys and heads;

- new throttle body gasket;

- protective gloves;

- carburetor cleaner;

- ear sticks for hard-to-reach places;

- old toothbrush.

The procedure for cleaning the throttle valve on a VAZ 2110:

1. Raise the hood of the car. Remove the terminals from the battery. It is enough to throw off the negative terminal. To do this, we use a key set to 10. 2. Dismantle the receiver. Loosen the clamps on the 5 pipes. We remove the pipes. Four pipes are visible from above, the fifth is located under the throttle valve assembly. 3. Disconnect the connectors from the sensor on the throttle valve and the idle air control (IAC). 4. Disconnect the throttle control cable. 5. Unscrew the throttle block from the receiver with a key. 6. Using a screwdriver, unscrew the idle speed control crosswise. We remove the IAC from the throttle block. 7. Using a cleaning product, an old toothbrush and ear sticks, we clean the throttle unit. We pay special attention to the channels and landing sites of the IAC. Remove carbon deposits and dig. Before using a special carburetor cleaner, you can wash the unit with plain gasoline. 8. It is recommended to apply lubricant to the idle speed control rod. To do this, we use silicone grease, which will help extend the service life of the IAC and the throttle unit as a whole. 9. Assemble the throttle assembly. We screw it to the receiver, not forgetting to install a new gasket. We connect all pipes and connectors.

An important part of the throttle valve is the “nickle”. Some car enthusiasts bore out the assembly chamber and install a “penny” of increased diameter. This can achieve a more enriched combustible mixture. Motor power increases. It is better to entrust the engine tuning operation to a motor specialist. You should not carry out such an operation on your own, without good preparation.

Another reason for unstable behavior of an internal combustion engine may be a faulty throttle sensor. On a VAZ 2110, you can replace the sensor yourself. Its price is low. It is recommended to use a non-contact sensor. Its cost is slightly higher, but the sensor will last significantly longer.

You can diagnose the sensor yourself. For this you need a tester. Let's look at it step by step:

- The ignition must be turned on. We measure the voltage between the potentiometer contact and the “minus”. The correct value on the voltmeter is 0.7 Volts.

- We turn the plastic sector to the limit, thereby opening the damper completely. The voltmeter should show 4 Volts.

- The ignition should be turned off, disconnect the connector from the sensor and measure the resistance of the potentiometer of the remote sensing sensor.

- We smoothly turn the sector and observe the tester readings. If the sensor is working properly, the needle will move without jerking and smoothly. If this is not the case, then the throttle sensor should be replaced.

If cleaning and replacing the idle speed sensor does not solve the problem of smooth running, you need to contact a motor mechanic; it may be necessary to conduct additional engine diagnostics or adjust the idle speed control. This operation is carried out using special devices.

After the car has been intensively used for several years, it will... In this case, it will need cleaning, as the engine will become unstable.

You can find out more about cleaning the throttle assembly on a VAZ-2112 in the video below:

These include:

- It becomes difficult for the engine to switch from high speeds to lower speeds and vice versa.

- and with great difficulty restores normal speed.

- . In order to start the engine, you need to turn it with the starter for a long time.

- You will smell gasoline from the exhaust pipe.

- The first few minutes after launch.

Causes of pollution

A mixture of dust and oil particles slowly covers the surface of the valve during operation. This is especially noticeable in places where there are air turbulences.

If you do not clean it on time, then over time the thermal gap will become overgrown with such plaque. Also, the valve stroke in the damper, which regulates the idle speed of the car, will decrease.

Cleaning the damper

This work must be done with the engine turned off. You also need to wait until it cools down to avoid burns.

Tools and materials:

- Screwdriver Set.

- The key is "13".

- Rags (you can take ear cleaning sticks).

- Pad.

- Flushing liquid.

Step by step guide

- Initially, you will need to remove the protection from the engine.

Decorative protection on the engine and its attachment points - Next, you need to unscrew the cap from the expansion tank to reduce the pressure in it.

Then you will need to loosen the clamps. Clamps holding the pipes through which the mixture is supplied to the throttle valve - The next step is to remove the forced ventilation hose of the air pipe.

This element must be visually inspected. If oil is visible in it, then most likely the forced ventilation channel in the throttle valve is clogged. Forced ventilation hose with traces of oil in it - Next, use a screwdriver to loosen the damper heating pipes.

They should also be turned off during work to prevent dust from getting inside. Damper heating pipes - After this, the throttle assembly itself is removed.

It looks like this: The throttle valve removed from the engine in a dirty state - Now you need to directly clean the damper. For this you need to use carburetor flushing fluid and a rag. You can also use a metal knitting needle to clean the channels.

Flushing the unit using carburetor cleaning fluidCleaning channels with a metal knitting needle

If necessary, the gasket must also be replaced. But when it is in its normal form, there is no need to change it.

After carrying out this work, the damper should be put back in place in the reverse order of disassembly. Next, you should start the engine and check its operation

.

Throttle valve upgrade for VAZ 2112

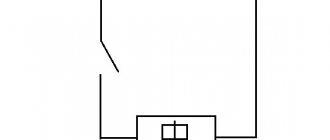

The standard mechanical regulator on the VAZ 2112 has a diameter of 46 mm.

Often, auto-tuning specialists replace the factory unit with a more advanced one, with a diameter of 52, 54 or 56 mm. What is the increase in power after such a procedure, we will analyze further. The usefulness of installing such a unit is explained by a decrease in the speed of air flow and, as a result, the efficiency of the intake air system increases. The ideal option would be to install it in pairs with a zero-resistance filter. Since the diameter of the receiver on the VAZ 2112 is 53 mm, it is first recommended to try updating the regulator to a size of 52 mm.

Installation will not be a problem, since no modifications are required from the car owner. You may need to trim the gasket if you decide to install a 56 mm unit. The following positive effects can be immediately noted:

- increasing the response speed of the accelerator pedal,

- disappearance of idle problems,

- improving the overall driving dynamics of the VAZ 2112.

Some car enthusiasts talk about an increase in fuel consumption according to the on-board computer, although in fact this is not always observed.

It seems that changes for the better arise precisely because the driver replaced his old unit with a new one of 52 mm or more. But it is possible that the old one was simply very dirty.

Often, simple flushing, as mentioned above, gives the same effect as installing a new unit, even with an increased diameter.

Why is it necessary to modernize the throttle valve on VAZ-2109, 2110, 2115

Spare parts stores sell throttle assemblies with valves of increased diameter (52, 54 and 56 mm) for VAZ-2109, 2110 or 2115 cars. According to the sellers, by installing such a valve instead of the standard 46 mm one, the car owner will receive significant advantages: the car becomes more responsive to the gas pedal, problems with idle speed disappear, vehicle dynamics improve, and this is especially noticeable if you replace the standard air filter. The main argument that they try to convince car owners is that the engine requires more air to operate efficiently, for which it is necessary to replace the standard throttle assembly with an improved one. They even give figures: the diameter of the VAZ-2109 or VAZ-2110 receiver is 53 mm, and a damper with a diameter of 46 mm allegedly “strangles” the engine.

Many VAZ-2109 and VAZ-2110 owners succumb to persuasion and replace the standard device with an improved one. After this, indeed, the engine works better and the car drives more dynamically. The reason for the improvements actually turns out to be much more prosaic: instead of the old, dirty throttle body, which had long been in need of thorough cleaning, the owner installed a new one. As a result, the engine returned to normal operation, which is perceived by the owners as the promised responsiveness and agility of the car.

We must not forget that increased air flow leads to disruption of mixture formation, since the ECU is not able to adjust the supply of gasoline. To eliminate this problem, car owners, as a rule, “reflash” the control unit and pay as a result with the increased appetite of the car.

It is very easy to feel the possible problems associated with the fact that the throttle valve on the VAZ 2110/2112 has failed.

The dynamics of engine operation and its power directly depend on the state of this functional element. The following characteristic symptoms of a malfunction are identified:

- * due to the lack of air passing through a clogged throttle, the car is extremely difficult to start both at idle and when the engine is warm. As a result, you can observe the “spitting out” of unused fuel from the exhaust pipe. You can make sure that the engine simply does not have enough air by manually moving the throttle with the accelerator.

- When switching to neutral gear and coasting, the engine tolerates a decrease in speed extremely negatively. It stalls, stalls or chokes.

Most likely, the following problems are possible:

Typically, the throttle mechanism must be cleaned every 50-60 thousand kilometers of the car. A negative tendency for a drop in power associated with contamination of the product can be observed after 30 thousand kilometers of the VAZ 2110. In this case, you should not delay the technical maintenance of the throttle valve.

Throttle assembly update result

It is worth noting the appearance of some problems in the operation of the engine on the VAZ 2112 after installing a throttle valve with a diameter of 52 mm.

The reason for this is a violation of the fuel-air ratio, which leads to incorrect operation of the ECU and engine. After this, many people prefer to use the ECU firmware editor, but there is no way to return the old throttle assembly to its place. Although the problem could have been simple contamination of the old regulator. After updating the firmware, a decrease in fuel consumption of 0.5 liters is noticed - maybe not significant, but still a plus. As a result, we can say that simply installing a throttle valve with a larger diameter will not give a significant increase in power and other indicators. Only in combination with a firmware update and other minor engine tuning will the effect be noticeable. However, the validity of these actions in individual cases must be taken into account. After all, even on forced engines there can be a damper of standard sizes (for example, 46 mm), which is enough for the correct operation of the air intake system.

Correction of a factory miscalculation

It is quite common for a throttle assembly to come out of the factory with something that cannot even be called a defect, but can still be attributed to design errors. In theory, air should flow into the space behind the throttle, for which a channel of approximately 2.5 mm is specially made.

But the whole problem is that this channel was pressed against the wall of the receiver, thus blocking the possibility of air flow. A slight modification of the throttle assembly can help in this case.

This material will help you install engine crankcase protection yourself:

Bored channel for air flow in the throttle

To do this, just take a file and use it to make a small groove in the indicated place. 2 - 3 mm will be enough. But before doing this, it is necessary to remove the throttle.

How to replace the throttle valve of a VAZ 2112 with your own hands

VAZ 2112 throttle valve 54

Replacing the VAZ 2112 throttle valve is carried out in the event of a breakdown of the unit, in other cases it is simply removed and washed (cleaned), and repaired if possible. However, today there is a kind of tuning, when the throttle valve on a VAZ 2112 56 (diameter 56) is installed instead of the 54 or 52.

A similar procedure is performed in order to increase the amount of atmospheric air entering the combustion chambers.

Checking the functionality of the sensor

With the ignition on, use a voltmeter to check the VAZ TPS voltage between the “minus” and the slider contact (it should not exceed 0.7 V). Open the damper by turning the plastic sector and measure the voltage again.

This time the sensor should output at least 4 V or a little more. With the ignition off, you need to pull out the connector and check the resistance between any terminal and the slider contact. As you turn the sector, watch whether the voltmeter readings change smoothly.

If they “jump,” then a replacement is necessary, preferably with a non-contact TPS.

As evidenced by the practice of a huge number of VAZ car owners, a contactless sensor will last much longer, it does not require additional adjustments, modifications, and inspection will be needed much less often.

REMOVAL OF THE UNIT

The purpose of the throttle assembly (abbreviated as DU) is to regulate the air supply to the engine cylinders. Thus, it controls the enrichment or leanness of the fuel mixture.

The appearance of remote control malfunctions causes improper operation (interruptions) of the motor. If problems arise, the remote control is usually replaced with a new one, but often such problems are solved by removing and washing the remote control yourself.

What you need for cleaning

To remove and clean the assembly you will need:

- Screwdriver Set

- Head "13" with ratchet

- Old toothbrush with stiff bristles

- Cleaner

- Cotton swabs

- Latex gloves

Removal

Replacing the throttle valve on a VAZ 2112 or flushing is performed (begins) by removing the unit, for this:

- We remove the terminals of the VAZ battery, de-energizing the electrical network of the motor

- Disconnect the connectors from the throttle position sensor, idle speed control, and also remove the cable from the throttle valve actuator

- To avoid losses, partially drain the coolant

- Then loosen the clamp securing the air hose to the throttle body

- Then a clamp securing the ventilation hose of the 2nd circuit (crankcase gases) to the pipe on the cylinder head cover

- Now you can remove the air hose along with the crankcase ventilation hose

After releasing the clamps, remove the air hose

- Take a Phillips screwdriver and loosen the clamp, then remove the hose for crankcase ventilation (from the 1st circuit) from the remote control fitting

- Then we loosen the clamps securing the hoses that discharge and supply coolant, and remove these hoses

- Now, using the “13” head, unscrew the nuts that secure the throttle assembly to the receiver, photo below

Using a ratchet and a socket “13”, remove a pair of nuts that secure the unit to the receiver

- Then we remove our throttle assembly from the studs and loosen the clamp to disconnect the hose for purging the adsorber (this is necessary if your car has a system for collecting fuel vapors)

- Carefully remove the sealing gasket under the assembly

- If you have never carried out the steps to clean the remote control, then it will most likely be necessary to replace the gasket

- Then we unscrew the screws that hold the IAC (idle speed regulator) and then remove the regulator (don’t worry, the holes for attaching the regulator are designed in such a way that it will not be possible to mix it up when installing it)

Cleaning

Instructions for cleaning the remote control, it was not difficult to guess, require the use of a cleaning agent, with cotton swabs and a toothbrush:

- We clean all channels, hidden cavities, in addition, special attention should be paid to the place for landing the IAC, as well as the area that is located next to the damper

- After finishing the work, the unit should be perfectly clean.

- Don’t forget to clean the crankcase ventilation duct at the same time.

- The size of the channel is large, which is why it is most convenient to blow through it with a cleaning agent

- It is more convenient to carry out blowing with a foot pump, since the diameter of the hose fitting coincides with the wheel

- And the last stage is replacing worn out remote control pipes and blowing the rest with compressed air

- Such procedures can significantly extend the life of your mass air flow sensor.

Assembly

Installation of the remote control is strictly in the disassembly sequence, only in reverse. A cleaned remote control unit makes engine operation stable at idle, and the engine speed no longer fluctuates. There is a clear response when the gas pedal is operated. Additionally, the throttle assembly may need to be modified, but first study the video on such modifications.

Cleaning

Even if the purpose of removing the throttle was to modify it, still do not forget that for stable operation it also needs periodic cleaning

There is, frankly, nothing complicated in this procedure, but it will help the engine perform better, which is quite important

For cleaning you will need:

- short and long screwdrivers;

- toothbrush (soft, or just old);

- cotton buds;

- cleaning agent;

- rubber or cotton gloves.

For cleaning to give the desired result, it must be carried out very carefully. First, you can go through all the cavities with a toothbrush, at the same time cleaning the idle speed control (it must also be removed). Further, more delicate, cleaning is done with cotton swabs

Pay special attention to the area where the throttle valve is located and the place where the XX regulator fits.

Please note that cleaning the crankcase ventilation duct with conventional means is not possible, but it can be easily done using the foot pump available in each trunk. The diameter of the fitting is similar to the wheel one, you just need to add cleaning agent and pump your foot several times.

If you have problems mentioned at the beginning that started recently, cleaning should fix them. If there were problems from the beginning, do not forget about improvements. Sometimes only replacing the throttle assembly helps.

TUNING WITH REPLACEMENT

The standard valve (throttle assembly) usually has a diameter of 46 millimeters; many fans of various tunings decide to replace this part with an alternative one:

- VAZ 2112 throttle valve 52 has a larger diameter (there are also valves of 54 and 56 millimeters)

- Is there any benefit from such tuning?

- In various online stores they often offer to replace the standard 46 mm throttle body (DU) and install 52, 54 or 56 mm

- The product description says that an enlarged throttle body (also known as the throttle body) leads to a decrease in air flow speed, which improves the performance of the air intake system

- The effect of installing an alternative damper will be clearly visible when using a zero-resistance filter in the system

- We recommend installing a unit with a diameter of 52mm, because... the diameter of its air inlet for a standard receiver is 53mm

The valve is standard (standard) on the left and new (increased flow diameter) on the right

- In order to install a remote control of a different diameter, as a rule, nothing needs to be modified

- The maximum necessary action is a small trimming of the gasket (this is most often necessary when installing a 56mm throttle assembly)

The following positive effects are noticed after such an installation:

- The car becomes more agile

- Problems with idle speed disappear

- The gas pedal also becomes more responsive.

Installation disadvantages:

- Fuel consumption increases, although many believe that the BC gives incorrect readings and consumption does not change

- Some owners see the effect exclusively on 16-valve engines

The picture we described above may appear completely different:

- All the positive effect that many people notice when installing a larger diameter remote control usually appears because the old remote control already needed cleaning and naturally the motor was not working correctly

- After installing a (clean) new remote control, the engine starts working in its normal mode, this seems like a “new breath”

- In other words, all the described effects appear after regular cleaning of the remote control.

- And besides this, after replacing the remote control, with a larger diameter you will have new problems with the operation of the motor that did not exist before

- This is due to a violation of the ratio of gasoline and air, which the ECU is no longer able to correct.

- And instead of simply returning the remote control to the standard diameter, the owners are recommended to replace the firmware, the price of which is higher, but there is no point

- There is also an opinion that a remote control with a diameter of 52, 54 or 56 millimeters is a completely useless thing, and only installed in combination with other engine tunings produces a noticeable effect

- It remains unclear whether this effect is caused by remote control or other modifications to the engine

- After all, if on a turbo engine with a power of no more than 200 horsepower, standard 46mm dampers are left and their work is quite enough

Replacement

In fact, changing this sensor is insanely easy. So don't rush to send your car to a service station. Everything can be done with your own hands, the quality will not suffer from this.

To remove the throttle position sensor, you first need to find it. As we have already noted, the desired unit is located on the side of the throttle pipe on the throttle valve axis. Having found the element, pick up a shaped screwdriver. Using this simple tool, unscrew a couple of bolts that hold the device. Pay special attention to the gasket that is available under the old regulator. We do not recommend using it again; it is better to immediately buy a new one

Often the gasket is already included with the throttle sensor itself. After removing the old sensor, you can slightly clean the place where it is installed if there is dirt there. Next, a new sensor is installed along with a new foam gasket and the bolts are tightened. Try to tighten the fasteners as far as possible, otherwise the new throttle sensor will quickly lose its effectiveness. The work will have to be done again. There is no need to make any adjustments after replacement. The zero mark on the controller will determine that the throttle is completely closed.

Foam pad

What to choose?

When replacing, many more or less experienced car owners have a question about which regulator is better to install. After all, there are two types.

Sensor type

Peculiarities

These sensors are usually factory installed. The service life of such a throttle position sensor is stated to be about 55 thousand kilometers, but in practice it has to be changed more often

The operation of such a device is based on the magnetic-resistive phenomenon; a Hall element is used. The cost is noticeably higher than the first option, but it is unlikely to have to be changed. Huge resource, high reliability

In pursuit of savings, many forget about the importance of quality. But it should be in the first place when choosing spare parts when repairing a car

TPS is an important, but easy to replace device. The repair operation will take you no more than an hour, even if you are just beginning to learn the joys of repairing your car yourself.

But under no circumstances delay repairing the sensor, otherwise this may negatively affect the operation of the engine, its service life and the cost of fuel, which you will overuse due to incorrect data from the sensor to the ECU.

Owners of VAZ-2110 cars often have to repair their vehicle. And the consequence of repair work can be both significant breakdowns and minor malfunctions. What type of failure is a malfunction of the throttle position sensor? What is this part responsible for in a car? How can we determine that this particular part is no longer functioning correctly? Read about it in our article.

LET'S SUM UP

| Supporters of replacing the remote control with a different diameter argue | Opponents of replacing the remote control with a different diameter argue |

| Replacement increases power and improves engine speed and gas pedal responsiveness | Washing or repairing a standard remote control gives similar effects |

| Does not affect gas mileage | Affects gas mileage, as everything is interconnected |

| Does not create problems in engine operation | Creates problems because the ECU cannot correctly adjust the ratio of air and gasoline in the mixture |

| Problems that arise can be solved with firmware | Problems are solved by flushing |

| Clearly, all tangible effects are associated with changing the remote control and are enhanced in combination with other improvements | Tangible effects are achieved by flushing the unit, and the use of other improvements improves the performance of the engine without replacing the remote control |

Here everyone decides for himself, we will not enter into disputes, there are simply different opinions, and we are obliged to warn about the pitfalls and the other side of the coin.

Cleaning the throttle assembly on a VAZ 21124 | Motorist's benefit

Preface: How does contamination of the inner surface of the throttle pipe (DP) affect engine operation? The main working element of the throttle pipe is the throttle valve (VV). It is she who, when opening, changes the flow area of the pipe. This ensures the supply of air volume necessary for complete combustion of fuel in the engine. But even when closed, with the gas pedal completely released and not pressed, the throttle body must allow a certain amount of air to pass through, which is necessary for the engine to operate at forced idle speed (FID) and idling speed (IDL). To do this, during the production of the DP, the closed position of the DP is adjusted so that there is a small gap, called thermal, between the internal and walls of the DP and the DP itself. The thread of the screw that regulates the thermal gap is coated with a special sealant to prevent spontaneous or intentional rotation in the future. Another purpose of the gap is to prevent the DP from biting against the DP walls when closed. When the DS is closed, air also flows bypassing the DS, through the bypass channel (the gap between the walls of the calibrated hole and the tip of the idle air control (IAC) rod). During engine operation, the position of the IAC rod is constantly changing, providing IAC regulation. The volume of air passing through the DP when the DP is closed is rigidly fixed in the controller firmware, so an actual change in air compared to a constant may make it impossible to regulate the idle. In practice this usually leads to the following

quite characteristic interruptions in engine operation:

1. The engine has difficulty returning to idle speed when the gas pedal is released. For example, when braking or coasting in neutral gear. Engine speed, instead of a smooth return to XX speed, suddenly drops sharply to 400-600 revolutions, after which the engine stalls or shakes violently, and XX speed

recover with difficulty.

2. Hot starting of the engine is very difficult, and if measures are not taken in a timely manner, cold starting. When trying to start the engine, you have to turn the starter for a long time. The exhaust pipe already smells of gasoline, but the engine still won’t start. But as soon as you open the remote control slightly, by 2-10%, by pressing the gas pedal, a miracle happens, the engine

starts, “wasting” the first few seconds.

The cause of the above malfunctions is a mixture of dust microparticles and oil particles passing through the air filter, coming from the crankcase ventilation system. During vehicle operation, this mixture gradually settles on the inner surface of the diesel engine, in those places where there is the greatest air turbulence. Those. immediately behind the remote control and on the IAC rod. As a result, over time, the thermal gap at the DZ becomes overgrown with dirt and the cross-section of the IAC bypass channel decreases. Thus, as a result, we get the following: the cross-section of the air channels is reduced, the composition of the mixture is enriched.

When dirt accumulates above a certain critical level, different for each engine, when the speed control system can no longer cope with the flow area in the combustion chamber that has changed due to dirt (which it also knows nothing about), characteristic interruptions begin to appear. Throttle pipes operating in systems controlled by GM controllers are much less susceptible to loss of functionality in the presence of dirt. In them, gases from the crankcase ventilation system are supplied to the throttle space. It should be noted that on 1.6-liter engines, due to changes in the channels of the crankcase ventilation system, several times more oil vapor began to enter the combustion chamber. What exactly and how it has been changed is not discussed in this article. From practice, dirt in the DP should be taken into account as one of the possible reasons for the unstable operation of the engine at IH and IH after 10-15 thousand kilometers. Naturally, this value may vary somewhat depending on the areas in which the vehicle is used. In the steppe

In areas with a lot of dust, it will most likely be less, and in areas of the far north, where there is snow most of the year, it will be more.

Unscrew the cap from the expansion tank to relieve pressure in the system.

Unscrew the trunk clamps on the remote control, on the mass air flow sensor and on the crankcase purge hose

We remove it and look, if there is oil leakage to the mass air flow sensor, then it’s time to change the oil separating mesh

Unscrew the crankcase purge hose at XX

Canister purge hose (if equipped)

prying the cable fixing bracket, remove it and disconnect the cable.

Unscrew the clamps of the remote control heating hoses

and disconnect. It is convenient to plug the hoses using old spark plugs.

by prying the latch, remove the connector from the throttle position sensor (TPS)

and idle air controller (IAC)

Using a 13mm socket with an extension, unscrew the upper nut,

lower fastening and carefully remove so as not to lose 2 washers

We take it to the table, use a Phillips screwdriver to unscrew the IAC.

easily pull it towards you and remove it

and try not to lose the o-ring. It will be impossible to find it separately from the new IAC.

This is the picture that appeared at the front door after a run of 20 thousand

We take a pre-purchased carburetor cleaner in a spray and cotton swabs, and wash off all the dirt that we can wash off.

Having spent a third of the cylinder and from 2 dozen sticks I got

Particular attention should be paid to the crankcase purge channel at idle. sometimes it becomes so clogged that it is difficult to pierce it with a wire

We also wash the IAC rod and cap and lubricate the rod itself with silicone. We perform assembly in reverse order.

Owners of one and a half liter engines will also need a new remote control gasket

Thus, we spent an hour of time and 100 rubles. Not a lot of time and money to be able to get rid of all sorts of glitches in engine operation

Istochink

.

Related publications:

sanekua.ru