Test before diagnosis: when does the murmur appear?

If it makes annoying noise while driving, find out where and when it happens:

- At low or high speed.

- On roads with good coverage or uneven areas, for example, when driving through potholes and various bumps.

- When turning with the steering wheel turned all the way or near the zero mark.

- In a sharp or smooth turn.

When the car is stationary, it is enough to pull the steering wheel, rocking the wheels from side to side. If there are knocks, there is no need to go anywhere. Take a partner so that you have someone to rotate the main control left and right, and you put your hand on all the joints in the “steering”. Now we’ll figure out what exactly to feel.

What is a steering rack

The wheel turning mechanism consists of two parts: rack and pinion. Rotating the steering wheel triggers the movement of the gear, which moves the rack left or right. As a result, the wheels turn in the desired direction.

Metal parts of the mechanism can be difficult to turn, which is why modern cars are equipped with amplifiers. There are two types of amplifier - hydraulic and electric. They make turning the steering wheel smooth and easy. The power steering or electric power steering is mounted directly on the rack.

Power steering improves driving safety by dampening vibrations and knocks from the road. The driver feels more confident behind the wheel. On the other hand, this slightly deteriorates the car's handling.

Safety on the road largely depends on the steering. In case of any malfunctions, maneuverability deteriorates, as a result, the driver cannot react to the road situation. Therefore, it is important to maintain the steering in working condition and pay attention to all symptoms of breakdowns.

We have a knocking sound when the steering wheel is rocking in place

The most vulnerable connection is the ball joints in the tie rod ends. Inspect them out of turn. The remaining pairings are tested in order:

- Electric power steering – mounting bracket (pressure bolts are loose).

- Emergency folding system (on older machines).

- Cardan between the rack and the column.

- Rail.

- Rods are a rack and pinion mechanism.

Some nodes can be checked in alternative ways:

- Rod ends. Jack up the wheel, grab it at the 3 and 9 o'clock positions and rock it from side to side. There should be no backlash or sounds. Diagnose both sides one by one.

- A system that is triggered in case of an accident. Press the steering wheel down and jerk it left and right. If the noise stops, the cause has been found.

- Kardanchik. A slight wear in the needle bearing is indicated by a knocking sound when turning the steering wheel in motion; on a straight line there is silence.

- Rail. If when driving it knocks only on a straight line, but not when turning and turning, the middle position of the gear is worn out. For replacement.

Advice! Do not tighten a worn rack. The play will stop, but in extreme positions the steering wheel will rotate tighter. Its arbitrary return to the zero position will become impossible.

Consequences of a faulty steering rack

Drivers are also often interested in the question of what causes a faulty steering rack, and can it be used in this condition? And to understand the consequences, it is enough to know the function of the steering rack.

That is, the first thing that threatens the failure of the rack is impaired control of the car. And if at the initial stage (when the rack just started to creak and/or hum) it still performs its functions, then if it completely fails, the driver may completely lose control of the car!

Analysis of typical complaints

The advice given at the beginning, to understand when the tapping occurs, makes it somewhat easier to find the cause. But this recommendation is effective only with a comprehensive diagnosis. For example, the mere fact of clanking in the pits is not enough; you need to listen to what is happening when the wheels are turned and whether there are any sounds in place.

If the test is done, go through common complaints.

- The noise only appears when the steering wheel is turned. If nothing is transmitted to the steering wheel, then see “ball” in more detail. Perhaps it is not tightly attached to the steering knuckle or lever. For example, bolts are often forgotten to be tightened during wheel alignment.

- The knock comes from the steering wheel. This is either a rack or a cardan on the shaft. If this only occurs on washboards and other irregularities, inspect the control shaft telescopic connection. Pay attention to the rack and pinion mechanism - the nuts securing it to the subframe or body may be loose.

- The rattle is only on the straight line, quiet in turns. Rack, cardan, ball joints.

Causes of steering rack malfunction

When driving carefully and using the car correctly, the only cause of a steering rack malfunction is its wear and tear.

For each part, the manufacturer sets its own service life; for a rack it is usually 100 thousand km. The timing may vary for each model. Most often, this part is changed by those who drive on bad roads. Getting into a hole wears out the suspension and steering. If you don’t slow down for bumps and potholes, you can become a regular visitor to car services. Also, the rack does not like sudden starts. It is not recommended to drive away suddenly if the wheels are turned to the side.

Another common cause of problems is a boot break. This delicate part protects important mechanisms and therefore requires constant attention. Even cracks on the boot are a reason to replace them. Moisture, dust or dirt that gets inside the device can cause serious damage.

Non-standard cases

It may not be the suspension or steering parts that are knocking. Shocks and body pecks lead to the movement of units. If they “sit” loosely and there is metal-to-metal contact, clinking cannot be avoided.

- Single dull knock when starting off. See rubber-metal engine or gearbox mounts, transmission driveshaft. For example, when starting, the motor may tilt and hit the spar.

- Rattling on small bumps and in turns. Listen to see if there is a knocking sound in the steering wheel when braking; if there is, the brake caliper guides are worn out.

- Intermittent impact sound, more common when turning at low speeds. Malfunction in the differential of a front-wheel drive vehicle.

Tighten the key bolts and nuts more often, refuel only at gas stations with high-quality gasoline, and remember: a worn CV joint does not knock, but crunches, and does this with the wheels turned out.

If you hear a noticeable knocking noise when you move the steering wheel left to right: diagnosis

Probable Causes

If an audible knocking sound in the front suspension when turning the steering wheel indicates wear in its constituent parts, then an extraneous clicking sound when the steering wheel rocks requires inspection of other structural elements. As a rule, the problem lies in the vehicle control system.

Statistics show that there is something to knock in the “steering wheel”. Any pairing may come under suspicion:

- Gap in the fit between the steering tip and the strut.

- Excessive play in the steering rack.

- There is a problem with the steering shaft driveshaft.

- Free movement of the steering wheel on the shaft.

- Gap in steering rod joints.

These parts are present in the design of any car. Knowing the location of all the landings, it remains to identify the defective pair.

For your information. Some old foreign cars have a folding steering column assembly, which breaks under the influence of a critical load that occurs during an accident. He can knock too.

How to identify knocking: expert methods

The classic approach to identifying a faulty unit will be explained in any garage. Its essence is trivial: just ask the assistant to shake the steering wheel and at this time put his hand on the mentioned connections.

Steering rack

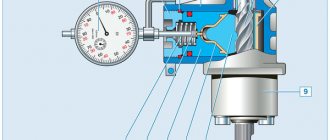

However, in some situations this technology loses its relevance. In particular, it will not be possible to identify a defect in the mechanism using this method. To identify a problem in the gear-rack engagement, it is necessary to carry out the following experiment:

- If there is power steering (hydraulic booster): a knocking sound appears when the steering wheel is rotated on a car with the engine turned off, but when the engine is running, there is no knocking at the place.

- There is no power steering: drive along a road section with a changeable direction - when you swing the steering wheel left to right, a knock is heard, but when turning, the rack does not knock due to the small wear of the working surfaces of the gearing in the extreme positions.

For your information. It is not recommended to tighten a worn rack. One of the owners of Hyundai Solaris performed this procedure and after 10,000-12,000 km the steering wheel began to bite. An autopsy showed that the mechanism was beyond repair.

Emergency system

It is also possible to determine experimentally whether the steering column folding assembly is the cause of the knocking. It is enough to swing the “steering wheel” to the sides, while simultaneously pressing it to the bottom. The sound disappeared - the problem is in the emergency system.

How to determine whether a steering rack is faulty

All steering rack malfunctions can be divided into three types - knocking, humming and leaking. Leakage is typical only for devices with hydraulic booster, since the power steering operates without oil, which means it cannot leak.

There are two types of knocks: superficial and internal. The first ones appear from the tie rod end. Through a torn boot, street dirt gets into the mechanism, the tip fails and begins to knock. You can change it yourself by looking at the steps of the process in the car manual.

An internal knock indicates that the pistons and guide rails have failed. It is very difficult to independently determine the cause, since you need to disassemble the entire mechanism.

What causes a knocking sound in the front suspension of a car when turning the steering wheel while driving?

The chassis and steering mechanism are tightly coupled and perform a single function. One rack command is not enough to turn the wheels in one direction. The racks, which are connected by tips and rods to the rack and pinion assembly, must not only absorb shock, but also rotate around their own axis. This became possible with the introduction of movable mounts.

What's causing the knocking?

When there is a knocking sound when turning the steering wheel while driving, but no extraneous sounds are observed in place, we can firmly state that there are problems with the suspension. Its design includes a sufficient number of connections that use bearings. Any support gradually fails, as evidenced by increased play.

- Strut support bearing.

- Spherical bearing.

- Wheel bearing.

How to identify tapping

You can calculate the knock in the front suspension of a car when turning the steering wheel experimentally. The work is carried out both on site and while moving - it all depends on the location of the defective area:

- The support bearing is checked by rocking the body to the sides: the hand lying on the “support” holder should not feel any play. The second diagnostic method: grab the front wheel spring and ask an assistant to rock the steering wheel to the sides - there should be no knocking.

- A metallic clatter will be heard in the worn out “ball” when bent with a pry bar.

- The hub support makes a dull knock when turning the steering wheel at small angles at a speed of 50-60 km/h.

For information

Often tapping occurs due to worn silent blocks. There are cases when the occurrence of a metallic sound is associated with the loosening of the nut securing the CV joints to the hubs. The hinge itself cannot knock - it is only capable of making a knock. A wheel spun with a small torque also interferes with acoustic comfort.

Inexperienced owners may confuse the symptoms of a steering malfunction with vibrations in the steering wheel when the car is braking. However, there the nature of the problem is completely different. Strong shocks in the steering wheel can be caused by poor-quality tires or imbalance in the wheel.

Replacing the tie rod end

Only experienced craftsmen can properly replace the tie rod end. Of course, if you have the knowledge and a set of suitable tools, you can replace the tip yourself. To do this you need to do the following:

– First of all, it is necessary to clean the crown nuts with which the tip is attached to the swing arm and to the steering rod; – The steering rod is disconnected from the swing arm; – To make it easier to set wheel alignment, the number of turns is counted when disconnecting the tie rod end; – The new tie rod end is installed in the reverse order, taking into account the number of turns; – After replacing the tie rod end, be sure to check and, if necessary, adjust the wheel alignment angle.

There are several types of steering mechanisms, but there is always a common part - this is the steering tip. The main task is to transfer a certain movement from the steering rod to the steering knuckle. Depending on the configurations, there can be from 4 to 6 parts.

For example, if the type of steering system is rack and pinion (the majority of them), then there will be four tips, 2 per rod (2 rods). If the mechanism is of the so-called “worm” type, there will be six, two per rod (rod 3).

Device

Please note that depending on the steering system configuration, they may vary in shape and size. The rod can be of different lengths or have bends, both in horizontal and vertical positions. Therefore, it is important to remember that if there is a bend, then the part is not interchangeable with the same one, but on the other side.

If they are initially the same in shape, there are no bends, then they can be replaced from one side to the other without consequences.

Remember, the main components:

• Directly the housing into which the steering rod is screwed.

• “Finger”, as a rule, on most models there is a thread or another type of connection, for example, a stud.

• Hinge housing uses wear-resistant metal for long service life.

• Various locking rings that prevent the pin, spring (to securely hold the liners) and liners from popping out.

• The “finger” nut is a fairly important part; without it it is impossible to secure the tip to the “fist”.

• Anther. Rubber pad that protects the device from dirt, dust, sand, and moisture.

Looking ahead, I would like to clarify the importance of maintaining this anther in an intact state. Otherwise, failure is inevitable. As a rule, in most cases, breakdowns occur due to a collapsed boot and the entry of foreign objects into it.

Almost all devices have the same shape, regardless of the car model. The only exceptions may be based on the format of the material used for production. For example, SUVs require more wear-resistant parts with increased protection due to the special conditions of possible operation.

Types of steering tips

Depending on what type:

It depends on whether there is a special hole on the support cover for pouring lubricant. As you understand, those being serviced have such a hole, which allows you to periodically add lubricant. The second option does not have this option, so after the lubrication is complete, they are thrown away because their maintainability is zero.

There is a second subdivision group:

Collapsible ones have a thread on the bottom cover (under the “finger”), which allows you to replace the hinge mechanism itself or the liner separately (a rubber or Teflon part that tightly fixes the “finger” in the “cup”). In modern cars, this principle is already difficult to find, because in terms of safety they are seriously inferior to non-separable parts. If the tip has failed in the car, you should inspect whether there is a thread on the cap or a retaining ring. If you do not find something like this, you can safely throw such a part into the scrap yard.

Quick Guide

The main reason for tapping is the formation of a gap in the joints. In the steering system, there may be knocking on the tips, ball joints of the rods, the rack, the “cardan” in the column, the steering wheel on the shaft, or the auto-folding system in case of an accident. The metallic sound is distinct and can be heard in place when rocking the steering wheel.

It is quite possible to mistake problems in the suspension for problems in the steering, since the initial stages of wear of bearings and supports only make themselves felt when cornering at speed. In the suspension part, the cause of the knock should be sought in the wheel bearings, ball joints and “supports”.

Causes of steering rack malfunction

There are three main reasons why you may hear a knock in the steering rack. This is wear of the worm pair (distributor), wear of the toothed part of the shaft, wear of the shaft along the bushing.

Thus, the most loaded unit in its design is the clutch between the gear and the gear base. Accordingly, the teeth here may collapse over time - partially or even completely. This can be understood by the knocking sound when holding the steering wheel while driving over uneven surfaces.

If there is no wear on the teeth but slight play on the rod, the situation can be corrected using an adjusting nut. By tightening it, you will establish the optimal distance between the teeth of the rack and pinion. If the teeth are completely broken, then such a rack must be replaced (sometimes only the gear can be replaced).

When a hole has formed in the bushing. Due to corrosion, due to the ingress of moisture, an abrasive appears inside, which eats the bushing (can be plastic or bronze). The malfunction is eliminated by replacement from a special repair kit.

Another cause of failure is wear of the tie rod end or the entire tie rod. This happens due to the rupture of the boot and washout of the lubricant. Usually these parts cannot be repaired, and accordingly, they are replaced with new ones. Same with the ball end.