The problem is this: when I start the engine, the tachometer needle moves jerkily, when I accelerate, the needle goes up, when I release the gas, the needle stays in place and does not go down. I accelerated a little more (less than the first) - the arrow went even further, I released the gas - the arrow did not go away. As a result, it goes beyond 8000 rpm and quietly floats there. And this happened constantly when it was hot outside. For example, in the morning or at night (when it’s cool) - this never happened. This is how I drive, in warm weather I start it, the tachometer needle goes over 8000, I got home, turned off the engine, the needle remains there. In the morning I got into a cold car, pressed the daily mileage reset lever, holding it down, turned on the ignition, a type of “testing” of the assembly occurs, and after that the tachometer needle goes to its proper place. and while I’m driving in the morning, everything is fine, the tachometer works adequately. As soon as it starts to get warmer outside, glitches appear again.

Now this began to happen at any air temperature (I thought that because of the heat something in the dashboard was glitching), before you were driving in the cold, everything was OK, but now you were driving in the cold - everything seemed to be OK, but then it started to glitch while driving.

I think maybe the ground is bad or the signal from the ECM is reaching the instrument panel! And so everything works in normal mode (pah-pah-pah...)

What do you think is the reason? I'm already tired of driving like this, because... I practically don’t use the speedometer, I’m used to looking only at the tachometer all the time!

Every driver knows that there is a device called a tachometer on the dashboard of a car. However, the principle of its operation, what exactly it measures is not known to everyone. The tachometer is a very important device in a car. It shows the engine crankshaft speed, that is, it actually shows the efficiency of the car engine. But this is only one of the functions of this device. Based on its indicators (the tachometer needle jumps or displays incorrect results), one can draw conclusions about the presence of certain malfunctions in the car.

Why does the tachograph needle jump: causes of malfunction?

Before you figure out why the tachometer needle is jumping, or try to find the cause of incorrect indicators in a malfunction of the engine, wiring or other elements of the machine, you should check the operation of the device itself. It is worth checking the spark plugs, wiring, contacts through which it is connected, and checking its settings. If the tachograph was changed or disassembled before this, then this is the most likely factor for incorrect indicators on the device. To fix the problem, just check its settings, if necessary, adjust it from behind using the toggle switch, check the zero position and correct installation.

Description of the problem

Here's how it happens:

Interestingly, the arrows move differently when the ignition is turned on. For example, on the tachometer and speedometer to half, and on the fuel scale and temperature scale - to the end.

The problem in this situation is considered only when the arrows do not fall back for a long time or do not do so at all. If they rise and fall into place after turning on the ignition, this is called self-diagnosis of the car. Many drivers even specifically want to have such a scheme (it is not found on all cars - mainly on sports cars, motorcycles and scooters).

When the ignition is turned off, the arrows rise

As for the problem, this is a “glitch” of the tidy, when the arrows do not fall back when the ignition is turned off. As a rule, the car owner in this case decides to remove the instrument panel. Inside, he tests the state of the elements, twirls the panel itself and the arrows, trying to find the cause of the problem. Some wash sensors and other components that are covered in dust, first removing the terminals from the battery, suspecting them of a “glitch” of the arrows. However, nothing helps.

What does the tachometer jump at high speeds indicate?

If the tachometer needle jumps during a trip or at high speeds, then the problem is also associated, as a rule, with the car’s engine. But before contacting a car mechanic, you can independently check the presence of fuel in the tank, inspect the camshaft drive chain, the timing belt that connects the crankshaft and the camshaft; perhaps it is loose and needs to be tightened. These are the main and frivolous reasons that can cause interruptions in engines and jumps in its speed.

If no visible problems are found with these elements, then you should go to an auto mechanic. Delay and failure to respond to a signal such as unstable tachograph operation can lead to serious damage to the vehicle’s cylinder-piston system and costly repairs.

It is better not to engage in diagnostics and independent repairs if the tachometer needle is floating. You should trust specialists who, using special equipment, will identify and eliminate the causes of the failure.

The tachometer informs the driver about the engine speed, allowing you to select the most profitable operating mode for the engine. If the tachometer needle jumps, the driver does not receive reliable information. The structure of the tachometer, its types, typical malfunctions and methods for eliminating them are described in this article.

What's the result?

If the driver notices malfunctions in the tachometer, it is important to immediately determine the cause of the malfunction. It should be borne in mind that problems with the device itself are not critical for the car.

For example, breakdowns that can be caused by misfires and other failures can quickly destroy the engine. For this reason, it is important to monitor the tachometer while operating the car. If it is noticeable that the engine speed is floating or jumping, it is necessary to accurately determine and properly eliminate the malfunction.

Types of tachometers

There are two types of tachometers: analog and digital.

Analog instruments use an induction magnetic coil, thanks to which the number of crankshaft revolutions is shown by an arrow moving along the scale. This device is installed as standard on most machines. It is almost the same size as the speedometer and is located next to it on the dashboard. This arrangement of the device is convenient for the driver, since it is always in front of the eyes and makes it possible not to be distracted from the situation on the road.

Types of devices

Tachometers are also divided into standard and remote ones, depending on the installation method. If everything is clear with the regular ones, then the remote ones can have several types of purposes.

First of all, the remote tachometer is intended for mounting on the instrument panel and giving the vehicle a more individual appearance. Depending on the preferences of car enthusiasts, such a device is more convenient.

Decorative stands and grips for mounting on a dashboard have been added to the design of the tachometer; it has a mainly digital signal processing principle. If it is available, there is no problem with how to check the tachometer, which is installed on the instrument panel; to do this, you need to compare the readings in different engine operating modes. Such devices are often used by professional sports racers and lovers of individuality in the design of their cars.

An external digital tachometer with a higher accuracy in determining the rotation speed is suitable for diagnosing a standard device. You can also use it to independently adjust engine operation with greater accuracy. When driving, it is more convenient to use a standard tachometer, since the eye perceives the angle of the needle well and high accuracy is not required when driving.

Incorrect arrow indication

If the tachometer needle twitches, then possible malfunctions can be determined using the following algorithms:

- It is necessary to check the “Check” lamp on the dashboard; if it does not light up, then, most likely, the system diagnostics will not determine the breakdown.

- It is necessary to check the electrical wiring. You need to test the voltage level on the plus and minus wires and check the condition of the connections. You should also be sure to check the weight, as this point is often missed. Especially if other devices or equipment are not functioning correctly.

- It is necessary to check the condition of the distributor contacts; this may be the reason that the tachometer does not work. You should also check the capacitor on the distributor cap; it could have broken through during operation (a common cause of tachometer failure).

- Check the ignition system circuits; its malfunction can also cause problems with the tachometer.

- If the tachometer needle twitches after repairing or replacing the device, then it needs to be adjusted. Adjust the position of the device itself, the zero position, the quality of the connection, make the adjustment using the toggle switch on the back of the device.

- If the tachometer needle twitches when reaching high speeds, then this is a hallmark of a breakdown of the switch, which should be replaced.

Often the reason that the tachometer does not work is the recent replacement of high-voltage ignition wires.

The instrument needle twitches or falls to the lower limit. The reason is that standard cables have a different cross-sectional resistance, this provokes a change in the shape of the pulse on the coil. This can be resolved by reducing the value of the external resistor on the control board.

Device

The tachometer makes it possible to switch to another speed in time so that the engine operates in economical mode. A novice driver can focus on the position of the arrow. If it approaches the red zone, then you need to shift to a higher gear. In addition, the device is used to adjust the operation of the power unit at idle and control the crankshaft speed while driving (author of the video - Avto-Blogger.ru).

Analog tachometers are reliable and simple measuring instruments.

Their design includes the following elements:

- pointer arrow;

- graduated scale;

- an electromagnetic coil with a shielded winding;

- cable for transmitting information from the crankshaft.

The operation of the device is based on the electronic principle. The signal from the crankshaft is transmitted through wires to a microcircuit, thanks to which the needle moves along the dial. Information can be taken directly from the shaft, from the generator or from other power take-off shafts. In this case, the original signal is converted with a certain coefficient.

Tachometers are divided into digital and analogue

Tachometers have the ability to reset received data. The accuracy of the readings is quite conditional and varies within 500 revolutions per unit of time (rpm), some devices provide accuracy in increments of 100 revolutions. The digital tachometer is distinguished by the presence of an electronic display that displays information about the speed of the power unit. Such tachometers are used when adjusting and tuning the operation of electronic ignition, the operating range of the economizer, and tuning the operation of the entire engine as a whole.

Possible malfunctions and ways to eliminate them

A jumping meter needle indicates a problem with the car. Repair depends on the cause of the problem.

You can list a number of reasons for device malfunction and ways to eliminate them:

- If there are poor contacts or damaged wiring, the source of signals from the motor to the device is lost. To detect a wiring fault, you need to check the electrical wires. If damage or breaks are found, the wires must be replaced. Poor contacts are often the result of oxidative processes. To restore functionality, the contacts need to be cleaned.

- Malnutrition. You should check the voltage on the positive and negative wires, as well as ground.

- If the tachometer needle floats or does not drop to zero, the reason may be a faulty sensor. In this case, it must be replaced.

- In the case of a digital device, it may not work if the LED screen is faulty. Such damage is possible with prolonged use. The display cannot be repaired; it can only be replaced with a working device.

- If the tachometer needle jumps at idle, there may be problems with the distributor. It is necessary to check the status of its contacts. In addition, the cause may be the distributor capacitor located on the cover. It is often punctured during operation.

- If the tachometer needle jumps, then the reason may be a violation of the integrity of the ignition system circuit. It needs to be checked and the fault corrected.

- The needle may move erratically after replacing the device. In this case, you need to configure it: adjust the position of the device itself, bring the pointer to zero, check the correct installation and connection. Adjustment is carried out using a toggle switch located on the rear panel of the device.

- If the needle jumps at high speeds, then the reason is the failure of the switch, which needs to be replaced. Problems with the engine are also possible, but these problems can only be detected by a specialist using special equipment.

- The cause of the malfunction may be the replacement of high-voltage wires of the ignition system, their wear or damage.

- The pointer may drop to the lower limit or twitch as the shape of the pulse on the coil changes. The reason is that the cross-section of standard cables has a different resistance. To resolve this problem, you need to reduce the value of the external resistor located on the tachometer microboard.

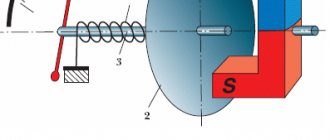

Classification by operating principle

- Mechanical or electromechanical tachometers with direct drive. The revolutions are transmitted to the dial indicator through a flexible shaft, which, through a worm gear, receives rotation directly from the crankshaft or one of the transmission shafts. The operating principle of the indicator is based on the phenomenon of eddy current induction. The operation and design of a magnetic tachometer are extremely similar to the operating principle of a car speedometer. In modern cars, a similar tachometer design is not used.

- Electric machine. A distinctive feature is the connection to a generator. It is used primarily on diesel engines, but for the purpose of unification, a device of this type can also be used on gasoline engines.

- Electronic. The signal can be taken either from the ignition system or directly from the computer. Installed on gasoline and diesel internal combustion engines.

Design and principle of operation

Main components of electric machine and electronic tachometers:

- measuring unit, or signal converter. It can be based on elements of analog circuitry or built using special microcircuits;

- display unit with analogue or digital display of the number of revolutions;

- auxiliary elements.

The operation of electronic tachometers is based on the conversion of individual signals or pulses captured from the computer, ignition system or generator into a signal “understandable” for the display unit.

Connection diagram

When looking for the reason why the tachometer does not work, it is first of all important to understand the connection diagram and the type of signal. There are 3 typical connection schemes:

- to a contactless ignition system (the tachometer wire is connected to the primary circuit of the ignition coil). The operating principle is based on measuring the frequency of voltage surges in the primary circuit of the ignition system. Calculating the ignition angle is impossible without focusing on the number of crankshaft revolutions, therefore the sparking frequency directly depends on the crankshaft rotation speed. On 4-cylinder internal combustion engines, a full revolution of the crankshaft corresponds to 2 voltage pulses in the primary circuit. Accordingly, the higher the crankshaft rotation speed, the greater the frequency of voltage surges;

- connection to the contact ignition system. The operating principle and connection diagram are similar to the BSZ, but the design of the measuring unit will differ depending on the voltage of the input circuit;

- connection to the engine ECU. The principle of operation is still based on recording voltage pulses in the primary circuit of the ignition system, but the signal to the tachometer comes from the engine control unit;

- connection to the generator (the tachometer signal contact is connected to terminal W of the generator). The rotation of the generator pulley is carried out by a belt drive from the crankshaft, so the rotation speed of the generator rotor will always be proportional to the crankshaft speed. The change in the number of revolutions of the crankshaft can be calculated by constantly measuring the amount of EMF generated on the winding. According to its principle of operation, an electric machine tachometer resembles a regular one class=”aligncenter” width=”448″ height=”412″[/img]

Typical faults

If the mechanical tachometer on a car stops working, there is mechanical damage to any of the structural elements. A broken cable of a flexible shaft, wear of the worm gear elements, the appearance of backlashes, deformations - all these reasons can cause the engine speed indicator to fail.

What to pay attention to if the electronic tachometer does not work:

- integrity of electrical wiring. In this case, it is important to check not only the signal wire, but also the ground and power supply of the instrument panel;

- quality of contacts. The presence of oxides and loose contact inside the chips may well cause the tachometer to fail;

- the integrity of the elements of the measuring unit, which are located behind the protective glass inside the dashboard. Among mechanical damage to transistors, burnout of microcircuits, tracks or swelling of resistors, the most common reason for a non-working tachometer is a violation of solder integrity. For example, on the Mitsubishi Padjero II, the appearance of microcracks in the soldering areas of the tachometer elements is a generally recognized disease.

On vehicles with an alternator connection, a non-functioning tachometer may indicate a faulty alternator. In this case, the breakdown is accompanied by the lighting of the low battery charge indicator and the sporadic lighting of a “garland” of warning lights on the dashboard.

In some types of design, changes in the linear resistance of high-voltage wires can make adjustments to the accuracy of the engine speed indication.

How to find the cause of the problem yourself

In addition to a visual inspection, for DIY diagnostics you will need a universal measuring device. If you know how to use a multimeter, you can easily check the power supply, ground, and also test the signal wire for a break.