The brake system, in particular pads and discs, is one of the most heavily loaded and intensively used components of a car. Theoretical replacement intervals are usually indicated in the operating manuals for specific machine models.

However, in practice, everything is different - they need to be changed as they wear out, the intensity of which depends on the material of manufacture, atmospheric conditions, condition of the road surface, driving style, etc.

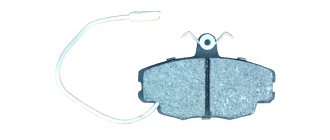

There is nothing complicated in the design of brake pads: they are steel plates to which are attached special linings made of high-strength materials that are resistant to friction and temperature changes.

Manufacturers' recommendations

The brake pad consists of a base made of thick metal with a lining made of friction material attached to it. Its components are rubber, graphite and mineral fibers bonded with technological resins. How often to change these important parts for safe driving is indicated in the car's operating instructions. Typically, passenger car manufacturers recommend observing the following intervals between replacements:

- on cars of post-Soviet countries, it is planned to install new parts after 10-15 thousand kilometers;

- on foreign cars, whose spare parts are traditionally of higher quality, the interval is from 15 to 25 thousand km;

- a separate category is powerful sports cars, where replacement is carried out every 5-10 thousand km.

Practice shows that the front brake pads experience greater loads than the rear ones, which is why they wear out faster.

Russian car enthusiasts should not rely entirely on the recommendations in the technical data sheet, since the wear of the linings is influenced by many factors:

- The more aggressive the driving style, the faster the working surfaces wear out, because on 1 km of travel you use the brakes twice as often as the average driver.

- Operating conditions of the machine. If you constantly drive on unpaved and poor roads, then wear accelerates due to dirt getting on the brake discs and drums.

- The quality of the material from which the part is made.

- Technical condition of brake drums and discs. When grooves appear on the surfaces of these elements, the linings wear out much faster.

- Constant transportation of goods.

This raises the question of how long brake pads last in real life.

The mileage range is quite wide - from 5 to 45 thousand km, depending on the brand of car and the degree of influence of these factors. That is why it is important to independently monitor the condition of the linings. This is interesting: How to reset it on a Peugeot 308

How to make the right choice

So, the decision about the need for replacement has been made. But how to choose brake pads? One of the main parameters when choosing such a product is the operating temperature of the device.

On average, this indicator should be in the range from 300 to 350 degrees Celsius. For VAZ cars, this indicator is sufficient. Adherents of sports driving or drivers who live in mountainous areas are better off giving preference to more “hardy” pads with an operating temperature of about 800 degrees Celsius.

The second important criterion is the friction coefficient. Until the pads reach operating temperature (about 200 degrees Celsius), the friction coefficient will be too low and the products will quickly wear out.

On average, this indicator should be from 0.3 to 0.5. But there is a pattern here - the higher the number, the higher the quality of the car’s braking.

We must not forget about the variety of types of pads, namely the material from which the device is made. Today there are several options:

1. Semi-metallic pads consist of 40-65% high-quality metal. As a rule, it is copper, graphite or iron. In combination with inorganic components, all these materials guarantee a high coefficient of friction, long service life and excellent heat transfer.

Disadvantages include rapid wear and poor braking quality at low temperatures. The average cost is from fifteen to thirty US dollars (much depends on the manufacturer).

2. Organic pads. Made from a special material that contains glass, Kevlar, resin, carbon components and rubber. The peculiarity of such products is increased softness, efficiency, and low noise level.

Among the disadvantages, it is worth noting a sharp decrease in the quality of braking when moisture gets on the product, rapid wear, and increased dust formation during braking. The last drawback leads to clogging of ventilated discs. You can read how to replace brake discs in this article. The average cost of such devices is from ten to 22 dollars.

3. Low-metallic (semi-metallic) pads. The peculiarity of such products is high quality and thoughtful composition. By the way, the pads contain the same components as the organic type, but with one feature - the addition of copper or steel. The disadvantage is the high rate of wear and the high price - from thirty to fifty bucks.

4. Ceramic pads. These devices are characterized by the greatest efficiency, but also the highest price. Their advantage is high braking quality, resistance to elevated temperatures and moisture.

Contains various metals and ceramic fibers. Ceramic pads are less susceptible to heat and are gentle on brake discs. The main and only drawback is the price, it starts from hundreds of dollars.

When the first signs of a pad malfunction appear, do not delay repairs - immediately measure the thickness of the device and replace it. Moreover, now you know how to identify the problem and choose the best pads. Good luck on the roads and of course no breakdowns.

Why might pad wear accelerate?

It is important to remember about difficult operating conditions, for example, driving along mountain serpentines or participating in amateur racing. In such modes, in a working brake system, the inner pad may begin to wear down many times faster than the outer one. Something similar once happened to my car. During everyday driving, the pads on the latest generation Volkswagen Jetta sedan wore evenly. This lulled my vigilance, and I stopped monitoring the condition of the internal linings. After participating in two stages of sprints (far from the most difficult for equipment), it turned out that the internal pads were almost completely worn out. This was especially noticeable on the left wheel. I was lucky that it didn’t come to the point of scuffing the brake discs!

Also, do not forget that if, for example, you drove 30,000 km and the wear of the front pads was about 50%, this does not mean that they will last up to 60,000 km. The smaller the thickness of the lining, the faster its further wear occurs. After all, the same portions of thermal energy from friction are absorbed by a less “fat” brake pad.

Wear limit

Each brake disc has its own limited resource. It is set by the manufacturer from the factory, and resource wear is affected by mileage, braking intensity, the condition of the entire braking system, the characteristic features of the vehicle itself, etc.

When buying a new set of brake discs for his car, the driver must always follow the recommendations of the car manufacturer. Therefore, first we look at the instruction manual, or according to convenient catalogues, based on the characteristics of our particular machine, we select a part via the Internet. If you take a high-quality kit from a trusted manufacturer, you can be sure that wear will not occur very quickly, and when braking hard, the car will definitely stop, as you expected. The same applies to buying new pads.

There are international norms and standards for the production of such components for passenger cars. They oblige all manufacturers to make appropriate engravings or markings on products.

The essence of the engraving is to indicate information that relates to the maximum permissible degree of wear.

There is such a thing as the thickness of the brake disc. And it has a certain maximum wear limit.

To obtain the relevant information, you should look at the end part of the product. It is there that, according to international standards, all manufacturers of certified parts are required to display data regarding the wear of the brake part. Information about the initial thickness, as well as what thickness is considered minimal, should be located here. As soon as the disk reaches this value, it must be replaced. In fact, the manufacturer thereby relieves itself of responsibility. If a driver wears a disc below normal and causes an accident, he will not be able to blame the brake manufacturer or auto company for this.

There is an interesting feature here. When the question arises about when to change brake discs, many people look at the end side of the old product, but find nothing there.

This happens, but only on products that have not been certified or are counterfeit. It is strictly not recommended to buy such parts without information about wear.

How often and when to change brake pads

Brake pads must be changed as often as stated in the vehicle's owner's manual. But it is natural that blindly relying on instructions is extremely undesirable, and sometimes dangerous, because each car is influenced to varying degrees by a huge number of factors: the driving style of the car owner, the properties of the metals of the drums and discs, the composition of the friction linings, and much more. Brake pads must be checked regularly and changed promptly, regardless of the recommendations of the car manufacturers. Sometimes you can rely on brake pad wear sensors, which have recently been installed in foreign cars. If the sensor light comes on, then it’s time to change the pads.

For some reason the light hasn't come on yet and the pads are long overdue for replacement. There can be many reasons, some of which are: rust, dirt, careless installation of new pads when replacing, various oxidations on the sensors transmitting the signal. To explain it more simply, at a certain distance from the end of the pad (in thickness) a special contact protrudes, which, when the pads wear out, begins to touch the brake disc. When you touch the dashboard light of the Hyundai Solaris 2014, a signal is sent. If, due to inept installation of new pads, this contact is bent or broken, then it will not give the required signal in time. Also, if during driving the contact becomes dirty, rusted or oxidized, it will also not send a signal to the panel to replace the pads. Therefore, a simple conclusion follows: brake pads must be checked regularly; You can do this yourself or take the car to a car service center.

Recommendations for selection

Rule one and very important: you cannot change the front or rear brake pads one by one. It is necessary to install a set of new elements on the front or rear axle, otherwise when braking the car may seriously drift to the side. Even when one pad is worn out, all four must be replaced . As a temporary option, it is possible to install 2 new parts on one rear wheel.

When choosing new pads in the store, use the following recommendations:

- Products must match the car model and be sold in high-quality packaging with included instructions. The inscriptions on the box are clear and without errors indicating Chinese origin.

- Make sure that the friction material is the same color, without foreign inclusions.

- The surface pressed against the plane of the disk must be flat. Small chips along the edges and depressions are allowed if they occupy no more than 1% of the total area of the working plane.

- Cracks at the interface between metal and friction material are unacceptable.

Ideally, you should buy original products in original packaging. This will save you from unpleasant surprises, unscheduled replacements and emergency situations when operating your car.

When to change brake pads

Do-it-yourself replacement of rear brake pads on a VAZ-2110

Let us immediately note that in principle there is no exact replacement period. The reason is that there are too many factors on which the integrity and lifespan of the device depends.

This includes driving style, operating conditions, and the quality of the pads themselves. On average, on the front wheels they last about ten to fifteen thousand kilometers.

Rear drum pads last a little longer, and can last up to sixty thousand kilometers or more.

But even here, wear can be influenced by many factors - distribution of braking forces, quality of braking devices, driving style, and so on. However, in practice, brake pads wear out much faster.

During operation, the thickness of the front or rear pads should not be allowed to be less than 1.5 millimeters.

Otherwise, the quality of braking decreases, the likelihood of damage to the piston of the working cylinder increases, and unnecessary sounds (creaking, squeaking, and so on) begin to irritate. By the way, read here why brake pads squeak.

If desired, you can install “smart” pads with a wear indicator. Their peculiarity is that when the minimum permissible thickness is reached, a characteristic creaking sound is emitted. It is a signal to the driver that the pads need to be changed.

What determines the wear of brake discs?

The degree of wear of brake discs depends on many factors. Among them:

- Driving style of a car enthusiast . Naturally, with frequent sharp braking, excessive disc wear and brake pad wear occur.

- Operating conditions of the machine . In mountainous or hilly areas, brake discs wear out faster. This is due to natural reasons, since the braking system of such cars is used more often.

- Transmission type . In cars with a manual transmission, discs and pads do not wear out as quickly. Conversely, in cars equipped with an automatic transmission or CVT, disc wear occurs faster. This is explained by the fact that to stop a car with an automatic transmission, the driver is forced to use exclusively the brake system. But a car with a manual transmission can often be slowed down using the engine.

- Type of brake discs . Currently, the following types of brake discs are used on passenger cars: ventilated, perforated, notched, and solid. Each of the listed types has its own advantages and disadvantages. However, as practice shows, solid discs fail most quickly, while ventilated and perforated ones last longer.

- Wear resistance class . It directly depends on the price and the type of disk indicated above. Many manufacturers, instead of wear resistance class, simply indicate the minimum mileage for the car for which the brake disc is designed.

- Brake pad hardness . The softer the brake pad, the more gentle it works with the disc. That is, the disk resource increases. In this case, the braking of the car will be smoother. Conversely, if the pad is hard, it will wear out the disc faster. The braking will be sharper. Ideally, it is desirable that the disk stiffness class and the pad stiffness class match. This will extend the life of not only the brake disc, but also the brake pads.

- Vehicle weight . Typically, larger cars (for example, crossovers, SUVs) are equipped with wheels with a larger diameter, and their braking system is more reinforced. However, this case indicates that a loaded vehicle (that is, carrying additional cargo or towing a heavy trailer) will wear out the brake discs faster. This is explained by the fact that to stop a loaded vehicle, more force is required in the braking system.

- The quality of the disc material . Often, cheap brake discs are made of low-quality metal, which wears out faster and may also develop defects (curvatures, sagging, cracks) over time. And accordingly, the higher quality the metal from which a particular disk is made, the longer it will last before replacement.

- Serviceability of the brake system . Malfunctions such as problems with the working cylinders, caliper guides (including lack of lubrication in them), the quality of the brake fluid can affect the rapid wear of the brake discs.

- Availability of anti-lock braking system . The ABS system works on the principle of optimizing force, in which the pad presses on the brake disc. Therefore, this extends the life of both pads and discs.

Please note that usually the wear of the front brake discs always exceeds the wear of the rear ones since they are subjected to significantly greater force. Therefore, the service life of the front and rear brake discs is different, but at the same time there are different requirements for wear tolerance!

On average, for a standard passenger car used in urban conditions, a disk check must be performed approximately every 50...60 thousand kilometers. The next inspection and wear measurement is done depending on the percentage of wear. Many modern wheels for passenger cars easily operate for 100...120 thousand kilometers under average operating conditions.

This is interesting: How to change the alternator belt on a Lada Granta

Main reasons for accelerated wear

Why do some owners' pads become unusable after only 10 thousand km, while another with the same model of car easily drives three times that distance? Wear is a very subtle parameter, depending on many factors:

- Vehicle driving mode – city or highway. In city traffic with frequent stops, the load on the brakes is higher than when driving freely on the highway. At what mileage the pads will wear to a minimum will depend on the routes taken.

- How often the replacement will be done depends on your driving style. A quiet ride helps to increase service life, while aggressive driving leads to frequent overheating and early wear of both discs and pads.

- Malfunction of the rear brake circuit. In this case, the front brakes have an increased load. If the rear of the car is additionally loaded, the force is distributed more evenly, and accordingly, the mileage of the front and rear pads increases.

- In the off-season, all parts of the brake system will be exposed to unfavorable climatic factors (moisture, dirt, ice), and in winter they will also be exposed to aggressive chemicals, which also does not extend service life. Those. The more often you drive in bad weather, the lower the resource.

- The presence in the car of complex electronic assistants that simulate the effect of differential locking by braking the wheel reduces the life of the pads.

Other reasons for replacing pads

In addition to situations with critical wear, it is necessary to change brake pads in the following cases:

- the thickness of the friction material is more than 5 mm, but the lining itself has begun to peel off from the steel base;

- cracks and chips appeared on the surface, the material began to crumble;

- stains of oil or brake fluid that reduce friction properties were found on the parts;

- when the brake drum or disc is replaced.

Another reason for replacement is due to the abundance of low-quality fakes on the automotive spare parts market . New pads purchased from an unreliable retail outlet begin to squeak or squeak terribly after 1-2 thousand km, although the working part is still far from completely worn out. The culprit is the material of the part, whose hardness is comparable to metal, causing the surface to “slick” and create a creaking sound. If the elements made from unknown materials are not replaced, then the production on the brake discs will increase sharply.

Many modern cars are equipped with special sensors that detect a decrease in the thickness of the friction layer and send a signal to the driver when it reaches a critical level. This is also a reason to remove parts with worn linings and install new ones.

True, the sensors often become clogged with dirt and lose their functionality, so it wouldn’t hurt for the car owner to check the condition of the brakes himself.

Why is it so important to monitor the condition of your brake discs?

Discs and pads are subject to high loads while driving. Like any other car part, they tend to wear out. This in turn can affect the overall safety and reliability of the vehicle. Consequently, every car enthusiast must calculate the most important parameter so that nothing serious happens on the road.

Brake disc covered with erosion

How are drum brakes different from disc brakes?

One of the disadvantages of drum mechanisms compared to disk ones is the lack of a self-cleaning effect. Wear products from the brake pads remain inside the drum and leave characteristic marks on the working surfaces of the friction elements.

Due to the abundance of wear products, characteristic grooves formed on the working surface of the pad. The actual wear of the linings was about 30%.

Due to the abundance of wear products, characteristic grooves formed on the working surface of the pad. The actual wear of the linings was about 30%.

Editorial Kalina is often used to participate in various competitions. That is, the conditions of its operation can be called difficult. However, to our surprise, the wear on the original pads turned out to be small - about 30%. Probably the reason is that the car has a relatively small mass, and its dynamic performance is not outstanding.

Deep grooves on the working surface of the drums are the result of exposure to wear products.

Deep grooves on the working surface of the drums are the result of exposure to wear products.

Alas, wear products have significantly damaged the working surfaces of the linings and drums. This can't be fixed. The next time you replace the pads, you will also have to update the drums, otherwise they will immediately damage the new pads. However, there is nothing criminal in the further operation of the car in this form. The reduction in rear brake performance is not noticeable even when driving on a race track. In general, drums, like discs, can survive two sets of friction linings.

How to independently assess the wear of brake pads and discs?

Photo: from the author’s archive

We buy brake pads

A cheap fish is a bad fish. This is an unconditional rule for purchasing important spare parts. Everything is very simple - all spare parts are divided (conditionally, of course) into four large groups:

- Spare parts supplied by the manufacturer to the assembly line. The most expensive ones, sellers call them “original” and charge crazy amounts of money. This type of hardware is rarely supplied to stores. The pads from the conveyor must be in the original packaging of the car.

- Aftermarket. Spare parts that are manufactured by the same manufacturer, but for the aftermarket. This is also the “original”, but in a simplified version. It may differ from a conveyor block by a slight but acceptable change in the composition of the friction lining, but the markings must always be in order - no smeared or unclear inscriptions.

- Cheap pads, the prices of which are adjusted taking into account the purchasing power of the countries in which they will be sold. But this does not mean that they are completely bad. There should be a recommendation from the car factory on the packaging; the markings and composition of the friction lining should at least be indicated in some way.

- Iron of unknown origin, which masquerades as original with all its might, sometimes quite successfully. A serious seller will not deal with such suppliers, and having bought brake pads that are three times cheaper than the original ones, the owner silently agrees with the inferiority and lack of quality of the brake pads. No one can give guarantees on them and the officials will not provide them.

The most expensive brake pads are pads from

Most often you have to deal with pads of the second and third categories. Let us repeat once again and say that they are suitable for use and certified. So, the same company can supply pads to the Volkswagen and Skoda conveyors, while the same pads will come from the Renault Logan conveyor. This can be determined by the inscription on the pads themselves.

We have decided on the brand, now we need to decide on the driving style and the requirements for the pads in terms of noise and hardness by choosing friction linings of the appropriate composition. They will provide comfortable and reliable car brakes, the main thing is not to miss the time for the next replacement.

We will answer your questions for FREE regarding deprivation of rights, road accidents, insurance compensation, driving into the oncoming lane, etc. Daily from 9.00 to 21.00

Moscow and Moscow region

St. Petersburg and Leningrad region

Free call within Russia 8-800-350-23-69 ext.418

Stages and features of diagnosis

The measuring stage of the test involves the use of a caliper, which will help make thickness measurements. At approximately 5-8 points, moving around the disk, measure the thickness. If it varies along the radius of the part, there are signs of curvature and uneven wear.

Check the information from the manufacturer to understand whether the wear limit has already reached or not. I cannot say which indicators are correct and which are not, since different discs have their own wear limits.

Then a visual inspection is carried out. The disc should be examined for cuts, chips, dents, scratches and other defects on its surfaces. If they are, the spare part will have to be replaced.

Do not forget about the rule of pairwise replacement on the same axis. That is, when the left front disc is changed, the front right one also changes at the same time.

If you want to assess the condition of the elements without removing the wheels, this can be done by checking while driving. With severe wear, characteristic signs appear:

- the car brakes jerkily;

- a grinding sound appears;

- there is a squeaking sound when you press the brake;

- other extraneous sounds are heard;

- the driver feels a beat on the steering wheel;

- the beating is also felt in the gas pedal;

- When the brake pedal is pressed, the braking system is locked.

I strongly do not recommend waiting for such symptoms to appear. It’s better to periodically do simple diagnostics in your garage through visual inspection and measurement. This is usually done every 10-15 thousand kilometers, if wear symptoms do not appear earlier.

..

How to determine the malfunction?

Checking the degree of wear and making a decision through the brake pads is very simple. It is enough to remove the front wheels one by one and inspect the condition of the disc pads.

If the thickness is less than one and a half millimeters, then the best option is to run to the store, buy a couple of new products and replace them.

Checking the rear brakes will be more difficult - it is necessary not only to remove the wheel, but also to dismantle the brake drum. Next, it remains to measure the thickness using the following algorithm:

Brake Pads, Front, Rear, Replacement Timing.

When to change

front and rear

brake pads

, uneven pad wear, when

to change

pads.

When to change brake pads

When to change

— expert advice on how to replace pads. New project.

In addition to thickness, there are several other reasons to replace the pads:

- Oily surface;

- poor quality of connection to the base;

- strong squeaking noise when braking;

- Pedal vibration when pressing the brake pedal.

Additional questions and answers

What is the service life of brake pads and brake discs?

There are many factors that influence the average lifespan of your brake components. These include pad type, rotor type, your personal driving style and maintenance. According to most brake pad companies, as well as qualified mechanics, brake pads can last between 30,000 and 120,000 kilometers . At the same time, the front ones wear out about 3 times faster than the rear ones. On average, it is recommended to change pads on domestic cars approximately every 10,000 km, and on foreign cars - every 20,000 km. Actual service life can vary greatly, the main thing is to prosodicly check them and their thickness.

Left - new pads, right - old

The service life of brake discs is quite long - 3-4 times longer than that of pads. But again, it all depends on many other factors, such as how you maintain your braking system and how you drive your car. On average, this is more than 100,000 km. Here you also need to rely on the thickness of the rotors when taking measurements.

How much do new brake discs cost?

The average cost of new brake discs varies from 3,000 to 5,000 rubles each. Some rotors with the best characteristics can cost from 7000+ rubles each. Additionally, prices vary greatly depending on the type, brand, and quality.

New brake discs

When it comes to replacing brake rotors, some people often wonder whether they should buy new or remanufactured parts. Each of these types has its own advantages and disadvantages. For example, aftermarket parts tend to be cheaper and available in a wide range of options, while new brake rotors are easier to select and offer greater quality assurance.

When to change pads

1. In accordance with the recommendations of the car or pad manufacturer.

A very controversial point, since the mileage a car travels, operating conditions, driving style are different for everyone. For some, the pads will last for a couple of years, for others – for a season. The manufacturer's recommendations are nothing more than recommendations, you need to listen, but whether to follow them or not depends on the factors listed above. 2. When the thickness of the friction linings becomes less than 5mm. This is an unconditional point and should be followed in any case. There are craftsmen who feel sorry for changing: “they’re still thick, you can ride.” In principle, yes, but you can get into trouble. When driving for a long time on worn pads, the piston of the brake cylinder constantly “peeks out” from the boot - the pad is thin and the piston stroke is increased. As a result, minor rust may form on the piston surface. And after replacing the pads, the cylinder is recessed, and this rust gets directly onto the sealing seal of the brake piston. As a result, the cylinder leaks, it needs to be replaced, and hassle with bleeding the brakes. I hope I convinced you - thinner than 5 mm. - change the pads.

3. Increased pedal travel, squeaking brakes, warning light. I’ll tell you about squeaks and pedal travel a little later, but here I’ll just add that the ideal option is if the car is equipped with a pad tracking system. If there is excessive wear, a light will come on on the instrument panel (unfortunately, such a system is not available on all cars). What if your car is not equipped with a state-of-the-art brake pad monitoring system (consisting of two contacts and a light)?

Signs of Brake Pad Wear

There are several signs by which you can determine the time, if not for replacing the pads, then at least for a preventive inspection.

1. Increased travel of the handbrake lever. Relevant for rear pads. Previously, the handbrake clicked 3-4 times, but now it has become 5-7, or the car, with the handbrake pulled, rolls down the slightest hill - check the pads. Maybe the reason is a stretched cable, but don’t tempt fate - check the pads, and of course, check the front ones too.

2. Increased brake pedal travel and decreased braking efficiency. There could be a simple brake fluid leak, but if everything is dry, it’s worth checking the pads.

3. Various creaks, noises, knocking when braking, and sometimes vibration. Vibration relates to the disc brake system (as on the front wheels), and can indicate, in addition to pad wear, disc warping - it’s a good idea to check: spin the disc and watch the beats. If the “figure eight” is visible - like on an old bicycle wheel, the disk must be replaced or re-grooved (if thickness allows) - there are no options.

No conversation about pads would be complete without mentioning a few things you need to know.

1. After replacing the pads, perhaps for several tens of kilometers the brakes will be worse - in any case, there is wear on the brake disc or drum, and while the pads are rubbing in, there is no need to be reckless.

2. Change all the pads on the axle, or even better, on the entire car. Don’t even think about replacing the pads on the left and leaving the old ones on the right. Such savings are a direct path to problems with brakes.

3. Inspect the pads according to the season - when you “change shoes” of the car - change winter tires to summer tires, and vice versa.

4. When replacing pads, inspect the condition of the discs and drums. If there is significant wear or deep longitudinal grooves appear, it is better to replace it.

And lastly, although this point is more likely to be classified as a curiosity, it nevertheless happens regularly. When replacing the pads, do not forget to take some fluid from the brake reservoir. If it is full, then at the time of replacing the pads (when you press down the pistons of the brake cylinders), the liquid will go back into the reservoir, and then through the top of the reservoir, leading to a local cataclysm. Any paint really does not like liquid - if you do not wash it off in time (which is very difficult - it will flow everywhere), it can destroy and lift the paint. I hope that after reading the article, you now have answers to your questions: when do you need to change brake pads, and what are the symptoms of their wear.