Engine valves VAZ-21116

The average consumer has access to only those that come with the car from official documents. What follows from them? Open the Grants service book. Replacing the timing belt - at 75 thousand kilometers for an 8-valve engine, not a word about the 16-valve belt! The same situation is with Kalina - I came across a book where there is nothing to say about one engine, but on the other we only check the condition of the belt, but there is no talk of a planned replacement. It’s even more fun with the Priora - there are service books where there is not a word at all about the gas distribution mechanism, but the air conditioning compressor belt is mentioned in almost every maintenance coupon.

With Vesta and Xray, progress is obvious - at 45, 75, 105, 135 and 165 thousand we adjust the gaps in the gas distribution mechanism. And for the first time we plan to remember the timing belt along with the rollers for 180 thousand kilometers! This is for 16-valve engines VAZ-21129, 21179 and 8-valve Vesta VAZ-11189. I can’t do without the quote: “2.11. Replace the timing belt along with the rollers. 2.12. Replace the crankshaft and camshaft sprockets. Replace the toothed belt, tensioner and support roller (for the VAZ-11189 8-cl. engine, only the tensioner) of the engine gas distribution mechanism drive. Adjust the tension of the toothed belt." Not only is the oil oil (we change the same belt twice), but of all the parts, they didn’t remember the most vulnerable one - the pump!

Review of manufacturers, part numbers of pumps for 8 (16) valve Lada Granta

| Catalog article / OEM number | Price, rub.) | Pump mileage (Thousand km) |

| LUZAR LWP 0190 | From 550 | 60 |

| GATES KP15631XS-1 | From 1100 | 80 |

| FENOX HB1001C3 | From 600 | 75 |

| DOLZ L126 | —/— | —/— |

| DOLZ L125 | —/— | —/— |

| METELLI 24-0833 | —/— | —/— |

| GATES KP15670XS | —/— | —/— |

*prices are current as of November 6, 2018.

Recommendations for the selection of parts and components

Considering that the service life of domestic water pumps is limited, service station technicians recommend purchasing foreign analogues. The cost of imports is 10–15% more expensive, however, the service life is 15–20 thousand km longer.

To avoid buying counterfeits, use the services of trusted stores, suppliers, and Internet sites.

Strictly follow the manufacturer's requirements for the timing of technical inspection. Check the catalog numbers with the actual data in the operating instructions.

Engine Cooling Water Pump

Here it is, a mine - a water pump. Refers to the cooling system, but is driven by a timing belt. If the pump wedges due to the death of the bearing, it will cut off the teeth on the belt, and then there will be destruction in the motor. And they “forgot” to mention this detail in the routine maintenance section of all service books. What to do with it? The consumer can only guess. Should we wait for death from natural wear and tear on a plug-in motor? Stupidity. And if changed, then when? It seems that the mine is not even the water pump itself, but the complete disregard for it in all the official VAZ “literature” for the consumer.

New VAZ engines are now equipped with high-quality timing belts from well-known brands. I believe that if no oil gets on it, it will cost 180 thousand. But is the difference in components really so great that on the 8-valve VAZ-11186 for Granta the belt must be changed at the 75th thousand, and on its closest relative VAZ-11189 at the 180th?

Let's continue the research. The pulleys are not demolished at all. Pressure roller bearing up to 180 thousand? Let's admit it, although it's hard to believe. But why change all this equipment at the 180th thousand, if the estimated life of the engine is 220 thousand km? Refresh before demise or major overhaul? If you don’t believe me, look at the photo taken in the workshops where VAZ engines are produced.

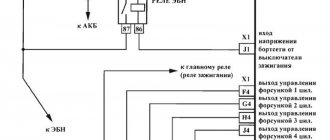

Description of the design and operating cycle of the pump

Passenger cars are currently equipped with a hydraulic pump that operates on a centrifugal principle. The task of the element is to ensure continuous movement of the refrigerant. Some pump components are located in hard-to-reach places, so an experienced driver should be able to identify the defect without removing the pump.

The device is housed in a durable metal case and consists of the following functional components:

- Bearings : have a limited resource, as they are lubricated with a pre-applied lubricant. On the other hand, they are completely closed to other components, so they take on a minimal part of the impact of negative factors.

- Axle : this element is fixed using the bearings described above.

- Impeller : the main functional element of the unit. Made of metal to ensure the required strength parameters. Continuously rotating, the impeller pumps up the required pressure in the coolant circuit.

- Pulley : transmits rotational impulse directly from the crankshaft to the impeller. Thanks to the pulley, the operating range of rotation of the impeller is maintained. The use of a pulley is beneficial from a design point of view: slippage of the drive belt is minimized.

Now let's schematically describe how it all works. The cooling pump is connected directly to the crankshaft via a belt. From it the device receives a rotational impulse and spins up to the desired range. The rotating part, with the help of wings, pumps up the necessary pressure and forces the coolant to continuously move along the cooling jacket.

Routine maintenance for VAZ engines.

Nowadays, new engines also use Korean pumps, which are rumored to be of better quality. But even if you cut me, not a single pump of 200 thousand comes out. I do not believe! Moreover, I see complete confusion in the service books, the lack of a unified approach to servicing the same gas distribution mechanisms from model to model and, most importantly, an indifferent attitude towards the consumer. Not from all factory workers - from those who are responsible for a specific direction and are killing the work of other creators of cars at the Volga Automobile Plant with stupid pieces of paper. But if the charge is planted, and the specialists did not help, then we will clear the mines ourselves.

Korean-made coolant pump for VAZ-21179 engine

The owner of any elderly foreign car with a timing belt will confirm that repairmen insist that during a scheduled belt change, they replace both the pump and the pressure rollers with bearing assemblies. And these parts are often sold as a set. Moreover, at a discount - the whole set is cheaper than the belt, rollers, and pump separately.

I don’t want to once again convince you that the stingy pays twice, but over the years I have come to the conclusion that Western manufacturers include in the regulations changing the belt not because of the belt as such, but because of the pump and tensioner bearings. They just needed a reason to reliably replace the entire set of parts associated with the camshaft drive, and they found it.

I propose to do the same with our engines. Why? Formally, at each maintenance it would be necessary to remove the cover and inspect the timing belt and water pump. You can see a tear in the belt, as well as a leak on the pump. In both cases, the part is changed without delay. But this is a malfunction. And if everything is outwardly normal, the ideal option is to include preventive replacement in the regulations.

Causes of malfunction

The following reasons are identified that affect the deterioration of the mechanism:

- Damage to the rotating components of the impeller : during intensive operation, small wings of the rotating part break off. This is especially true for plastic impellers. When the wings break off, the pump can no longer pump antifreeze at the required intensity - the engine constantly overheats.

- Drain hole clogged . This problem leads to the fact that antifreeze cannot fully circulate through the circuit. Clogged drainage can be easily tracked without removing the pump. If you suspect that the drain holes are clogged, simply turn on the cabin heater.

- De-synchronization of element and timing pulleys . In this case, the seals and bearings work in extreme conditions and wear out extremely quickly. The reason for such a breakdown is a manufacturing defect: either low-quality materials were used during assembly, or an unreliable assembler was used.

We recommend: What to do if the fan of the VAZ-2112 stove does not work

We need to speak in more detail about the third reason. No car owner is insured against manufacturing defects. But in this case, everything is serious with the prefix “hyper”. If you install a pump with potential out of sync, then the use of such a defective unit will lead to a sharp increase in timing wear. In the best case, the driver may encounter a broken belt, in the worst case, the valves “knock”.

Chronic overheating of the internal combustion engine caused by other factors can also lead to wear and tear of the cooler.

Another marker of wear (which, however, can only be seen after disassembling the mechanism) is play in the rotating parts. Backlash indicates imminent failure of the pulleys, displacement of the central axis and damage to the seals.

The last life hack for motorists who do not want to remove the pump, but want reliable information about its functional condition. Carefully inspect the junction of the cooler and the internal combustion engine. If there are significant antifreeze leaks, then the water pump does not have long to live.

Timing belt

How would you act on your own without clear instructions in the service book? On both an 8-valve and a 16-valve engine, I would change at least the pump, and better yet, the belt and tensioner between the 60th and 70th thousand kilometers. According to the period, if the mileage is small, for the sixth year of operation.

Many owners of domestic LADA models know that Granta, Kalina, Priora, Vesta and XRay are classified as “plug-in”, that is, when the timing belt breaks, the pistons meet the valves and then the engine faces expensive repairs.

To prevent this from happening, you need to change the pump, tension rollers and the belt itself in time.

What the manufacturer is silent about

The average car owner has information on servicing his VAZ model only from the factory instructions. For example, the booklet for the LADA Kalina indicates the service life of the belt, but there is no mention of its planned replacement. In the LADA Granta operating book, the manufacturer indicates the mileage of the timing belt for an 8-valve engine, while there is no information at all about the 16-valve version.

In some LADA Priora service books, the timing belt is not mentioned at all.

Vesta and XRay car owners are “lucky” - the service book indicates the timing for adjusting the timing belt gaps.

The planned replacement of the timing belt and rollers is indicated only in the instructions for the 8-valve engine of the Vesta and VAZ-11189 models, while it is recommended to replace the same belt twice, while there is not a word about the pump at all.

Water pump

Neglecting to replace and maintain the water pump can render the power unit inoperative. Let us remember that the pump belongs to the cooling system, but is driven by a timing belt. When the pump jams, due to bearing wear, the teeth in the belt are cut off and the motor is destroyed. All these details are familiar to the craftsmen, while the manufacturer did not even think to mention the need to monitor the condition of the water pump.

When to change the belt and pump

It should be noted that the new AvtoVAZ engines have high-quality timing belts, and if oil does not get on them, then they will run for the indicated 180 thousand kilometers.

Replacing the pump

How to identify a faulty pump on a Lada-Kalina and replace the part yourself

After checking the water pump, repairing it, or purchasing a new element, all that remains is to install it in place. We advise you to pay maximum attention to the moment of installing the gasket and tightening the fastening bolts. Some experts advise using sealants to provide reliable protection against leaks. Sometimes this is not possible because on some vehicles the sealant will prevent the pump from being loosened in the future to replace the timing belt.

In addition, follow the manufacturer's recommendations regarding bolt tightening torque (this information is in the service manual). Otherwise, you may pinch the gasket or damage the threaded connection. Finally, you need to fill in the coolant.

In the process of adding antifreeze or antifreeze to the cooling system, it is necessary to get rid of air pockets. After installing a new or restored pump and warming up the power unit, be sure to inspect the installation site for coolant leaks.

An important component of the Lada engine is the pump or water pump of the cooling system. This model features engines with the serial index VAZ-11183, VAZ-11186, VAZ-21126 (also with automatic transmission) and VAZ-21127.

This unit should be selected according to the part numbers

After all, the Grant pump is responsible for the safety of such an important engine part as the timing belt. Pump (water pump of the cooling system) Lada Granta catalog number – 21114-1307010-00, 21114-1307010-01

You can do a self-diagnosis of the pump malfunction yourself. This will only require a visual overview of the CO water pump department. When dismantling the pump, it will be easier to find the cause of the breakdown. Determination of malfunction Grant, pump:

• Makes noise, an unusual hum of bearings in the pump section. • Leaks in the pump area indicate the need to replace the gasket. • There may also be leaks in the drainage section of the pump - this is wear on the seal. • If the pump impeller wears out/breaks, there will be poor circulation of coolant in the system. • If axial play of the pump shaft is detected, the bearing is worn out.

The water pump ensures proper circulation of coolant in the car engine

Thus, infrequent monitoring, in which you should pay attention to the coolant pump section of the Lada Granta - the pump and the units associated with it, will serve you faithfully. And your car is no longer in danger of engine overheating due to a sudden malfunction

Do not forget that the performance of the stove also depends on the quality of the pump.

Unfortunately, counterfeit pumps are often found; be careful and always keep your purchase receipt or negotiate return conditions. Beware of fakes; after installation, carefully check the operation of the pump on a cold and warm engine.

The Lada Granta pump is represented by two reputable manufacturers. These are the companies TZA (Togliatti Plant of Units) and LUZAR (Lugansk Plant of Automobile Radiators)

Pay attention to the colors of the original pump. Compare grooves and ribs of the impeller

Compare all inscriptions on the pump with the original.

In auto markets you can find many water pumps for the Lada Granta. Choosing a good one without experience is not easy. Of course, it would be ideal to have the factory-made original with you for comparison. After all, the quality and prices at the bazaars are different, it is better to buy from official manufacturers; for comparison, the price of a pump on a grant is:

• TZA pump (21116-1307010-00) – from 815 to 1100 rubles. • LUZAR pump (21116-1307010-00) – average cost 1240 rubles. • Kraft – from 1550 rubles. • HEPU – from 1800 rubles. • In the markets you can also find supposedly “original” pumps for only 500 rubles. But it’s up to you to decide whether this untested part is worth purchasing.