Why does antifreeze boil? This situation can arise for a variety of reasons, for example, the cap of the expansion tank of the cooling system has depressurized, the thermostat has malfunctioned, the coolant level has decreased, bad antifreeze has been filled in, the cooling fan or temperature sensor has failed. The main thing that the driver of a car with antifreeze boiling should remember is: further movement is impossible! Failure to comply with this rule can lead to complete engine failure, which can lead to costly and complex repairs. However, eliminating the causes of antifreeze boiling is actually not that difficult, and sometimes even a novice car owner can do it.

Causes of boiling and their solutions

To begin with, we will analyze in detail all the reasons why antifreeze boils.

- Faulty thermostat .

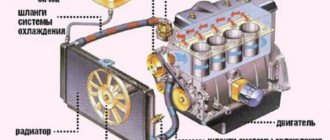

The main task of this device is not to supply coolant to the radiator until the engine reaches a certain operating temperature (usually +85°C), that is, to transfer it to the so-called “large circle”. However, if the unit does not turn on in time and does not circulate the coolant through the system, it will quickly heat up in the “small circle” along with the engine and simply boil because it will not have time to cool. Dirty thermostat - Faulty radiator . The function of this unit is to cool the antifreeze and maintain the cooling system in working order. However, it may suffer mechanical damage or simply become clogged from the inside or outside.

- (centrifugal pump) failure Since the task of this mechanism is to pump coolant, if it fails, its circulation stops, and the volume of liquid that is in close proximity to the engine begins to heat up very much and, as a result, boils.

- Low antifreeze level . A cooling system that is not filled to the required level does not cope with its task, so the temperature exceeds the critical temperature and the liquid boils.

- Cooling fan failure . Its function is to force cool the elements of the system of the same name and the liquid. It is clear that if the fan does not turn on, the temperature will not drop and this may result in the antifreeze liquid boiling. This situation is especially critical for the warm season.

- Presence of an air lock . The main reason for its appearance is depressurization of the cooling system. As a result, several factors harmful to it arise at once. In particular, the pressure drops, which means the boiling point of antifreeze decreases. Further, when air remains in the system for a long time, the inhibitors included in the antifreeze deteriorate and do not perform their protective function. And finally, the coolant level drops. This has already been mentioned earlier.

- Temperature sensor failure .

Everything is simple here. This unit has not sent the appropriate commands to the thermostat and/or fan. They did not turn on and the cooling system and radiator boiled. Pump corroded by antifreeze - Poor quality antifreeze . If the car is filled with low-quality antifreeze, that is, a liquid that does not meet the necessary requirements, which means there is a high probability that the radiator will boil. In particular, we are talking about the fact that counterfeit coolant often boils at temperatures below +100°C.

- Antifreeze foaming . This can happen for various reasons. For example, low quality coolant, mixing incompatible antifreeze, using antifreeze that is not suitable for the car, damage to the cylinder block gasket, which causes air to enter the cooling system, and as a result, its chemical reaction with the coolant to form foam.

- Depressurization of the tank lid . The problem may be either a failure of the safety bleed valve or a depressurization of the cover gasket. Moreover, this applies to both the expansion tank cap and the radiator cap. Because of this, the pressure in the cooling system is compared to atmospheric pressure, and therefore the boiling point of the antifreeze decreases.

To restore the functionality of the cooling system, and in future to prevent situations where antifreeze or antifreeze boils quickly, it is necessary to inspect the components listed above. Let us list the sequence in which it is necessary to check the specified components in accordance with the probability and frequency with which they fail.

Antifreeze foaming

- Expansion tank and its cap . This is especially true if the antifreeze in the expansion tank has boiled and steam is coming from underneath it. It is better to replace the entire cap and valve.

- Thermostat . This unit needs to be checked if the radiator is cold and the antifreeze is boiling when the engine is turned on. It also makes sense to check the thermostat after replacing the coolant if it immediately boils.

- Cooling Fan . It rarely fails, but it makes sense to check. As a rule, problems arise in dropped contacts or breakdown of the insulation of the stator and/or rotor windings.

- Temperature sensor . The device is quite reliable, but sometimes fails on older machines. Actually, it controls the operation of the fan on the radiator

- Centrifugal pump (pump) . This is similar to the previous point..

- Cooling radiator . It is necessary to carefully inspect it for damage and possible coolant leaks. If it leaks (this will be accompanied by a situation where antifreeze is leaking), then it is necessary to dismantle it and solder it. As a last resort, replace it with a new one. You can simply clean it if it is very clogged. For external cleaning it is better to remove it. And internal cleaning occurs along with the entire cooling system (without dismantling).

- Check the antifreeze level in the system . It can leak from a damaged system, and the remaining volume cannot withstand the heat load and boils. If a low-quality liquid with a low boiling point is used, it must be replaced completely. Otherwise, you can simply add antifreeze.

- Check whether the added antifreeze is suitable for the current car . If there was a mixing of two brands of coolant, make sure that they are compatible with each other.

- Check the operation of the safety release valve . You can check the operation of the valve on the lid using polyethylene.

- Check the quality of the filled antifreeze . This can be done in several ways, using both professional equipment and improvised means available in the garage or at home.

Bad antifreeze is death to the engine

The boiling and freezing points of coolant depend on the composition. The consequence of pouring bad (fake) antifreeze is boiling and destruction of the engine. Find out the signs and testing methods to determine that it is bad Read more

As a rule, you only need to complete one of the listed points. However, in difficult situations, failure of several of the listed units is possible.

Remember that all repair and maintenance work on the cooling system must be performed only when the engine is cool. Under no circumstances should you open the expansion tank cap when the engine is hot! This way you risk getting a severe burn!

Often, boiling occurs when the car is moving in a lower gear while the engine is running at high speeds, for example, during long driving in the mountains or in city traffic jams in the summer heat. The situation is aggravated if the air conditioning is turned on, since it puts additional load on the cooling system, in particular the main radiator. Therefore, before traveling to the mountains, be sure to check the condition of the engine cooling system, including the level of antifreeze in it. If necessary, top it up or replace it.

It is not recommended to use antifreeze that contains more than 60% ethylene glycol by volume and less than 40% water by volume.

Often the cause of antifreeze boiling can be the formation of an air lock in the cooling system. Symptoms of its formation are problems with the thermostat, antifreeze leakage, problems with the pump and the interior heater. Therefore, if at least one of the listed problems exists on your car, then it is recommended to correct the situation, since ignoring it can cause the engine to boil.

Some drivers are interested in the question of why antifreeze boils after stopping? There are several options here. The first is when the car is stationary with the engine running. This means that this is just a coincidence, and you are lucky that you discovered a situation when antifreeze boiled not while driving, but on the road or in the garage. In this case, immediately turn off the engine and set the car to the handbrake. We'll talk about further actions a little later.

Low antifreeze level

Another possibility is that smoke (steam) continues to come from under the hood after you have detected a boil and pulled over to the side of the road. It is necessary to understand that most liquids, and antifreeze is no exception, have a high thermal specificity. This means that it takes a long time to heat up and cool down. Therefore, the situation is when you observe boiling coolant, which will stop evaporating some time after stopping the engine.

There are exotic options when it bubbles in the expansion tank after the engine is turned off. For example, the situation described below is relevant for the Chrysler Stratus. It consists in the fact that after stopping the engine, the radiator safety valve releases pressure into the expansion tank. And the effect is that everything is boiling there. Many car enthusiasts mistake this process as a blown cylinder head gasket and rush to change it. However, there is no need to rush, but instead it makes sense to carefully study the cooling system diagram of a particular car.

Boiling point of antifreeze

Initially, on the first cars, water was used as a coolant. The boiling point of water is 100 degrees Celsius. The reasons why it was decided to abandon water lay in its low boiling point, which was not designed for heavy loads, and its freezing in winter. After all, when it froze, it turned into ice, and its volume expanded significantly. Such phenomena led to the fact that the cylinder block simply cracked and the entire engine failed, the block of which could only be replaced.

Such disadvantages are absent in antifreeze. The fact is that antifreeze has a certain chemical composition that allows it to withstand fairly low temperatures, which makes it possible for the car to operate normally in winter. In addition, the boiling point of antifreeze is much higher than that of water and is 125 degrees Celsius.

However, such a value as temperature can vary from 108 to 125 degrees. This is due to the chemical composition of the coolant, which, accordingly, changes the boiling point. Changing the composition makes the production of antifreeze more economical, the price for it falls, but at the same time, the boiling point also decreases. Therefore, when buying antifreeze, you should not pay special attention to savings, since the proper cooling of your engine will depend on this.

You should be especially careful with antifreeze with qualitative inconsistencies. Typically, such coolant costs quite little, which is tempting for drivers. However, the boiling point of some specimens is even 85 degrees, which is dangerous for a car engine. Therefore, be careful and do not buy low-quality coolant. This will save you a lot of nerves and money.

What are the consequences when antifreeze boils?

The consequences of antifreeze boiling depend on how overheated the engine is. And this, in turn, depends on the brand of the car (engine power and body weight), the design of the motor, as well as the time between when the engine began to boil and when it stopped (the moment when it turned off and began to cool). Let us conditionally divide the possible consequences into three degrees - mild, moderate and severe.

So, with slight overheating of the engine (up to 10 minutes), slight melting of the engine pistons is possible. At the same time, they can slightly change their geometry. In most cases, this situation is not critical, unless there were problems with the geometry before. If you notice the boiling of antifreeze in time and take appropriate measures, which will be discussed later, then it is enough to eliminate the cause of the breakdown and everything will be fine.

Engine overheating

More details

The average case of overheating occurs approximately 20 minutes after antifreeze or antifreeze boils. So, the following types of breakdowns are possible:

- curvature of the cylinder head housing (relevant when the engine temperature reaches +120 degrees and above);

- cracks may appear on the cylinder head (both microcracks and cracks visible to the human eye);

- melting or burning of the cylinder block gasket;

- failure (usually complete destruction) of the inter-ring partitions located on the motor pistons;

- The seals will begin to leak engine oil, and it can either flow out or mix with the boiling antifreeze.

The breakdowns already listed are enough to imagine the scale of the tragedy that can happen to a car if the antifreeze boils. All this is fraught with a major overhaul of the engine .

Expansion tank with cap

However, if the driver for some reason ignores the boiling and continues to drive further, then the so-called critical “wave of destruction” occurs. In very rare cases, the motor may simply explode, that is, completely burst and fail, but this does not happen often. As a rule, destruction occurs in the following sequence:

- Melting and combustion of engine pistons.

- During the above-mentioned melting process, molten metal falls on the cylinder walls, thereby impeding the movement of the pistons. Eventually the piston also breaks down.

- Often, after the pistons fail, the car simply stalls and stops. However, if this does not happen, then problems with the engine oil begin.

- Due to the fact that the oil also reaches a critical temperature, it loses its performance properties, which puts all rubbing parts of the engine under attack.

- Typically, small parts melt and stick to the crankshaft in liquid form, naturally making it difficult to rotate.

- After this, the valve seats begin to fly out. This leads to the fact that, under the influence of at least one piston, the crankshaft simply breaks, or, in extreme cases, bends.

- A broken shaft can easily pierce one of the walls of the cylinder block, and this is tantamount to complete engine failure, and what is most interesting is that such an engine is unlikely to be restored.

Obviously, the consequences of boiling antifreeze in the cooling system can be very sad for both the car and its owner. Accordingly, it is necessary to maintain the cooling system in order, regularly monitor the antifreeze level, and, if necessary, top it up to the normal level. And if boiling does occur, you need to react as quickly as possible and take action to correct the problem.

Pump failure

If the pump (water pump) breaks down, the liquid in the cooling system will not circulate and the antifreeze will boil. Most often, the impeller on the pump falls off. Sometimes problems with the pump are caused by insufficient tension or slippage of the timing belt. In this case, the pump axis does not rotate and the circulation rate of antifreeze drops.

Pump leak

What to do if antifreeze boils

What to do if the engine boils

However, the most interesting and interesting question for drivers is the following - what to do if antifreeze/antifreeze boils on the road or in a parking lot. The first thing to remember is not to panic, that is, to keep the situation under control! It is advisable to draw attention to the fact that the cooling system has partially failed as soon as possible. This can be done either using instruments on the panel or visually by looking at the steam coming out from under the hood. The sooner you take appropriate action, the greater the likelihood of getting away with inexpensive repairs.

There is a simple algorithm that every car enthusiast should know, even those who have never encountered a similar situation. It consists of the following steps:

- Switch to neutral speed and reduce engine speed to idle.

- Continue driving and do not suddenly slow down. The oncoming air will blow the engine as much as possible to cool it.

- While still driving turn on the interior heater to the highest possible temperature. Moreover, this must be done regardless of the time of year, that is, if necessary, even in the summer heat. This procedure is done in order to remove heat from the radiator as much as possible so that it cools down as much as possible at no-load speed.

- You need to roll for as long as possible, until it comes to a complete stop (if this happens in the summer, then it is advisable to find a stopping place somewhere in the shade , without direct sunlight). Afterwards the engine must be turned off. In this case, the ignition must be left on in order to allow the stove to work for another 5…10 minutes . After this, turn off the ignition.

- Open the hood in order to give maximum access to natural air into the engine compartment. Without touching any engine parts with your hands (now they are at an extremely high temperature), wait a certain time . In summer it is about 40...50 minutes, in winter - about 20. Depends on weather conditions and the time the car was “boiling”.

- Call a tow truck or a car that will tow the car to a service station or to a good mechanic with the appropriate diagnostic equipment.

Dirty radiator - If there are no cars nearby, then after the mentioned time, making sure that there is no more boiling and the liquid has “calmed down,” carefully unscrew the cap of the expansion tank of the cooling system and add clean water . If you are traveling close, you can use some non-carbonated drinks. Fill to the mark.

- Start the car, turn on the heater to maximum and continue driving at low speeds. As soon as the coolant temperature reaches +90°C, you need to stop and wait again for about 40 minutes . If you're not far away, you're in luck. Otherwise, you need to look for an option with a tow truck or tug.

- Upon arrival at the service station, tell the technicians about the problem; usually they can easily find the breakdown (among those described above) and fix it.

- Also be sure to ask them to change the antifreeze , since the liquid that is currently in the system has already lost its performance properties.

- Carry out a breakdown diagnosis in order to find the cause of the boiling and eliminate it so that the situation does not recur in the future.

The algorithm of actions is simple, and even an inexperienced driver can cope with it. The main thing is to notice the process of antifreeze boiling in time. And it is advisable to always have a small supply of coolant (similar or compatible with that currently used) in the trunk, as well as engine oil. The canister does not take up much space, and can come in handy at a critical moment.

Driver actions

Having noticed that antifreeze begins to boil in the expansion tank, you need to take a number of mandatory measures. Don't wait for the coolant to start splashing out onto the hot engine. Once the liquid boils, there are corresponding reasons.

Pour antifreeze into the car

You already know at what temperature antifreeze usually boils in cars, what causes overheating and what consequences this can lead to. Therefore, no one wants to encounter something like this in their own car. It is necessary to start cooling the engine using available methods, not forgetting that the coolant is now under high pressure.

There are several useful tips and a certain algorithm of actions that allows even a beginner to figure out what to do if antifreeze suddenly boils.

- Be sure to try to quickly unload the engine. To do this, you can put the gearbox in neutral and drive until it comes to a complete stop.

- Turn on the fan and stove at the same time. Even if it’s hot outside, the heater will take away some of the heat, thereby speeding up the process of the engine temperature dropping.

- After stopping the car, turn off the engine. At the same time, leave the stove in working condition.

- Pull the handle or press the button to open the hood from the passenger compartment and access the engine compartment. There is no need to stand in front of the hood and open it, as hot steam will immediately come out.

- By opening the hood slightly, steam will come out and fresh air will begin to flow into the engine. Wait a while. Then lift the hood and lock it. It is better to have gloves or a rag with you so as not to grab possibly hot elements with your bare hands.

- Do not try to open the expansion tank cap immediately. Otherwise, you risk your own health. Liquid under pressure, even if the lid is opened slightly, can splash out and get on your skin.

- Wait about 30 minutes. At this time, you can try to find a driver who will take you to the service station, or call a towing service.

- When the engine has cooled down a little, open the expansion tank cap. Surely the coolant has become much less than the proper level. Add liquid into the reservoir in small portions. At the same time, the stove is still working.

- There is no need to immediately pour in a large volume of antifreeze if its level becomes minimal after boiling. Abrupt mixing of cold antifreeze or antifreeze with hot coolant can provoke dangerous negative consequences.

- If you can only get to the service station on your own, after adding coolant and cooling the engine, start it and set off on the road, trying not to load the engine. When the temperature again reaches above 100 degrees, stop, turn off the engine and wait for it to cool down again.

You can't sit and do nothing either. If the coolant continues the boiling process, the engine will overheat first to medium and then to high levels. You already know about the consequences of such heating.

Based on everything discussed above, we can speak with confidence about the seriousness of the problem of coolant boiling. To prevent such situations, carefully monitor the condition of the cooling system, check the functionality of the main components and try to carry out timely maintenance.

What not to do when the engine is boiling

There are a number of strict rules that limit the driver’s actions during a situation when antifreeze boils in the radiator, expansion tank or other element of the cooling system. These rules are designed to protect human health from causing serious injury, and to minimize material losses that may arise in the described situation.

- Do not load the engine (do not accelerate, but instead you need to reduce the speed to idle as much as possible, usually around 1000 rpm).

- Do not stop abruptly and turn off the engine, thinking that the engine will stop boiling; on the contrary, everything will only get worse.

- Do not touch hot parts in the engine compartment!

- While steam is coming from under the cap of the expansion tank or other unit and while the antifreeze is bubbling in the system, you should absolutely not open the cap of the expansion tank! This can only be done after the time specified above has passed.

- Do not pour cold water on the engine! You need to wait for the engine to cool down on its own.

- After the engine has cooled down and new antifreeze has been added, you should not drive after the temperature reaches more than +90 degrees.

Compliance with these simple rules will ensure the safety of the driver, and also minimize the degree of breakdown and, consequently, possible material costs.

How dangerous is bubbling antifreeze?

This phenomenon is considered normal when the engine is warmed up to an operating temperature of 90–95 °C, provided that there are no losses of coolant, leaks outside the tank and other abnormal signs. Part of the antifreeze circulating in a large circle is discharged into the expansion tank. To an inexperienced car enthusiast, it may seem that it is boiling, although in reality an intense discharge is taking place.

Important point! A sign of serious danger to the engine is an increase in coolant temperature. If the device does not show it, overheating is excluded.

Not all seething is harmless. If it occurs on a cold engine and is accompanied by side symptoms, there is a reason to check the condition of the cooling system. What these signs and possible malfunctions look like:

- Antifreeze suddenly begins to bubble 2–5 minutes after stopping the engine. Most likely, the problem is a faulty valve built into the radiator cap. When circulation stops, the fluid in the cylinder head quickly heats up and increases in volume. Since the radiator valve is open, it rushes into the tank through the upper outlet pipe.

- Seething and drips on the expansion tank body indicate a stuck plug valve. Air and steam break out at a weak point - along the plastic thread, but they can also “explode” the container.

- There is a large amount of white smoke coming out of the exhaust pipe, and streaks are visible on the cylinder block. The reason is a broken gasket between the block and the cylinder head. The gas pressure created by the pistons is transmitted to the cooling system, causing the antifreeze to bubble and boil in the expansion tank.

Coolant selection

First, you need to figure out how much coolant is provided in the VAZ 2110. This will allow you to purchase the required amount of antifreeze and correctly carry out the replacement procedure.

So, the expansion tank should be filled with 7.8 liters of coolant. Although in reality, when draining, you will only get about 7 liters. Part remains inside. Therefore, when filling, there is no need to fill all 7.8 liters. 7 liters is enough.

We have already understood how much coolant is provided in the VAZ 2110, and how much needs to be filled. So it's time to choose.

In order to make a smart purchase of a new antifreeze, follow a few simple rules.

- Purchase a liquid with the same characteristics, color and production that was used previously. Of course, if the previous coolant worked effectively. Mixing different types of antifreeze is a common mistake that can lead to unpredictable consequences.

- Take a closer look at the packaging of the liquid you purchased. Today they sell both ready-to-fill formulations and concentrates, which must be diluted before use.

- Replace antifreeze only when the engine has completely cooled down.

- Start the engine after replacing the coolant strictly after all connections are made and the expansion tank cap is closed.

Replacement procedure

So, we got to the most important thing - replacing the antifreeze in your VAZ 2110. The process consists of several successive stages.

- Put on protective equipment - glasses for your eyes, gloves for your hands. When the engine is boiling, never touch the reservoir cap with your hands.

- Place the car on a level surface. Although if you raise the front of the car a little, this will allow you to drain more coolant.

- Remove the negative cable from the battery.

- Remove the bracket and ignition module. This will allow you to get to the cylinder block.

- Place a container under the drain plug to catch the old coolant.

- Remove the plug located on the expansion tank. This will create pressure in the system, which will allow the liquid to drain faster. Let the antifreeze drain until the liquid flow stops on its own.

- Next, place the container under the radiator, unscrew the cap and allow the liquid to drain from there. Be patient if coolant flows out slowly. The more you drain it, the better for your car.

- When the flow stops, check the condition of the pipes, plugs, and fasteners. If there are defects, damage or cracks, be sure to replace the elements.

- To prevent an air lock from forming on the injection engine, be sure to remove the hose where it connects to the fitting for heating the throttle pipe. If the engine is carburetor, a similar connection is dismantled, only this time the carburetor is heated.

- Try to measure the volume of drained antifreeze. It is the same amount of new coolant that should be poured into the system. One way or another, the CO must be completely filled with coolant. In this case, antifreeze.

- After completing the replacement procedure, close the expansion tank cap as tightly as possible. Reinstall all the hoses, install the ignition module in its mounting socket, and connect the wire to the battery.

- Only after this can the engine be started. Let it warm up a bit. During this time, the liquid level may drop. This indicates that an air plug has formed in the system, which was pushed through. Of course, leakage can also occur if you have not secured the hoses and clamps well. It's okay if the coolant level drops a little if there are no leaks. Just add the missing amount, bringing the volume of antifreeze in the tank to the optimal level.

Successful replacement of antifreeze depends on just a few factors:

- Use of high-quality coolant;

- Accurate and consistent work;

- Check all connections for integrity and absence of leaks.

As you can see, replacing the coolant in the coolant system of a VAZ 2110 car is not a complicated procedure. To do this, it is not at all necessary to resort to the help of professionals.

Almost every car owner of a 16-valve VAZ-2112 has encountered the fact that the coolant in the expansion tank boils. But not everyone understands why this happens. In this article we will look at why the liquid boils in the tank and how to fix it.

What causes the liquid to boil in the expansion tank? Of course, this is due to the cooling system. If you look at this in more detail, the problem will lie in one of the details that caused it. So, let's look at what directly causes the effect:

- Thermostat.

- Radiator.

- Fan and wiring fault.

When all the reasons have been considered, you can proceed directly to troubleshooting methods.

Elimination methods

The 16 valve valve began to boil. Never open the coolant reservoir

Before considering options for resolving the issue, it is worth noting that this should not be allowed to happen, since the consequences can be very unpredictable, and repairs can cost a considerable amount of money. So, let's consider the sequence of actions to eliminate the malfunction.

Thermostat

New thermostat

The most common reason, especially in summer. Thermostat jamming is very common and few drivers have not gone through this.

. In addition to the fact that hot coolant circulates in a small circle, and even if the fan does not work, then you definitely need to wait for it to boil.

In this case, the elimination method is quite simple - it normalizes the work. Of course, there are times when a new part fails very quickly, but this is directly related to the quality of the product.

Radiator

Radiator

A clogged radiator can cause pressure to build up, causing fluid to flow into the tank and leave the system. If you add to all this a non-working thermostat, the result is that the liquid will boil.

To eliminate the causes, it is necessary to dismantle the clogged radiator and clean it

. If this does not help and the cooling does not flow normally, then it is necessary to replace the part, since the sediment on the walls of the product has reached a critical level.

Fan and wiring

Cooling Fan

One of the most common malfunctions is the fan and its malfunctions.

This is especially true in the summer, when there is not enough natural cooling. Thus, failure of a part can lead to boiling of the liquid. It should also be noted that the connectors of the fan electrical circuit wires may become oxidized, but no power will be supplied to the unit and it will stop working to provide cooling.

You can fix the problem by simply testing the wiring and the product itself. If necessary, it must be replaced. Also, it is worth checking the fan fuse and, which could have blown due to a short circuit.

ECU

List of ECU error codes

The last reason for boiling is worth looking in the electronic control unit, since the cooling temperature sensor could have burned out. If you connect to the “brains”, then everything will become extremely clear and understandable, because on the screen there are problems that need to be eliminated.

Self-diagnosis indicating an error of increased engine temperature (video)

When to change coolant

Not all motorists know what the life cycle of antifreeze is. It is approximately 150 thousand kilometers. In theory, maybe more, but it’s better not to risk it and, for the sake of prevention, change it even more often.

There are several situations that will require you to carry out a mandatory coolant replacement procedure.

- The color of the coolant has changed. The liquid may take on a rusty color. This indicates the need for replacement.

- An oil film has formed on the surface of the cooler.

- Antifreeze often bubbles in the expansion tank of a VAZ 2110. Moreover, there were no prerequisites for such a phenomenon. The Ten is a car for good speeds, because when driving at low speeds, the antifreeze in the expansion tank on the VAZ 2110 often boils. This is because the cooling fan does not turn on.

- A coolant that is no longer suitable for further use may also boil, the composition of which has changed significantly since it was poured into the expansion tank.

- Antifreeze is leaking somewhere from the expansion tank on a VAZ 2110. The situation is common, but it cannot be solved by adding or replacing coolant. It is necessary to find where the antifreeze is leaking from the expansion tank of the VAZ 2110. Usually the leak is found on the clamps, although it would not be a bad idea to check the entire system.

- The coolant level may be normal, during operation it does not emit antifreeze from the expansion tank of the VAZ 2110, the color is normal, but still the boiling process occurs quickly. Most likely, the reason lies in the airlock.