Three main mistakes when installing the timing belt that lead to engine breakdowns

New modern cars are equipped with a timing belt drive, which will require replacement almost every 50-80 thousand kilometers.

If all service work on the engine is carried out with your own hands, then the car owner will invariably be faced with the need to replace the timing belt. Let's talk in more detail about common mistakes when performing such a service. Often car owners do not pay due attention to the condition of the gas distribution mechanism drive or change it without following all the recommendations of the car manufacturer, which ultimately leads to critical engine failures. The fact is that when the belt teeth slip, the pistons hit the valves that are not yet closed, which leads to serious damage to the engine and the need for major repairs. That is why it is necessary to carry out such a procedure in full compliance with all technical aspects, or contact specialized workshops where professionals will charge 10-15 thousand rubles for such work.

The car owner must remember that for such work it is imperative to use high-quality original spare parts. During vehicle operation, the belt and pressure rollers are subject to increased loads, and premature wear of the drive and low-quality spare parts will invariably lead to irreparable consequences. And yet it should be said that the main cause of belt rupture and damage to the rollers is incorrectly performed repair work.

The main reasons that reduce the life of the timing chain. How to determine wear and when to change a chain drive?

Previously, most manufacturers installed internal combustion engines equipped with a timing belt

, the resource of which quite rarely exceeded 90 thousand kilometers.

However, over time, almost all the world's automakers introduced a timing chain

, which, by definition, should not fail during the entire service life of the power unit (on average, 250-350 thousand kilometers, depending depending on the type of internal combustion engine).

We recommend reading the article: “ Signs

indicating

engine camshaft wear

.”

{banner_adsensetext} Indeed, according to auto experts, a power plant equipped with a chain

indicates that the gas distribution mechanism is more reliable, durable and durable.

However, a chain drive

, like

a belt drive

, tends to fail before the time limit regulated by the manufacturer.

Therefore, drivers must always be prepared, since the design of most modern internal combustion engines is designed in such a way that if a gear tooth jumps or a timing drive component breaks, fatal bending of the valves

, after which the car owner will no longer be able to get by with a banal replacement of the gas distribution kit; he will have to prepare for expensive engine overhaul.

How to determine wear and malfunction of the timing chain?

It is worth saying that in contrast to

the timing belt

drive

, which is, as it were, placed outside the power unit, the drive

chain

with

gears

is installed directly inside the engine and is completely invisible under the hood, which on the one hand is an advantage (it makes much less noise during operation and It is better lubricated with oil, due to which it can serve for a long time), and on the other hand, it makes diagnostics and possible replacement much more difficult (without dismantling the valve covers, it is quite difficult to visually determine the current technical condition of an internal combustion engine component).

The main and most significant

of

wear

or

problems in the chain drive is a clear

rumbling sound

that comes from under the valve cover during the operation of a gasoline or diesel engine.

As a rule, the appearance of a rumble indicates a weakening or, worse, stretching of the timing chain

(this sound cannot be confused with anything and is heard precisely from the side where the gas distribution mechanism is located).

For reference, we note that loosening

with a gap of up to 1 centimeter

increases

the risk of

the timing

chain

jumping over

tooth

when starting the power unit by 50-60%.

In addition to the key symptom described above, no less serious hints that directly indicate severe

wear

or

stretching of the timing chain

also include the following symptoms: - The appearance of metallic noise when the power plant is idling, coming from under the hood.

— Excessive engine rattling or vibration at idle speed. Check Engine

indicator appears on the dashboard . — Complete or partial stop of the power plant without the possibility of starting.

{banner_reczagyand}

TOP

-

3 CORRECT REASONS

THAT

REDUCE THE LIFE OF THE TIMING CHAIN 1

.

Chain design defects

: Some vehicles, even new ones, may exhibit alarming symptoms almost immediately after leaving the dealership.

An example is the drives installed on the entire series of cars of one of the largest German car manufacturers (for example, Volkswagen

, which were equipped with

TSI

from 2010 to 2014, suffered from a critical problem associated with rapid wear of the timing chain, as a result of which some models did not even take care of 50-60 thousand kilometers).

According to auto experts, increased wear among owners of new Volkswagen

/

Seat

/

Skoda

arose due to the fact that

the timing chain

vibrated strongly when starting and stopping the engine, and all due to the fact that the manufacturer, the

VAG

, used when assembling the power unit, a defective rack responsible for directing the drive chain.

Thus, using the example of the best-selling brand on the planet,

Volkswagen

, we can see how a small design flaw can lead to very disastrous consequences for car owners.

We also note that before buying a used car with mileage, it is advisable to familiarize yourself with information about the engine, especially the timing

, which is installed in a particular series of internal combustion engines. Thanks to this, you can avoid unplanned stretching or, worse, breakage of the timing gear drive.

2

.

Quality and quantity of motor oil

.

While older car models that were equipped with engines with a timing belt

could cover many tens of thousands of kilometers on oil alone, newer models with chain synchronization require regular lubricant changes (preferably every 8-12 thousand kilometers).

In addition, it must be a high-class oil. Poor oil quality or an incorrectly selected lubricant specification can have an extremely negative impact on the parts of the gas distribution system. In addition, too low

or too

high

oil levels in the power plant can also seriously impair the operation of the engine, especially the

timing

.

3

.

Short distances and high revs

.

A car that constantly travels short distances is much more susceptible to valve timing problems. This is due to the creation of insufficient operating conditions for the power unit. Optimal engine operation is possible when the oil reaches the required temperature and pressure. In a situation where a cold engine operates at high speeds and short distances, its timing drive

wears out much faster.

For reference, we note that in modern cars of popular Japanese (Toyota, Lexus, Mitsubishi, Subaru and others) and German (Mercedes-Benz, Volkswagen, Audi and others) brands, in the vast majority of cases a double-row type drive

chain

, capable of running up to 400- 500 thousand kilometers (even more than the engine itself).

In contrast to German car brands, double-row timing chains

, installed on many popular Korean car models from such famous manufacturers as

Kia

and

Hyundai

, run surprisingly little (quite often there are cases of timing

chains

on children's runs up to 60-90 thousand kilometers ) and this is not even taking into account the appearance of such a serious problem as the formation

of scuffing

in

the cylinders

.

Video

:

“The main reasons

that

reduce the life of the timing chain of a car engine ”

In conclusion, we note that on average, the life of the timing chain drive in modern engines ranges from 150 to 250 thousand kilometers, depending on the make of the car (many Chinese have even less) . As a rule, the final indicator of durability also varies depending on the driver’s driving style, as well as the frequency of replacement and the quality of the engine oil used, poured into the power plant during its interval maintenance (lubrication is necessary to lubricate the links and gears of the gas distribution mechanism). In addition, the durability of the hydraulic timing chain tensioner also depends on the quality of the engine oil.

THANK YOU FOR YOUR ATTENTION

.

SUBSCRIBE TO OUR NEWS

.

SHARE WITH YOUR FRIENDS

.

Incorrect positioning of marks on pulleys

Most gas distribution drive systems have special marks on the gears along which such a belt is aligned. When servicing the engine yourself, it will be necessary to correctly position such marks, since an error of even one tooth will cause problems with ignition. And if you make a mistake by just a few teeth of the gear, then already at the first start of the engine the piston will break the valves. In the future, such an engine will require serious and expensive repairs.

Symptoms of wear

The failure of a circuit can be determined by the following signs:

- You can determine a worn chain element by the condition of the ignition system. If its recent adjustment quickly goes wrong, then you can reasonably suspect that the timing chain is stretched.

- In addition, this is also evidenced by a knocking, metallic grinding sound when the engine is running while driving a car.

- Indirect signs of timing drive wear are overheating of the engine, a decrease in its power, bluish exhaust gases, and loud sounds inside the muffler.

- At idle, the power unit operates intermittently and roughly, making strange sounds.

- Most modern cars have special indicators that signal the slightest malfunction of the gas distribution mechanism. Based on such signals, you can safely change the stretched, worn-out element.

If you ignore such signals, the valves may bend, and in the worst case scenario, the cylinder block will completely fail.

Therefore, during each scheduled inspection of the car, this timing element should be checked. When purchasing a used car, this element should be given sufficient attention.

Incorrect belt tension

Another common problem that is often noted when replacing the timing drive yourself is that the belt is not fully tightened, which leads to its weakening and the likelihood of jumping several teeth. Many car owners are afraid to tighten the belt too much, since, in their opinion, in this case, increased loads are placed on the drive, which leads to its damage. Indeed, an overtightened belt will be subject to increased load, which increases its likelihood of breaking even at runs of up to 50 thousand kilometers. However, an insufficiently tightened belt can also lead to complete engine failure.

Timing Belt Troubleshooting

A damaged drive belt has catastrophic consequences and is a particularly common failure. Let's look at the causes of timing belt failure.

So, most often the element fails due to a break in the straight cord. This may be due to the fact that the belt was broken before installation on the engine. The second reason is the rupture of the twisted cord.

This happens if any foreign body gets between the belt and the camshaft pulley. As a result, it cut deeply into the rubber belt and the cord broke. This can also happen if the installation is incorrect. It happens that this malfunction is caused by carelessness - the camshaft pulley could be rotated with a sharp screwdriver.

Incorrect fixation of the pressure rollers

According to the technology, it is necessary to tighten the timing roller nuts using a special torque wrench. This tool allows you to correctly calculate the force that will be required to fix the rollers and fasten them. Carrying out such work with your own hands, there is a chance to overtighten the nut, which leads to bending of the stud. If the nuts are not tightened enough, this leads to loosening of the gears, the belt begins to dangle, which causes it to break.

To prevent such problems, it is necessary to use a torque wrench when performing such a service yourself, which will also be required when performing various other car repairs. It wouldn’t hurt to purchase such a special tool, especially since its cost today usually does not exceed 500 rubles.

Let's sum it up

If a car owner independently carries out maintenance and repair of the car, he will invariably be faced with the need to replace the timing belt. To perform such work, you will need to purchase not only high-quality pressure rollers and the drive itself, but also a special torque wrench. It is necessary to tighten the roller nuts using such a special tool, correctly tensioning the belt and correctly positioning it along the special marks on the pulleys. This is the only way to perform high-quality maintenance of the car engine, while eliminating the engine wedge and the need for subsequent complex and expensive repairs.

When servicing the motor yourself and changing the timing drive yourself, you need to accurately align the belt to the marks, tighten the roller nuts using a torque wrench and install the belt correctly.

Source

Timing belt repair and maintenance

The main problem with this mechanism is worn journals, cams and increased clearance in the bearings. To reduce the gap, grinding of the camshaft journals is necessary. At the same time, the grooves for oil supply are also deepened. The necks are ground to repair size. Next, after repair, check the height of the cams.

There should not be even minimal damage on the supporting parts under the necks. There should be no cracks in the bearing housings. After cleaning and washing the camshaft, be sure to check the gap between the journals and the hole in the cylinder head support.

The chain should not be stretched or have mechanical damage. As long as it is not worn out, it can be adjusted. Unscrew the locking bolt half a turn. Then turn the crankshaft 2 turns and then tighten the locking bolt.

What is a timing belt for?

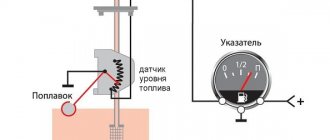

The timing belt is a rather complex unit in terms of design. It is based on a camshaft located in the cylinder head. With its help, the intake and exhaust valves are pushed. The valves, in turn, ensure the supply of a combustible mixture to the engine cylinders, and also help remove gases from the vehicle system. The operation of the camshaft is possible due to the presence of a crankshaft in the system. Thus, the mechanical force from the second to the first is transmitted using a drive belt.

A malfunction of the camshaft drive will disrupt the gas exchange process in the cylinders. The engine will not be able to function normally, and this is fraught with serious consequences for the main power unit

The belt is subject to temperature and mechanical influences; it is logical that sooner or later it will wear out. It stretches and cracks form on its surface, which negatively affects the operation of the entire system. Its slippage will affect the functioning of the valves: they will stop opening at the moment corresponding to the engine operating cycles. But the breakage of a rubber product is much more dangerous. During a break, the gas distribution mechanism remains inactive, therefore, the valves do not close until the piston rises, an impact occurs, after which the valves themselves bend, and defects form on the piston.

Timing device

To begin with, let us briefly recall how these mechanisms work. On most engine models, the gas distribution mechanism consists of the following components and parts.

So, the valves are controlled by the camshaft. Most often it is made of steel or cast iron. It is installed in the crankcase. This crankcase is covered by the timing cover. Also on modern engines, the camshaft can be found in the cylinder head. When the shaft rotates, it acts on the cams, which, in turn, act on their valve.

The design also includes pushers - they can be steel or cast iron. Their function is to transmit force from the camshaft and cams to the valves.

The mechanism has two valves - inlet and outlet. Their task is to supply the fuel mixture to the combustion chamber and then remove the exhaust gases. The valve is a rod with a flat head. The inlet and outlet elements are different from each other. The difference concerns the diameter of the head or plate. These timing elements are made of steel and heat-resistant steel (in the case of exhaust valves). The leg is a rod with a groove. It is needed to secure the springs. The valves can only move towards the bushings. To prevent oil from getting into the cylinders, sealing caps are used. An external as well as an internal spring is attached to each of the valves. Rods in the timing device are necessary to transmit force from the pushers to the rocker arm.

The camshaft rotates due to the drive. It can be chain or belt. The drive transmits rotation from the crankshaft. The distributor makes one revolution per two revolutions of the crankshaft - this is the operating cycle of the engine.

Why and when you need to change the timing belt

As is clear, the timing base is the camshaft, which is located in the cylinder head and pushes the intake/exhaust valves. The camshaft is driven from the crankshaft by a drive belt. Timely opening and closing of valves must be carried out in a strictly established order and in accordance with the engine operating cycles.

In other words, during the intake stroke the intake valve must open, so air or a fuel-air mixture (depending on the type of engine) enters the cylinders. Next, the consistency is compressed (the piston moves to TDC), at this moment all valves are closed. After the fuel charge is ignited and useful energy is released to the piston, the exhaust valve opens to remove exhaust gases from the engine cylinder. This is how the gas distribution process is carried out.

We recommend: How to drain the coolant and flush the engine cooling system on a VAZ 2114

It becomes clear that any malfunction of the camshaft drive will lead to disruption of gas exchange in the cylinders, as a result of which the operation of the engine will be disrupted. As for the timing belt, this element is a rubber product that stretches, cracks, etc. over time. Belt slippage causes the valves to stop opening at the correct moment in relation to the engine operating cycles. Moreover, for many engines, a broken timing belt is especially dangerous. The fact is that if the belt breaks, then the gas distribution mechanism stops, the valves simply do not have time to close before the piston rises, an impact occurs, after which the valve usually bends, defects appear on the piston itself, etc. In such cases, the power unit needs to be repaired, and the repair itself will require significant financial expenses.

You should also take into account a number of reasons that can significantly reduce the service life of any belt. For example, engine oil getting on the timing belt as a result of leaks in the crankshaft front oil seal can quickly render the designated camshaft drive element unusable. Problems with the tension roller, jamming of the pump and other malfunctions are the reasons why the belt breaks or wears out quickly.

If signs of wear on the timing belt are noticeable or the time for its scheduled replacement is approaching, then it is not much to simply install a new element. When replacing, the belt should be set correctly. To replace and expose, you need to prepare tools; it is also better to service the car on a lift or in a garage with an inspection pit. The smallest set for this operation can be considered a jack, screwdrivers, spanners and socket wrenches, a socket wrench, preferably a wrench with a socket head, etc.

The car does not start after replacing the timing belt, timing chain or carrying out other work on the gas distribution mechanism drive. Main prerequisites, advice.

The timing belt has broken: what to do, reasons, signs

Car owners know about such a malfunction as a broken timing belt. For newbies behind the wheel, this topic is a kind of horror story. Quite often, after a broken belt, a car requires serious engine repairs. This article describes the main causes of breakdowns, describes what to do in such a situation, and also how to prevent breakdowns from occurring.

What happens to the engine when the belt breaks?

When the car is running, the engine pistons move in a certain direction. The piston moves down during the intake stroke and rises during the exhaust stroke. When the cylinder block is at the top point, each valve must be closed.

When the timing belt is torn, the valve stops rotating and stops. However, the crankshaft rotates and the pistons are directed towards the open valves. After their meeting, the parts bend and become unusable. Regardless of whether the car is idling or in gear, the likelihood that the pistons will knock on the valves and bend them is quite high.

But still, the higher the speed, the worse the likely consequences. In addition to the fact that the valves will be damaged, the pistons may be damaged and the guide bushings may burst.

If the timing belt breaks at high speeds, then all the valves will be damaged, and fragments of the bushings will pierce the pistons. Repairing the mechanism after such damage will be very difficult and expensive. In some engines it is easier to replace the entire head after this.

What to do if the timing belt breaks while the car is moving

If the timing belt breaks while driving, do not panic.

If a break occurs, the car's engine will stop working or start turning too easily. You need to pull over to the side of the road and put up a warning triangle.

First actions in case of timing belt breakage

- Open the hood and assess the situation.

- If you see a torn belt, immediately call the service station.

- To avoid part breakage, it is necessary to replace it in a timely manner. The car can be towed to a car service center or a tow truck can be called.

If it turns out that you don’t have a spare belt, you shouldn’t try to “fix” it; nothing good will come of it. On some engines, if you have experience, you can replace the belt on site, having a spare set on hand. But we recommend contacting the service.

The cost of replacing a belt depends on the car model and its production date. The approximate price range is from one thousand to ten thousand rubles. To avoid having to spend extra money and your time, carry out timely replacement and routine inspection of timing belts.

To avoid having to repair your car, you must follow a number of rules:

- Read the operating instructions and follow them.

- Periodically check the serviceability of the timing belt.

- Buy a spare part and always carry it with you.

- Write down the phone number of the service station.

On which engines do valves bend?

If the timing belt breaks, the consequences can be different. Some will get away with an easy replacement of the necessary part, while others will require complex repairs.

When the timing belt breaks, the valves will suffer the main losses. After a break, the upper shaft stops working and the valves freeze in one position. At this moment, the crankshaft pushes the piston up, and it exerts a mechanical force on the parts. The valves are bent. This leads to very expensive repairs.

And also quite serious consequences after a belt break occur in diesel engines. This is due to the design of the mechanism; after one part breaks, a chain reaction is started, which causes irreparable damage to the remaining elements: the camshaft, bearings, pushers, etc.

Sometimes a broken belt leads to a broken camshaft or deformation of the top of the piston. After this, you will have to disassemble the engine, replace valves, etc. In some cases, such repairs will cost about thirty thousand rubles or more. And when the pistons need to be replaced, the amount increases even more.

Not all cars will need complex repairs. Some piston models have special recesses and when the belt breaks, the piston rises, but the valve remains motionless, the piston falls into the “hole”, the valve is not deformed. The driver just needs to install a new belt and the engine will start working.

Not all mechanisms are equipped with such recesses, as they reduce engine power. And manufacturers of famous brands are fighting for it as best they can.

The conclusion is simple: replace parts in a timely manner and no troubles will arise.

How to understand that the timing belt has broken

Inexperienced drivers will not always be able to independently determine what kind of breakdown has occurred in the car.

Signs of a broken timing belt:

- The car has stalled and the engine will not start. The compression is broken and the car will not start. Inexperienced drivers try to prevent the engine from starting and drain the battery. Such actions only worsen the situation. The piston causes mechanical stress to the bent valve, and when trying to start the engine, the damage becomes even greater.

- The engine turns very easily. This is due to the fact that there is no compression and nothing holds the pistons.

If you open the hood, in some car models you can see pieces of the timing belt. Let us note that it is important to timely replace the entire timing system, including belts, pumps, rollers, etc. By observing these requirements, the engine mechanism of your car will last a long time.

Why does the belt break?

The main reason why a belt breaks is due to the careless attitude of the car owner. It's all about untimely replacement of a worn part. The average belt replacement interval is sixty thousand kilometers. The first time drivers change a part at a service station, and then they simply forget about this event.

There are a number of main reasons why a belt may break:

Quality of spare parts

The quality of spare parts depends on the brand of timing belt manufacturer. You should not skimp on such details. For the middle price segment, belts from the following brands have become very popular: Balakovo, Bosch, Lemforder. More expensive - Gates, Contitech, Dayco. To avoid any troubles during operation of the part, carefully select parts. The roller jams or releases spontaneously.

Incorrect belt installation

Quite often, a break occurs after 1000-2000 km. after the previous replacement. The main reason is insufficient or excessive tightening. It is best to carry out such work from trusted professionals, and also check the condition of the car after the work. Listen to see if the sound the engine makes has changed. Check to see if the belt has slipped or cracked.

Broken tension rollers

Tension rollers are designed to tension the timing belt. They prevent parts from jumping off and slipping. A roller is a kind of bearing with a special coating. All parts have their own service life. A worn roller is noisy and if you do not replace it, it will ruin the timing belt in a short period of time.

Pump wedge

Most often, cars from Russian manufacturers are susceptible to such breakdowns. This is a rare occurrence in foreign cars. If the pump jams, the belt breaks and requires replacement.

Late replacement

Aging and wear of the part is one of the most common causes of rupture. According to average indicators, belt breakage occurs after sixty thousand kilometers. In foreign-made cars, this figure can reach one hundred and fifty thousand kilometers. But everything has its limit. During use, the part wears out and becomes unusable. Belt wear is the most common cause of component damage. In Russian cars, the service life of the belt may be even lower than described above, so when buying a used car, it is better to immediately replace the timing belt.

Foreign elements

Sometimes oil and dirt can get on the part and jam the distributor or crankshaft. Be sure to check the protective cover and fasteners. If necessary, replace.

Please note that if the car operates in difficult conditions (frequent short trips, cold seasons, insufficient engine warming up), then the timing of replacing the timing belt is reduced.

Consequences of timing belt breakage and likely costs

The consequences of a break depend on the type of engine, the presence of grooves on the pistons, the quality of the parts and the reasons for the timing belt break.

The most common consequences:

- Buying and replacing a belt

- Engine repair.

Read more about possible engine problems

- Overhaul of the entire engine.

- The need to repair the entire gas distribution mechanism. The most significant problem is bent engine valves that cannot be repaired. This problem most often affects cars in which the combustion chamber is reduced or the pistons do not have recesses. In order to accurately determine the level of damage, you need to take the car to specialists.

- Sections of the piston system are deformed. Such damage most often occurs in Japanese cars. When the blade breaks at high speed, the bushing breaks and the pistons are damaged by the fragments. The consequences are an expensive replacement of all parts.

Diesel engines suffer serious consequences after the fabric breaks.

Car owners will need to replace a number of main parts of the gas distribution mechanism:

- Camshaft.

- Cylinder head.

- Connecting rods.

- Valves.

Costs for eliminating the results of timing belt rupture

The average cost of a valve is about one thousand rubles (excluding replacement). To calculate the total cost, you need to take into account the number of valves that need to be replaced. If there are sixteen of them, the total cost will be high.

Additionally you need to buy small parts:

- Timing belt or complete timing gear kit with all bearings.

- Cylinder head gaskets and manifolds.

- Valve plugs.

- Fasteners.

- Pump (all belt manufacturers recommend changing the pump at the same time as the timing belt)

If the driver carries out car repairs himself, he will also need various tools

Preventive measures

To avoid problems with the operation of the timing belt, it is necessary to periodically replace it. It is best to buy original spare parts, not to wait until the blade is completely worn out.

Periodically (every 30 thousand km) check the condition of the belt to prevent breakage, monitor the belt tension level, the condition of the pump and tensioners.

When is it necessary to replace the timing belt and set the marks?

Without exaggeration, a worn timing belt can be called a “ticking time bomb.” The importance of this element in the car system is difficult to overestimate. Usually it is made of high-quality rubber, the service life of which is designed for 50-60 thousand kilometers. But, if the vehicle is operated in unfavorable conditions, the replacement interval will be different.

Replacing a belt and pump is a labor- and financially expensive process. But all the work will cost much less than repairing a failed engine due to a broken gear mechanism. In no case should you save money and put off scheduled car maintenance “for later.”

In most cases, the replacement interval is indicated by the manufacturer in the documentation for the vehicle. In addition to the resource built into the belt, it is worth considering the following factors that shorten the service life of the rubber element:

- Engine oil getting on the surface of the timing belt

- Leakage of the front crankshaft oil seal

- Tension roller malfunction

- Pump jamming

As you can see, there can be a sufficient number of breakdowns in the car system that directly affect the service life of the belt. If the scheduled replacement time has come, or its resource has been prematurely exhausted, it is not enough to simply replace the old mechanism with a new one - you also need to take care of the correct installation. To successfully do all the work, it is enough to arm yourself with the necessary tools and know how to align the belt with the marks.

Belt edge wear

If the belt is visually very worn on one of the edges, then there may be damage to the flange or wear. In this case, it must definitely be changed.

For a long time it was believed that a chain was much more reliable than a belt drive. And this is true, but the chain is far from immortal. Timing chain malfunctions also occur. If the belt breaks, then there is, albeit a small, chance to save the engine. In the case of an open circuit, the situation can be much worse. The chain is more massive than the belt, and if it breaks, it literally grinds the engine. Severe damage to valves and pistons occurs. In general, there is only one fault with the chain - it breaks.

Among the reasons include the quality of the oil. The chain's lifespan is 250 thousand kilometers, but they rarely run for that long. There are widely known cases when the chain in the engine broke after a mileage of 100, as well as 60 thousand kilometers. But this is more often a factory defect in specific cars. Often problems are associated not only with oil, but also with engineers’ mistakes.

How to correctly set marks during the process of replacing/installing a belt on a “nine”

The timing belt on cars with front-wheel drive is carried out using a toothed belt. Each successive replacement of the AvtoVAZ belt is recommended after 65,000 miles. In addition to replacing the element itself, it is also recommended to change the roller.

The algorithm for replacing the timing belt is as follows:

- First of all, a new belt and roller are purchased (it is advisable that both elements are recommended by the car manufacturer);

- The car is placed on a level surface;

- The battery is de-energized (due to the exception of a short circuit during the work process);

- The car is secured with special anti-rollback stops;

- The protective cover is removed from the timing system;

- The power unit is set according to the marks.

What's the result?

In relation to internal combustion engines with a timing belt drive, it should be taken into account that slippage of the belt even by one “tooth” can lead to malfunctions of the power unit or its breakdown. As mentioned above, if the belt breaks, there is a risk of bending the valves. As for diesel engines, a broken timing belt can render the camshaft unusable.

As a result, I would like to add that when replacing a timing belt, aligning it to the marks is the main task. In this case, if you are not convinced of your own abilities or have problems identifying the marks, then it is better to give up trying to set the belt on your own and turn to experienced specialists.

>

We set the timing belt ourselves

The process of setting tags yourself is not that complicated, but it does require some in-depth knowledge. Among other things, it is periodically necessary to check the position of the shafts, since they tend to change their location relative to other timing elements for various reasons. In the following two situations, you have to set marks almost every time:

- During a complete timing belt replacement: the shafts will need to be set in the correct position, otherwise engine operation will be impossible

- During repair of the gas distribution mechanism, adjustment of their position is also required

It should also be taken into account that on cars with a sports camshaft, the principle of setting the drive belt may be completely different. To know exactly how to do all the work on sports or tuned cars, it is best to familiarize yourself with the detailed information provided in the instructions for a specific power unit.

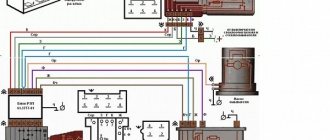

Having all the necessary tools in hand, you can proceed directly to the main work. All work comes down to the following steps:

- Removing the battery

- Jack up the right front wheel

- Then we find the camshaft and crankshaft

- Then you need to find a risk on the shaft pulley

- Find the mark on the engine block

- Align the two marks by turning the wheel

- Rotate the wheel until the two marks completely coincide

How to replace a timing chain with your own hands

To replace the timing chain, you will need a standard set of socket wrenches, as well as a “gas” wrench, which can be used to conveniently unscrew the crankshaft pulley. In addition, you may need a slotted screwdriver, a hammer, pliers, and a flashlight. For ease of operation, it is recommended to remove the radiator grille and the radiator itself, after draining the antifreeze from the system, and dismantling the valve cover.

Article on the topic: What category of license is needed for an ATV

A complete chain replacement kit includes not only the chain itself, but also shaft sprockets, engine front cover gasket, and mounting bolts. At the same time, you can refuse to replace sprockets if the old parts are in good condition.

Replacing the timing chain begins with removing the front engine cover. We should not forget that in addition to the 9 front bolts, it is secured with three bolts, accessible from below. After this, the camshaft is turned so that the mark on it is opposite the protrusion in the upper part of the camshaft “bed”. Turning must be done clockwise.

Note: the force required to turn the shaft will be less if you first unscrew the spark plugs.

After this, you need to unscrew the chain tensioner bolt, loosen the generator fastenings and remove its drive belt. Next, the car is put in first gear, secured with a parking brake and additional “heels” for the wheels. Instead of the latter, you can use stones, bricks and other available materials.

Having secured the machine, bend the cotter pins on the pulley nuts and unscrew them using keys of the appropriate size. By removing the nuts, you can easily remove the chain that has become slack after dismantling the tensioner and, if necessary, the sprockets.

Reassembly is carried out according to the following algorithm:

- Tensioner shoe (if necessary, the VAZ-2107 chain tensioner is replaced, the example of which is discussed in the procedure);

- Tranquilizer;

- A crankshaft pulley with a chain loop thrown over it. When installing, check that the pulley mark matches the long mark on the block;

- Oil pump gear;

- Camshaft pulley with the drive attached in the position corresponding to TDC of the 1st cylinder (at the tide on the valve cover).

Article on the topic: Polish for car body from scratches

After this, the chain is tensioned using the tensioner bolt. The latter is loosened, the motor is turned two turns and tightened again. You can check the tension manually. A well-tensioned chain does not bend under finger pressure by more than 5-10 mm. After tensioning the drive, you need to check the marks again. It happens that they shift during the installation of the chain. After replacing the timing chain, further assembly is carried out in the exact reverse sequence.

Note: an alternative way to replace the chain is possible. The old and new chains are separated and fastened together, after which the new section is pulled along the pulleys. Next, the old chain is removed, and the new one is riveted in place. The disadvantage of this method is that the factory strength of the chain drive is compromised.

Another domestic car with a timing chain drive is the Chevrolet Niva. In terms of the chain replacement procedure, the Niva differs somewhat from the “classic” models. Here, to gain access to the drive, you must dismantle the hydraulic chain tensioner, the crankshaft position sensor, and remove some of the cooling system pipes. Otherwise, the manipulation is carried out in the same way as on a Zhiguli car.

Have the cams turned on the camshaft, or is this a scam for money?

“Is it possible to turn the cams on the camshafts when the timing belt slips in a 1.7 Isuzu diesel engine, 16 valves? The belt slipped when they tried to start the car with a tow. The repairmen said that the impact on the valves caused the cams on the camshaft to rotate. The car was driving at low speed, so was the impact really so strong that the cams turned? It is alarming that the repairmen, by “lucky” chance, had camshafts from the same engine. They offer to supply them instead of mine. Could this be the case, or do they just want to scam me?”

The repair specialists we interviewed for Opel cars, which were equipped with 1.7-liter Isuzu diesel engines, encountered various consequences of the timing belt slipping or breaking in the specified engine.

Even if the car was driving at low speed, it happened that the force of the pistons hitting the valves was enough not only to break the rocker arms, bend the valves, but also to break off their plates, as well as damage the pistons and even break the camshafts, their supports and bed.

The problem is aggravated by the fact that they tried to start the car from a tow. After the belt breaks and the moving piston further collides with the valve that has stopped and therefore does not have time to hide in the seat, the crankshaft, as a rule, also stops and the engine stalls. But when the belt slipped, while the car was being towed with the gear engaged, the crankshaft and camshaft continued to rotate, and the pistons continued to move and hit the valves. There were most likely several impacts until the driver of the towed car pressed the clutch pedal and turned off the gear.

However, the repairmen did not remember a single fact when, as a result of the timing belt slipping or breaking in a 1.7 diesel engine, the cams turned on the camshaft. We do not rule out that similar facts will emerge when discussing the question asked of us on the ABW.BY forum, but for now we have to rely on the experience and practice of our consultants.

This raises the question: did the repairmen to whom he contacted correctly convey to the owner of the car the essence of what had happened, and also did he correctly understand what he heard from them, and then put it in his letter? It happens that, for the sake of clarity, repairmen resort to incorrect terms and comparisons that can be misinterpreted.

Nevertheless, be that as it may, I would like the repairmen to justify their conclusion more strongly than with just a verbal explanation. What prevents them, in the presence of other camshafts from the same engine, from clearly showing the owner how the standard camshafts became different from them after the impact, what exactly was wrong with them as it should be? If the repairmen themselves are somehow convinced of this, then let them now convincingly visually or by measuring the position of the cams prove to the owner the need for replacement. Otherwise, there is grounds for suspicion that people who repair engines, in addition to the desire to do their job, are driven by additional motives and material interests.

Sergey BOYARSKIKH Photos by the author and from open sources are for illustrative purposes ABW.BY

You have questions? We have the answers. Topics that interest you will be expertly commented on by either specialists or our authors - you will see the results on the website abw.by. Leave questions on the forum or use the “Write to the Editor” button

How to set timing marks on the crankshaft and camshaft

On many domestic cars, in particular VAZ, this procedure predetermines the following actions:

- Remove the old belt and install a new tension roller

- Rotate the camshaft pulley until its mark matches the mark on the cylinder block

- We turn the crankshaft to the level when the mark on the pulley is positioned strictly vertically

- You can verify the correct installation through a special window with a plug in the clutch housing

- Pull out the plug and see if the mark on the flywheel is located opposite the cylinder block strip or not? If yes, then the work can be considered completed

If everything was done correctly, first put the timing belt on the crankshaft pulley, and then on the camshaft pulley. It is also worth saying that the location of the shafts does not depend on the type of gas distributor. Therefore, the procedure for replacing the timing chain is largely identical.

Labeling

Before starting work, you need to understand that it is important that during the process of replacing the timing belt, the pre-set risks do not go astray. Otherwise, you will have to go deeper into the settings and spend more than one hour installing the part.

When installing the timing belt, it is important to align the pistons so that in the first cylinder the piston is at the highest point of the first cylinder. In this position, the piston is at its maximum distance from the crankshaft. This is the position the engine is in when the marks are correctly set. In this position it is necessary to change the timing belt.

The number of marks, as well as their location, may vary depending on your engine type.

The following marks can be distinguished:

- Mark on the flywheel.

- Mark on the pulley.

- Camshaft mark (two on a 16 valve engine).

Phased mitigation

Setting up tags

To avoid such situations when the car does not pull after replacing the timing belt, it is necessary to immediately correctly align the crankshaft and timing pulleys according to the marks.

Let's consider the process using the example of a domestic VAZ car with a 16-valve engine.

The marks on the pulleys are aligned

- The photo below shows a diagram of placing marks on the disks of the distribution and crank pulleys. As shown in the diagram, points A, B, D and E must be aligned. In addition, points C and F on the discs and element guard should be aligned. In the case of the VAZ engine, they are marked and clearly visible, so they cannot be confused.

- To control the position of the crank pulley, the plug on the gearbox should be removed. This plug is located under the coolant temperature control device (thermostat). Once you do this, you will be able to see the flywheel. If, after changing the timing component, you immediately set all the marks correctly, then by looking through the hole, you will also be able to see a mark on the flywheel and a cut in the metal protection.

- If you did not align the marks during replacement, then you will have to find this mark on the flywheel. To do this, you will turn the flywheel. If the car is relatively new, then finding the mark will be problematic. In addition, on old VAZ engines the flywheel may be slightly deformed or “beaten”, so there may be several such marks. But the one you need will stand out from the rest. The marks on the crank pulley disk and the oil pump must be aligned.

- In general, when setting marks after replacing the timing belt, you need to make sure that they match on the shaft and oil pump, on the metal protection and the flywheel. When all the marks are set correctly, the flywheel will need to be secured. You can insert a screwdriver into the box so that the flywheel remains in place and cannot turn. When the job is done, you can begin installing and tensioning the timing belt.

Aligning the belt according to the marks and how to set the timing belt without marks

Let's start with the fact that below we will focus on the general rules and instructions regarding how to set the timing belt. With all this, it should be taken into account that on cars with tuned sports camshafts, as well as on some models with 2 or only one camshaft, the order and features of the drive belt alignment may differ. To obtain clearer information, it is better to consult with specialists or separately study the operating instructions for a specific internal combustion engine model.

The timing belt jumped a tooth. Symptoms and consequences. VAZ 8 class.

In our case, the teeth on the belt are cut and the timing is off.

Before work, you should keep in mind that the main task will be to ensure that the previously set marks do not get lost during the replacement. This will help simplify the process because there will be no need for advanced configuration ahead.

- So, when installing a new timing belt, the most important step is to set the position of the pistons in the engine so that in the first cylinder the piston will be at top dead center (TDC). Then the marks are checked. Let us add that you can set the pistons to the required position using one of the available methods. The easiest way is to find a special notch on the pulley, as well as an arrow located on the timing belt casing. The indicated notch and arrow should be combined with each other. Alignment implies a position where the notch is in a vertical position and the arrow is pointing down.

- The second method, which complements the first, is to detect a special mark on the flywheel, after which the marked mark is aligned with the “tooth”. The mark is located in the control window, which is located in the upper part of the gearbox bell.

- The third and most unreliable method of aligning the pistons is to unscrew the spark plug in the first cylinder, after which a suitable screwdriver or a metal rod of suitable length is inserted into the spark plug hole. Then the rod rests against the piston, after which, as a result of turning the crankshaft, the point at which the piston is in the last upper position is determined. Please note that a similar method should only be used in this case if labeling is not feasible for some reason.

Let's imagine that the mark has moved backward in relation to the camshaft sprocket. In this situation, the mark is aligned with the upper left edge of the valve cover gasket. If the mark has moved forward and is marked “from”, then the marked mark is aligned with the arrow located behind the camshaft sprocket. In the case when the camshaft mark is shifted by 180 degrees or so, then the crankshaft rotates one revolution.

We also note that in the process of setting TDC in the first cylinder, it is recommended to remove the distributor cover. This is necessary in order to control the placement of the notch on the distributor body. The notch should coincide with the center of the slider. To detect the notch, the plastic casing covering the Hall sensor is raised slightly. When all the marks listed above match, this means that you can install a new timing belt. Let us add that before installation, many also fix the flywheel by inserting a screwdriver into the hole in the box. After which you can install the belt and rollers.

How to tension the timing belt?

If tensioning of the rubber element is required, then simply insert a special key or screwdriver into the tension roller. If in the longest section the key turns 90 degrees, then the tension is normal. The inability of the key to turn will indicate that the tension is too strong, which means it needs to be loosened a little. The nut in the tension roller is loosened, after which the tension level is checked again. Evidence of a low tension level will be the ability to turn the key idle.

Repair cost

The average price for replacing a belt and roller in car services ranges from one to three thousand rubles. The price range is due to the fact that replacing parts on foreign cars costs approximately 2–3 times more than on domestic cars.

If it turns out that you also need to change the engine water cooling pump and the crankshaft oil seal, then the price will increase by another 1 - 1.5 thousand rubles.

Although there is a huge selection of products on the market at different price levels, you should only choose brands recommended by the manufacturer or their high-quality analogues. Using cheap parts can lead to serious damage and expensive repairs.

It's all about the oil

The approximate resource of a modern chain is at least 200-250 thousand km. However, it often does not last that long. There are widely known cases of chain breaks after a mileage of 100,000 km, and even 60,000 km. The fact that this only occurs with certain car models suggests a birth defect. Moreover, a “disaster” does not always occur due to poor-quality manufacturing of the chain and tensioner. Sometimes the problem is caused by a lack of lubrication. This happened with the first Peugeot-Citroen 1.6 THP gasoline engines (Euro 4) and the BMW 2-liter diesel engine (BMW 3 E90, 320d N47).

Thus, failure to comply with the manufacturer’s recommendations regarding the amount, type of oil and replacement intervals greatly increases the likelihood of a malfunction. Do not forget that almost every chain is held in tension by a tensioner, the effectiveness of which directly depends on the pressure in the lubrication system. A typical example is the Fiat 1.3 Multijet turbodiesel, which is used in Opel models with 1.3 CDTI. With frequent movements in urban environments, the oil level drops significantly. If this is not noticed in time, then the pressure in the system begins to decrease, and, consequently, the chain tension.

But, of course, it cannot be done without errors in the design of the design of the chains and tensioners themselves. A striking example is the VW 1.4 TSI and 1.2 TSI gasoline engines.

What happens if you set the tags incorrectly?

The consequences of a job done incorrectly can range from minor to significant. It is for this reason that it is important to approach all work responsibly. If you don’t have the proper attitude or self-confidence, entrust the work to a professional auto mechanic. Depending on the brand of the car, the following troubles may arise during the operation of the car:

- Misaligned phases often cause valve burnout

- Valve bends on some VAZ family cars

- Possible deformation of the cylinder head, failure of the guide bushings, and the formation of cracks inside the elements

- Remaining oil on spark plugs

The above consequences of incorrect label installation are observed in most cases. But, for example, on an 8-valve VAZ-2114 engine, the valves do not bend or bend even in the most severe cases. But the 16-valve power unit of the “fourteenth” does not have such advantages, so a major overhaul of the engine may be required.

Source

Compression reduction

One of the symptoms of malfunctions is a decrease in engine compression and popping noises in the exhaust pipe. This happens after carbon deposits and shells form on the valve. Often the element may burn out. The cause of the burnout lies in the loose fit of the intake and exhaust valves to their seats. Other factors also influence the reduction in compression. These are deformation of the cylinder head, broken or worn springs, jamming of the rod in the bushing, lack of space between the valve and the rocker arm.