Why is a simplified charge recovery scheme used?

Dismantling a standard battery does not cause difficulties the first time you perform such a procedure. Remove the key from the ignition switch. Remove the protective cover and release the screw fastenings with fastening strips. The “negative” terminal is removed first to prevent breakdown to the housing and voltage surges.

But even careful implementation of standard rules cannot eliminate problems. In electronics, the state of factory and user data is stored in read-only memory units. The functionality of some microcircuits is provided by power supplies built into the board, the health of which is not monitored in any way.

Switching fluctuations can also have a negative impact on the recorded information. Errors appear as follows:

- settings for audio and video equipment, climate systems, and the position of an electric chair disappear;

- the performance of power windows and other electric drives is impaired;

- it is difficult to start the engine.

Fewer problems arise with a security alarm that is connected to an autonomous power system. However, complete blocking of the on-board computer is possible. For restoration procedures you will have to visit a service center. The noted facts explain the popularity of charging the battery without removing the terminals.

In what cases is it necessary to charge the battery without removing the terminals?

If the car is equipped with volatile electronic devices, even a short-term power outage can cause important settings to be reset, which car owners try to avoid. Another unpleasant consequence of a power outage is the activation of the device’s security lock.

If removing the protection by entering digital codes does not take much time (provided that the driver remembers these codes), then you will have to tinker with restoring the settings.

But the worst thing that can happen when removing the battery is resetting the data in the ECU memory. For example, about daily mileage and fuel consumption, which will affect other related parameters (maintenance period, etc.). When using additional equipment, restoring settings may require contacting the manufacturer's website or service center, which means a large loss of time. Finally, careless or incorrect removal or reattachment of terminals can lead to a voltage surge with very unpleasant consequences for the electronic equipment, especially the powertrain controller. Such a failure will require flashing or, even worse, replacing an expensive unit.

Features of operation

Manufacturers advise checking the battery voltage at the output terminals every 3-4 months and more often in winter. It should be remembered that the charge decreases relatively quickly when the air temperature drops below zero. Careless users do not perform control operations, hoping for the efficient operation of the car generator.

This approach is wrong. In normal mode, the car power supply is limited to 14±0.1V at any engine speed. This protection is necessary to comply with safety regulations. It prevents the formation of explosive hydrogen and other gases. Meanwhile, to replenish to the maximum rated capacity, it is necessary to increase the voltage to 14.6±0.1V.

Charging the battery without errors: pros and cons of two methods

The first really safe way is to use an additional DC power supply. The “standby” battery is connected in parallel using wires of a suitable cross-section. Choose a model with sufficient capacity to maintain a voltage of 12V throughout the entire procedure. It is advisable to use rigid clamping, which prevents sparking or accidental breaking of the circuit.

After this, you can disconnect the main battery and remove it to replenish the charge. The main disadvantage is the need to purchase an additional battery. You will have to maintain it in good technical condition, which increases overall costs and the list of responsibilities.

To charge without removing it from the car, use the following algorithm:

- put the car in the garage to exclude negative weather influences;

- in the cold season, it is necessary to wait until the formation of condensation on metal surfaces stops;

- remove the key from the ignition switch, turn off the radio and other consuming devices;

- remove the protective casing, unscrew the plugs to allow gases to escape;

- connect the positive and negative terminals in series (red and black color designation, respectively);

- connect the charger to a 220V network;

- set the switches to the desired mode, taking into account the type of battery, output voltage and charging current;

- if there is a timer, select a time interval for automatic shutdown (55 Ah from 7 to 9 hours);

- Disconnect the terminals in reverse order and continue normal operation.

What is the problem?

Or why charge the battery without removing it from the car? Monitoring forums, autoblogs, stories from friends and acquaintances and, perhaps, even personal experience, allows us to identify the following pattern: when the battery is disconnected, all settings and settings of the on-board computer, multimedia system and other devices connected to the network are lost. Of course, you want to avoid lengthy reconfigurations of all electronics, which are abundant in a modern car.

In the opposite situation, there is a risk of equipment failure. On the one hand, the loss does not seem critical if we are talking about a radio or a clock; on the other hand, new cars can be equipped with rather expensive electronic devices, the performance of which, in addition, can be fundamental for the normal functioning of all car systems.

Different charging methods, routine maintenance

Several technologies are used to restore battery functionality. When charging with direct current, a time schedule is used with a gradual decrease in strength from 5.5 to 1.25 A. The process is fast and has good results - up to 100% of the initial charge.

Attention! Active charging must be carefully controlled to avoid creating a dangerous situation.

In everyday life, it is more convenient to use equipment that maintains constant voltage. The current strength in the charging circuit is checked by a built-in device. When it drops to 190-210 mA, the 220V power supply is automatically turned off. Leveling up speeds up the process:

| 24 hour 12 V battery charging in different modes | |

| Terminal voltage, volts | Degree of capacity recovery in % |

| 14-14,5 | 75-80 |

| 15-15,5 | 85-90 |

| 16 | 95-100 |

Sometimes urgent capacity restoration is necessary. In such a situation, a charger with a special Boost mode or with adjustable current will come in handy. Set the maximum value, which should not exceed the nominal value by more than 25-30%. If the technical data sheet indicates 4A, set to 5.2A. Exceeding the threshold will accelerate electrolysis with the possible formation of defects on the surface of the metal plates. This method will accumulate a charge in 15-20 minutes, which is enough to start the engine.

Important! Frequent use of the accelerated mode reduces the battery life.

Along with charging, they check the condition of fasteners and wiring, the operation of the generator and devices for automatically maintaining normal voltage in the on-board network. In serviced batteries, the fluid level in all banks is checked (at least 10-12 mm above the plates). Removes traces of corrosion and dirt. Using a hydrometer, the density of the electrolyte is monitored.

Check numbers for a typical 12V battery are given in the table:

| Electrolyte density at +15°C in grams per cm3. | Freezing point of the solution, °C | Voltage at battery terminals with load (without it), V | Battery charge level, % |

| 1,12 | -8 | 8,5 (11,8) | 6 |

| 1,16 | -14 | 9,15 (12) | 31 |

| 1,19 | -24 | 9,6 (12,19) | 50 |

| 1,27 | -60 | 10,8 (12,66) | 100 |

Charging the battery not from the car is carried out using similar circuits. It is necessary to make corrections taking into account the rated voltage, capacitance, and design features. Maintenance-free models are designed in a design that does not allow individual testing operations to be performed.

To remove or not to remove terminals?

When connecting an external power supply, a danger arises from the risk of exceeding the permissible voltage level in the on-board network. But electronic controllers are designed for voltage surges up to 15.7 V, which is lower than the parameters of an external charger.

A number of external units are equipped with low-quality voltage regulators that allow peak increases in the parameter to 17.5-18 V. Before switching, it is necessary to check the maximum voltage in the charging circuit with a test device.

If a car uses a calcium battery of early modifications, then for restoration it is used to supply an increased voltage, reaching 16-17 V. Due to the increase in parameters, there is a risk of damage to the electronic components of the car, designed for a voltage of 14.5 V.

But modern calcium power supplies are equipped with plates made of an alloy of lead, calcium and additional elements that allow the voltage to be reduced to a standard value.

When using an external unit, please note that some products are equipped with protective devices that prevent an increase in output voltage. But some modifications do not have fuses; the behavior of such equipment when it fails is unpredictable.

Since battery restoration occurs without the presence of the owner, it is recommended to disconnect the battery from the on-board network.

To save the settings of electronic units, a small-sized 12 V current source is used, temporarily connected to the electrical wiring terminals. The equipment is connected to the car body and the positive terminal using wires equipped with clamps.

A 12 V current source is connected to the wiring terminals to maintain the settings of the electronic units

Then the main battery is turned off, which is removed from the car. The backup battery must have a capacity sufficient to power the machine's electronic circuits for 10-12 hours (the average charging time for a lead-acid battery).

If the carburetor

When using a carburetor power system, the question of whether it is necessary to remove the terminals from the battery contact pins does not arise.

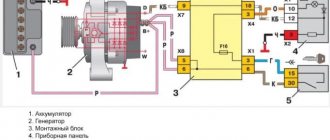

Russian-made cars use a single electronic unit that regulates the voltage in the generator circuit.

Connecting an external charging unit does not have a negative effect on the device, which only responds to the supply of outgoing voltage. The electronic switch of the ignition system also does not respond to the connection of an external charger.

Some imported cars used carburetors with an electronic controller that adjusted the composition of the fuel mixture based on signals from the catalytic converter.

Carburetor with electronic controller

Since these cars were produced in the second half of the 90s. last century, the owners dismantled the electronics and installed domestically produced mechanical carburetors. If the electronics are preserved, then charging should be carried out by analogy with cars equipped with engines with distributed fuel injection.

If the injector

Engines with distributed fuel injection are equipped with a microprocessor unit that regulates the composition of the fuel mixture depending on driving conditions and information received from various sensors.

The design of the generator retains a rectifier unit with a voltage regulator, which has increased accuracy of voltage settings in the on-board network. The design of the electronic controller provides protection that cuts off power when the voltage rises, but you should not rely entirely on the fuse.

When using a charging unit, there is a risk of a voltage surge in the circuit, so it is recommended to disconnect the battery from the vehicle's on-board network.

Some car manufacturers do not recommend removing the battery from the car - information is indicated in the factory documentation. In this case, charging is carried out on the vehicle in accordance with the instructions given in the operating instructions.

With the engine running

After starting the power plant, the generator starts working, charging the battery and supplying power to the vehicle’s on-board network. If additional voltage is supplied from the charging unit, there is a risk of damage to the regulator on the generator and the controller installed in the charging unit.

The electronic engine control unit will not be damaged, but recharging the battery from an external device while the engine is running is prohibited.

If the terminals are dirty and there are oxides

Before charging the battery in a car, it is necessary to assess the condition of the contact elements, which are covered with a layer of oxides. The material has reduced electrical conductivity; when the terminals are put on, the battery is not charged properly.

The presence of traces of deposits from road reagents or electrolyte further worsens the conditions for restoring battery capacity. Before charging the battery, it is necessary to remove foreign matter from the contact surfaces.

Severe oxidation of battery terminals

Ways to protect lead terminals and battery posts:

- cleaning with abrasive materials;

- surface treatment with protective compounds;

- wiping the surface from traces of moisture and reagents.

Compliance with safety regulations

The hydrogen released during charging forms an explosive compound when mixed with oxygen. For this reason, it is imperative to ensure good ventilation. Access by children and unauthorized persons should be excluded. It is better to carry out such procedures not in a residential building, but in a garage or other technical room.

If you do not open the plugs in the battery being serviced, the gases can create excessive pressure, leading to the destruction of the housing. To prevent damage from acid and other harmful components of the electrolyte, you should use gloves, goggles, and other personal protective equipment.

Before performing work, it is necessary to exclude the presence of open flames, working machines, and other potentially dangerous objects nearby. The current, voltage and time intervals specified in the instructions should not be exceeded. The charger is connected to the power supply through a circuit breaker.

Conclusions and additional recommendations

A new car is stored in a warehouse for several months before being handed over to the buyer. It is possible that the battery parameters will have to be restored. This procedure will eliminate unnecessary problems during operation. Given the frequent monitoring, it makes sense to think about purchasing a charger as your own.

It is preferable to use a dismantling power source and an option with an additional battery. This technique will prevent errors and failures of electronics and software. Timely, high-quality maintenance will extend the life of the battery.

You may also be interested

.

Batteries 0