Repairing a VAZ 2103 car is in many ways similar to working with the 2101 model. Since the engines of these cars are only slightly different in size, identical problems arise. Most of the cars of these models are already veterans of the auto industry and are reaching their last years, but their owners still do not give up and repair their cars. From every Zhiguli owner you can hear practical advice on how to keep your car running.

Self-repair of VAZ-2103 engine

The VAZ-2103, which is still driving around the Russian expanses, is today at a fairly advanced age, by automotive standards. Accordingly, their owners are increasingly faced with the need for repairs, including the engine. According to the manufacturer’s recommendation, the resource of this engine is 125 thousand kilometers. In practice, the Troika’s power units were looked after much more, of course, subject to careful treatment, as well as competent and timely maintenance.

VAZ engine overhaul services at low prices

VAZ cars are the best-selling in Russia due to their relatively low cost and adaptability to Russian operating conditions. The presence of a large number of cars of this brand determines the demand for services related to their repair. In particular, a VAZ engine overhaul is often required, which is carried out quickly and efficiently by specialists.

There are various reasons leading to the need for a complete restoration of a car engine. Repairs may be required due to untimely replacement of engine oil, incorrectly selected spark plugs, poor condition of filters, and in other cases. The more serious the degree of damage, the higher the cost of repairing a VAZ engine will be. We set a minimum price for such services, since we have in stock all the spare parts and modern equipment necessary for repairs.

To get an answer to the question of how much it costs to overhaul a VAZ engine, a comprehensive diagnostic of the power unit is carried out. When it is completed, our specialists name the exact cost and stipulate the deadline for completing the work. The final price is influenced by the number of parts that must be replaced during repairs, as well as the complexity of the work. Despite the low prices, the work is performed to the highest quality, which is confirmed by a long-term guarantee.

To return a VAZ car engine to full functioning, many operations are often required. In addition to cleaning and replacing parts, this may include grinding the crankshaft, honing the cylinder block, or other actions. By contacting Mechanics, you get professional engine repairs for your VAZ car at an affordable price!

Repairing the VAZ-2103 engine is quite possible to do on your own

The design of this power unit is quite simple. Accordingly, many car enthusiasts can do all engine-related repairs themselves. This option helps to save a certain amount due to the absence of the need to pay for the work of the craftsmen. There are a number of signs that indicate the need for repairs. Among them are:

- increased fuel and oil consumption;

- smoky exhaust with a clear bluish tint;

- uneven operation of the engine in idle mode;

- the appearance of soot on candles;

- clearly decreased power and sluggish dynamics;

- tripling;

- “sneezing” of the carburetor;

- “shots” in the silencer;

- constant overheating.

The simplest type of engine repair is replacing consumables. In principle, these works can even be classified as maintenance. If you want the engine of your “troika” to serve for a long time, you should change spark plugs, filters, and oil in a timely manner. Every 10 thousand kilometers it is necessary to adjust the valves.

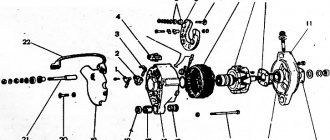

It makes no sense to describe all possible repair options. It would probably be more correct to talk about how the engine is disassembled. Immediately before this, you should remove the engine from the car and wash it thoroughly. Now you can proceed directly to disassembly. We remove the carburetor, having first disconnected the hoses and throttle linkage, then the distributor and fuel pump, coolant temperature sensor. Now you can unscrew the spark plugs. Next comes the turn of all the hoses and pipes of the cooling system.

This must be done carefully, unless, of course, you plan to change them. After this comes the pump and generator drive belt, after which these components themselves are dismantled.

The oil filter is unscrewed using a special tool. Many Soviet-era car enthusiasts have it in their garages. Therefore, if you don’t have one, ask your friends so as not to spend extra money on the purchase. After unscrewing the filter, you can remove the oil pressure sensor. The next stage is dismantling the crankcase ventilation breather and the entire assembly. Now remove the drain tube clamp and remove the oil separator.

The ratchet can also be unscrewed using a special wrench. Now we fix it from turning and remove the crankshaft pulley. After this, you can begin to dismantle the camshaft drive cover and cylinder head. Next you will need to sweat a little. First, remove the bolts holding the oil pump and camshaft sprockets. Next, remove the chain tensioner and shoe. All that remains is to unscrew the limiting pin and remove the sprockets. That's it - you can pull out the chain.

Now we proceed to dismantling the crankshaft. Here you first need to unscrew the nuts of the studs securing the bearing housing. After this, the latter are removed along with the crankshaft. Next, you need to unscrew the mounting bolts and remove the cylinder head along with the manifolds. From there we remove the oil pump drive shaft, having previously dismantled the thrust flange. Next, we arm ourselves with a special puller and remove the crankshaft sprocket. In order to remove the pistons and connecting rods, first unscrew the nuts of the corresponding bolts. One important point is worth emphasizing here. Experienced car enthusiasts advise to be sure to mark connecting rods, bearings (as well as their caps) and pistons. This is necessary so that when reassembling you do not mix up anything.

After this, you can unscrew the flywheel mounting bolts and remove the washer. Here, in principle, everything is simple. Next, we remove the flywheel itself, after which, using a puller, we pull out the gearbox input shaft bearing from its socket in the crankshaft. However, the last step can be done later. This, as they say, is at your discretion. Now all we have to do is remove the crankshaft oil seal holder, the main bearings (after unscrewing the corresponding bolts), and the crankshaft itself. That's all - engine disassembly is complete.

All you have to do is determine which parts need replacing, buy new ones, and reassemble in the reverse order. As you can see, there is really nothing particularly complicated here. Of course, you will have to spend some time, and not every car enthusiast has the space to carry out such work. Nevertheless, many owners of “threes” prefer to repair their cars with their own hands.

Disassembling the VAZ 2106 and 2103 engine.

Once you have moved the removed engine to a bench, you can begin disassembling it. It is best if the engine is installed and secured on a special rotary table - moving it during disassembly is a very inconvenient operation. When starting disassembly, you should stock up on a standard set of sockets and open-end wrenches, as well as a hammer and screwdriver. We will need keys for “10”, “13”, “14”, “17”, “19”, “21”, “22”, “36”. Socket wrenches for “12” and “13” will also not be superfluous. To remove the crankshaft pulley if you do not have a special wrench, you can use a gas wrench. It’s a good idea to also stock up on an oil filter remover, because it is with the removal of this filter that the disassembly of our engine begins.

- Once you have removed the oil filter, remove the cylinder head cover, and, using the special cylinder head removal manual, remove the engine cylinder head itself.

Also remove the generator. To do this, loosen the lower nut on which the generator is attached, the tension nut, and, moving the generator towards the engine, completely remove the tension bar. Then remove the belt and the alternator itself.

- Remove the ignition distributor by unscrewing the clamping bracket.

- When removing the fuel pump, remove it together with the spacer and gaskets, do not lose them, and also do not forget to remove the pusher.

- Unscrew the oil pressure sensors - first the emergency one, and then the index one. After this, you need to remove the breather cap along with the dipstick.

- After unscrewing the fastening nut, remove the crankshaft pulley and unscrew the three bolts that secure the oil pan to the camshaft drive cover from the front.

- After completing these steps, you can loosen and remove the cover itself. You will see the camshaft drive mechanism.

- Unbend the locking petals of the special drive sprocket washer for auxiliary mechanisms, and, having jammed the crankshaft from turning, first loosen the sprocket mounting bolt.

We unscrew the limiting bolt and remove the drive chain together with the sprocket, completely unscrewing the previously loosened bolt. - We remove the crankshaft sprocket, and, after unscrewing the bolt, remove the tensioner shoe.

- Now you can begin to remove the oil sump. We do this by carefully removing the remaining bolts and not losing the washers.

- We remove the flywheel.

- Unscrew the two nuts and remove the front clutch housing cover.

- Remove the crankshaft rear oil seal holder,

- Removing the oil pump

- Remove the auxiliary mechanism drive shaft. Helping yourself lightly with a screwdriver, remove the gear that rotates the oil pump and ignition distributor. This gear is popularly called “piglet”.

- Lock two nuts on the threads of the oil separator stud against each other, and, turning one of them with a wrench, unscrew the stud. Unscrew the nuts securing the oil separator tube bracket and remove it by sliding it along the tube.

- Then remove the oil separator itself.

- You can now begin removing the pistons and connecting rods. Remember that the connecting rod caps cannot be changed or confused with each other, since each of them is adjusted to its own connecting rod during manufacturing, so before starting this operation, mark them at least with a core. For example, on the connecting rod and cover of the first cylinder there is one hole, on the second cylinder there are two, etc.

- Unscrew the connecting rod nuts and, using light hammer blows through a wooden spacer, separate the cap from the connecting rod bearing and remove the pistons along with the connecting rods.

- All we have to do is remove the crankshaft. To do this, unscrew the main bearing caps and remove them by lightly tapping them with the handle of a hammer. Then remove the thrust rings of the rear crankshaft support - the rear half ring and the front ring. The last operation is to remove the liners from the main and connecting rod bearings.

Some technical features of the VAZ 2103

The main difference is the size and volume of the cylinders. The design and location of components and engines is considered classic. For a long time, textbooks and manuals on domestic cars were compiled based on it. The power point is directed along the center line at the front, the driving drive is at the rear. Thanks to the clutch, manual transmission, cardan axle shaft and rear axle axle shaft, the engine torque is transmitted to the rear axle. The engine is mounted on rubberized supports in three places. The car's engines are four-stroke, in-line, with an overhead camshaft and a carburetor. The lubrication system involves the use of special oils with a complex of additives. The closed-type ventilation system ensures the suction of gases from the crankcase into the intake manifold and increases the service life of the engine.

We are starting to overhaul the VAZ classic engine

The VAZ-2103 car is a subcompact Zhiguli car. It is distinguished by good dynamic qualities and comfort. The main difference between cars is engines with different cylinder displacements. But as a rule, VAZ 2103 engine repairs are no different.

The arrangement of components and engines on the VAZ-2103 is classic, i.e. The power unit is located in front along the centerline of the car, rear-wheel drive. Torque from the engine is transmitted to the rear axle through transmission components: clutch, manual transmission, cardan shaft and rear axle axle shafts. The VAZ-2103 engine is fixed at three points on rubber mounts.

The design of the VAZ-2103 complies with active and passive safety requirements, to which the Volzhsky Automobile Plant paid great attention. VAZ-2103 meets all safety requirements of the UN Economic Commission for Europe.

The VAZ 2103 is equipped with unified engines with different power depending on the model and modification.

The engines are four-stroke, with a carburetor, in-line, with an overhead camshaft. The engine lubrication system has a full-flow oil filter and requires the use of special oils with a complex of additives to give the oil high lubricating properties, oxidation resistance and allow the engine to operate at high speeds.

The crankcase ventilation system is of a closed type, which ensures the suction of gases from the crankcase into the intake manifold and increases the service life of the engine. The liquid cooling system is of a closed type.

Malfunctions leading to repair of the VAZ 2103 engine

As a rule, the need to repair the VAZ 2103 engine appears over time due to mechanical, abrasive, corrosive or fatigue wear. The procedure is most often performed after 50, 100 or 200 thousand kilometers. This depends on the average load and service life.

Obvious signs of impending repair are a change in the sounds of the running engine, and some knocking appears. The need for work can also be determined visually by inspecting the machine and in relation to the service life.

Problems that require the intervention of a specialist include:

- wear of the camshaft or other components;

- the degree of tension of the chain; when it weakens, tension adjustments are necessary;

- changed valve clearances (checked regularly);

- valve burnout;

- contamination of individual parts.

Sequence of work during repairs

In most cases, it is better to entrust adjustments to the operation of a machine engine to a professional technician. However, repairing a VAZ 2103 engine with your own hands is also possible. There are many videos in which experts share their experience, commenting step by step on each stage, paying attention to various details and nuances. You can find recommendations regarding breakdowns of any kind, as well as for preventive inspection of the car.

Before repairing the VAZ 2103 engine with your own hands, it is recommended that you carefully study the video below. In it you can find advice for both beginning craftsmen and professionals, compare different options for approaching work, and choose the most suitable technologies. There are also various options for improving existing models.

When repairing a VAZ 2103 engine, it must first be removed. They start with the pallet. Next, sequentially unscrew and carefully remove the oil pump and connecting rod, onto which the cushion is immediately placed. Determine the degree of piston wear by first pushing it up.

By measuring the thickness, you can bore the block with pistons if it has never been done before.

The clutch basket is unscrewed and removed, the cushions are removed from the crankshaft (you must remember their original position so as not to swap them in the future).

All parts are washed and polished, and a replacement list of necessary spare parts is compiled.

After the replacements are completed, the engine is assembled in the reverse order and installed on the machine.

To reduce the cost of work performed, it is necessary to repair components in a timely manner, without waiting for their emergency wear.

When operating a car, you should take into account the average load (three adults, or about 200 kg), and also not allow the engine to operate constantly at high speeds.

Car maintenance after major repairs

After overhauling the engine with your own hands, the car must be operated carefully. During the break-in, the basic rules must be followed; the ride must be calm. During this period, frequent oil changes are required: every 500 km. When the mileage reaches 2000 km, the oil is changed unscheduled for the last time. Next, it needs to be changed like in any car after 10-15 thousand.

After overhauling the engine yourself, with proper operation, the car will delight the owner for many years. The main thing is to change consumables on time and use high-quality, proven products.

You can see how the overhaul of a VAZ engine takes place in the video.

Source

How is a VAZ 2103 car repaired?

Repairing a VAZ 2103 car is in many ways similar to working with the 2101 model. Since the engines of these cars are only slightly different in size, identical problems arise. Most of the cars of these models are already veterans of the auto industry and are reaching their last years, but their owners still do not give up and repair their cars. From every Zhiguli owner you can hear practical advice on how to keep your car running.

Engine Features

The carburetor engine of the VAZ 2103 with four cylinders has a volume of only 1.5 liters. The limit of the engine's operational capabilities, according to factory calculations, is about 125-130 thousand km, but can reach almost 200 if it is constantly looked after. In fact, the operating limit can be even greater if all parts are changed in time. Problems with such a motor often arise with overheating (this is due to the rather weak characteristics of the engine), as well as with the chain drive, which requires constant tightening. The total engine power is 71 hp. s., while the maximum number of revolutions per minute can reach only 5-6 thousand. Despite the weak characteristics, the VAZ 2103 engine has several undeniable advantages:

Conclusion: the motor is mediocre, but can last a very long time. In order for it to work for ten years, it requires care, constant replacement of working fluids and parts, and timely repairs. Now let's talk about care in more detail.

Engine malfunctions and repairs 2103

Engine VAZ 2103 1.5 l. carburetor in-line 4-cylinder with an overhead camshaft, the timing belt of the 2103 engine has a chain drive. The VAZ 2103 engine block is tall, more on that below. The service life of the 2103 engine, with careful operation and timely maintenance, exceeds the 125 thousand km established by the factory and reaches 180-200 thousand km. The main differences between the 2103 engine and the 2101 are the increased block height by 8.8 mm from 207.1 mm to 215.9 mm to allow the installation of a crankshaft with an increased piston stroke, thanks to which the engine volume has increased to 1.5 liters. As noted in previous articles, Lada engines have a problem with camshaft wear. Due to the fact that the chain drive does not have a tensioner, the chain needs to be tightened, the engine also needs constant (every 10 thousand km) adjustment of the valve clearances, this will be indicated by a loud knocking sound in the VAZ 2103 engine when the engine is idling, audible from a standstill driver with the hood closed. Many people have a question, why adjust the valves, the answer is simple - power will decrease, fuel consumption will increase, the valve will burn out and many other pleasures of life. Adjustment of the VAZ 2103 engine valves must be done either by a master or with his own hands. Among other problems, Weber and Ozone carburetors constantly require CO adjustment and cleaning. It often happens that the VAZ 2103 engine gets hot, look for the problem in the pump, 99% this is it. Often when the engine in a 2103 misfires, there can be a lot of reasons, most often a burnt-out valve; in any case, you need to measure the compression and show the car to a mechanic. Many VAZ 2103 engine malfunctions repeat the problems of the 2101, due to their close relationship. For a more complete picture and so as not to miss anything, read about the 2101 motor here. Nevertheless, according to popular opinion, the 2103 engine is the most reliable and unpretentious among the classic line of engines, and given the prices for spare parts for the VAZ 2103 engine, you don’t have to wonder why the classics are still driving along our streets.

Long-term operation

Maintenance is very important for the VAZ model 2103. Timely replacement of oil, spark plugs, fuel and parts significantly extends the operating life of the engine, so serious repairs in such conditions are practically not needed.

Much attention should be paid to the selection of oil. Since mechanical wear of most parts is the main problem that promises early engine failure, you need to choose a good technical fluid with an optimal set of additives. When changing the oil, it is advisable to also replace the oil filter. The amount of fluid when replacing should be 3.5 liters out of 3.75 liters. In addition to mechanical wear, using high-quality oil will also prevent corrosion damage to parts.

Don't forget to change the air filter as well. Both filters should be replaced and checked regularly.

If frequent VAZ engine repairs are not part of your plans, pay attention to the condition of other elements. Replacing sensors, timing belts and spark plugs allows you to maintain the good condition of the entire assembly.

In cases where the engine starts to stall, try changing the brand of gasoline.

Maintenance

Considering the design of the internal combustion engine, the manufacturer recommends the following maintenance schedules:

| Maintenance object | Time or mileage (whichever comes first) |

| Valve train chain | replacement after 100,000 km |

| Battery | 1 year/20000 |

| Valve clearance | 2 years/20000 |

| Crankcase ventilation | 2 years/20000 |

| Belts that drive attachments | 2 years/20000 |

| Fuel line and tank cap | 2 years/40000 |

| Motor oil | 1 year/10000 |

| Oil filter | 1 year/10000 |

| Air filter | 1 – 2 years/40000 |

| Fuel filter | 4 years/40000 |

| Heating/Cooling Fittings and Hoses | 2 years/40000 |

| Coolant | 2 years/40000 |

| Oxygen sensor | 100000 |

| Spark plug | 1 – 2 years/20000 |

| Exhaust manifold | 1 year |

What parts need to be repaired?

The VAZ 2103 engine has many problems.

But it’s worth considering the most popular of them:

- The first thing that should alert you is a knocking sound from the hood during idle. This sound occurs when the valve clearances need to be adjusted. The adjustment is carried out with your own hands if there is a diagram of the position of the elements in the valve mechanism.

In all of the above cases, you need to replace the parts with new ones and get rid of the old ones.

Recommendations

Do not forget that for the VAZ 2103 engine, high speed is very destructive.

Overheating and overloading of the unit can lead to serious damage to parts, after which many structural elements will have to be replaced. You should not push the maximum on the track without installing special parts, otherwise the engine will turn into a cauldron of fire.

If you do not want to frequently repair your VAZ engine, replace worn parts with similar ones. If you install more powerful spare parts, the structure may simply not hold up.

The only option to increase the performance of such weak engines is to install additional parts. In the case of Zhiguli, a good option for increasing power would be to install new pistons and cylinder head, as well as update the exhaust system elements. To do this, you will need to bore the cylinders to 79-82 mm. Other tuning options affect the overall service life of the car and are therefore not recommended.

Servicing VAZ engines is not difficult if you need to replace parts at home. If you have instructions, you can dismantle and replace almost any element of the engine assembly. But if you are not sure of the cause of the breakdown, it is better to visit a service station, where a technician can identify and fix the problem.

VAZ-2103 engine repair

The VAZ-2103 car is a subcompact Zhiguli car. It is distinguished by good dynamic qualities and comfort. The main difference between cars is engines with different cylinder displacements. But as a rule, VAZ 2103 engine repairs are no different.

The arrangement of components and engines on the VAZ-2103 is classic, i.e. The power unit is located in front along the centerline of the car, rear-wheel drive. Torque from the engine is transmitted to the rear axle through transmission components: clutch, manual transmission, cardan shaft and rear axle axle shafts. The VAZ-2103 engine is fixed at three points on rubber mounts.

The design of the VAZ-2103 complies with active and passive safety requirements, to which the Volzhsky Automobile Plant paid great attention. VAZ-2103 meets all safety requirements of the UN Economic Commission for Europe.

The VAZ 2103 is equipped with unified engines with different power depending on the model and modification.

The engines are four-stroke, with a carburetor, in-line, with an overhead camshaft. The engine lubrication system has a full-flow oil filter and requires the use of special oils with a complex of additives to give the oil high lubricating properties, oxidation resistance and allow the engine to operate at high speeds.

The crankcase ventilation system is of a closed type, which ensures the suction of gases from the crankcase into the intake manifold and increases the service life of the engine. The liquid cooling system is of a closed type.

VAZ 2103 engine malfunctions

The most common defects found on the engine:

All these malfunctions are associated with various reasons, which will be discussed below.

The engine gets very hot

Experts call the main reason for overheating of the engine unit a lack of refrigerant in the system. According to the rules, before leaving the garage, the driver is required to check the level of all technical fluids each time. But not everyone does this, and then they are surprised to find themselves with a “boiling” internal combustion engine on the side of the road.

Antifreeze may leak from the system. In this case, there is a malfunction - a violation of the integrity of the cooling system. Antifreeze stains on the floor of the garage in which the car was parked directly indicate to the owner that there is a leak. It is important to eliminate it in a timely manner, otherwise there will not be a drop of liquid left in the tank and system.

The reasons for the leak are as follows.

Another reason for engine overheating is a non-working radiator fan. On a VAZ 2103, the quality of cooling by the engine blades is extremely important. The slightest sagging of the drive belt has a negative effect on it. But this is not the only reason for the element to be released.

Finally, overheating of the internal combustion engine can occur due to damage to the thermostat.

Engine knock

On a VAZ 2103, engine knock is detected without special equipment, by ear. A 1-meter wooden pole is taken and one end is applied to the motor in the part being tested. The other side of the pole should be clenched in your fist and brought to your ear. It turns out something like a stethoscope.

VAZ 2103 engine smokes

As a rule, at the same time as the smoke, the engine eats up oil. It may be gray in color and increase with increasing idle speed. The reason is related to the oil scraper rings that require replacement. It is also possible that one of the candles is not working.

In some cases, this happens due to a ruptured gasket or insufficient tightening of the head bolts. On older engines, there may be a crack in the block head.

Troubles the engine

The phrase “troubling engine” means that one or more cylinders are not working. The power plant is not capable of developing full power and does not have the required traction force - accordingly, fuel consumption increases.

How to reduce engine repair costs

It is important to be on time, i.e. Before emergency wear occurs, repair the unit - in this case, repair costs will be significantly lower.

Repair of the VAZ 2103 engine must be done depending on the operating conditions from 50 thousand, and from 100 thousand, and from 200 thousand km or more - a lot depends on the timely maintenance. The mileage period before major overhaul of the VAZ 2103 engine, established by the factory, is determined depending on the average load in operation.

The average load of a VAZ 2103 is considered to be about 200 kg, approximately 3 adults in the car. And if the load of the VAZ 2103 is 400 kg during most of the mileage, then before a major overhaul it is half that.

If the VAZ 2103 engine constantly operates at high speeds due to high speeds, major repairs are often required. For example, sports cars are repaired almost before every race, since they exhaust their service life in previous races.

Whether a VAZ 2103 engine needs repair can be determined by diagnosing a running engine without instruments using indirect signs: acoustic, visual and operational.

Engine repair

The easiest way to repair a power plant is to replace consumables. However, real restoration of the internal combustion engine involves its removal, disassembly and subsequent installation.

Before you begin the operation, it is important to prepare the correct tools.

How to remove the engine

Now you will need to prepare protection for the body - install a wooden block between the engine and the body. He will insure in case of possible damage.

Replacing earbuds

They are thin semicircular plates of steel, and are cages for bearings.

The earbuds cannot be repaired as they have a fixed size. Parts have to be replaced due to physical wear and tear, as over time the surfaces wear out and a backlash appears, which is important to eliminate in a timely manner. Another reason for replacement is rotation of the liners.

Replacing piston rings

The entire procedure for replacing piston rings comes down to three steps:

If you have a puller, removing old rings from the piston will not cause any difficulties. If you don’t have a tool, you can try using a thin screwdriver to open the ring and remove it. First of all, the oil scraper ring is removed, then the compression ring.

New rings must be inserted using a special mandrel or crimp. Today they are sold in any auto store.

Oil pump repair

The oil pump is the most important component of the VAZ 2103 engine lubrication system. With its help, lubricant is pumped from the crankcase through all channels. The first sign of a pump malfunction is a decrease in pressure, and the cause is a clogged oil receiver and a clogged crankcase.

Oil pump repair involves draining the oil, removing the pan and washing the oil receiver. Other causes of unit failure include a broken pump housing. To restore the part, special tools are used, such as an impact driver, a soldering iron, a set of wrenches and a screwdriver.

Video: about repairing the VAZ 2103 engine

The VAZ 2103 engine and its modifications are considered one of the best in the class. However, over time they also require repairs and replacement of components.

Source

Do-it-yourself VAZ 2103 Engine Repair Video

How repairs

VAZ car

2103

?

Repair

The VAZ

2103

is almost in every way similar to working with the 2101 model. Since the engines of these cars are only slightly different in size, the tasks appear similar. Most of the cars of these models are already veterans of the automotive industry and have reached their last days; alas, their owners still do not give up and repair their cars. From every Zhiguli owner we hear practical advice on how to keep your car running.

Tuning the VAZ 2103 engine

Since VAZ 2103 cars have long been outdated, owners of these car models often upgrade their engines to increase the power of the car. Often, car owners resort to modifying the DAAZ-2107 OZONE, for which they should convert the pneumatic drive of the throttle valve, which is located in chamber 2, to mechanical. After which you should begin to refine the GDS of chamber 1, and you will have to select the most correct position of the air damper, that is, one in which so-called operational failures will not occur. It will be necessary to work on the GDS 2 cameras.

To increase the power of the VAZ 2103 engine, they often resort to installing a sports camshaft. It is important to install the exhaust cam so that it opens the valve in a special way, which will allow the cylinder to be cleared of combustion products. If this is not done, unburned gases will begin to mix with the new mixture.

Remember that if you have little understanding of the structure of cars in general and engines in particular, you should not try to repair or upgrade the VAZ 2103 engine yourself - it is better to entrust this to professionals.

Engine Features

The VAZ 2103 carburetor engine with 4 cylinders has a volume of only 1.5 liters. The limit of the engine's operational capabilities, according to factory calculations, is about 125-130 thousand km, but sometimes it reaches almost 200 if it is constantly looked after. You will like the real limit of the working condition even more if it’s time to change what remains to be done by our client. Problems with such a motor often appear with overheating (this is due to the rather weak properties of the engine), additionally with a chain drive, which requires constant re-tensioning. The total engine power is 71 hp. s., with all this, the majority of rpm sometimes reaches only 5-6 thousand. Despite its weak properties, the VAZ 2103 engine has several irrefutable advantages:

- with proper care, the operating time is multiplied;

- repairs

are quite inexpensive; - parts for replacement are painfully easy to find;

- has a small supply of resources for improving traits.

Do-it-yourself VAZ 21099 body repair video.

Conclusion: the motor is mediocre, unfortunately it can last a long time. For it to work for ten years, it requires care, constant replacement of working fluids and parts, and timely repairs. Now let's talk about care in more detail.

Long-term operation

Maintenance is very important for the VAZ model 2103. Timely replacement of oil, spark plugs, fuel and parts significantly extends the operating life of the engine, so serious repairs in such conditions are practically not needed.

Attention should be paid to the selection of oil. Since mechanical wear of most parts is the main problem that promises early engine failure, it is necessary to choose a good techno fluid with a good set of additives. When changing the oil, it is better to change the oil filter as well. The amount of water during change should be 3.5 liters out of 3.75 liters. In addition to mechanical wear, using high-quality oil will also prevent corrosion damage to parts.

Overhaul of the VAZ 2103 engine. Part 1.

Communication, commercial requests Help channel: PrivatBank 5168 7556 3188 1725, WMZ.

Do-it-yourself overhaul of the VAZ 21099 engine.

Don't forget to change the air filter as well. Changing and checking the condition of both filters should be carried out frequently.

If frequent repairs are not part of your plans, pay your attention to the condition of other parts. Replacing sensors, timing belts and spark plugs allows you to maintain good condition of the entire assembly.

When the engine starts to stall, try changing the brand of gasoline.

We are starting to overhaul the VAZ classic engine

Today we’ll start talking about the capital of the VAZ classic engine. Where should you start? This is what we will talk about today.

Overhaul of VAZ engine

Thanks for subscribing!

You have decided that the engine needs a major overhaul. I wrote about how to understand that the engine needs a major overhaul here. Next, we will go point by point, having completed all the steps, we will prepare the engine for major repairs. 1. Washing the engine compartment. I highly recommend that you do this, as it is not very practical to dig under the hood when it is dirty. Also, by thoroughly washing the engine compartment and engine, you will minimize the ingress of dirt and sand into the engine itself. 2. After you have thoroughly washed everything under the hood, you can drain the antifreeze from the cooling system and the oil from the sump. We also remove the hood cover, it’s a bit difficult without an assistant. Without a hood, it is very convenient to remove all the equipment under the hood, and it is problematic to remove the engine without removing the hood. 3. Now we remove all engine attachments - fuel pump, carburetor, manifold, water pump, radiator, starter, generator, in a word, everything from the engine and everything that will interfere with engine removal. If you are afraid that you will not remember the location and connection points of the wires, write down which one was connected where. It is convenient to write on masking tape, which must first be used to wrap the wires. 4. After all attachments have been removed, you can unscrew the engine mount to the transverse beam (on the cushions), and after first removing the clutch slave cylinder, unscrew the 4 bolts that connect the gearbox and the engine. Also, don’t forget to unscrew the flywheel mudguard; it is attached at three points. Next, you have several ways to solve the problem of removing the engine from the engine compartment. If you have a hoist or winch, this greatly simplifies the process of removing the engine from the vehicle. If everything is done manually, then I would recommend that you disassemble the engine right under the hood, removing the valve cover, camshaft, and cylinder head. Thus, we will significantly reduce the weight of the engine and it will be much easier to get it. If there is nothing to mechanically lift the engine, then the solution is quite simple - just a wooden stick a couple of meters longer than the width of the car, a cable to attach the engine to the stick. Further, the scheme of actions is very simple - it is enough to lift the engine with two people, and the third, using a mounting tool, separates the engine from the box; you need to push it away with the mounting tool so that the gearbox input shaft comes out of the clutch. Then everything is simple, lift the engine from the engine compartment and lower it to the ground. Thus, the engine in front of you needs to be cleaned of dirt and oil from the outside, after which you can remove the clutch, flywheel, and rear engine oil seal. In a word, you can completely disassemble the engine, but I advise you to pay attention to the connecting rods, the fact is that if you do not know the repair history of this engine, then perhaps the engine does not have a set of connecting rods installed, but one of them has been replaced (it is necessary to change the connecting rod if it has turned the liners). On each connecting rod there is a stamp on the side with a cylinder number from 1 to 4, check that all numbers are present, if there are connecting rods with the same numbering, then mark in which cylinders they are located. After this, you can disassemble the engine to scratch, remove the crankshaft, intermediate shaft, etc. Everything is thoroughly washed, especially the block and crankshaft, both outside and inside. I don’t know what the procedures are in your grooving workshops, but we usually give for grooving: • Block • Crankshaft • Intermediate shaft (pig) Thus, we send these parts for grooving. To be continued…

What parts need to be repaired?

Problem with VAZ engine 2103

a lot of.

Alas, it is worth considering the most popular among them:

- The first thing that should make you think is an unfamiliar knocking sound from the hood when idling. This sound occurs when the valve clearances need to be adjusted. The adjustment is carried out at home, if, of course, the diagram of the position of the parts in the valve mechanism.

- The second problem is rapid wear of the crankshaft. If the passage is at the limit, a breakdown sometimes happens at once, or you will hear a corresponding knock of an unfamiliar motor, a little less distinguishable than at the beginning. Home repairs consist of dismantling and replacing the crankshaft.

- Overheating of the engine is caused by a faulty cooling system. It is worth checking the fan, pump and thermostat. From time to time, gasoline with the highest octane number becomes a prerequisite for overheating.

- If there is smoke coming out of the engine, check the piston rings and carburetor. Oil probably got into the combustion chamber due to burnouts. Valve seals become unusable less often, which leads to the need to carry out a complete repair

of the VAZ engine.

Do-it-yourself overhaul of the VAZ 2115 engine.

In any of the above cases, it is necessary to replace the parts with new ones and get rid of the old ones.

Recommendations

Do not forget that for a VAZ engine 2103

the highest speed is very disastrous.

Overheating and overloading of the assembly leads to severe damage to the parts; after completion, many parts of the structure will have to be replaced. There is no need to push the maximum on the track without installing special parts, otherwise the engine will turn into a cauldron of fire.

If you do not want to frequently repair your VAZ engine, replace worn parts with similar ones. If you install more massive parts, the structure may simply not hold up.

The only option to improve the performance of such weak engines is to install additional parts. For which the design with Zhiguli is intended, a good option for increasing power would be to install new pistons and cylinder head, as well as update parts of the exhaust system. For this purpose, it will be useful to bore the cylinders to 79-82 mm. Other tuning options affect the overall resource of the car, and therefore we do not recommend it.