avtoexperts.ru

In this article we will try to understand the question of why the engine is breathing, what the consequences may be and what problems will come to light when diagnosing a power unit with a similar malfunction.

It’s worth mentioning right away that any completely serviceable engine can vent. This is due to the fact that the piston rings are not able to hold the entire volume of the burned air-fuel mixture in the cylinder, and some of the air will still end up in the engine sump. This, in turn, creates conditions for the appearance of excess pressure inside the engine, which will try to squeeze the oil through the oil seals and various connections, plus it will negatively affect the properties of the engine oil. But since gas breakthrough is minimal on a working engine, the gas pressure will be minimal.

In order to reduce excess pressure in the engine crankcase, a crankcase ventilation system was developed. On different types of engines it differs in its design, but the essence remains the same - to relieve excess pressure inside the engine.

The system operates on the principle of a breather (breather is a breathing valve), that is, it is a device that serves to equalize the pressure in the crankcase with atmospheric pressure.

Breather operation diagram

The engine crankcase is connected to the engine valve cover through a hose or metal tube. When the engine is running, the piston creates a vacuum during the working stroke, in turn drawing air out of the crankcase, thereby relieving excess pressure in the sump.

An oil separator is installed in the valve cover, with the help of which some of the oil that has entered with air from the crankcase is returned to the sump.

In addition to the main crankcase ventilation system through the breather, some of the air is also drawn in through the throttle assembly connected to the cavity of the valve cover. And since, in addition to air, oil vapors that have not settled in the oil separator are also drawn in, as the piston group wears out, a large amount of carbon begins to accumulate in the throttle valve, causing unstable engine operation.

Reasons why the engine is breathing

CPG

The first obvious cause of excess pressure in the engine is wear of the cylinder-piston group. With use, natural wear occurs on the cylinder walls, pistons and piston rings, which contributes to an increase in the breakthrough of gases into the engine sump.

Crankcase ventilation system

The ventilation process involves a closed cycle of crankcase gas movement. That is, from the crankcase through the breather, gases enter the oil separator, where they are freed from oil droplets trapped in the air and through the outlet hose from the valve covers, they again enter the air intake, returning to the engine combustion chamber.

A valve is built into the system, the so-called CCVV (crankcase ventilation valve), whose task is to open the ventilation system when excessive pressure occurs in the crankcase. It only works to suck out gases, not letting them back in. The valve is equipped with a membrane and has two compartments that operate at normal and elevated pressure. If the valve is faulty for any reason, that is, stuck in the open or closed position, then this will immediately affect the operation of the engine.

So, when stuck in the open position, part of the crankcase gases will constantly enter through the compartment with normal pressure into the engine combustion chamber, depleting the mixture, causing interruptions in engine operation (possible misfires) and increasing fuel consumption. This will especially have a negative effect on injection engines of the latest generation, where the crankcase gas outlet cuts in after the throttle valve assembly.

When the valve gets stuck in the closed position, high excess pressure will be created in the engine and the oil will simply try to be squeezed out through the seals and various connections. Plus, high pressure will squeeze oil into the combustion chamber, throwing the spark plugs, layering carbon deposits on the valve plates, and even squeezing oil through the spark plugs into the spark plug wells. At very high pressure, it is even possible to squeeze the oil dipstick out of its channel. As a rule, all this is accompanied by increased consumption of engine oil and, as a result, “starvation” of the crankshaft and other rubbing pairs, which can damage the engine.

Ways to solve the problem:

1. Engine repair

Depending on the condition, this may be simply replacing the rings, or replacing pistons and piston rings of repair sizes, which is associated with boring the cylinders of the block.

The cylinder head must not have wear on the guide bushings and the valves themselves, otherwise replacing the valve stem seals will not solve the problem.

2. Cleaning the valve, replacing the membrane or the ventilation valve itself with cleaning of the entire ventilation system (sometimes completely clogged with mud deposits);

3. Cleaning the oil separator.

How to check crankcase ventilation conditions

With the engine running, remove the oil filler cap on the valve cover. If the engine is in good working order, the cover can be easily removed, and oil will not splash out of the neck or blue smoke will come out. If two or three drops of oil slip through, this is normal and means the piston group, like the crankcase ventilation system, is working properly.

Otherwise, when opening the lid, oil will splash out, air will be breathed out, and exhaust may appear, like from an exhaust pipe.

How not to solve a problem

It seems that the problem can be solved by disconnecting the crankcase ventilation hose from the valve cover and leading it bypassing the engine under the car. However, in this case, the ventilation hose, in addition to emitting gases, will act as a dust collector, since during the suction of the pistons it will pick up air from the street. Such savings on solving a problem. It may result in rapid wear of both the CPG and crankshaft and complex and expensive engine repairs. Such a measure may be acceptable in extreme cases, when you need to get to the garage from a short distance, and the engine is filled with oil.

What not to do

It is wrong to solve the problem by disconnecting the crankcase ventilation tube from the valve cover and leading it under the car - this is only a last resort measure to help you get to the garage or a nearby service center. The fact is that the hose will begin to collect dust, sucking in dirty street air when the pistons operate. Such savings on a full system restoration will only worsen the situation. Everything can end with a complex overhaul of the unit, since the CPG, crankshaft and other components quickly wear out.

It is advisable to inspect the breathers every 10-15 thousand kilometers, especially if the car was often operated off-pavement. You should also pay attention to these details when you detect an oil leak on the internal combustion engine. This is done by removing the device and inspecting the movement of the cover. It should move freely without sticking.

Why is the VAZ 2106 engine breathing?

Recently I got another VAZ 21074, produced in 2003, with a 21213 NIVA engine. The guys who brought it to me told me that there was smoke coming from the breather and that the valve stem seals needed to be replaced. But are they the problem? And why is there a smoky mist coming from the breather? I decided to look into it in more detail.

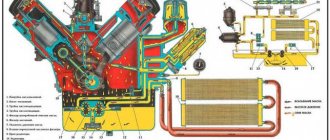

From the theory, “a breather is a device through which a container communicates with the atmosphere to maintain equal pressure. For example, in internal combustion engines, the breather serves to equalize the internal pressure of the crankcase with the external one during heating and cooling of the mechanism, as well as when atmospheric pressure changes. When the pressure in the crankcase cavity exceeds the outside pressure, oil can be squeezed out of the crankcase through leaks in the connection, and when the pressure drops, outside air containing dust is sucked in.” Wikipedia. The crankcase is a closed container and the breather is a very important element. VAZ engines use a closed-type forced crankcase ventilation system. That is why the breather hose is routed into the air filter housing, and not just into the atmosphere. There are two reasons for this. The first is ecology. Re-combustion of gases, oil, gasoline and water with intake air. The second is air purification when a vacuum forms in the crankcase. On this occasion, there is a lot of controversy about the correct supply of hoses to the air housing, because... idle ones “fail” and begin to float. I will write ways to solve this problem in the next article. Now let's try to understand the causes of the smoky fog. VAZ crankcase ventilation diagram:

To summarize, we can put together the arguments. Smoky fog from the breather is primarily a malfunction of the cylinder-piston group and replacing the valve stem seals will not fundamentally solve this problem. Also, connecting the breather hose directly to the air filter housing will clog the intake system.

To avoid this, many people simply lower the breather hose to the ground and forget about it.

but I made the following modification, thanks to the Internet, and did not lower the hose:

1) I placed a disk in the breather itself (made by me, with holes. Fig. 1)

2) Hammered a wooden plug into the pan where the hole goes to the carburetor.

3) Drilled 7 small diameter holes. directly from the hose attachment to the pan into the pan.

4) Put a flame extinguisher in the pan.

1) The hose is in place (no faults during the technical inspection.)

2) The carburetor is not clogged with all sorts of oil and rubbish flying from the crankcase.

3) Once every 2-3 months you just need to replace the air filter in the pan.

4) Crankcase gases are processed by the carburetor and do not pollute the environment.

Drivers often ask why the engine is breathing, the causes and consequences of this malfunction. To answer this question you need to know what the breather is used for in a car. This system is designed to relieve excess pressure from the crankcase, as well as to ventilate it and remove gases generated during operation.

On the first automobile engines, this system was a simple hole covered with a mesh to avoid oil loss. Later designs vent gases into the air filter housing or exhaust manifold. Many problems with the motor are indirectly related to it.

Lada 2106 “My six” › Logbook › 95. Cleaning the breather. Emulsion. And a little chat :)

Hi all.

It all started with the fact that yesterday morning I didn’t start, dropped the Akum, and basically went crazy :( I had to go to work by trolleybus in a hurry. Yesterday morning it was -16, and today it’s already +3, what a winter it is. What we have - I tried in the morning started on gas, picked up the engine, ran for a bit and stalled :( I drove all the gas with the starter, switched to gasoline, pumped it up with a gas pump, tried to start - no luck, it seizes and immediately stalls. Again I drove all the gasoline out of the float chamber, boiled the kettle, poured it on the gearbox , defrosted it - tried to start it - no, it didn't work anymore, I turned it on until the battery barely started turning, there was no time to wait. I left everything like that, locked the car and went to work. It was only in the evening that I figured out what I needed when the car stalled on gas, boil a kettle and pour boiling water on the gearbox, maybe then it would have started without problems. But again the dipstick would have squeezed out 100%, so it’s good that I didn’t go after all. On the way home from work I stopped at my father-in-law’s for a charger and came home - started it on gas, in the evening it was already -5. But another problem appeared - by the way, the same situation happened in the morning - the engine starts and literally after 20-30 seconds of operation the oil dipstick squeezes out. I took off the carb cover - and the hole from the breather was all in emulsion, and frozen :(

The polystyrene foam saved us from the snow - snow fell and covered the entire engine, it was fun to poke around under the snow.

After that I decided to check the hose itself going from the breather to the pan, it was oak - like it was made of plastic, I tried to remove it and it broke :(

The breather itself is surprisingly relatively clean

I cleaned what I could on my knee. When it's warm, I'll take everything off and clean it thoroughly.

But the only thing was that she stood at the very bottom in the hose coming from the breather. Should she be standing here? Not near the pan?

I was thinking about what to do next - it was snowing, the hose was broken. I searched at home but couldn’t find anything with a suitable diameter from the available tools. The solution came spontaneously :)

Only the insulation was crap, and was lying in the car - I could barely scrape off a roll of it, but it was a pity to twist good insulation here - anyway, today I’ll go get a new hose and throw out the old one. The most interesting thing was that I had to warm up the hose - in order to put it on the pan - it became stiff again while I was poking around. Then I look into the pan and the condensation in the hole has not gone away. I found a syringe, extracted everything I could from it, did not remove the pan - it was already about 10 pm. Then I decided to add oil - because this was not the first time the dipstick had fallen out, and the oil was at a minimum. I took off the oil filler cap and everything was in emulsion. The reasons for this are clear - I go to work by car every day, it’s 7 km there and 7 km back, driving close the car doesn’t really have time to warm up, apparently. Now the question is - is emulsion bad for the engine? How does it affect it - and how can it be corrected and prevented from the formation of an emulsion? I don’t warm up the car for a long time - I get out, start the car, clear the snow, clean the windows and drive out - in total, a maximum of 5 minutes pass, the engine, judging by the temperature sensor, warms up to 50 degrees, the needle just begins to deviate from the initial position. I drop my child off at kindergarten and go to work. When I arrive at work, the engine temperature is already 90. Well, I just leave work, start it up, 1-2 minutes and drive home. The car heats up even less - well, until it warms up, of course, I rev the engine for 2-2.5 thousand, but don’t rev it up at high speeds. I solved the main problem, but the question of what to do now with freezing condensate and emulsion remains open. Who can advise?

P.S. Yesterday I realized that even thorns will not save you everywhere in winter. The day before yesterday I was driving home - I pulled into the street, sat down - paddled up to the ice under the snow and that's it - the wheel was slipping on the ice, I had to swing back onto the road and go around this place a little further. Yesterday, a colleague gave me a lift in a Lanos, on studded Rosava Snowguard, and in the place where I usually drove without problems, I got stuck. The same situation, I shoveled the snow and got on the ice - and essentially skidded the same way as I did without spikes, and somehow jumped out with the same swing - as it seemed to me, I accelerated very sharply and the wheels quickly scooped up all the snow and the car got on the ice and began to slip .

And with the weather and winter we have a complete arctic fox:( Either -10 outside or +2 and it’s raining. And then it all freezes - and there’s ice everywhere, and then snow falls on this ice again and it gets even worse. A day later this snow becomes water, and again it is slippery to the point of impossibility. The roads are poorly cleaned, so you can only rely on yourself and the car. But in principle, I have never experienced any problems with movement - I drove everywhere, on wet ice and in snow and downhill - I’m happy with my tires And after last year's trip on March 7 - when it rained and immediately froze on the road, forming a very slippery crust of ice and, worst of all, smooth, it was very difficult to drive until it was sprinkled with snow. And on that day I had to go around the whole city, from one end to get to the other and then return to the center. And it was after these adventures that I am no longer afraid of any difficult weather conditions - well, the only thing except heavy snowfall - where I just bury myself and sit on my belly - although I made myself a small shovel, especially for digging out - so you can dig yourself out and move on. Driving in winter greatly improves your driving skill. I notice that every day I drive bolder and bolder in the snow and on ice) Because in almost 10 years of driving, this is the second full winter; before that, the car spent the winter in the garage and was driven a couple of times a month in winter and on summer tires :) I made another conclusion about driving with rear-wheel drive in winter - it’s much easier to move with front-wheel drive - I revved up the throttle - the wheels just slip and don’t go anywhere, but with rear-wheel drive it can even turn on the road if you stomp on the throttle madly, relying on the electronics. But I still remain a supporter of rear-wheel drive :) Clean roads everyone! And more free fuel :)

Source: www.drive2.com

What it is?

Why is the engine breathing? The causes and consequences of the problem can be varied. First you need to determine the symptoms of this malfunction.

Sometimes you can see smoke similar to exhaust escaping from all the open openings of the engine. This can happen through the air filter, through the oil filler neck, and so on. Usually at the same time there is an increase in oil consumption. This is what is called - the engine is breathing. These are the main symptoms. Sometimes it shoots out of the hole so that the hood lid opens. This occurs when there is a sudden disruption of crankcase ventilation.

Causes

They can be associated both with the crankcase ventilation system and with problems in the engine itself:

- Contamination of the ventilation system;

- Occurrence of rings;

- Problems with the cylinder-piston group.

As you can see, this symptom may indicate the very problems. The solutions are different for all options. To more accurately indicate the cause, be sure to undergo engine diagnostics.

Ventilation system

This is perhaps the most dangerous problem. If in all other cases this was a consequence of a malfunction, then here the problem can lead to serious damage.

A little higher we talked about the “shot” from the breather, this is the consequences of a clogged ventilation. A clogged vent does not relieve pressure

formed in the engine crankcase. At one not very wonderful moment, a sharp release of gases occurs through a blockage in the filter. The tube connecting the breather to the manifold flies out with a sharp bang. This is quite frightening for the driver and the people around him.

And this is the simplest option. There were cases when the gases ruptured the valve cover, broke engine parts, and tore out the pan.

In this regard, be sure to rinse

crankcase ventilation system. This can be done by adding a special additive to the oil. It will clear the blockage in the breather filter. You can also disassemble it by hand and wash the filter yourself in gasoline.

Occurrence of rings

A common cause of this phenomenon is a problem with the piston rings. In this case, part of the exhaust gases enters the engine crankcase. Gases at increased pressure begin to look for a way out. As a result, you can see the exhaust flying out of all the cracks. At the same time, an increase in oil consumption is observed. Part of it squeezes out through the dipstick

, the other part, entering the combustion chamber, burns out along with the fuel. In fact, this reason is a consequence of a malfunction.

Often such a problem can be indicated by a lit “check” on the dashboard. It's all about changing the composition of the exhaust gases. Therefore, if such readings on the dashboard coincide with the engine breath, you should immediately check the condition of the engine. To do this, check the compression. If in at least one “boiler” the indicator is less than 11 points, then you will have to disassemble the motor and fix the problem.

Wear of the cylinder-piston group

Gases formed as a result of combustion of the fuel-air mixture in the engine cylinders inevitably break through the piston rings and enter the engine crankcase. The amount of gases and the pressure they create in the crankcase directly depends on the size of the thermal gaps between the pistons and cylinders, in other words, on the degree of wear of the CPG. Natural wear and tear of the CPG elements is inevitable, and improper operation of the engine only speeds it up; the time and money required to repair the engine directly depend on the degree of its wear.

In case of non-critical wear, the geometry of the CPG elements and engine characteristics can be restored using XADO technology. Using XADO technology allows you to save your time and money; there is no need to disassemble the power unit and take it out of service. The use of revitalizant gels allows not only to compensate for accumulated wear, but also to protect engine parts from wear and tear for up to 100 thousand km of vehicle mileage.

To treat your car's engine, we recommend using:

However, if there is a significant degree of wear or destruction of the CPG elements, the use of revitalizant gel will be ineffective. The car owner will have to carry out a major overhaul of the engine, and after the overhaul, it will still be necessary to run in the engine.

Typical VAZ 2106 engine malfunctions

Every car owner sooner or later encounters an engine malfunction. It cannot be said that VAZ 2106 engines are exceptions to this rule. Some breakdowns occur more often than others. In this article we will look at the most common problems with a six-wheel engine and how to fix them.

- troit engine for VAZ 2106;

- the motor gets very hot;

- a knock is heard in the engine;

- the power unit smokes;

- the engine is breathing;

- works unstably and intermittently.

When and how often do you need to repair the gearbox on a VAZ 2107?

(“Volzhsky Automobile Plant”) provides comprehensive information on when and how often the gearbox needs to be repaired. It turns out that this mechanism does not have a service life as such. The only thing AvtoVAZ engineers insist on is the timely replacement of transmission oil:

- After the first 2 thousand kilometers on a new car.

- After 60 thousand kilometers.

- Further, as necessary, depending on the care of the owner and the frequency of use of the car.

Accordingly, the plant does not have any specific wishes or requirements for preventive or repair work. However, in any case, regardless of the mileage, it is necessary to carefully monitor all the nuances in the “behavior” of the box, since repairs will be necessary if the slightest malfunction occurs.

In winter, due to temperature changes, the box experiences additional load

Engine troubles

Everyone has heard this word “triple”. But not everyone fully understands what this word means. But this term was coined precisely in our country to designate a common problem. The fact is that sometimes one of the cylinders in the engine begins to malfunction or completely stops working. The mixture of air and fuel in it either burns poorly or does not burn at all. As a result, only three working cylinders remain. Hence the word “triple”.

The driver understands that this problem has arisen by how much the engine begins to vibrate. There is a feeling that he is ready to break free of his fastenings. In this case, the car does not move. Sometimes you can hear fuel flashes that pop into the muffler.

If the VAZ 2106 is tripping, there may be three reasons for this:

- Less or more air enters the cylinder than necessary. This may be due to loss of air tightness in the air system. We check whether the system is leaking air somewhere. To do this, use a compressor to pump air into the system to increase the pressure and listen to where it hisses. If there is no hissing, then the system is still sealed. You also need to check if the air filter is clogged. The air supply dampers may also be faulty. Particular attention should be paid to the throttle valve.

- More or less fuel enters the cylinder than required. This is checked by measuring the pressure in the fuel system. If the pressure is low, you need to look for a problem in the fuel pump and in the pressure valve. If the pressure is normal, you need to diagnose the injectors for contamination or failure.

- Low compression. If this is the reason, then you need to prepare yourself for a long, expensive repair. Compression is reduced or reset to zero if the piston burns out, if the piston wheel is worn out, or if the valve is faulty. To find out the true cause, you will have to completely disassemble the engine and troubleshoot it. Often you have to do major repairs.

The engine gets very hot

It is worth noting that a carburetor engine encounters this problem much less often than an injection engine. Even on hot summer days it holds the temperature well and does not exceed 96 degrees. Why does the engine get hot?

- The thermostat malfunctions. As they say, the valve “caught the wedge.” This can be checked very simply: you need to touch the bottom of the thermostat with your hand. If it is cold, then the problem is in the thermostat valve. Another sign of a non-working thermostat: the radiator outlet is very overheated. As a result, this valve is kept closed, the liquid does not enter the radiator and boils. If in this state it penetrates into the piston part, as well as into the oil sump, this can lead to critical engine failure. Therefore, if a malfunction is detected, you need to turn off the engine and replace the thermostat with a working one.

- The appearance of an air lock in the radiator pipes. To eliminate this problem you will have to bleed the entire system.

- The radiator is clogged. To avoid this problem, you need to clean the radiator regularly, especially during the hot summer season. You also need to use only high-quality coolant to avoid clogging the radiator from the inside.

- You can also pay attention to whether the fan is broken.

- Another common reason that the VAZ 2106 engine may overheat is a breakdown of the water pump. Often there is a leak in the pump. You can check the operation of this part as follows: at engine operating temperature, sharply squeeze the inlet pipe on the radiator. In this case, the working pump produces a noticeable pulsation. It also doesn’t hurt to check the pump seal, which starts to leak from time to time.

Engine knock

If at one point you begin to hear extraneous knocks and noise when the engine is running, you need to pay serious attention to this. It is best to stop right away and try to find out the reasons. Indeed, in some cases, continuing to operate the engine can be very dangerous. Let's look at the most common problems associated with knocking.

- The main bearings are knocking. This is very dangerous, so you need to turn off the engine immediately. You will have to tow the car to the repair site. The problem can be easily recognized: the sound has a low pitch. It comes from the bottom of the crankcase and increases when you press the gas pedal. The oil pressure sensor turns on.

- The connecting rod bearings are knocking. You need to turn off the engine immediately. His further work is very dangerous. You will have to go to the repair site in tow. The sound is resonant, has a metallic tint, a medium tone and a certain rhythm. Intensifies with increasing load.

- Piston pins are knocking. You must continue to operate the engine very carefully. It is better to go slowly and immediately to the place of repair. The sound has a high metallic tone with sharp tones and is rhythmic. If you disconnect the spark plug, it goes away immediately.

- Cylinders or pistons are knocking due to wear. You can continue driving, but without putting too much load on the engine. It is better to immediately go to the repair site. The sound is very similar to the knocking of clay dishes. It sounds more clearly until the engine has warmed up to operating temperature. As the engine warms up, it gradually quiets down.

- Valves are knocking. You can continue to move carefully, but it is better to head straight to the repair site. There is a dull noise with metallic knocks. Knocks are especially audible at low and medium speeds. It comes from the side where the valves are located.

- Engine detonation. You should immediately go carefully to the repair site. Sounds occur during acceleration. The problem is resolved by installing a later ignition. The problem may arise due to poor ignition control, due to the use of low octane fuel, or due to engine overload as a result of early engagement of a high gear. You also need to check if there is carbon deposits in the combustion chambers.

Lada 2106 “My six” › Logbook › 95. Cleaning the breather. Emulsion. And a little chat :)

Hi all. It all started with the fact that yesterday morning I didn’t start, dropped the Akum, and basically went crazy :( I had to go to work by trolleybus in a hurry. Yesterday morning it was -16, and today it’s already +3, what a winter it is. What we have - I tried in the morning started on gas, picked up the engine, ran for a bit and stalled :( I drove all the gas with the starter, switched to gasoline, pumped it up with a gas pump, tried to start - no luck, it seizes and immediately stalls. Again I drove all the gasoline out of the float chamber, boiled the kettle, poured it on the gearbox , defrosted it - tried to start it - no, it didn't work anymore, I turned it on until the battery barely started turning, there was no time to wait. I left everything like that, locked the car and went to work. It was only in the evening that I figured out what I needed when the car stalled on gas, boil a kettle and pour boiling water on the gearbox, maybe then it would have started without problems. But again the dipstick would have squeezed out 100%, so it’s good that it didn’t start after all.

On the way home from work I stopped at my father-in-law's for some charge, came home and started it on gas, in the evening it was already -5. But another problem appeared - by the way, the same situation happened in the morning - the engine starts and literally after 20-30 seconds of operation the oil dipstick squeezes out. I took off the carb cover - and the hole from the breather was all in emulsion, and frozen :(

The polystyrene foam saved us from the snow - snow fell and covered the entire engine, it was fun to poke around under the snow.

After that I decided to check the hose itself going from the breather to the pan, it was oak - like it was made of plastic, I tried to remove it and it broke :(

The breather itself is surprisingly relatively clean

I cleaned what I could on my knee. When it's warm, I'll take everything off and clean it thoroughly.

But the only thing was that she stood at the very bottom in the hose coming from the breather. Should she be standing here? Not near the pan?

I was thinking about what to do next - it was snowing, the hose was broken. I searched at home but couldn’t find anything with a suitable diameter from the available tools. The solution came spontaneously :)

Only the insulation was crap, and was lying in the car - I could barely scrape off a roll of it, but it was a pity to twist good insulation here - anyway, today I’ll go get a new hose and throw out the old one. The most interesting thing was that I had to warm up the hose - in order to put it on the pan - it became stiff again while I was poking around. Then I look into the pan and the condensation in the hole has not gone away. I found a syringe, extracted everything I could from it, did not remove the pan - it was already about 10 pm. Then I decided to add oil - because this was not the first time the dipstick had fallen out, and the oil was at a minimum. I took off the oil filler cap and everything was in emulsion. The reasons for this are clear - I go to work by car every day, it’s 7 km there and 7 km back, driving close the car doesn’t really have time to warm up, apparently. Now the question is - is emulsion bad for the engine? How does it affect it - and how can it be corrected and prevented from the formation of an emulsion? I don’t warm up the car for a long time - I get out, start the car, clear the snow, clean the windows and drive out - in total, a maximum of 5 minutes pass, the engine, judging by the temperature sensor, warms up to 50 degrees, the needle just begins to deviate from the initial position. I drop my child off at kindergarten and go to work. When I arrive at work, the engine temperature is already 90. Well, I just leave work, start it up, 1-2 minutes and drive home. The car heats up even less - well, until it warms up, of course, I rev the engine for 2-2.5 thousand, but don’t rev it up at high speeds. I solved the main problem, but the question of what to do now with freezing condensate and emulsion remains open. Who can advise?

P.S. Yesterday I realized that even thorns will not save you everywhere in winter. The day before yesterday I was driving home - I pulled into the street, sat down - paddled up to the ice under the snow and that's it - the wheel was slipping on the ice, I had to swing back onto the road and go around this place a little further. Yesterday, a colleague gave me a lift in a Lanos, on studded Rosava Snowguard, and in the place where I usually drove without problems, I got stuck. The same situation, I shoveled the snow and got on the ice - and essentially skidded the same way as I did without spikes, and somehow jumped out with the same swing - as it seemed to me, I accelerated very sharply and the wheels quickly scooped up all the snow and the car got on the ice and began to slip .

And with the weather and winter we have a complete arctic fox:( Either -10 outside or +2 and it’s raining. And then it all freezes - and there’s ice everywhere, and then snow falls on this ice again and it gets even worse. A day later this snow becomes water, and again it is slippery to the point of impossibility. The roads are poorly cleaned, so you can only rely on yourself and the car. But in principle, I have never experienced any problems with movement - I drove everywhere, on wet ice and in snow and downhill - I’m happy with my tires And after last year's trip on March 7 - when it rained and immediately froze on the road, forming a very slippery crust of ice and, worst of all, smooth, it was very difficult to drive until it was sprinkled with snow. And on that day I had to go around the whole city, from one end to get to the other and then return to the center. And it was after these adventures that I am no longer afraid of any difficult weather conditions - well, the only thing except heavy snowfall - where I just bury myself and sit on my belly - although I made myself a small shovel, especially for digging out - so you can dig yourself out and move on. Driving in winter greatly improves your driving skill. I notice that every day I drive bolder and bolder in the snow and on ice) Because in almost 10 years of driving, this is the second full winter; before that, the car spent the winter in the garage and was driven a couple of times a month in winter and on summer tires :) I made another conclusion about driving with rear-wheel drive in winter - it’s much easier to move with front-wheel drive - I revved up the throttle - the wheels just slip and don’t go anywhere, but with rear-wheel drive it can even turn on the road if you stomp on the throttle madly, relying on the electronics. But I still remain a supporter of rear-wheel drive :) Clean roads everyone! And more free fuel :)

The engine smokes

Usually a small amount of smoke comes out of the exhaust pipe. However, sometimes there come moments when thick smoke can literally pour out of your six. To understand what the problem is, you need to pay attention to its color.

- Transparent color. Transparent or slightly white smoke that is almost invisible. It's not even smoke, but rather steam. It occurs because the system has not yet warmed up. This is especially noticeable in winter after the car has been sitting in the yard all night. There's nothing wrong with that. After the system warms up, the steam will practically disappear.

- Black color. This phenomenon looks quite scary. One of the reasons may be the usual overload of the motor with heavy weight. Try unloading the trunk if you have placed something particularly heavy in it. However, most often this problem does not arise for VAZ 2106 owners due to the small size of the vehicle. Therefore, also pay attention to how the mixture formation process proceeds. Most likely there is too much fuel entering the engine. The result is not only black smoke, but also increased fuel consumption. Try changing the air filter. You also need to measure the compression. Check the condition of the cylinders and whether the engine control sensors are working correctly. Check the spark plugs to see if they have a black coating on them, which may indicate the need to repair the engine.

- White color. Unlike the clear smoke described above, this smoke has a thick white tint and does not disappear as the engine warms up. It indicates that there is a malfunction in the cooling system. This is a sure sign that urgent measures need to be taken, because a breakdown can lead to a major overhaul of the engine. Check the candles to see if they have developed a coating similar to what appears on a kettle due to scale. If this happens, it means water is getting into the cylinders.

- Bluish color. The reasons for this phenomenon can be various breakdowns. For example, you can check the serviceability of the valve stem seals. If they are damaged, oil may leak and enter the idle engine. You will also have to check the oil rings. Due to their wear, excess oil may flow into the cylinders.

Here we have listed only the most common causes of excess smoke. If this information does not help, you need to contact the service center.