The main reasons for the reduction in engine power

1. Malfunction of the crankshaft position sensor

There are situations when the DCPV untimely sends a control command to supply the air-fuel mixture. As a result, the power of the power unit drops before our eyes. The main cause of the failure is the shift of the toothed star relative to the pulley and the delamination of the damper. In such a situation, it is necessary to carefully inspect the damper and replace it.

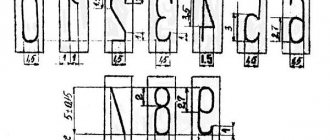

2. Increasing (decreasing) the gap between the spark plug electrodes

During operation, due to strong temperature effects, the distance between the electrodes of the spark plug may decrease or increase. To exclude or confirm your suspicion, you need to check the size of the gaps using a round feeler gauge. If the distance is less or more than acceptable, you need to make an adjustment by bending the side of the electrode or replace the spark plug. As for the optimal spark gap distance, it can be different (depending on the type of spark plug) - 0.7-1.0 mm.

The appearance of carbon deposits on the spark plugs is another clear sign of a problem.

If the engine does not pull well, you need to unscrew all the spark plugs one by one and inspect them. If obvious carbon deposits appear on the electrodes, the device must be cleaned using a brush with metal bristles. It is important not only to clean the spark plugs or replace them, but also to find out the cause of this phenomenon.

Failure of spark plugs

A decrease in engine power may be caused by product failure. In this case, it is necessary to check the performance of the spark plug on a special stand. If the suspicions are confirmed, then the only way out is to replace the set or one spark plug.

There is no gasoline in the tank

You can diagnose the problem using the fuel level indicator. If it is faulty or there is a suspicion that it is “inadequate,” then the presence of fuel can be determined by removing the fuel pump.

Fuel filter contamination, water freezing in the system, pinched fuel wire, fuel pump failure

All these malfunctions can be safely classified into one category, because they all have the same symptoms - the starter cranks the engine, but there is no smell of fuel from the exhaust pipe. If the car has a carburetor, then the reason must be sought in the float chamber. Most likely, fuel is not supplied to it. In the case of an injector, it is easier to check the presence of fuel in the ramp by pressing a special spool (installed at the end of the ramp).

To correct the problem, you need to warm up the engine thoroughly and bleed the power system with a tire pump. After this, all system pipes, hoses and the fuel pump itself are changed.

Fuel pump produces too little pressure

This problem can only be determined by special measurements (taken directly at the outlet of the fuel pump). After this, the quality of operation of the fuel pump filter is checked.

The solution is to clean the fuel pump filter, replace it (if repair is not possible) or install a new fuel pump.

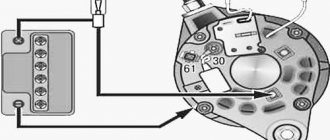

Poor contact quality in the circuit

Poor contact quality in the circuit that powers the fuel pump or failure of its relay. The first thing you need to do to check is to make sure the quality of the “ground” on the car and measure the resistance using a multimeter. If the resistance level is really too high, then the only way out is to clean the contact groups, crimp the terminals well, or install a relay (if the old one is faulty).

9. Failure of injectors or malfunction in the supply system

If there is a suspicion of failure of these elements, it is necessary to check the resistance of the windings using a multimeter for a break or an interturn short circuit. If the cause of the problem is a malfunction of the computer, then such a check can only be carried out at a service station.

There are several ways to eliminate a decrease in engine power for this reason (depending on the depth of the problem) - install a new ECU, clean all injectors, ensure good contact in the electrical circuit, and so on.

DPKV failure

Failure of the crankshaft position sensor or damage to its circuit. In such a situation, the Check Engine light comes on. The first thing to do is to inspect the integrity of the DCP itself, make sure that the gap between the ring gear and the sensor is normal (it should be about one millimeter). The normal resistance of the sensor coil is about 600-700 Ohms.

To solve the problem, it is enough to restore normal contact in the electrical circuit and install a new sensor (if the old one turns out to be faulty).

DTOZH is out of order

The DTOZH - the sensor that controls the temperature of the coolant - has failed. Symptoms of the malfunction are as follows: the engine malfunction lamp comes on. If there is a break, the system’s electric fan begins to rotate continuously. In addition, it is necessary to check the serviceability of the sensor itself.

If engine power has dropped for this reason, then it is necessary to restore the quality of contact in the electrical circuit and install a new sensor.

TPS is out of order

The TPS sensor, which monitors the correct position of the throttle valve (or its chain), has failed. As in previous cases, the “Check engine” lamp comes on here. If there is a break in the TPS circuit, then the engine speed usually does not drop below one and a half thousand revolutions.

The solution to the problem is to clean the throttle assembly and restore the quality of the contact connection throughout the entire electrical circuit. If the sensor is faulty and cannot be repaired, it must be replaced.

DMRV has failed

The mass air flow sensor, the sensor responsible for monitoring mass fuel consumption, has failed. The optimal action here is to check the integrity of the mass air flow sensor or replace it with a working device. If the failure of the mass air flow sensor is confirmed, then it is necessary to make an attempt to clean it, and if repair is impossible, simply replace it.

Knock sensor failure

Damage to the knock sensor. In the event of such a malfunction, the engine malfunction lamp necessarily lights up on the instrument panel. In addition, if the motor fails, there is no detonation in any of the operating modes of the power unit and the engine power also drops. With such a problem, the best option is to restore the integrity of the contact group in the electrical circuit and install a new sensor.

Why the VAZ-2114 engine pulls poorly: the main reasons and repairs

At the same time, in many cases the engine runs smoothly, does not tremble, there are no increased vibrations, extraneous sounds, knocking or noise during operation of the internal combustion engine. Let us note right away that there is a fairly wide list of possible reasons why a warm engine does not run, and there is a loss of engine power when cold and/or when hot.

In this article we will talk about why the engine does not pull, and also consider the most common malfunctions that manifest themselves in the form of loss of traction of the power unit.

Causes

There may be several reasons for the lack of proper speed gain:

- There are problems with the air supply;

- The ignition has failed;

- Fuel system malfunctions have occurred;

- There were problems with the exhaust system.

Fuel system problems are common in gasoline engines. They are the most common. Therefore, you should start with checking it.

Fuel system

If problems arise when accelerating the car, start checking by inspecting the fuel system.

- Most often, the engine stops gaining momentum because the fuel pump fails. At first, this may have a slight effect, sometimes unnoticed. Over time, as the pump wears out, the speed and power will begin to drop, and the acceleration dynamics will decrease.

- If the fuel pump is partially damaged, it still partially performs its functions, but is no longer capable of delivering the same volumes of fuel. This results in fuel starvation and power loss.

- The best solution to a problem with the pump is to replace it. It is better to trust repairs to specialists.

Ignition

If the ignition fails, you will have to conduct a comprehensive check of all system components that may cause a drop in engine power and speed.

What to check

Peculiarities

Checking timing marks

If the marks are installed incorrectly, fuel will not be injected in a timely manner, and the correct frequency of spark supply will be disrupted.

You will have to check all the sensors that take part in the operation of the ignition system. Pay special attention to the crankshaft and camshaft position sensors. A regular test allows you to quickly determine whether the sensors are really to blame

If the belt has been in use on your vehicle for a long time, it may be at the end of its service life. Or it was installed incorrectly when replacing it. After all, it is enough to make a mistake by one tooth, and the performance of the car will be impaired, the car will not be able to accelerate properly

In some cases, they do not allow the car to start at all if there is a malfunction, but sometimes they lead to a noticeable drop in power. Remove them, check their condition, clean them, measure the distance between the electrodes. If they fail, simply replace them with new ones.

To finally verify the presence or absence of problems in the ignition system, it is recommended to conduct more detailed diagnostics.

Diagnostics

We suggest you familiarize yourself with several steps aimed at diagnosing the condition of the ignition system. This may help determine why the engine is not revving up.

- Make sure that the electronic control unit is performing its functions. First of all, turn on the ignition and listen to whether the fuel pump starts working.

- Measure the pressure in the fuel line. If the readings fall within 2.5-3.0 kg/cm3, then everything is fine.

- If the measurement readings are normal, check the BitStop parameter using scan tools while cranking the crankshaft. If the parameter is indicated “no”, then the ECU receives the command to create a spark at the plugs and works well.

- Using a high-voltage spark gap, you can check for the presence of a spark. After all, it’s not uncommon for worn-out, dirty spark plugs to be to blame.

Air supply

It is not uncommon for engine thrust to deteriorate due to a disruption in the normal air supply to create the air-fuel mixture.

If there is more air, the mixture will be lean because the amount of oxygen will exceed the amount of fuel. Hence the drop in power and decrease in traction.

The easiest way to solve an air supply problem is to replace the air filter. In order to prevent and prevent problems from occurring, this element should be changed twice a year.

Checking the mass air flow sensor

If the engine speed increases, but the speed does not increase, there are several possible explanations for this phenomenon:

- The pressure in the fuel system is too low;

- The operation of the mass air flow sensor is disrupted. The sensor most often returns to its previous performance after cleaning. If it doesn't help, replace it;

- The air filter is clogged. It is better to replace it;

- The nozzle is clogged. This is mainly due to the low quality of the fuel you fill your car with.

Why the VAZ-2114 engine pulls poorly: the main reasons and repairs

VAZ-2114 cars, from the start of production, are equipped with eight-valve engines with a volume of 1.5 liters. Since 2007, they have been equipped with an eight-valve 1.6 liter engine with an environmental class of Euro-4. The operation of the car, sometimes incorrectly, brings “surprises” over time. The engine does not perform its functions at full power, and thrust decreases. Let's try to understand the causes and methods of elimination.

VAZ-2112 accelerates poorly 16 valves: poor acceleration dynamics

There are many deterioration in dynamics, the main ones can be defined as follows.

: reduction of compression in one or more cylinders, suction of additional air into the engine

. Coking of the exhaust system or damage to the exhaust gas converter (if the vehicle is equipped with a catalytic converter).

2. Malfunction of the power supply system: clogged injectors and fuel filter, hoses of the fuel supply system. Insufficient fuel pump supply. Use of low quality fuel.

3. Malfunction of the ignition system: failure of the spark plug, breakdown of the high-voltage circuit of the system.

engine control: failure of system sensors. If any sensor fails, the electronic control unit switches to working according to a backup program, allowing you to get to a garage or car service center, but at the same time the power and economic characteristics of the engine are reduced.

5.Clutch slipping due to wear or misadjustment.

6. Malfunction of the brake system: braking of one or more wheels while driving, incorrect adjustment of the parking brake.

7.Insufficient air pressure in tires.

Full diagnostics of the car should be carried out by highly qualified technicians using special diagnostic equipment, so contact a car service center.

You can carry out the following work yourself.

1.Check and adjust tire pressure to normal.

2.Check the operation of the service brake system and parking brake. It is not necessary to remove the wheels for this. Find a flat section of the road and, in dry, windless weather, conduct a test run to determine the vehicle's run-out. The car must be fully fueled, with only the driver in the cabin. Accelerate the car to 50 km/h, level out the speed, then switch off the gear and coast until it comes to a complete stop. Do another run in the opposite direction. The run-out should be about 500 m.

Other reasons for reduced engine performance

The condition of the exhaust system also greatly influences engine power. The fact is that to protect the environment from harmful emissions during operation of the internal combustion engine, catalytic converters are installed in the exhaust.

As a rule, official services offer to replace a worn-out element, but the price of the spare part is very high. For this reason, on many cars in the CIS, the catalyst is simply knocked out, and the control unit is “deceived” by software or other available methods.

Also, when engine power decreases, it is necessary to separately check the installation of the timing belt or chain according to the marks in order to eliminate the possibility of valve timing failure. Sometimes there are situations when the belt can jump one tooth, the chain stretches, etc.

In this case, the synchronous operation of the valve mechanism in relation to the operating cycles of the internal combustion engine may be disrupted. This leads to various failures, unstable operation of the unit and reduced power.

Let us also add that engine wear and certain malfunctions also affect engine power. As a rule, worn-out internal combustion engines with mileage usually lose about 10% of their declared power.

One way or another, any leaks in the combustion chamber will lead to expanding gases breaking out of the cylinder during fuel combustion. This means that the pressure of these gases on the piston will decrease, and the internal combustion engine itself will draw poorly and operate unstably.

Finally, we note that the reason that the car has lost dynamics may not be the engine, but the transmission. In other words, the power unit develops enough power, but it is not fully transmitted to the wheels.

If, when coasting, it is noticeable that the car immediately begins to slow down, then the problem is obvious, the wheels are slightly blocked. If no problems with the brakes are identified, then automatic transmission diagnostics are necessary. It is better to entrust this procedure to experienced specialists by delivering the car to a service center.

Purpose, design features, installation location of the fuel pressure regulator of an injection engine. Signs of RTD malfunctions, checking the device.

As a result, jerks and dips appear when accelerating, and the car jerks in motion during transitional conditions. Causes and troubleshooting.

The most common reasons why an engine does not develop full power. Why do they occur? Common problems with gasoline and diesel engines.

Why the engine may not pick up speed: gasoline engine, diesel unit, car with LPG. Fault diagnosis, useful tips.

When you sharply press the gas pedal, the engine jerks, jerks and dips appear, the car does not pick up speed: the main causes of the malfunction and diagnostics.

Signs of a non-working cylinder (tribbing and vibration) of a diesel engine. Troubleshooting: compression, diesel injectors, glow plugs, injection pump and others.

Please help. VAZ 2110 has lost traction, there are no errors. The pressure is normal, the module has been changed, spark plugs, filters, throttle sensors, DPKV, phase sensor have been changed, I don’t know where to dig further. The traction is gone.

Similar articles

16 comments on “The craving is gone. VAZ 2110 lost traction”

Alternatively, change the gas station. Changed TNK to Lukoil, started flying instead of driving)))

Couldn't the timing belt have jumped?

100% belt jumped

Change the gasoline, or buy a fuel activator, I think it’s called, I had this on 12

Check the injector wires.

Look at the DPKV pulley rod and timing belt

Perhaps a key has been cut off on the crankshaft gear or on the damper. I had this until it didn’t happen at all. If it is turned a little, then the ignition will be late, the sensor will not read the position of the shaft cranks correctly and it will be too late to give a spark, and for this the traction will be greatly lost

1. Engine malfunction: decreased compression in one or more cylinders, leakage of additional air into the engine intake tract. Coking of the exhaust system or damage to the exhaust gas converter.

2. Malfunction of the power supply system: clogged injectors and fuel filter, hoses of the fuel supply system. Insufficient fuel pump supply. Use of low quality fuel.

Main reasons

There are many reasons for this phenomenon and in most cases they are associated with a malfunction of the systems and mechanisms of the power plant.

Some of them are trivial and very easy to fix, others require quite serious repairs.

The main problem with the fact that the engine does not pull is not related to eliminating the malfunction, but to finding it.

In some cases, it is very difficult to determine what caused the reduction in traction effort and you have to go through almost the entire engine.

Therefore, we will try to indicate the main reasons why the car accelerates very “sluggishly”.

Since engines on different cars have their own design features, we will consider specific models.

The engine does not pull, where to look for the reasons

In the life of motorists, a situation often arises when, when driving out onto the road and trying to accelerate, it is noted that the engine does not pull.

That is, the acceleration dynamics are very “sluggish”, the car is reluctant to pick up speed, and it feels like something is holding it back.

This problem can arise with almost any car - domestic or foreign, gasoline or diesel, with a carburetor power system and injector.

Often, a drop in traction is accompanied by additional symptoms - extraneous sounds appear when the engine is running, the engine may stall in one of the modes (usually at idle), the crankshaft speed is not stable and “floats”.

But this is not always the case; it happens that the unit behaves perfectly in all respects, but does not develop power.

Content:

- Main reasons

- Power drop on a VAZ carburetor engine

- Supply system

- Ignition system

- Exhaust system, timing belt and crankshaft

- VAZ injection engines

- Supply system

- Ignition and exhaust system

- Main reasons with engines of other cars

- If the diesel engine doesn't work

- Other reasons

VAZ injection engines

In injection engines VAZ-2110, 2112, 2114, 2115, both 8-valve and with a timing belt with 16 valves, it is more difficult to identify the cause of the decrease in power due to the more complex design of the main systems.

Supply system

Any injector consists of a mechanical executive part and an electronic control part, and problems can arise in both of them, which will lead to a drop in power.

Let's look at the mechanical part first. Here, cravings can be influenced by:

- Severely clogged mesh filter on the fuel pump;

- Decrease in fuel pump performance due to wear;

- The fine filter is dirty;

- Malfunction of the fuel rail pressure regulator;

- Clogged injectors;

- Fuel filter dirty;

- Air leak in the manifold.

In general, almost every element of the injector executive part can be the culprit for a decrease in dynamics.

The situation is approximately the same in the electronic component.

The operation of the engine with the injector is controlled by an electronic unit, which constantly monitors the parameters through sensors installed on different systems.

The number of these tracking elements is considerable and the breakdown of any of them leads to the fact that the ECU incorrectly evaluates the indicators on the basis of which it controls the executive part.

Thus, the lambda probe, DPKV, mass air flow sensor, DPZ, phase sensors, detonation sensors and coolant temperature sensors in the event of a breakdown lead to a decrease in power, so you will have to check all of them in search of the cause.

Reasons why an injection engine does not develop full power. List

Download PDF

Any self-respecting driver will begin to find out the reasons why an injection engine does not develop full power, as soon as he notices a drop in the prescribed characteristics.

Even if you don’t really need all the power of the car at the moment, slow acceleration or dullness when driving are very annoying. In addition, such signs clearly indicate that not everything is in order with the engine. And even a beginner can understand that it is impossible to skip diagnostics - this can lead to serious consequences that will cost more than eliminating the problem in its initial stage. And most drivers treat the car more like a friend than an object. And people care about the health of their loved ones on an instinctive level.

The reasons why an injection engine does not develop full power can be general - common to all types of engines - and individual, which are typical exclusively for injectors.

VAZ 2110 slowly slows down

For normal engine operation and acceptable fuel consumption, it is necessary that all power unit systems operate properly. In this case, the engine should operate normally both under load and in idle mode.

In practice, drivers quite often encounter a problem when, after releasing the gas, engine speed does not fall or falls with a long delay. It is quite obvious that high idle speed indicates a problem and is the cause of increased fuel consumption.

Why does the engine speed drop when idling the VAZ 2110 injector and carburetor

Let's start with the fact that on many cars with an injector, the ECU raises the speed while the internal combustion engine is warming up. This is necessary to ensure that the power unit operates stably after a cold start.

However, after the temperature rises, the control unit reduces the idle speed, bringing it to normal. On many cars with a carburetor, the driver independently increases the speed during warm-up, using the so-called “choke”.

Moreover, after the engine is warmed up, the normal idle speed is, on average, 650-950 rpm. If you press the gas and release the accelerator, the speed should increase, and then decrease again to the specified values.

Also, a situation often arises when the speed drops slowly or is constantly kept at around 1.5 thousand rpm, 2 thousand revolutions, etc. Naturally, in such cases, consumption increases and the internal combustion engine wears out more, which indicates the need for diagnostics.

Problems with carburetor cars

So, let's start with common carburetor problems. Often the engine speed does not drop due to problems with the throttle valve. For example, when the driver steps on the gas, the throttle must be opened wider to allow more air to enter the cylinders to burn fuel. After the gas pedal is released, the throttle closes and the speed decreases.

If the damper does not close completely, an over-enriched mixture enters the cylinders, and the speed is increased. The cause may be severe contamination of the throttle assembly or damage to the valve itself (deformation). First you need to clean the damper; carburetor cleaning liquid is suitable as a cleaner.

We also note that the damper does not close tightly even when the drive cable is worn out. In this case, the cable must be replaced. On carburetor cars, engine speed often does not drop even if the gasket between the carburetor and the cylinder head has failed. The culprit may also be an intake manifold that is damaged.

It should be noted that after cleaning the carburetor and fuel system, the engine speed slowly drops due to a failure in the adjustments of the idle system itself. In other words, after any manipulations with these components, the carburetor should be separately configured and adjusted.

The main task is to find the correct ratio of fuel and air. Often, a high level of fuel in the carburetor float chamber also leads to increased speed. The check should begin with the needle valve.

Reasons for floating speed on fuel-injected cars

Now let's move on to the injector. Please note that on many injection cars, after cleaning the throttle valve, the assembly also needs to be additionally “trained”. As for problems, the injection system itself is more complex, that is, there are more reasons for high speeds compared to the carburetor.

Coolant sensor - coolant

As a rule, problems with speed can be caused by problems with both mechanical elements and electronic components. In the list of main malfunctions, experts highlight malfunctions of the coolant temperature sensor, which is installed in the cooling system.

In simple words, if the specified sensor gives an incorrect signal, the ECU considers that the engine is cold and activates the warm-up mode. In this case, the control unit raises the speed so that the power unit operates stably and reaches operating temperature faster.

Idle air control - IAC

Also, problems with speed can begin due to problems and malfunctions in the operation of the IAC (idle air regulator). It also happens that the throttle cable gets stuck and becomes wedged. The spring that closes the throttle valve may also become stretched or damaged.

Air leak

Special attention should be paid to gaskets, since air leaks can lead to disruption of mixture formation. This means that you need to separately inspect manifold gaskets, injector seals, etc.

Floating speed: reasons

Note that in some cases the revolutions do not just slowly fall or remain at the same level, but “float”. In this case, the engine may become unstable. Floating speeds first fall, then increase sharply and everything repeats. A common cause of this phenomenon is the supply of excess air, which leads to “jumps” in speed.

Candles

If the ignition is on (VAZ 2110 injector 8 valves included), the battery is charged and the fuses are intact, you need to check the spark plugs. This is one of the common problems that occurs on injection engines. For some reason, the car does not start, but gasoline continues to flow into the combustion chamber. As a result, the spark plugs become flooded with fuel. And instead of producing a spark, the flammable mixture extinguishes the candles. They become wet.

The spark misses the electrode and ignition does not occur. Advice from experienced motorists: when turning the ignition key, you need to press the accelerator to the floor. This will dry out the combustion chamber - more air will enter it. If after three to five attempts you are unable to start the engine, do not discharge the battery. To check, we need to unscrew the spark plugs. Here you will need a special hex key. It has a different diameter for each candle model. First, remove the high-voltage wire. This must be done very carefully. If you pull it by force, it will break and it will be impossible to repair it. Rotate it clockwise and counterclockwise and pull it slightly towards you (at the base). We unscrew the element and look at the electrode. If the end of the candle is wet, and it itself has a characteristic smell of gasoline, it means it has been “flooded.”

Main reasons with engines of other cars

Next, we will go through other cars, and we will indicate the most frequently occurring problems that lead to a drop in power.

So, on a Mitsubishi Lancer 9, the problem most often arises with the exhaust gas exhaust system. This car uses a double catalyst, which becomes clogged with carbon deposits relatively quickly.

Therefore, many owners of this car, when the power drops, recommend first of all paying attention to this system.

But in the ZMZ-406 and 405 engines, which are equipped with GAZelle and Volga cars, a drop in power often occurs due to:

- Ignition coil malfunctions;

- Losses in high-voltage wires;

- Non-working spark plugs;

- Failure of sensors (primarily DPKV).

But do not forget about the other above-mentioned elements of the power supply, ignition, as well as timing and CPG systems.

In Ford Focus cars, in general, problems with loss of traction arise due to malfunctions of sensors, as well as elements of the power system - especially the fuel module, which includes both a fuel pump and a filter, combined into a single structure.

Much the same applies to a car like the Renault Megane. In this machine, power loss may occur due to:

- Wear of the distributor cover;

- Faulty spark plugs and high voltage wires;

- Weak exhaust system capacity;

- Worn fuel pump and dirty filter elements;

- Damaged injector sensors.

In general, first of all, you should look for the cause in the power and ignition systems, and only then move on to the timing belt and CPG.

Power drop on a VAZ carburetor engine

To begin with, let's take VAZ cars with a carburetor power system and an 8-valve timing system - VAZ-2109, VAZ-2110, VAZ-2114, VAZ-2115.

The same power plant is installed on these cars, so the reasons are identical.

Let's go through those components, due to malfunction of which a drop in dynamics may occur.

In general, the main reason that the engine does not pull is a change in the processes in the combustion chambers - a mismatch in the proportions of the air-fuel mixture, the combustion process is disrupted, the filling of the cylinders and the removal of exhaust gases does not occur as required.

Supply system

Very often, a drop in traction occurs due to the power system. Structurally, the carburetor fuel system used on cars from VAZ-2109 to VAZ-2115 is very simple and is almost completely mechanical, so identifying the cause is not particularly difficult.

A decrease in power can occur due to:

- Severely clogged fuel filter (its throughput drops and the pump is simply not able to pump the required amount of fuel);

- Contamination of the carburetor channels (the jets and fuel channels in this element have a small cross-section and debris often clogs them);

- There is air leakage in the area from the tank to the pump (because of this, the performance of the fuel pump drops sharply);

- Damage to the fuel pump membrane (a small crack in it leads to the fact that the vacuum required for pumping fuel is not created in the pump chambers);

- The fastening of the carburetor or intake manifold is loose (due to this, air leaks around the carburetor and the proportion of the air-fuel mixture is greatly disturbed);

- The hole in the fuel tank cap is clogged (because of this, a vacuum is created in the tank and it is much more difficult for the gas pump to pump gasoline out of it);

In addition to the elements responsible for supplying fuel, a drop in power also occurs due to severe contamination of the air filter element.

Ignition system

This system also takes part in the combustion of the mixture, which means a failure in its operation can affect power.

In carburetor engines VAZ-2110 and others, a decrease in traction can occur due to:

- Faulty spark plugs or changes in their thermal gap;

- Excessive wear of the contacts and the central electrode of the distributor;

- Voltage losses in high-voltage wires;

- Violations of the ignition timing.

Irregularities in the power supply and ignition systems most often cause a drop in power, so testing to identify the cause should begin with them.

If the operation of these systems does not raise suspicions, other components of the engine should be diagnosed.

Exhaust system, timing belt and crankshaft

Loss of traction can also occur due to the exhaust gas removal system, although problems with it rarely occur on carburetor engines.

The main reason here is the reduction in throughput due to large deposits in the muffler. Because of this, exhaust gases, without having time to escape from the cylinders, “choke” the engine.

The reasons for the drop in thrust are also often the gas distribution mechanism and the cylinder-piston group.

Here the reduction in power occurs due to:

- Violations of the thermal clearance of valves;

- Heavy carbon deposits on the valve plates and seats, or their burning;

- Occurrence of rings;

- Limit wear of the CPG;

- Cylinder head gasket failure.

In general, problems with the timing belt and CPG cause a drop in power in any engine - carburetor, injection, diesel. Therefore, we will not mention these mechanisms further.

Causes of poor speed gain

General view of the engine under the hood

So, let's look at what the problem is and where exactly you need to look for it:

- Fuel pump and pressure.

- Injectors.

- Fuel rail.

- Ignition system.

- Electronic control unit.

Now that all the causes are predetermined, you can begin sequential diagnosis and methods for solving the problem.

Options for solving the problem

To diagnose all of the above systems you will need a set of wrenches and screwdrivers, a tester, a little knowledge and hands growing from the right place. The main task remains to correctly distribute the sequence of operations. This is exactly what we will talk about next. So, let's look at where we need to go to remove the effect that has arisen.

Fuel pump, filter, rail and injectors

Fuel pump in the process of disassembly and diagnostics

First of all, for diagnostics it is necessary to diagnose the gasoline module (pump). If the car drives at high speeds, then everything is fine with the pump itself, but the problem may lie in the filter mesh . For inspection, you will have to remove the fuel pump and replace the cleaning screen on it, which is primarily responsible for purifying gasoline. Most likely, it is dirty and needs to be replaced.

General view of the fuel filter

The second problem may be the fuel filter, which needs to be replaced. It is often dirty and needs to be replaced. After the first two elements of the fuel system have been replaced, you can try to drive it and see if the problem goes away.

General view of the fuel rail with injectors

If, nevertheless, the car continues to gain momentum poorly, then you need to crawl under the hood and look for the problem directly in the fuel injection system. To do this, you need to measure the pressure in the fuel rail.

To do this, dismantle the fuel rail with injectors and disassemble the assembly. The first element must be checked for leaks. Injectors are often installed on a special stand, cleaned and diagnosed. If necessary, all damaged elements are replaced.

Ignition

Unscrewing the spark plugs from the engine

If the fuel system has been checked and is working properly, then you need to look for a problem in the ignition system. So, the high-voltage wires are dismantled and the spark plugs are unscrewed. Both elements are checked using a tester . Of course, it is best to diagnose spark plugs on a special spark plug stand. As practice shows, the problem in 50% of cases lies precisely in this unit, so after checking it is necessary to replace the damaged elements. We conducted a special survey on the choice of candles.

ECU error codes

If all of the above reasons are eliminated and the components are working properly, then most likely the firmware has failed or a critical number of ECU errors have accumulated.

To eliminate the cause, you need to connect the laptop to the engine control unit and carry out diagnostics.

Supply system

All problems with the power system of an internal combustion engine, which can affect power and speed, can be divided into three main ones, namely:

Below we will consider each of them in more detail.

Fuel system

If the car does not pick up speed when you press the gas pedal, first of all, experts recommend checking the fuel supply system. In both gasoline and diesel engines, several common reasons for the absence or disturbance of traction can be noted:

Let's look at each of the problems in more detail.

Fuel pump or injection pump

A fairly common reason for reduced traction is a malfunction of the fuel pump. Moreover, both “mechanical” and electric pumps fail with approximately the same frequency. Due to a malfunction of the fuel pump, the fuel supply is reduced, and the engine cannot develop its full power when you press the gas pedal.

It is worth noting that in diesel engines it is the fuel injection pump that is one of the weak points. Most often problems arise with the plunger pair. For diesel engines, such a malfunction can lead to the engine refusing to work at all.

The fuel pump, as a rule, does not fail immediately. The exception is when the wiring to the pump is damaged. Most often, the reduction in power occurs gradually as the vehicle is used. Eventually the pressure generated by the pump will be so low that the engine will only be able to idle. When the load on the engine increases or when you try to increase the engine speed, the car may simply stall, not raise the speed, and so on.

Fuel filter

Another culprit that can reduce the amount of fuel supplied to the engine may be the fuel filter. Like any other filter, this element in the car can also become heavily clogged, thereby causing engine speed restrictions, when the needle on the tachometer cannot rise above a certain value, or failures during acceleration. In this case, the car may jerk while driving, and also respond for too long when you press the gas pedal or when trying to reduce engine speed.

It is worth noting that in this case there may not be any difficulties with starting the engine, even when idling. Since the fuel entering the engine will be sufficient to operate at minimum speeds, problems usually begin during active driving.

If the diesel engine doesn't work

A decrease in traction can also occur in diesel engines. If we look at old cars that have completely mechanical power systems, then the most common cause is depressurization of the system.

As a result, air enters the fuel, which is why the fuel injection pump is unable to provide the required pressure.

Don't forget about:

- clogged filters;

- weakly pumping fuel priming pump;

- damaged plunger pair;

- Coking of injector nozzles.

And if we also add possible problems with the timing belt and CPG, then identifying the cause will not be so easy.

In modern diesel installations, where an additional electronic component is used, the search range will increase.

For example, the Common Rail system uses all the same sensors as the injection engine. And if at least one of them breaks, this will certainly affect the operation of the control part.

Other reasons

Finally, we note that some reasons are very rare and can be considered specific.

These include loosening the exhaust manifold, although initially it may seem that this cannot affect the engine.

In fact, on many cars, heat from the manifold is used to warm up the air entering the cylinders, and for this purpose a special screen is used, to which the air duct fits.

So, if a breakdown occurs and the exhaust gases break out, then most of them will enter the cylinders again through the air duct, and due to a lack of air, the power will decrease.

Also, the reason may lie not in the engine, but in the transmission elements, especially for cars equipped with automatic transmission.

Malfunctions in the box lead to the creation of excessive load on the engine, which will be perceived as a loss of power.

Source

Why the car doesn't pull: reasons (carburetor)

If such an engine loses traction, the fuel pump fitting may be dirty or there may be low pressure in the system.

It is also possible that the carburetor is simply dirty or there is some problem with the needle valve. There may be errors or incorrect settings for adjusting the composition of the fuel mixture. If the carburetor flaps are not open enough, traction may be lost. When the fuel level in the engine decreases, traction also disappears. When there are any problems with traction in the engine, it is urgent to carry out a full diagnosis.

You definitely need to find out why the car pulls poorly; we have already looked at the reasons. If a malfunction is found, it should be corrected immediately. If you could not find the reason for the decrease in cravings on your own, there is no need to hesitate. A more in-depth examination should be carried out at the service station. But basically, the cause can still be identified and eliminated independently.

So, we found out why the car loses traction.

If the car does not show its former power and traction, you will not get any pleasure from driving. Moreover, the consumption of gasoline or diesel fuel often increases, and the risk of failure of any units increases. The car owner intuitively understands that something is wrong in the design of the vehicle. Therefore, there is a desire to check the car, find the cause of the defect and get specific solutions to the problem. Today we will talk about why the car does not pull, and also what needs to be done in such situations, where you should look first. If you encounter such a problem suddenly, it is worth quickly diagnosing the main components of the machine, identifying the problem and eliminating the cause of the loss of power. If the problem has been present for a long time, it’s time to go to a service station and solve this issue.

If you drive for a long time with most of the problems that cause loss of traction, you can completely ruin the power unit and end up needing expensive repairs. So we strongly recommend that you immediately pay attention to a noticeable loss of engine power or a real feeling that someone is holding you by the exhaust pipe and is not allowing you to accelerate. The longer you think it will go away over time, the more damage you can do to your car. This will also cause excessively expensive repairs in the long run. Let's consider the main reasons for this phenomenon.