Location of all sensors on the injection VAZ 2114

It cannot be said that the VAZ 2114 is a very modern car filled with electronics.

However, the list of sensors used that are connected to the electronic control unit is quite impressive on the fourteenth. Each of these devices is responsible for certain functions and collects data transmitted to the main computer of the car. This way, the ECU controls the entire process and makes appropriate changes, so that the driver does not have to look for the reasons for the failure or insufficiently efficient operation of a particular unit.

List of devices

Sensors are needed to report on the performance of systems, signal the level of cooling liquids and oil, and prevent or anticipate emergency situations.

These small devices, despite their size, play an incredible role in the performance of the machine. Therefore, it will not be superfluous to know which sensors are on your car.

Let us list the main ones present in the VAZ 2114 systems. We include sensors in this list:

Coolant temperature;

Coolant level in the expansion tank;

Mass air flow rate indicator;

Engine idling;

Brake fluid level in the system;

Camshaft position (it is called a phase sensor);

Outside air temperature;

Uneven road surface.

This list is very, very extensive. But even this, the owners of the VAZ 2114 do not want to stop, which is why they are introducing several more different sensors into the system:

- Light devices;

- Reverse;

- A device that signals open doors;

- Brake pad wear indicator, etc.

Where are they located?

But knowing about their presence in your VAZ 2114 car is not enough. In case of problems, when the electronic control unit receives incorrect data from signaling devices, they have to be changed.

Whatever one may say, every sensor that has ceased to function properly and transmit correct data on the state of the systems to the electronic control unit must be replaced. Almost all sensors cost no more than a few hundred rubles. But even low cost and small size do not indicate the uselessness of these devices. Change devices promptly.

To do this, you need to understand how to get to this or that sensor. Therefore, we invite you to familiarize yourself with the location of key alarm and measurement devices.

Sensor

Location

On 8 valve engines it is located at the bottom of the valve cover in the cylinder head, and on 16 valve engines it is located on the left end of the camshaft bearing housing

Coolant temperature (engine temperature sensor)

Look for it near the tasty cylinder head cooling jacket pipe

Coolant level

It is located directly on the tank, inside of which there is coolant (antifreeze or antifreeze). Looks like a simple plastic cover that connects to an electrical connector

Brake fluid level

This is a float device located inside the brake fluid reservoir.

Idle speed (IAC)

Look near the throttle valve on the throttle body

Mass air flow

You will find it near the large intake pipe, directly on the air filter housing

Throttle Positions

Located on the throttle body

Crankshaft position (timing sensor)

Its location is near the electric generator drive pulley

Camshaft position (phase sensor)

Near the cylinder head cover, viewed from the air filter side

Oxygen (lambda probe)

Installed in front of the resonator in the intake manifold of the exhaust system

Located between cylinders 2 and 3 near the fan

It should be looked for inside the intake chamber of the fuel tank

Located directly on the gearbox

Look near the cup on the side of the right mudguard. You can get there through the engine compartment

Ambient temperatures

It is installed directly behind the front bumper, exactly in the middle

Each sensor has its own strictly designated place. Having studied their locations, you can easily replace devices in the event of breakdowns or malfunctions.

Some measuring and signaling devices are located literally on the surface, so there is no need to carry out additional dismantling work. To get to others, you will have to seriously dig into your VAZ 2114 and remove quite a few parts.

The integrity of your car, the safety of the driver, passengers and all other road users depend on their performance. Therefore, treat the sensors with appropriate respect, monitor their condition and change them in a timely manner if the need arises.

A little about car idling

Idling refers to the operation of the power unit in a static position of the car, that is, when the car is stationary and the neutral gear is engaged.

When the engine operates this way, the load on it is negligible, and, therefore, fuel consumption is low. Idling is usually used to warm up the system in winter frosts in order to disperse the oil and prevent freezing. This mode is also used when it is impossible to turn off the motor.

During normal idling, the tachometer needle points to 2,000 rpm and slowly drops to eight hundred rpm. But, if there is a failure in the system, then the revolutions seem to live their own lives, sometimes soaring to incredible heights, sometimes falling to the very bottom.

In this case, the revolutions can fluctuate from a minimum of five hundred to a maximum of one and a half thousand revolutions per minute.

This happens especially often in new VAZ models equipped with an electronic pedal, E-gas, which, on the one hand, opens up new horizons for the driver, and on the other, gives him even more headaches in troubleshooting such fragile and unreliable electronic equipment.

It is worth saying that determining the true cause of an idle problem is not an easy process, but if you leave everything as it is, it can lead to serious problems, which may result in a complete stop of the engine and the need for expensive repairs.

And now about all the problems and how to fix them in more detail.

Floating speed on carburetor engines

The main cause of this problem in cars with a carburetor engine is a malfunction of the carburetor. In fact, it may simply be incorrectly adjusted. Air leaks or a breakdown of the XX solenoid valve can also cause floating speed. Sometimes the reason lies in the air filter; it is recommended to check it for deposits. But much more often the problem is caused by the carburetor. It is necessary to carefully configure it, adjusting the level of quality and quantity of fuel used.

By the way, if the solenoid valve still raises suspicions, it can be easily checked without disconnecting the power supply. With the ignition on, it is enough to touch the valve with the wire from the contact. You should hear a click. If it does not sound, this does not always mean that the valve is faulty. You can touch the contact with the cord connected to the battery positive. If there is no click again, the valve is faulty. To repair it, just clean the jet. Now you know the main reasons for the occurrence of floating speed in a VAZ-2114 car and how to eliminate this problem.

A short video that discusses the main possible causes of floating engine speeds

Problems and solutions

There are a lot of reasons for unstable idle, and they apply to both carburetor and injection engines and even diesel engines, both to the old type design and to the new E-gas pedal, which AvtoVAZ is so proud of. Let's start with the problems that occur in carburetor-type engines:

- The fuel-air mixture has become lean. To fix the problem, you just need to make an adjustment to the level of eight hundred revolutions.

- Unstable running can also occur due to wear on the carburetor valve. In this case, the engine operates exclusively with the choke mode extended. To fix the problem, you need to replace the defective part with a new one.

- It also happens that the system channels become dirty. Then the fuel does not receive the required portion of air and leads to failure. Here you just need to clean the channels.

What is an exhaust gas recirculation valve?

Welcome, friends, to the DIY auto repair website. Buying a car is a real holiday. A new car increases the level of comfort, makes life more convenient and gives pleasure. But this is only one side of the “coin”.

Exhaust gas recirculation valve

On the other hand, you have to constantly learn - study the technical structure of the equipment, make repairs and replace faulty parts.

At the same time, some nodes are a real mystery for beginners. One of these is the exhaust gas recirculation valve.

What is it - Exhaust Gas Recirculation Valve

The purpose of the valve is a kind of “cleaning” of the car exhaust and elimination (reduction of volumes) of nitrogen oxide in its composition.

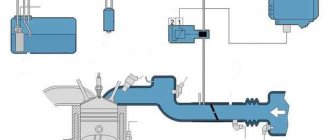

This is achieved by returning part of the gas to the exhaust manifold. Such a system is called by three Latin letters EGR (full name - “Exhaust Gas Recirculation”).

The presence of the system helps reduce fuel consumption, increase the efficiency of the power unit, reduce the “hardness” of work in a diesel engine and detonation in a gasoline engine.

As a rule, car enthusiasts rarely understand the principle of operation and the features of repairing the device.

When the first problems appear, everything ends with the “neutralization” of the system and, as a result, deterioration of the car’s performance.

If maintenance and repairs are carried out correctly, the exhaust gas recirculation system will last a long time and bring many benefits.

Exhaust gas recirculation in diesel and gasoline engines

It may seem a little strange that engine exhaust gases do not always exit completely through the exhaust pipe immediately. In fact, the exhaust gases are returned to the engine. This technical trick lowers the combustion temperature of diesel fuel, which subsequently reduces the formation of harmful nitrogen oxide (NOx). Recirculated exhaust gases displace fresh air in the intake duct, namely low oxygen levels in the exhaust gases, and then absorb some of the combustion heat in the combustion chamber, resulting in a significantly reduced combustion temperature. As a result, the formation of harmful nitrogen oxide drops sharply.

This EGR valve is controlled by vacuum. When the valve (inside) opens, it clears the way for exhaust gases to enter the intake duct.

See also: New law on control over technical inspection from January 1, 2017

Gasoline engines also use an exhaust gas recirculation system. Here, the return of exhaust gases to the engine serves to reduce fuel consumption, since the throttle valve can be further opened by pressure from the returned exhaust gases. In this way, the so-called energy losses when opening the throttle valve are reduced, which helps reduce fuel consumption and, accordingly, leads to a decrease in the level of harmful substances in the exhaust system.

Purpose of the recirculation valve

Another “secret” for beginners is the purpose of the device. Everything is simple here. As soon as the temperature in one of the cylinders reaches a certain temperature, nitrogen and oxygen interact.

The result is nitric oxide is formed. It is no secret that in gasoline cars the air-fuel mixture is formed by mixing fuel and air.

Due to the chemical reaction, oxygen becomes less (it was “taken away” by nitrogen). As a result, the air-fuel mixture does not burn completely, engine power decreases, and additional “portions” of CH and CO are released into the atmosphere.

At the same time, the “gluttony” of the vehicle increases. In turn, the EGR system, the basis of which is the exhaust gas recirculation valve, opens the way for the return of part of the exhaust to the intake manifold.

In this case, the exhaust gases are mixed again with a new portion of air. And here we remember chemistry. The presence of oxygen increases the combustion temperature.

In turn, the exhaust gas that comes back reduces it. The result is a decrease in the amount of nitric oxide.

The second positive point is the reduction of pumping losses. This is realized due to sudden changes in pressure across the throttle valve.

Reducing combustion temperature eliminates engine detonation. As a result, you can set the ignition early and increase torque.

Methods for eliminating floating engine speeds

When starting to find and eliminate the reasons that cause unstable operation of the engine in idle mode, you first need to check:

- Condition of the air filter and spark plugs. If they become critically dirty, they need to be replaced.

- Integrity of insulation of high-voltage wires. If damage is found, they must be replaced.

It is recommended to make sure that there is no suction at the junction of the intake manifold with the engine cylinders. To do this, with the engine running, you need to sequentially spray all joints at the joints with carburetor cleaner or other flammable liquid. If atmospheric air enters there, the car engine jerks sharply, which is why, if a damaged gasket or plug is detected, the element is replaced.

Checking the tightness of the intake manifold (video guide)

Let's consider the remaining elements of the car, the malfunction of which can affect the smooth operation of the VAZ 2114 engine in idle mode.

Solenoid valve diagnostics

Cars with engines equipped with a carburetor are equipped with idle speed solenoid valves. Devices are checked as follows:

- Disconnect the power cord.

- Start the engine to warm up.

- Connect the wire. If a clear click is not heard, the part must be replaced.

Attention! To fully ensure that the valve is working properly, be sure to clean the nozzle and repeat the test.

Adjusting the idle speed on a carburetor engine (with video)

Note that the main reason for the appearance of floating idle speed in engines of this type is the incorrect operation of the carburetor. The device is adjusted by rotating the fuel quality and quantity screws.

Is the EGR system on the injector working?

"Floating" speed can be caused by jamming of the exhaust gas recirculation (EGR) valve, which is installed in the exhaust manifold. It is necessary to periodically remove dirt from the valve seat and its seat using a carburetor cleaning aerosol, avoiding liquid getting on the sensor diaphragm.

Keep the valve seat clean

Attention! If cleaning the unit does not give a positive result, the device must be replaced.

Is the idle air control valve working correctly?

The IAC is checked by measuring the electrical resistance at the contacts - to diagnose the device you will need a tester (multimeter) set to the “ohmmeter” operating mode. To check the details:

- Let's turn off the ignition.

- Disconnect the connection block.

- Let's measure the resistance on contacts A - B and C - D of the device. The optimal readings of the device vary from 40 to 80 ohms.

- Let's repeat the measurements with contacts B - C and A - D. In this case, the multimeter should show “infinity” or an open circuit.

Any violation of the normal resistance values means a malfunction of the regulator. IAC failure is a common cause of floating engine speed at idle, and if a malfunction is detected, the device must be replaced. Before you begin dismantling the part, you must disconnect the negative wire from the battery. After installation, the new IAC is calibrated - the removed terminal is returned to its place, the ignition is turned on and after 5-10 seconds (there is no need to start the engine).

Features of the exhaust gas recirculation system

The EGR valve is located between two manifolds (intake and exhaust) after the throttle valve. The vacuum cavity of the device is combined with the intake manifold.

When the engine is idling, the throttle valve is closed and there is no vacuum in it.

In this mode, there is almost no formation of nitrogen oxide. As a result, the idle speed is stable and the engine runs smoothly.

As soon as the loads increase, the throttle valve opens and a vacuum of air appears behind it.

The latter acts on the system diaphragm and promotes the opening of the valve. As a result, even at medium loads the EGR system actively performs its functions.

When the engine speed increases and the engine operates at maximum load, the throttle valve opens completely. The result is a reduction in vacuum to a minimum level.

Electronic systems

Devices based on the pneumatic principle are very reliable and have shown their best performance. The only negative is low accuracy at different load levels.

As a result, manufacturers began developing a more efficient system - electronically controlled Exhaust Gas Recirculation.

The principle is the same here. The only difference is that all commands are given by the engine ECU. The “brain” receives commands from a number of sensors (throttle position, engine temperature, pressure in the intake manifold, and so on).

Based on the data received, the ECU makes a decision and sends a signal to the recirculation valve. The latter opens to a specific amount, and a certain volume of exhaust gases returns to the cavity of the intake manifold.

How the USR system works and the cause of breakdowns:

If you do not decide to turn off the system, then the malfunction may be in the following elements:

- The main component is the EGR valve. It transfers gases from the intake manifold to the exhaust manifold. This valve constantly interacts with a hot environment, and this is the most vulnerable part of the entire system. The main malfunction is valve depressurization. The system can operate either electrically (mostly GM cars) or pneumatically (most brands of cars).

In the case when the valve opens electrically, this occurs as a result of the readings of a special sensor that transmits a signal directly to the engine. The next method that is responsible for the operation of the valve is electro-pneumatic.

- EGR solenoid . It is located in a system where the valve is controlled using pneumatics. The main malfunction remains the same - depressurization.

- USR valve opening position sensor. Sometimes it happens that they fail, but in this case only the lamp on the instrument panel lights up, signaling a malfunction of the engine. There are no other consequences.

Different systems may have a different set of component elements, but the main one is the EGR valve. Let's see how all these breakdowns can affect the operation of a car engine.

It was said above that the main malfunction is depressurization, which results in uncontrolled suction of air masses into the intake manifold.

As a consequence, this may lead to:

- Engine with an air flow meter - the fuel becomes leaner due to the presence of additional oxygen.

- Engine with a pressure sensor - the fuel will be additionally enriched due to the increase in pressure in the intake manifold.

- Those engines that use both of these methods to control oxygen levels will have a sharply richer fuel mixture at idle and leaner at other engine operating conditions.

In all cases, when the level of oxygen becomes less in the air that enters the engine, the ignition of the fuel in the engine cylinders is impaired. We can say that the dependence here is quite complex and, in view of this, the failure of the USR system is quite complex and it can manifest itself differently on different brands of cars.

An important indicator will be the level of exhaust gases that enter the intake manifold. In other words, you are interested in the opening indicator of the USR valve. In addition, the overall percentage of engine wear (spark plugs, fuel pump or clogged fuel injectors) will affect this.

Now let's talk about how the fuel system will affect the breakdown of the USR valve if you do not decide to turn off the system. Each control unit has special software that balances the idle speed and fuel quality in the car. At the same time, the level of opening or closing of the mechanism that regulates idle speed, as well as the injection duration, have a specific indicator. When the control unit balances the idle speed in different operating modes, it cannot cope with the quality of the fuel mixture.

This occurs because when the driver presses the gas pedal, the pressure in the exhaust manifold of the exhaust gases penetrating into the intake manifold increases. This can lead to deterioration in vehicle acceleration dynamics and unstable operation of the vehicle engine. Then the picture will change. When hot gases mix with oil fumes in the manifold, this can cause more carbon deposits to accumulate inside the manifold, on the intake valves, the outer parts of the injectors become dirty, and soot appears on the spark plug contacts. Because of this, it will become more difficult to start the engine, poor idling, the car will jerk and the engine will run unevenly. And if you sharply press the gas pedal, flashes will appear in the intake manifold. To avoid this, timely cleaning of all these elements is necessary, and in an emergency, you can turn it off.

Basic malfunctions and valve diagnostics

During operation, the EGR valve may become clogged or jammed. In this case, he will respond more slowly to commands or not follow “orders” at all.

As a result, engine power decreases, idle problems appear, fuel consumption increases, and controllability decreases.

To avoid problems, it is important to periodically inspect the condition of connectors, tubes and other elements of the system.

With pneumatic adjustment, the problem can be eliminated using a vacuum pump. As for systems with control from the ECU, it is better to check and repair them at specialized service stations.

At first glance, it may seem that the EGR system is ineffective and absolutely unnecessary. But that's not true.

Experienced car enthusiasts are well aware of the benefits of the valve and diagnose and replace it from time to time. Have a good trip and of course no breakdowns.

Why does the car accelerate on its own when idling? Learning to make diagnostics

Sometimes you can hear questions about why the car accelerates on its own at idle? This can manifest itself at the most inopportune times, and the strength of the “self-reversal” often varies. In some cases, the speed may fluctuate slightly between 800-1200 rpm. In other situations, the car can scare others at traffic lights, spontaneously raising the speed to 4000-5000. But, regardless of the size of the jumps, it is advisable to fix the problem as soon as possible. This will avoid many unpleasant moments, including increased fuel consumption, as well as increased wear of parts. Why does the car accelerate on its own when idling? To answer this question, you will need to conduct a detailed diagnosis. There are many reasons for this behavior of the car, so you will have to take turns checking all the parts whose malfunction can lead to such jumps. You should start with the simplest options and end with the most complex elements. It’s not bad if it is possible to conduct computer diagnostics. This will simplify the troubleshooting process.

Location of all sensors on the injection VAZ 2114

It cannot be said that the VAZ 2114 is a very modern car filled with electronics. However, the list of sensors used that are connected to the electronic control unit is quite impressive on the fourteenth.

Each of these devices is responsible for certain functions and collects data transmitted to the main computer of the car. This way, the ECU controls the entire process and makes appropriate changes, so that the driver does not have to look for the reasons for the failure or insufficiently efficient operation of a particular unit.

List of devices

Sensors are needed to report on the performance of systems, signal the level of cooling liquids and oil, and prevent or anticipate emergency situations.

These small devices, despite their size, play an incredible role in the performance of the machine. Therefore, it will not be superfluous to know which sensors are on your car.

Let us list the main ones present in the VAZ 2114 systems. We include sensors in this list:

Coolant temperature;

Coolant level in the expansion tank;

Mass air flow rate indicator;

Engine idling;

Brake fluid level in the system;

Camshaft position (it is called a phase sensor);

Outside air temperature;

Uneven road surface.

This list is very, very extensive. But even this, the owners of the VAZ 2114 do not want to stop, which is why they are introducing several more different sensors into the system:

- Light devices;

- Reverse;

- A device that signals open doors;

- Brake pad wear indicator, etc.

Where are they located?

But knowing about their presence in your VAZ 2114 car is not enough. In case of problems, when the electronic control unit receives incorrect data from signaling devices, they have to be changed.

Whatever one may say, every sensor that has ceased to function properly and transmit correct data on the state of the systems to the electronic control unit must be replaced. Almost all sensors cost no more than a few hundred rubles. But even low cost and small size do not indicate the uselessness of these devices. Change devices promptly.

To do this, you need to understand how to get to this or that sensor. Therefore, we invite you to familiarize yourself with the location of key alarm and measurement devices.

Sensor

Location

On 8 valve engines it is located at the bottom of the valve cover in the cylinder head, and on 16 valve engines it is located on the left end of the camshaft bearing housing

Coolant temperature (engine temperature sensor)

Look for it near the tasty cylinder head cooling jacket pipe

Coolant level

It is located directly on the tank, inside of which there is coolant (antifreeze or antifreeze). Looks like a simple plastic cover that connects to an electrical connector

Brake fluid level

This is a float device located inside the brake fluid reservoir.

Idle speed (IAC)

Look near the throttle valve on the throttle body

Mass air flow

You will find it near the large intake pipe, directly on the air filter housing

Throttle Positions

Located on the throttle body

Crankshaft position (timing sensor)

Its location is near the electric generator drive pulley

Camshaft position (phase sensor)

Near the cylinder head cover, viewed from the air filter side

Oxygen (lambda probe)

Installed in front of the resonator in the intake manifold of the exhaust system

Located between cylinders 2 and 3 near the fan

It should be looked for inside the intake chamber of the fuel tank

Located directly on the gearbox

Look near the cup on the side of the right mudguard. You can get there through the engine compartment

Ambient temperatures

It is installed directly behind the front bumper, exactly in the middle

Each sensor has its own strictly designated place. Having studied their locations, you can easily replace devices in the event of breakdowns or malfunctions.

Some measuring and signaling devices are located literally on the surface, so there is no need to carry out additional dismantling work. To get to others, you will have to seriously dig into your VAZ 2114 and remove quite a few parts.

USR valve: purpose, principle of operation, maintenance and repair

The number of cars on the world's roads is growing rapidly. It is no secret that absolutely any vehicle equipped with an internal combustion engine poses a threat to the environment and human health.

They seriously thought about how to make the “iron horse” safer and more environmentally friendly in the 70s of the last century. It was then that the Exhaust Gas Recirculation system, or as it is commonly called for short, EGR, was developed.

What is an EGR valve

The operation of the valve is quite simple - part of the gases from the exhaust system is mixed with air from the exhaust manifold. If the percentage of nitrogen oxide is too high, this leads to high temperatures in the combustion chamber. We all know from school that oxygen acts as a catalyst for combustion. And gases from the intake manifold, mixing with the air flow, minimize the percentage of oxygen. As a result, the combustion temperature decreases and toxicity decreases.

How the USR system works

Everything will depend on the engine on which such a valve is installed. In diesel engines, the valve will be open already at idle speed, and will provide 50% of the intake air. As soon as the engine speed increases, the valve will gradually close. And it will close completely as soon as the engine speed reaches its maximum value. When the engine warms up, the valve will also be completely closed. During idle speed of the internal combustion engine, the USR valve will be closed, and it will not turn on at maximum engine speed. In other engine operating modes, the EGR valve supplies air to the intake from 5% to 10%.

The principle of operation of the EGR valve and what it is

Engineers and designers of leading automobile companies work every day to improve the vehicle exhaust system. During operation of the internal combustion engine, exhaust gases are released into the environment, and it has long been a known fact that these gases contain a large number of chemical compounds hazardous to health. Nitrogen oxide and dioxide are considered the most harmful. Deviation of the concentration of these substances in the air from the norm provokes the occurrence of a number of diseases of the human cardiac and respiratory system.

The most rational way to reduce the toxicity of exhaust gases today is the use of the EGR system, the principle of which is exhaust gas recirculation. Ignition of a flammable mixture is possible only at high temperatures and appropriate pressure. But the catch is that these are the conditions that are ideal for the formation of oxide by combining oxygen with nitrogen.

The EGR valve allows some of the exhaust gases to be sent to a portion of fresh air. The consequence of this is a decrease in the amount of oxygen in the mixture. A lean mixture needs a completely different temperature. It no longer requires 1400 or more degrees Celsius to ignite.

Many drivers believe that the EGR valve reduces engine power, which has a detrimental effect on the technical performance of the car. It is for this reason that the system has not yet found proper distribution in the post-Soviet space. However, experiments and studies show the opposite: EGR does not reduce engine power, but increases it. This may be by reducing the number of detonations in the gasoline power unit.

Summing up the intermediate results, it can be noted that the USR valve allows:

- Improve the quality of fuel combustion;

- Reduce engine detonation;

- Reduce the amount of emissions of harmful substances;

- Provide auxiliary control of exhaust gas toxicity.

It remains to be found out on what principle the valve works? Today, modern cars are equipped with an ECU, which is a real “brain center”. Based on the data received from various sensors (TNA sensor, EGR level sensor), the control unit determines the optimal time for supplying exhaust gases to the intake manifold. Gas supply is possible due to a signal from the computer, which forces the solenoid valve to open and conditions are created for a vacuum in the pneumatic valve.

EGR valve: defects and symptoms

Often the exhaust gas valve (EGR) is coated with a mixture of soot and oil.

In the photo you can see what the exhaust gas recirculation valve looks like after thousands of kilometers of vehicle operation. EGR valve malfunction can manifest itself in different ways. Here are signs that may indicate a faulty EGR valve:

— When accelerating, the car picks up speed jerkily

— Fluctuations at idle

— Loss of engine power

— Appearance of the “Check Engine” icon on the dashboard (Check Engine - emergency engine operation program)

— The level of nitrogen oxide increases in the exhaust gases

— Black smoke from the exhaust pipe

— Increased fuel consumption

Because the EGR valve and its control mechanism are located in the exhaust gas stream, it is the most sensitive component of the exhaust gas recirculation system. Due to the soot contained in the exhaust gases, the control mechanism of the exhaust gas recirculation valve may begin to work incorrectly over time - the valve may no longer open or close normally.

The valve can also become dirty due to oil vapors from the oil separator, which, in combination with soot, do their evil work over time.

As a result of improper operation of the exhaust valve, the level of harmful substances in the exhaust system can significantly increase. There may also be a delayed response from the vehicle when you press the gas pedal (throttle response). The most common symptom of a faulty exhaust valve is a severe loss of engine power. This usually happens when the valve fails to close properly. Along with the loss of power in this case, black smoke may appear in the exhaust pipe, which is formed due to the lack of the necessary portion of fresh air at full load.

See also: Everything you need to know when using AdBlue in your car

If the EGR valve is stuck in the closed position, you may not notice any signs of malfunction while driving the car. But if you measure the level of nitrogen oxide during this type of malfunction, you will find that it is significantly higher than normal.

A contaminated exhaust valve (which also inevitably means contamination in the engine intake system) can lead to increased fuel consumption. By the way, sometimes all these signs can appear periodically (not constantly), since the USR valve can restore its function on its own. However, even temporary symptoms should not be ignored, since this clearly indicates its malfunction. This means that in the near future, problems with the exhaust valve will become more frequent and sooner or later this will lead to failure of the valve.

How to clean equipment

Due to low quality fuel, premature failure of the EGR valve or another component of this system, for example, a sensor, occurs. After only 50 thousand kilometers traveled, the valve may break. There can actually be many reasons, but most often the breakdown occurs due to carbon deposits on the surface of the valve. Carbon deposits violate the tightness of the system and also have a negative impact on the quality of the signal received by the ECU.

Due to unstable idle speed, transmission breakdowns are common. What should a driver do in such a situation? There is only one solution - regularly clean the EGR valve from carbon deposits. However, it is worth remembering that even regular maintenance of the system will not guarantee its uninterrupted operation. Cleaning the valve from carbon deposits generally occurs in several stages: placing the components in a light solvent, blowing and washing the channels.

Idle speed control

The first thing you should check is the idle speed control. To do this, you will need a tester (multimeter) set to ohmmeter mode.

The check is performed as follows:

- turn off the ignition;

- disconnect the block;

- measure the resistance between contacts A * B and C * D of the regulator. If it is working properly, the device will show a resistance value in the range from 40 to 80 Ohms;

- measure the resistance between contacts B * C and A * D. If the regulator is operational, the ohmmeter will go off scale (on some devices an “open circuit” may be indicated).

If the results obtained during measurements differ from those given above, then the idle speed controller is broken. By the way, its failure is one of the most common reasons why the idle speed of a VAZ 2114 injector fluctuates. If a breakdown is detected, the part should be replaced with a new, similar one (since the IAC is not a repairable device). Do not forget that before starting to replace the device, you should disconnect the battery ground terminal.

After the new regulator is installed, it should be “calibrated”. To do this, turn on the ignition for 10 seconds and then turn it off. There is no need to start the engine.

Cleaning and main signs of system failure

At the first stage of cleaning, the recirculation channels are placed in a special cleaning solution. Many experienced drivers use carburetor flushing agent as a solution. At the second stage, the channels are blown out using special devices. It is recommended to do this work only with the valve open.

If it was not possible to clean the device, then the only correct solution would be to purchase a new copy. Carbon deposits are not the only reason for the failure of the USR. A number of other malfunctions associated with the vacuum booster and thermal valves occur in the recirculation system. The valve itself is considered the most vulnerable point in the system. In addition to clogging and soot, it is constantly exposed to high temperature. For this reason, it may periodically jam in the open or closed position.

The valve breaks down, the system stops performing its duties, the amount of nitrogen oxide in the exhaust gases exceeds all permissible levels. But this is not the only problem that arises due to EGR failure. The following symptoms are usually classified as malfunctions:

- At idle, unstable engine operation is noted;

- Decrease in diesel power;

- Manifestation of vehicle jerking at high speeds;

- Rapid wear of spark plugs and clogging of injectors.

Is there an effective way to determine the cause of a breakdown and which specific system component has failed? A quick and effective diagnostic method is scanning the system using electronic equipment. This pleasure is not cheap, but even if it is possible to undergo diagnostics, the result will not always be positive. The reason is that there is not a sufficient information base on errors and there is no way to compare the actual and nominal characteristics of the element.

Some of the most common mistakes:

- USR system error - code P0400;

- EGR valve error - code P1403;

- Gas recirculation circuit error - code P0403;

- Error in valve operating elements - code P0404.

Drivers also often wonder: where is the EGR valve located? It is impossible to give a definite answer to this question, since the location of this element in different brands of cars varies significantly. But, as a rule, the valve is always located near the main power unit of the machine. For example, on the Opel Astra the USR valve is located under the engine protective cover in the right corner, and on the Opel Omega on the right side of the ignition distributor. In any case, if you cannot find this element of the engine compartment, you should always first focus on the tube that is connected to the valve.

Checking TPS

The sensor must be checked using a multimeter or a special diagnostic device such as ELM-327, but since not everyone has this device, we will consider checking with a multimeter.

The test is carried out in two stages: checking the power circuit and checking the sensor itself.

Checking the power circuit

This test is to determine whether the sensor is receiving power. Sometimes it happens that the fault of the sensor is not the sensor itself, but its power circuit.

- On the multimeter, set the switch to the mode for measuring constant voltage with a limit of 20 Volts.

- Remove the connector from the sensor and turn off the ignition on the car.

- We connect the probes of the device to the connector. A voltage of at least 5V should appear on the device.

Sensor check

The sensor is checked by measuring the resistance of the sensor while rotating its central moving part.

- We switch the multimeter to resistance measurement mode;

- We connect the device to the terminals on the sensor;

- We rotate the central part of the sensor and look at the readings of the device, they should change smoothly without jumps and sharp drops ad infinitum;

- If all conditions are met, the sensor is operational;