Speakers for a 12-inch subwoofer occupy an intermediate position between small acoustic radiators and the most powerful devices with a diameter of 18-20 inches. Speakers of 6-8 inches allow you to get quite powerful sound, but some, especially strong bass, will not stand out against the background of other instruments. Drivers with a diameter of 46 centimeters are the basis of a super-powerful low-frequency system, which not everyone needs, so 12-inch speakers are considered the golden mean. The box for a 12-inch subwoofer can be made according to any design.

The easiest one to make with your own hands is a closed type column. This means that only one hole is cut into the side of the box for the speaker. The box for a 12-inch subwoofer must be made of such material as to completely eliminate vibration and rattling when reproducing low frequencies.

Types of subwoofers

When figuring out how to make a subwoofer, it is necessary to evaluate the properties of the main types of these devices. The user can choose among the following varieties:

- Active subwoofer.

- Passive type models.

Active designs are available with an amplifier and crossover, which guarantees good sound with suppression of the high-frequency range. Such models can work with any sources.

Samples of the second group are not equipped with amplification units, and are connected to the standard radio. The disadvantage of a passive device is that the channels are fully loaded, which degrades the quality of the reproduced sound.

Depending on the design features, the following types of boxes are distinguished: open and closed boxes (CL). The former are built into the finishing elements of the interior, and the latter are made in the form of independent boxes, inside of which a speaker with a low-frequency range is installed.

What to make from

To make a subwoofer with your own hands, it is important to take care of the materials for its creation. First of all, you should prepare the following:

- Speakers. When choosing a speaker, you should evaluate its technical parameters: they must correspond to the capabilities of the car radio. If a new part is purchased, then all the characteristics will be indicated on the packaging or in the package insert.

- MDF sheets. Enclosures for subwoofers are also made from plywood, chipboard and fiberboard. The type of material is selected taking into account the dimensions of the future structure.

- Acoustic cable.

- Sealing compound or PVA glue.

- Fastening elements. They use self-tapping screws, since nails are prohibited for such work.

- Epoxy resin.

- Paint and varnish product.

What materials do we need to assemble the subwoofer?

The material for making the subwoofer box must be durable, dense and well insulating sound. Multilayer plywood or chipboard is perfect for this . The main advantages of these materials are their affordable price and ease of processing. They are quite durable and provide good sound insulation. We will make a subwoofer from 30 mm thick multilayer plywood.

To make a subwoofer box we will need:

- Wood screws (approximately 50-55 mm, 100 pieces)

- Soundproofing material (Shumka)

- Drill and screwdriver (or screwdriver)

- Jigsaw

- Liquid Nails

- Sealant

- PVA glue

- Carpet, approximately 3 meters

- Klemnik

Which speaker to choose

To make a subwoofer from a regular speaker, you need to take a number of parameters into account, since they affect the size of the future speaker box. Often, inexperienced drivers make a mistake and choose a device based on power. However, these values only indicate the load capacity that the speaker can handle for an hour or a few seconds. Therefore, a powerful device does not guarantee good and clear sound.

When choosing a product, you first need to evaluate the properties of the diffuser. To get less distortion at peak volume, it is better to use large designs with a small amplitude of vibration.

Since the diffuser is subject to increased air resistance, the material from which it is made must be strong and reliable. Paper products are only suitable for “sound-in” speakers. Models based on polypropylene are sensitive to temperature changes and have minimal rigidity, which is why they are used in budget car acoustics. The best solution is considered to be carbon fiber and Kevlar.

As for metal acoustic systems, they provide precise sound production with intense resonance. However, these features only appeal to some users.

When choosing a speaker, its sensitivity is also taken into account. The characteristics can be assessed by the dimensions and power of the magnetic element.

You should also pay attention to the resonance frequency.

How to calculate a box

The calculation of the box is made using ready-made algorithms or from scratch. There are a lot of calculators on the Internet that allow you to make an accurate calculation for the case, determine what volume the box is needed and what the optimal dimensions are. To eliminate deviations, you need to take into account a number of rules.

First, let's calculate the volume of the subwoofer. For two speakers with a diagonal of 15 inches, it is better to calculate a 60-liter box, and for 12 inches, a 45-liter box. The optimal height is h=340 mm=34 cm=0.34 m, and the permissible length L=680 mm=68 cm=0.68 m. 1 liter = 1•10−3 m³ 1 l = 0.001 m³ then V= 45 l = 0.0 4 m³.

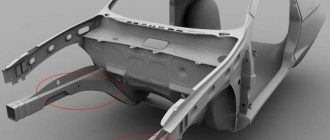

If the body will be located in the wing niche and have a complex geometric design, it is necessary to calculate the body for all parts, separating the volumes of both sides.

Box detailing

The size and number of parts for building the box, i.e. you can give the drawing to a company that provides wood cutting services (furniture), and after a certain time pick up the finished parts. Or you can save money and make the cut yourself. The dimensions of the parts are as follows:

We also have calculations for two Ural molot 12 subwoofers

Box characteristics

Frequency response box

This graph shows how the box will behave in a medium-sized sedan, but in practice small deviations are possible since each sedan has its own interior characteristics.

We are sure that you will be satisfied with the result, you can find a large number of answers to questions in the subwoofers section, and you can also ask us a question by filling out the form below. This will help us make our portal even better and more informational.

Sources used:

- https://caraudioinfo.ru/chertezhi/korob-dva-molot-12.html

- https://dinamikservis.ru/blog/sabvufery/podklyuchenie-saba-2×2-4×4-1-om/

- https://caraudioinfo.ru/chertezhi/korob-dlya-sabvufera-ural-molot-12-38hz.html

How to assemble a subwoofer

After preparing all the tools and materials, work on the construction of the structure can begin. Making a box for a 12-inch subwoofer with a diameter of 30 cm is quite simple. First of all, you should make a hole for the future speaker, maintaining a distance of 20 cm from the center to the walls.

Next you need to follow the following instructions:

- We are preparing the main elements of the future homemade building. Their parameters are calculated in advance on a trusted resource with online calculators.

- We make a hole in the front of the plywood sheet or MDF, chipboard.

- We cut a slot above the hole for the bass reflex tube and screw the compartment.

- We glue the side elements with PVA glue and fasten them with self-tapping screws. It is important to tighten the fasteners all the way, as any voids will negatively affect the sound quality.

- We cut out places for the wires at the back of the case.

- Before connecting all the components, we place the speaker in the box.

- The final stage involves finishing the interior space. Joints and crevices should be sealed with caulk or epoxy to improve sealing.

- External finishing consists of covering the body with carapet fabric. The carapet is stretched and secured with epoxy or a furniture stapler.

After completion of all stages, final assembly is carried out with connection to the standard car radio.

Since the closed bass reflex box (FI) is large in size, car owners prefer to install a compact “Stealth” subwoofer made by themselves. The mini model provides clear sound over a wide range of frequencies and takes up less space in the car.

In most cases, the box for the 10th subwoofer is placed in the trunk, but some people practice mounting it in the fender or spare tire niche.

The optimal volume for uninterrupted and high-quality operation of the device is 18 liters if 12-inch subs are used.

To properly make a box for a subwoofer, you can consider a simplified option by creating a closed box. It is created according to the same principles as the bass reflex model, but without making a gap. The ZYA has a hole for the speaker, so its design looks quite simple.

All kinds of bandpasses represent a full-fledged bass reflex, but in a modified format. Therefore, assembling a homemade sub is quite simple.

The most complex design is considered to be a subwoofer in the form of a horn. Due to the complexity of manufacturing, novice craftsmen abandon this option, preferring more simplified models. However, the horn is distinguished by volumetric lows and provides deep sound at all frequencies. But any deviation from the drawings will make all efforts useless, because... The sub won't sound right.

Therefore, experts recommend choosing the option of a closed box or bass reflex box for the subwoofer. The bandpass is also characterized by its simple design.

When assembling a box for a subwoofer, it is important to follow all safety rules and be careful. The work involves the use of piercing and cutting objects, as well as electric tools. The use of faulty devices is prohibited.

Types of boxes

There are different types of acoustic design, including:

- Closed.

- Bass reflex.

- Bandpass loudspeaker.

The first types are in great demand because they are easy to build with your own hands. Sound vibrations in such a design are isolated from the environment and damped, creating surround sound. But during the attenuation process, the energy released contributes to heat transfer, which affects the acoustic parameters.

To eliminate this phenomenon, the interior of the box is equipped with soundproofing materials (wool or synthetic padding). As a result, less heat is generated and the speaker sounds more spacious. When tested, this method gives up to 15-20% increase in volume.

Despite the ease of manufacture, such a box for a subwoofer has a lot of advantages. The first is the ability to quickly calculate the volume of the box. The second is the minimum probability of speaker overload. The third is the lack of competitors in sound quality when choosing a suitable subwoofer head and proper design of the housing.

However, in addition to the advantages, closed systems also have disadvantages. The key disadvantage is the low efficiency indicators compared to other types.

Bass reflex boxes are distinguished by the presence of a special tunnel, which contains a small amount of air. Its volume is selected according to the following principle: a second oscillatory system should be placed inside the structure, which receives waves from the rear part of the diffuser and transmits them to the desired location. Within the permissible frequency range, efficiency indicators increase.

In addition to high efficiency, the bass reflex has a large hole in the housing, which restrains the movement of the diffuser and reduces the amplitude of its vibrations.

The disadvantages include high requirements for settings and parameters, because... To make a box with your own hands for an eight-inch speaker, you need to take into account the following nuances:

- Box volume.

- Cross section.

- Tunnel length. We calculate it taking into account the technical parameters of the loudspeakers.

If you need to hide an active subwoofer, it is better to use a bandpass speaker that combines high- and low-pass filters. Primitive designs are distinguished by a closed volume with a tunnel. The speaker is located in the partition between the chambers, so the 2 parts of the diffuser operate at full power.

How to install a subwoofer

Installing a subwoofer box in a car with your own hands is not a difficult task. However, for successful installation you need to have some skills and tools. In addition to placing the subwoofer and amplifier, you should take care of the following related devices:

- Circuit breakers.

- Wiring.

- Capacitors.

- Plastic clamps.

- Spanners.

- Electrical tape and wire cutters.

After choosing the optimal location for installing the subwoofer, you need to make sure that it can cope with resonances from the device. It is not allowed to place the box on fragile machine structures.

The wires are connected according to the following diagram:

- First you need to connect the cable to the amplifier.

- Next, the amplification unit is connected to the car radio.

- A cable with a positive value is wrapped in corrugation to protect it from deformation.

- The fuse is fixed on the same wire, maintaining a minimum distance between the batteries.

Before starting a homemade sub, it is important to check whether the battery is disconnected. This rule will allow you to protect yourself from electric shock and avoid damage to the radio.

Settings

The next step involves completely setting up the subwoofer. However, experts in the field of car audio recommend checking all parameters when designing the box in order to eliminate deviations and errors.

To properly configure the system, it is important to monitor the speaker parameters. If the model is characterized by high sound quality in a FI case, the port is adjusted both higher and lower, taking into account the music being played.

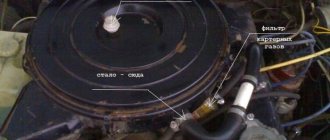

Setting up a low-pass filter begins by turning on this component. On factory subs it is called LPF (low pass filter).

Next, another filter called “sabsonic” is used, operating in the high-frequency range or sub-bass region. It is used to remove infra-low frequencies. However, not all amplifiers support this option, but if it does, it is better to activate it.

The task of the “subsonic” is to protect the subwoofer speaker from damage when playing frequencies that are outside the audible range, i.e. 20-25 Hz or lower. Working at such frequencies, the diffuser increases its stroke, which increases the risk of coil failure.

Experts recommend setting the filter 5 Hz below the frequency of the bass reflex port. If the selected frequency is 35 Hz, then the “Sabsonic” setting is performed at 30 Hz.

Particular attention should be paid to adjusting the acoustic phase. It helps the front speakers sound correctly together with the rear ones. If the sound is heard only from behind the car, it means that errors were made during setup.

Some amplifiers are equipped with a phase shifter “twist”, which ensures uniform phase rotation.

You should also set delays. This feature is only available on processor devices or when connecting external modules.

In many speaker systems, low frequencies are reproduced with a delay, which degrades the sound quality and does not allow you to fully enjoy your favorite song. To eliminate this problem, you need to make adjustments to the delays.

How to make a subwoofer box

When figuring out how to make a subwoofer with your own hands, you need to choose the body material, perform some calculations and drawings, and also follow step-by-step assembly instructions.

What to make from

Different materials are used in the manufacture of subwoofer boxes. But most often, craftsmen create boxes from chipboard or MDF, since such boards are quite reliable and affordable.

However, today transparent plastic or plexiglass is in demand, allowing you to recreate a special effect in the hi-tech style. However, wood products have better sound quality than options made from other materials.

When assembling a subwoofer box, you cannot use simple wood or plank panels. These must be structures with special dispersion, i.e. plywood, chipboard or MDF. When choosing plywood sheets, preference should be given to multilayer options, which are characterized by the following advantages:

- High quality sound in the cabin.

- No rattling or interference problem.

- Vibration resistance.

Other materials do not have such properties, so experienced craftsmen choose only plywood. But in addition to plywood or chipboard, you will need to prepare related elements, including fabric for sound insulation. It is sold in specialized audio equipment stores or on the market. You also need to prepare a construction stapler with staples, glue 88 and metal corners to increase the strength of the structure at the corners.

If you choose the right manufacturing materials, making a subwoofer enclosure with your own hands will be quite simple.

How to calculate a box

To calculate the box, you can use special computer calculators such as WinISD or JBL Speakershop.

In the empty fields you need to enter the initial data for calculating the boxes, including the parameters of the speakers from the database or other sources. You can also use the software to find the best option for accompanying components for the best sound.

It is not difficult to carry out calculations for a closed-type subwoofer enclosure, since such a system is the simplest to implement and does not require high accuracy of values. To determine what volume of the box is needed, you can use special formulas based on 3 speaker parameters to select the internal volume.

If the nameplate value of the resonant frequency to quality factor is less than 100, such a speaker is not suitable for closed boxes.

When using formulas for calculations, you must adhere to the following requirements: the resonant frequency cannot exceed 50 Hz, and the quality factor cannot exceed 0.7.

If you need to calculate the volume of a bass reflex box, it is better to give preference to speakers with a quality factor of 0.3-0.5 and a ratio of resonant frequency to quality factor of 50. You will also need to determine the dimensions, cross-sectional area and length of the pipe.

Calculation of the body of a car with your own hands is carried out according to the same principles as when arranging a closed structure, but taking into account the permissible quality factor of no more than 0.6-0.65.

The length of the bass reflex is calculated so that it corresponds to the recommended value.

A 12-inch subwoofer box should have a volume of 47-78 liters. A box for an 8-inch device can have a volume of 20-33 liters. If you need to organize a box under 15 inches, a calculation of 79-120 liters is taken.

How to assemble

When starting to assemble a cabinet for an 8, 10 or 12-inch speaker, you need to study each step of the work ahead and follow the step-by-step guide. First of all, you need to create a beautiful box:

- The outer surfaces where the head is located are made double. Therefore, it is better to use 2 sheets of plywood. If the thickness of 1 material is 18 mm, when assembled it should be 36 mm, which will increase the degree of rigidity. You can also make a small hole in the first sheet, and a larger one in the second, so that the head is recessed into the body.

- Next, you need to glue the sheets together with a special adhesive base and secure them with self-tapping screws. Fasteners must be placed on every 1 cm² of surface, i.e. every 3-5 cm.

- To connect the walls of a box for 2 or more speakers, furniture screws, rather than self-tapping screws, are used. This type of work will require the use of an electric drill and glue. The presence of screws contributes to better fixation, since they do not deform even with prolonged use.

- The triangular strip is glued inside the box at the corners. It is necessary to increase rigidity and prevent deformation. Similar actions are necessary for a 10-inch or 15-inch subwoofer, since they have increased dimensions.

When constructing a homemade car box, it is important to take care of good protection for the body. For this, craftsmen use different materials and methods:

- In order to increase the moisture protection of the box for an 8-inch subwoofer (10, 12 or 15 subwoofer), the surfaces are coated with a special varnish impregnation.

- The internal parts are glued with vibration-isolating material, which protects the structure from negative influences and increases the degree of rigidity. Someone applies such a coating to the outer parts, which gives good low frequencies.

- The joints and connections require special attention, since the crossover wires and other elements of the audio system are located there.

Some experts believe that closed boxes for cars should not have holes in their body. In addition, many of them recommend assessing the degree of tightness by pouring water inside.

If the subs sound better without the box than with it, you can place cotton wool or padding polyester inside.

Some drivers want to learn how to create a Stealth subwoofer with their own hands, since such a box is characterized by increased practicality and functionality. It takes up less space than a standard square active subwoofer design and can be placed inside the fender or in the spare tire mounting area. For a 12" or 10" speaker you will need an 18L box.

The production process requires the preparation of the following components:

- Speaker with dimensions of 10-12 inches.

- Protective grilles and sockets for connecting the device to the amplifier.

- Wires.

- Multilayer sheet of plywood or chipboard, 20 mm thick.

- A piece of fiberboard.

- Adhesive composition (it is better to choose epoxy).

- Brush.

- Fiberglass.

- Scotch.

- Polyethylene.

- Self-tapping screws for wood.

- Drill and jigsaw.

Having decided on the place where the hand-made box will be installed, you need to prepare the trunk and begin assembling the case.

Some drivers first remove the trim in the trunk to install the structure as close as possible to the inside of the wing.

Polyethylene is applied to the floor covering, which helps protect the casing from glue and provides a good mounting location for fixing the subwoofer.

The next step is to glue the wing using mounting tape. For better fastening, use 2 layers of those same masking tapes.

Next, you need to cut the fabric into small pieces of 20x20 cm and glue it using masking tape and epoxy glue. We gather the fabric overlapping to prevent the appearance of joints or seams.

Each layer of fabric material is applied to each other with epoxy lubrication.

This is done until the sheet reaches a thickness of 10 mm.

The curing time for the material is 10-12 hours. To speed up the process, you can use a lamp. Next you need to cut out the bottom and glue it to the body. The joints are impregnated with sealant and epoxy resin.

Next, the housing for the subwoofer needs to be adjusted to the shape so that it fits with the trunk hinges and does not interfere with normal opening or closing. Then all that remains is to cut off the excess elements, cut out the side parts and the top cover from the chipboard. The rounded surface is created from a plywood sheet.

The particle board is pre-treated with epoxy or sealant, and then connected using self-tapping screws. If the box is made of fiberglass, the use of epoxy resin is permitted. After the mixture has dried, self-tapping screws are used.

In order to increase the tightness of the structure in the car, craftsmen glue the seams twice.

At the next stage, you need to calculate the dimensions of the front panel and cut it with a jigsaw, providing for a circle for 1 or two speakers. Self-tapping screws are used to secure this part. A hole is made in the end part for the socket.

The last step is to secure the socket and install the speaker. Then you can carry out finishing work by painting the subwoofer or covering it with suitable material. The first option is more complex because it requires proper surface preparation before painting.

Blueprints

Drawings of subwoofer boxes and diagrams are useful and informative materials that simplify the process of calculating the volume and assembling the structure. If a box is created for a 12-inch speaker, the optimal volume should vary between 40-50 liters. The box drawing is based on the following approximate diagram:

- External dimensions parameters: width - 700 mm, height - 450 mm, depth - 260 mm.

- Panel dimensions: front - 700x450 mm, rear - 700x450 mm, left and right - 450x260 mm, top and bottom - 750x260 mm.

How to choose speakers

Having designed a subwoofer enclosure, you need to take care of suitable speakers that will be installed in it. The speakers used must clearly reproduce low frequencies by converting the electrical signal into air vibrations.

In most cases, electrodynamic heads are placed in cars, which begin to oscillate under the influence of electric current in the voice coil. Such mechanical phenomena contribute to the conversion of the signal into a sound wave.

The performance of loudspeakers depends on various factors, which are indicated in the technical documentation. Key parameters include:

- Resonant frequency (Fs).

- Quality factor (Qts).

- Equivalent volume (Vas).

A speaker is an oscillating system that reproduces sound signals at different frequencies. The lower the weight of the diffuser and the higher the rigidity of the suspension, the more the resonant frequency will increase. To reproduce low frequencies, it is customary to use soft suspensions with heavy diffusers. Large speakers have a resonant frequency of 20-50 Hz.

Quality factors affect the damping of resonant oscillations of the diaphragm.

The last parameter in the form of an equivalent volume is equal to the volume of air, but does not depend on the dimensions of the column. The exact values are determined by the mechanical parameters of the suspension and the dimensions of the diffuser. The unit of measurement is liters.

Skillful car owners can make a subwoofer from a regular speaker without putting much effort into it. The main thing is to know that good sound quality with correct signal conversion is only possible when using large diffusers with 6-15 inch heads.

How to install

The subwoofer installation process is quite simple, so even a beginner can do it. When installing low-frequency systems, it is customary to choose the following places:

- Interior lining of a vehicle.

- Trunk floor covering.

- A separate building, created taking into account the calculations. This option is in demand due to the economical consumption of free space in the trunk and the ability to install mini audio systems.

Subwoofers are also compact for 4-inch speakers and can be installed under car seats.

Possible malfunctions and repairs

Do-it-yourself subwoofer repair may be required if its elements are mechanically damaged. If the coil encounters an audio frequency that exceeds the permissible limit, it may fail. A similar problem occurs when listening to music at maximum gain, which causes the cone to rupture. Repairing the unit is quite simple, because it can be replaced with a new one.

Restoring the functionality of a diffuser or coil is a difficult task that will require a lot of time and effort, and every specialist who has repaired such a unit will recommend replacing it.

Overheating of the internal parts of the subwoofer often leads to breakdown. The problem is related to the contamination of the internal space with dust and technical debris. First, you need to evaluate the voltage in the power supply using a tester - if it is missing, you will have to replace the power supply.

When inspecting the interior, you may find swollen capacitors or blackened windings. Damaged elements need to be desoldered with a soldering iron and replaced with new, serviceable ones.

Speaker repair begins with disassembling and dismantling the subwoofer head. All actions must be performed without haste, since sudden movements can damage the reel sleeve.

Pros and cons of a homemade box

A homemade enclosure for subwoofer 12 has both pros and cons. The positive features of these products include:

- Saving money. The manufacturing process involves minimal monetary costs.

- Ease of DIY creation. If you stick to the drawings, correctly calculate the box and follow the step-by-step instructions, the work will not take much time.

- The ability to make a beautiful box for any interior geometry. When assembled, the small case will look stylish and give the car interior additional elegance.

The disadvantages include a limited set of functions and a number of problems when setting up the speaker system.

- What are tweeters in acoustics

- Car radio Soundmax SM CCR3064F

- Starline M15 manual

- How to find out the Tomahawk alarm model by key fob

Cutting parts

So, you have decided on the shape for the sub box and you have a drawing.

Mark the sheet according to the parts and cut according to the marked dimensions. Use a disk with a large number of teeth; the smaller the tooth size of a circular saw blade, the fewer chips you will get, and their size will be insignificant.

If you use a manual circular saw and your hand is not full, it is better to use a guide so as not to accidentally “fill up” the cut.

It is better to do this work together, since it is quite inconvenient for one person to turn large sheets and hold them while working.

Below is a good video from Rockford Fosgate, albeit in English, but everything is clear here without translation - choosing the shape of the body, lining up the parts, cutting.